blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Ferric Ammonium Alum problems…

Last year I synthesised about 200 g of NH4Fe(SO4)2.12H2O, ferric ammonium alum (FAA), from technical FeSO4 heptahydrate, technical H2SO4 (95 %),

nitric acid (38 %), (NH4)2SO4 and water.

The overall reaction is:

FeSO4 + ½ H2SO4 + 1/3 HNO3 + ½ (NH4)2SO4 === > NH4Fe(SO4)2 + 1/3 NO + 2/3 H2O (water needs adding to obtain the dodecahydrate)

1 mol of FeSO4.7H2O is mixed with 200 ml of water, 30 ml of H2SO4 (95 %) and 55 ml of HNO3 (38 %) and heated till dissolution of the FeSO4 and

subsequent oxidation of the Fe (II) to Fe (III) occurs: you then basically have a hot solution of Fe2(SO4)3. Adding the (solid) (NH4)2SO4 (65g, 99 %),

dissolving, cooling and icing overnight then yields the crystals of FAA. They’re often quite large and amethyst coloured.

But this year things didn’t go so well. Various problems with undesired precipitates leading to discarded batches caused me to revise the mixing

sequence a bit, until I got decent looking crystals again. Except: they weren’t nicely amethystsy but much darker coloured.

What needs to be added is that during the oxidation of Fe (II) to Fe (III) an intermediate complex, (Fe.NO)<sup>2+</sup> (ferrous nitrosyl

complex ion), forms between the reaction product NO and unreacted Fe<sup>2+</sup>. This is very dark coloured and can be easily confused

with a concentrated solution of Fe<sup>3+</sup> which through hydrolysis (encouraged by the high temperature of the solution) form various

dark coloured Fe (III) OH species. So judging when the oxidation is complete isn’t that easy.

I suspect that the darker colour of the new crystals may have been due to some (Fe.NO)SO4 co-crystallising with the FAA (this is no more than a

hypothesis), so I decided to recrystallise. For recrystallising FAA I’ve found this procedure to work well: for every 100 w. parts of FAA crystals,

add 50 w. parts of (soft) water, heat till dissolved, cool, add seed crystal and ice overnight. Yield: 70 to 80 %. If any particulate matter was

present, filter before cooling: it filters well because FAA is slow to crystallise.

After recrystallising the product looked much better, much lighter in colour but still not amethyst.

Ideally FAA, an important reagent to prepare Fe (III) titrant solutions for redox titrations, should be free of Fe (II). That’s usually tested by

means of hexacyano ferrate (I forgot which one now) but I have neither of these, so I devised my own test.

50 ml of a 0.5 N solution was prepared with a little 1 M H2SO4 and using the recrystallised sample. 10 ml (each) of this yellow solution was

transferred into 4 empty test tubes. Respectively 0, 1, 2 and 3 drops of KMnO4 0.1 N solution were then added to the 4 test tubes.

Between 1 (control) and 2 (1 drop) I saw no difference: this points to small amounts of Fe (II) being oxidised by permanganate.

But tubes 3 (2 drops) and 4 (3 drops) discoloured very clearly by excess permanganate. It can thus be estimated that the Fe (II) contamination must be

between 0.1 to 0.2 mol % of the present Fe (III). Not bad and certainly unlikely to be the cause of any colour problems.

Elsewhere on this forum ‘kmno4’ claimed that the purple colour is in fact due to manganese contamination (although he didn’t specify Mn (II) or

Mn (III)). I’m now testing this by recrystallising 40 g of the sample with significant Mn (II) present (as chloride). Wait and see. Certainly Mn

could be a common contaminant in technical FeSO4, obtained from dissolving scrap iron in sulphuric acid…

Some here will recommend hydrogen peroxide as an oxidiser but I only have 9 % and H2O2 is quite wasteful anyway.

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

Did you perform the recrystallization step on your first [successful] batch or did you only do it this time around after noting the unexpected color?

Did you use the same feeds as you did before?

I noticed that almost all of your reagents are technical grade. I assume your iron and ammonium sulfates were purchased as fertilizer; H2SO4 as drain

cleaner. All of these can have a degree of impurity that varies wildly. Maybe you'd be better off analyzing each individual reagent rather than trying

to purify and analyze your contaminated product.

Couldn't you get away with using off-the-shelf 3% H2O2 for the oxidizer? Or as an alternative, electrolysis (sans HNO3) with iron electrodes. Perhaps

the power supply and/or current densities can be tweaked to boost complete oxidation of Fe(II) to Fe(III) as well as removing some of the excess

water. It's a bit of a stretch, I know. It would certainly get around the (Fe.NO)2 complex but may generate a new set of problems - particularly at

the cathode.

Thinking out loud again.

Tank

|

|

|

cyanureeves

National Hazard

Posts: 744

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

blogfast25. you got dark purple color crystals? i would've been thrilled to get that. all i got was mustard colored crystals. it looked so easy i

tried it with ammonium sulfate made with homemade ammonium hydroxide and epsom salt,3% peroxide and homemade iron sulfate. i spent weeks of tweaking,

adding a bit more of each chemical. today i finally discarded the whole mess.. i would even google it to see the pretty magenta crystals that i

thought i would soon have.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Firstly the latest results.

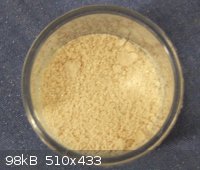

The recrystallisation, doped with Mn2+, yielded 85 % of very nice looking crystals, light grey, but no purple. This is about 35 g of it:

Compare to the ‘amethyst’ ones from last year, the largest chunks are about 1 - 1.5 cm:

This latest batch of grey crystals will be tested for Fe (II).

I also ran another replica for ¼ mol of FAA, with HNO3 and obtained very low yield after icing: about 9 %! This cannot be due to recrystallisation

losses only, so it has to do with poor oxidation yield.

132 g of supernatant liquid was decanted off (the total weight was 170 g!), then reduced in volume to about 75 ml, at which point the solution became

very lively and shedloads of NO2 were released: belated oxidation? That product is now cooling and will be iced. I bet the total (combined with the 9

%) yield will be ‘normal’ but what will the crystals look like? My bet is: ‘nice and purple’!

And today I initiated a ¼ mol synthesis, with 9 % H2O2. 70 g of FeSO4 hydrate, 8 ml of conc. H2SO4, 50 ml of water were combined and stirred, then 50

ml of 9 % H2O2 was added. The oxidation started immediately but with much effervescence (presumably oxygen gas) and that shouldn’t happen: the

O<sub>2</sub><sup>2-</sup> (O (-I)) should be reduced to H2O (O (-II)), not oxidised to O2 (O (0)). Ammonium sulphare was then

added.That batch is cooling and I’ll be curious to know the yield and colour.

Tank, to answer your questions:

No, the purple product was never recrystallised, as far as I recall: my lab notes are scant on that run.

The source reagents are the same. Technical grades are needed to keep cost down: recrystallising should provide reasonable purity.

Electrolysis is definitely worth considering but I’m wondering about time needed, plus start-up teething problems.

Cyanureeves:

You’re not the first one to obtain something mustardy: see here chemoleo’s results:

http://www.sciencemadness.org/talk/viewthread.php?tid=5650

I have seen similar yellow deposits myself, with HNO3, I believe them to be iron (III) hydroxy thingies…

[Edited on 26-6-2011 by blogfast25]

|

|

|

woelen

Super Administrator

Posts: 8023

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

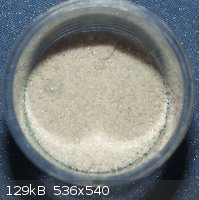

Are you sure the amethyst crystals are the right stuff? I have a commercial sample, reagent grade, and this material looks much more like your final

pale brown material of this year.

|

|

|

cyanureeves

National Hazard

Posts: 744

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

wow exactly the yellow i got but i wont compare my stuff with ya'lls any further because i dont know zip about Fe(II )OR Fe(III) or equal

stoichiometry. i can follow with ml. and such but thats it. i could see the purplish hue appear when i held the red solution like chemoleo's 3rd pic

up to a light. that is at the point when the peroxide is added, i could see blue light refracted on the surface. oh well i got nitric so i might do it

that way.

|

|

|

kmno4

International Hazard

Posts: 1502

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  |

Elsewhere on this forum ‘kmno4’ claimed that the purple colour is in fact due to manganese contamination (although he didn’t specify Mn (II) or

Mn (III))

|

Where ?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by woelen  | | Are you sure the amethyst crystals are the right stuff? I have a commercial sample, reagent grade, and this material looks much more like your final

pale brown material of this year. |

Hi woelen:

I go by several descriptions that describe it as ‘purplish’, so having obtained that I thought I was spot on. And I have used the product

successfully in redox titrations, 0.1 N titrants in 1 M H2SO4... I also bought commercial FAA from a British photolab and it too was purple, slightly

less than mine though. Could it be MnO4- ?

What I’ve noticed also is that slightly wet product tends to look darker: that should be no surprise, this stuff is amazingly soluble (my own data:

about 100 g of dodecahydrate per 100 ml of water at about RT) and these solutions are always brown. It could explain the colour of the RCed product

shown.

My bad, kmno4. Right thread, wrong member: in the thread linked to above it was in fact chemoleo (top post) who made that remark about manganese

contamination, NOT you. My apologies.

[Edited on 26-6-2011 by blogfast25]

|

|

|

pantone159

National Hazard

Posts: 590

Registered: 27-6-2006

Location: Austin, TX, USA

Member Is Offline

Mood: desperate for shade

|

|

I have some ferric ammonium alum, and when purchased, the crystals were pale violet. Upon storage, they have changed to brown, with the bottle being

kept well closed except for occasionally opening it.

|

|

|

woelen

Super Administrator

Posts: 8023

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

I have read something about this compound in one of my older German books (Lehrbuch der Anorganische Chemie, 1956) and that book has a long story

about uncertainty of the color. The only agreement is that the color of a pure sample must be pale and the crystals must be transparent. The book

tells that some sources claim the material to have a very pale violet color, while other sources claim the material to have a very pale brown/grey

color and everything in between. Personally I believe that all these very pale grades are perfectly good material and that the differences in color

are caused by trace amounts of impurities. Keep in mind that even a 0.01% impurity can have large impact on the color of an otherwise nearly colorless

chemical.

If the material is turbid and has opaque brown yellow spots, then it is of lesser quality. These impurities are due to the presence of basic sulfate,

products of hydrolysis. A solution of the salt tends to become slightly turbid on standing, due to hydrolysis.

One nice test of purity is the following: Make a fairly concentrated solution of the salt. This will have a pale brown color. Add some dilute nitric

acid. The solution then should turn colorless! Pure hydrated (and non-hydrolysed) [Fe(H2O)6](3+) is nearly colorless, the intensity of the color is

comparable to the faint color of manganese(II) ions. Brown colors always are due to hydrolysis products and yellow colors are due to complex formation

with chloride:

http://woelen.homescience.net/science/chem/solutions/fe.html

[Edited on 27-6-11 by woelen]

|

|

|

LanthanumK

Hazard to Others

Posts: 298

Registered: 20-5-2011

Location: New Jersey

Member Is Offline

Mood: No Mood

|

|

As you can see, the lighting condition affects the color of my commercially produced ferric ammonium sulfate (is this the same thing as the alum?).

The purity of mine is suspected as it is only slightly soluble in water.

[Edited on 27-6-2011 by LanthanumK]

hibernating...

|

|

|

ScienceSquirrel

International Hazard

Posts: 1863

Registered: 18-6-2008

Location: Brittany

Member Is Offline

Mood: Dogs are pets but cats are little furry humans with four feet and self determination!

|

|

My procedure is here;

http://www.sciencemadness.org/talk/viewthread.php?tid=5650#p...

I used science madness grade reagents  with no problems. with no problems.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Some more results.

The remainder of the HNO3 batch, ‘reoxidised’ and recrystallised gave a combined yield of over 90 % (combined with the first, poor crop). Crystals

are very nice looking… and pale violet!

The peroxide test gave a yield of 69 %, slightly less than what I get with most nitric batches nowadays. Also really nice crystals… of identical

pale violet colour!

Both batches will now be RCed (together) to eliminate traces of nitric/peroxide and to recheck colour.

@ Woelen:

Yes, I think you’re right, colour is probably not so important and my products are basically all fine. It was the striking difference between

batches that was puzzling…

@ Lant:

FAA is indeed ferric ammonium sulphate dodecahydrate. It’s highly soluble in water at nearly all temperatures (but it tails off at about 5 C), if

your product isn’t there’s something wrong with it alright.

@ science squirrel:

It was linked to above.

@ All:

Some tips:

If anyone here wants to use nitric (preferable to H2O2 in my book), make sure the oxidation is complete. For this, simmer the solution of FeSO4, H2SO4

and HNO3 in a very roomy container on a very low light until a sudden ‘whoosh!’ of NO2 occurs.

RT solid FAA crystals are quite hard, so much so that if they formed in a glass beaker you may find it difficult to prize them out w/o damaging the

beaker. No worries: FAA has a very low MP: just over 40 C (where it melts into its own crystal water: that’s how soluble the stuff is!) So by gently

heating the container on low flame or bain marie you can melt the outer layer: the clump of crystals can then be removed easily. Works for me!

The high solubility makes me believe the double salt is in fact an ‘imperfect complex’: somewhere between a double salt and a perfect complex.

It’s otherwise difficult to explain how the union of two otherwise quite moderately soluble substances can lead to such high solubilities.

With classic alum (KAl(SO4)2) I observe something similar: when I added a concentrated solution of K2SO4 to the Al2(SO4)3 solution, much heat is

generated. Creation of ‘Al(SO4)2(-)’ ‘complex ions’?

|

|

|

woelen

Super Administrator

Posts: 8023

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

Intereasting observation of generation of heat. I hardly can imagine that this is due to formation of Al(SO4)2(-) ions. These ions could also be

present in Al2(SO4)3. I personally think that the heat is due to formation of solid KAlSO42.12H2O. These crystals initially are very small and they

are colorless, so it might be that initially you don't see them. Did you get a crystal meal after some time?

I also noticed something else. I have reagent grade Fe2(SO4)3, anhydrous, in the form of a very fine powder. When this is brought in water, then a

suspension is formed and a few minutes later everything is at the bottom of the test tube. But one day later, most of it has dissolved and another day

later all of it has dissolved. Quite some ferric sulfate can be dissolved, it takes a lot of time though.

A similar observation I had with anhydrous NiSO4 (a yellow powder with a greenish hue). It really takes days to dissolve this, but finally all of it

dissolves giving the well known green solution of aqueous nickel(II).

A final example I want to mention is As4O10. This compound seems to be only sparingly soluble in water, but when you have patience, then a LOT of this

can be dissolved. I'm quite sure that more than the weight of the water can be dissolved, but it takes a day or so. On heating near boiling it takes

an hour or something like that.

So, it might be that what you say is 'quite moderately soluble' in reality is very slowly dissolving, but in the end a lot can be dissolved.

I always had the impression that alums are less soluble than the combined weight of the constituent salts, otherwise no alum crystals would be formed.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Woelen:

Holleman actually describes alum as ‘an imperfect complex’.

I first observed the enthalpy release when adding solid K2SO4 to hot Al2(SO4)3 solution (designed in concentration so that no alum would crystallise

immediately). It was a real nuissance because it made the hot solution boil and splatter. I thought at that time it might be hydration energy of the

K2SO4.

So I started adding the K2SO4 as a hot, saturated solution. Well, I still had to be careful: it behaves much like adding conc. H2SO4 to too little

water.

Today I make alum by dissolving Al into a calculated excess of strong, boiling KOH, then allow to cool, then neutralise the excess KOH with 50 %

H2SO4, carefully. Hot filter, then allow to crystallise. It’s easier that way: concentrated solutions of K aluminate are well behaved but

concentrated Al2(SO4)3 solutions are a nuisance.

I wonder if what you see with your anhydrous Fe2(SO4)3 is similar to what I sometimes observe when making ferric alum: a yellowish precipitate

sometimes forms, which upon adding the ammonium sulphate and some simmering, usually disappears.

Update on the current FAA:

The combined last batches or peroxide and nitric alum have been recrystallised (100 alum + 50 water) at 83.3 % crystallisation yield, this calculates

to a solubility of about 30 g alum (dodecahydrate) /100 g of water at fridge temperature (just above 5 C). The crystals are… pale violet.

Simultaneously last year’s 200 g were recrystallised and they were pale violet too.

|

|

|

woelen

Super Administrator

Posts: 8023

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

These observations indeed are quite interesting. I do not have K2SO4 (I never considered this an interesting chemical and never purchased it), but I

can make some by dissolving KOH in dilute H2SO4 or a solution of KHSO4. I might try this experiment next weekend. It is easy to do and might give some

interesting insights.

The interesting thing to check out though is what happens after mixing the conc. K2SO4 and Al2(SO4)3 solutions. Does the solution remain clear (also

check with a light beam, such as from a laser pen, through the solution to rule out a colloid) for a long time after mixing and after heatig up? If

that is the case, then my hypothesis about heat due to crystal formation is false.

-------------------------------------------------------------------

Your yellowish precipitate which you sometimes have when making ferric ammonium alum most likely is not the same as I have with dissolving anhydrous

Fe2(SO4)3. I think that your precipitate is the result of hydrolysis of ferric ions and the somewhat acidic nature of ammonium ions gives enough free

acid to redissolve the precipitate.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

I used hot filtered and recrystallised K2SO4, starting from garden grade.

I’ll see if what I’ve got in terms of lab notes on these syntheses. The solutions, before combining, were designed so that no alum crystallisation

was supposed to take place upon mixing. Of course you can’t exclude local saturation, not even with the best of agitation. It all struck me as

‘possibly a bit of chemistry going on’.

In your case it might be better to start from quite strong but cold (or warmish) solutions so as to better observe any heat dissipation.

[Edited on 29-6-2011 by blogfast25]

|

|

|