3p-N-Pyrrolidylcholestene-5 (IIb). (a) Sodium Borohydride

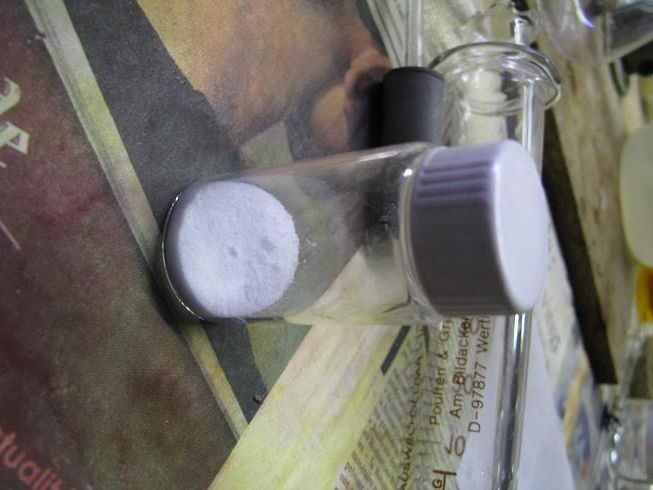

and Acetic Acid Reduction.-A mixture of 50 mg. of 3-

N-pyrrolidylcholestadiene-3,5,m~ .p. 136-141", and 25 mg. of

sodium borohydride in 1 .5 ml. of anhydrous tetrahydrofuran

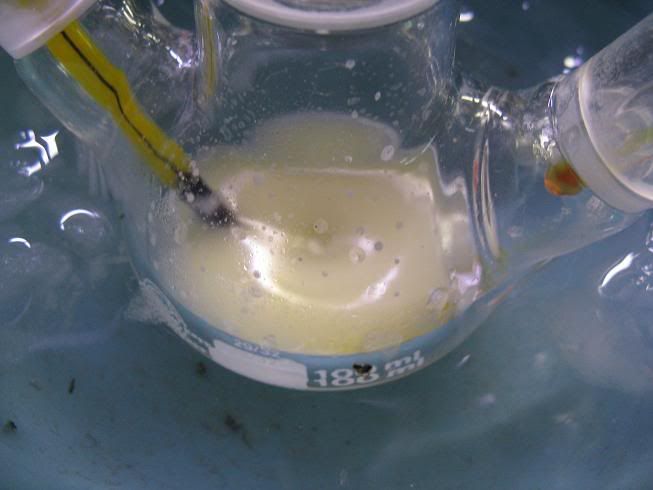

was stirred under nitrogen, and 0.5 ml. of glacial acetic acid was added dropwise. A 0.5-ml. aliquot was removed, made basic with 10% sodium

hydroxide, and extracted with ether-ethyl acetate.

The extracts were washed with water, saturated brine,

and dried over anhydrous granular sodium sulfate. Removal

of solvent left 14 mg. of colorless [amine-borane complex]

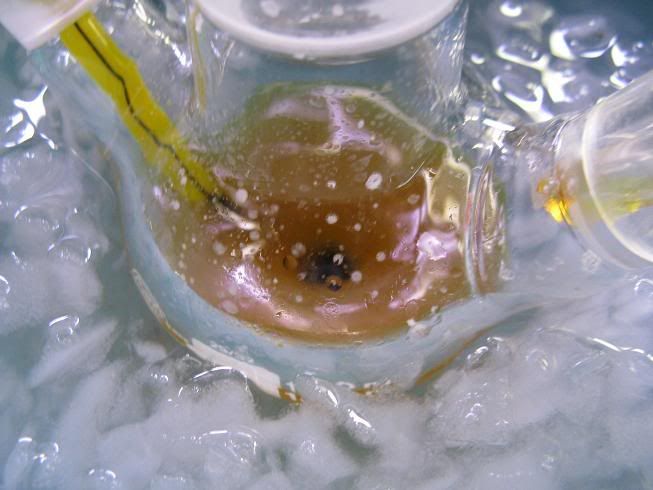

The remainder of the reaction mixture was refluxed for 1 hr.,

and the product was isolated as above to give 36 mg. of crude solid.

Recrystallization from ethanol afforded 16 nig. (44% yield allowing for removal of the aliquot) of lustrous white plates, m.p.165-175O.

The infrared spectrum of this material was identical

with that of material prepared as described below (part b).

Admixture of the two substances gave no depression in melting

point.

The utilization of diglyme as the solvent led to a substantial

improvement in yield. Thus, a solution of 50 mg. of 3-Npyrrolidyl~holestadiene-3,5,m~ .p. 136-141 ", and 20 mg. of

sodium borohydride in 2.0 ml. of anhydrous diglyme was stirred

under nitrogen during the dropwise addition of 2.0 ml. of glacial

acetic acid. The mixture was allowed to stand for 10 min. and

heated on a steam bath for 1 hr. The crude product was isolated as described above and crystallized from ethanol to give 30 mg. (60% yield) of

3@-N-pyrrolidylcholestene-5, m.p, 160-172'. The mother liquors afforded 17 mg. (34% yield) of an

oil, the infrared spectrum of which was nearly identical with

that of crystalline amine IIb.

|

The KOH seems good for my purposes, I was thinking of using P2O5, but I prefer keeping non-acidic conditions to avoid any H2 evolution if

a grain of NabH4 falls on the P2O5 for some reason...

The KOH seems good for my purposes, I was thinking of using P2O5, but I prefer keeping non-acidic conditions to avoid any H2 evolution if

a grain of NabH4 falls on the P2O5 for some reason...