Good work!

I assume you have read Strepta's method a few pages back (he attached it as a Word file)?

He obtained about 50% P4 yield by increasing the amount of aluminum above theoretical (although I would be careful with that, you don't want to bind

the P as phosphide again- perhaps increase the amount of SiO2 as well) and using pyro grade "black" aluminum powder.

I would also use diatomaceous earth (calcined before use) as the SiO2 source, as it's finely divided and very reactive (but not pure SiO2).

What kind of Al and SiO2 did you use?

Strepta also used CO2 as a protective atmosphere inside the test tube, but I would advise against that, as Al vigorously reacts with it, forming CO, C

and carbide. Perhaps that's why he had to increase the amount of Al?

N2 is also not an optimal choice (forms AlN).

If Ar is not available, H2 could perhaps be used.

|

- some other products may - one has to look at the fine print on the package. Algal blooms & such are a p.i.t.a....

- some other products may - one has to look at the fine print on the package. Algal blooms & such are a p.i.t.a....

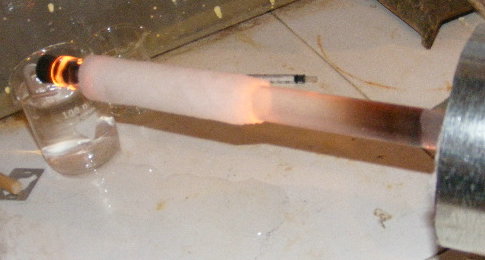

It is a really nice experiement and easily carried out by anyone @ home.

It is a really nice experiement and easily carried out by anyone @ home.