Copper

Dendritic copper crystals made by electrolysis. | |||||

| General properties | |||||

|---|---|---|---|---|---|

| Name, symbol | Copper, Cu | ||||

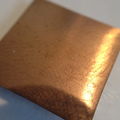

| Appearance | Reddish metallic | ||||

| Copper in the periodic table | |||||

| |||||

| Atomic number | 29 | ||||

| Standard atomic weight (Ar) | 63.546(3) | ||||

| Group, block | , d-block | ||||

| Period | period 4 | ||||

| Electron configuration | [Ar] 3d10 4s1 | ||||

per shell | 2, 8, 18, 1 | ||||

| Physical properties | |||||

| Reddish metallic | |||||

| Phase | Solid | ||||

| Melting point | 1357.77 K (1084.62 °C, 1984.32 °F) | ||||

| Boiling point | 2835 K (2562 °C, 4643 °F) | ||||

| Density near r.t. | 8.96 g/cm3 | ||||

| when liquid, at | 8.02 g/cm3 | ||||

| Heat of fusion | 13.26 kJ/mol | ||||

| Heat of | 300.4 kJ/mol | ||||

| Molar heat capacity | 24.44 J/(mol·K) | ||||

| pressure | |||||

| Atomic properties | |||||

| Oxidation states | −2, +1, +2, +3, +4 (a mildly basic oxide) | ||||

| Electronegativity | Pauling scale: 1.90 | ||||

| energies |

1st: 745.5 kJ/mol 2nd: 1957.9 kJ/mol 3rd: 3555 kJ/mol | ||||

| Atomic radius | empirical: 128 pm | ||||

| Covalent radius | 132±4 pm | ||||

| Van der Waals radius | 140 pm | ||||

| Miscellanea | |||||

| Crystal structure | Face-centered cubic (fcc) | ||||

| Speed of sound thin rod | 3810 m/s (at ) (annealed) | ||||

| Thermal expansion | 16.5 µm/(m·K) (at 25 °C) | ||||

| Thermal conductivity | 401 W/(m·K) | ||||

| Electrical resistivity | 16.78·10-9 Ω·m (at 20 °C) | ||||

| Magnetic ordering | Diamagnetic | ||||

| Young's modulus | 110–128 GPa | ||||

| Shear modulus | 48 GPa | ||||

| Bulk modulus | 140 GPa | ||||

| Poisson ratio | 0.34 | ||||

| Mohs hardness | 3.0 | ||||

| Vickers hardness | 343–369 MPa | ||||

| Brinell hardness | 235–878 MPa | ||||

| CAS Registry Number | 7440-50-8 | ||||

| History | |||||

| Naming | After Cyprus, principal mining place in Roman era (Cyprium) | ||||

| Middle East (9000 BC) | |||||

Copper is a transition metal with the symbol Cu and the atomic number 29. It is a widely available commodity and can be obtained in numerous forms. It is an amphoteric metal that exists in two common oxidation states, +1 and +2, and can also exist in a +3 and a +4 state. Copper itself is chemically resistant, but its oxidation states show tendencies to react. It can be plated out of solution or replaced by a more active metal.

Contents

Properties

Physical properties

Copper is a reddish-pink metal that is highly malleable and ductile. It can take a high polish, but often appears dull. Older pieces may be coated with the black copper(II) oxide. It has extremely high conductance of both heat and electricity.

The softness of copper partly explains its high electrical conductivity (59.6×106 S/m) and high thermal conductivity, second highest among pure metals at room temperature (after silver). This is because the resistivity to electron transport in metals at room temperature originates primarily from scattering of electrons on thermal vibrations of the lattice, which are relatively weak in a soft metal. However, this is only true for a few soft metals.

Chemical properties

Copper is notable for its varied chemistry. Copper metal will not dissolve in strong acids, but the addition of an oxidizer such as hydrogen peroxide permits the dissolution of the metal in most acids. Nitric acid is a sufficiently strong oxidizer to dissolve copper metal.

- 3 Cu + 8 HNO3 → 3 Cu(NO3)2 + 2 NO + 4 H2O

The nitric oxide produced may react with atmospheric oxygen to give nitrogen dioxide. With more concentrated nitric acid, nitrogen dioxide is produced directly in a reaction with 1:4 stoichiometry:

- Cu + 4 HNO3 → Cu(NO3)2 + 2 NO2 + 2 H2O

In both cases copper will exist in the +2 (cupric) state, the most common for copper. Compounds of copper(II) are generally blue or green in color.

When a sufficiently strong reducer, such as iodide, ascorbic acid or glucose, is used to oxidize copper 2+, it may enter the +1 (cuprous) state.

- Cu2+ → Cu+

Addition of hydrochloric acid to copper(I) oxide forms copper(I) chloride:

- Cu2O + 2 HCl → 2 CuCl + H2O

If excess HCl is added, a stable, soluble copper(I) complex is formed:

- CuCl + Cl- → [CuCl2]-

Copper(I) compounds are generally insoluble in water and highly reducing. Most of them are white, though copper(I) chloride may vary in color due to various impurities, and copper(I) oxide is red, or yellow when prepared by certain routes.

Copper also has extensive coordination chemistry in both the +1 and +2 states. While copper(I) compounds are insoluble in water, the proper ligand, such as ammonia, cyanide, thiosulfate, or chloride, the copper(I) ion becomes soluble in water. Copper(II) compounds undergo dramatic color changes with the addition of proper ligands: with chloride, a green complex forms (though a red complex, trichlorocuprate, is known to exist); with ammonia and ethylenediamine, a dark blue complex forms, with bromide, a maroon complex forms, and with ascorbic acid, a yellow complex forms.

Copper(III) compounds can be made in the amateur chemist's lab with sodium persulfate and potassium periodate.

One copper(IV) compound is known to exist, but is inaccessible to the amateur due to the requirement of fluorine gas.

Availability

Copper is a common coinage material, and can be found in United States pennies made before 1983. These are an alloy of 95% copper and 5% tin.

Several types of wiring contain copper metal. These wires may be glazed and will require removal before use.

Many electronics contain copper, such as transistors (the back metal plate that is in contact with the heat sink or covered by the plastic case), diodes (the wire), pins (though most are brass), rectifiers, PCBs, computer chips, on rare occasions some heat sinks are made of copper (or brass) etc. Some transistor heat sinks sometimes have an extra copper plate, for better heat dispersion.

Preparation

Copper metal powder can be made from copper(II) sulfate, available as root killer for septic systems, with the addition of either zinc metal or aluminium metal and a chloride source (such as table salt).

Copper powder can be made by reducing a copper salt, such as copper sulfate with iron. If impure iron, such as steel is used, the carbon from the steel will contaminate the solution and may slightly passivate the metal. However the black powder also contains copper(II) oxide, which too is black. The copper powder will require washing, though a simple decantation will suffice, as copper is denser than both contaminants.

Under certain circumstances, a copper foil may be produced instead of powder, usually if copper(II) chloride is used, in an acidic solution.

Clean, superfine, and air-stable copper powder can be created by adding ascorbic acid (vitamin C) to a solution of copper sulfate followed by boiling for a time. An excess of ascorbic acid yields the copper powder and a yellow solution; the composition of this solution has yet to be determined.[1]

Projects

- Make copper(II) oxide

- Make copper(II) sulfate

- Illustrations of Le Chatelier's principle

- Growing crystals

- Copper soap

- Copper alloys

- Cast beautiful copper metal items

Handling

Safety

Copper metal poses little toxicity and clean copper metal items are known to have antiseptic properties, thought not as powerful as silver. As such, getting scratch by a fresh cut copper wire is less hazardous that if it was some other metal.

Copper compounds also have antibiotic properties, being used as preservatives in sample analysis and biology. They are however moderately toxic, and excess intake of copper is harmful. They are also irritant on contact with the eyes, mucous or inhaled. Contact with the bare skin may reduce copper compounds to copper oxide or some other insoluble copper compounds, which will slightly stain the skin. Copper halides or oxohalides will visibly stain the skin.

Storage

Copper metal will develop a thin layer of oxide on its surface, that is usually not a problem and can be easily removed. However, if the copper metal was cleaned with acid before and hasn't been thoroughly washed, there is a risk of forming a patina. Copper powder is more sensitive and in moist air will rapidly oxidize to CuO. It is best stored in closed containers, either in inert gas (CO2 is enough) or under water or any other solvent. In case of the latter, there is the problem when drying the powder, as it may oxidize if done at a temperature too high in open air.

Hygroscopic copper compounds should be stored in sealed containers, to prevent them from absorbing the water from air.

Disposal

Special disposal procedures are required with copper compounds. All copper waste should be converted to the +2 state with peroxide and converted to the carbonate. This waste should never be dumped down the drain: rather it should be taken to the proper disposal facility or recycled.

Recycling copper back to metallic form is very easy: dissolve the copper(II) carbonate in a suitable acid, such as sulfuric acid, and then add in a reducing agent. Iron, zinc or aluminium are a good choice as they're cheap and available in large quantities. If aluminium is used, a chloride source should be added to promote replacement and break the protective Al2O3 layer.

Gallery

See also

References

- ↑ Experiment performed 6/17/14 by No Tears Only Dreams Now

Relevant Sciencemadness threads

- Pyrophoric copper: How?

- Precipitated copper powder

- Copper Thermite

- 500 ml copper flask

- removing trace copper impurities from AgNO3

- Copper plating isn't going too well

- Copper electroplating non-conductive material with PC power supply?

- Electroforming Copper Liners

- Electrolysis of Copper Sulfate (Electrodes)

- Copper Cathode Electrolysis

- copper bar stock

- Finding copper in common items?