| Pages:

1

2

3

4 |

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Synthesis of 3-(p-Hydroxyphenyl)-2-Butanone "raspberry ketone"

As a weekend distraction, I'm thinking of trying to synthesise this flavor at home.

HO-Ph-CH(CH3)-CO-CH3

(EDIT: apparently this is a isomer of the so-called "raspberry ketone". See the ohter posts. These two paths are obviously not revelant.)

Two paths came to my mind:

1°- Enolate synthesis: Forming the enolate of MEK with NaOMe, and reacting it with a protected p-halophenol. The phenol would react with the

methoxide, and could/would form an ester. I'm not sure on what to use for a protection, maybe reacting the phenolate with BnX or forming another

ether..

From the information available, using DMF as a solvant for the alkylation, and either FeSO4 or UV as catalyst. I'm not sure how well the reaction

would proceed.

2°- Acetoacetic ester synth of the protected bromophenol, followed by alkylation with MeI of the formed ester with another equivalent of alkoxide

at the benzylic carbon, followed by hydrolysis/decarboxylation.

Then of course deprotection of the formed ketone. Would the clivage of an ether with a Lewis acid damadge the ketone?

Any advice, ideas, suggestions? Any other ideas of pathways would be welcome.

[Edited on 27-12-2007 by Klute]

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

Hydroxybenzaldehydes

Christian Maliverney1 and Michel Mulhauser1

Kirk‑Othmer Encyclopedia of Chemical Technology

Abstract

Among the hydroxybenzaldehydes, only mono-, di- and trihydroxybenzaldehydes are known. Salicylaldehyde (2-hydroxybenzaldehyde) and

4-hydroxybenzaldehyde represent more than 99% of the hydroxybenzaldehydes' market. The physical and chemical properties of hydroxybenzaldehydes are

described. 2-Hydroxy and 4-hydroxybenzaldehydes react in a similar manner as phenol toward electrophiles. The aldehyde function can be reduced or

oxidized to form a variety of compounds depending on the reagents and conditions used. Hydroxybenzaldehydes undergo the normal reactions of aromatic

aldehydes.

Most industrial methods for the manufacture of hydroxybenzaldehydes are based on phenol, but other routes exist, starting from hydroxybenzoic acids,

by reduction, or from cresols, by oxidation. Both p-hydroxybenzaldehyde and salicylaldehyde have a low to moderate acute oral toxicity, but

salicylaldehyde is, in addition, corrosive toward skin and appreciably irritating to the eyes.

The hydroxybenzaldehydes are used primarily as chemical intermediates to a variety of products. The largest single use of salicylaldehyde is in the

manufacture of coumarin. Both are used as intermediates in the synthesis of agrochemicals, pharmaceuticals, fragrances, and in electroplating.

Condensation products of salicylaldehyde and diamines have important chelation properties, and have wide use in the stabilization of petroleum

products, and in chemical processing, especially as oxidation catalysts. These and other applications to polymer chemistry are described.

Keywords: Hydroxybenzaldehydes; Agricultural chemicals; Disinfectants; Coumarin; Flavors; Fragrances; Salicyladehyde; Electroplating; Pharmaceutical

intermediates

[Edited on 25-12-2007 by solo]

Attachment: Hydroxybenzaldehydes.pdf (160kB)

This file has been downloaded 3320 times

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Bunce, R.A., and Reeves, H.D. 1989. Synth. Comm. 19:1109-1118.

Tateiwa, J.-I., Horiuchi, H., Hashimoto, K., Yamauchi, T., and Uemura, S. 1994. Cation-exchanged montmorillonite-catalyzed facile Friedel-crafts

alkylation of hydroxy and methoxy aromatics with 4-hydroxybutan-2-one to produce raspberry ketone and some pharmaceutically active compounds. J. Org.

Chem. 59:5901-5904.

Halogen isn't going to come off the phenol very easily. This sounds more like the palladium catalysed reactions, you might even be able to get MVK to

couple with the halo-phenol, the reduce the alkene which should happen easily as it's a,b to the keto.

[Edited on 25-12-2007 by not_important]

|

|

|

leu

Hazard to Others

Posts: 368

Registered: 13-10-2005

Member Is Offline

Mood: No Mood

|

|

Description of GB2416770

Raspberry ketone (p-hydroxyphenyl-2-butanone) is a key flavour molecule with typical raspberry flavour characteristics and a low odour threshold.

Raspberry ketone is one of the most expensive flavour components used in the food industry. Up to $20,000/kg may be paid for the natural compound.

Raspberry ketone can be found in raspberries and other fruits (such as peaches, grapes, apples and various berries), vegetables (e.g. rhubarb) and in

the bark of tree (e.g. yew, maple and pine).

Raspberry ketone can be used in the aroma formulation of, for instance, strawberry, kiwi, cherry and other berries. However none of these fruits are

used to obtain the raspberry ketone as the low content of raspberry ketone in these fruits makes the extraction and purification process unprofitable.

Raspberry ketone can be produced chemically via the condensation of p hydroxybenzaldehyde with acetone.

However, the chemical synthesis of compounds can often result in environmentally unfriendly production processes and in undesirable racemic mixture of

the compound of interest (Vandamme and Soetaert 2002; J Chem Techno Biotechnol 77:1323-1332).

In raspberries, the synthesis of raspberry ketone is one part of the phenylpropanod pathway. This pathway has been described by Borejszaysocki and

Hrazdina (1994). In the first step, coumaryl CoA (which Is present In many plant tissues) is condensed with one malonyl CoA into benzalacetone

(p-hydroxyphenylbut 3-enc-2-one). The enzyme catalysing this step is called benzalacetone synthase (BAS). In the second step, the double bond in

benzalacetone is reduced, resulting in raspberry ketone (p-hydroxyphenyl-2-butanone). The enzyme catalysing this step is called benzalacetone

reductase (BAR), this enzyme requires the presence of NADPH. Benzalacetone synthase (BAS), EC 2.3.1.-., is a member of the polyketide synthase family.

Benzalacetone reductase condenses one acetone unit from malonyl CoA with one p-coumaric acid to form benzalacetone. Chalcone synthase (CHS), EC

2.3.1.74, is another member of the polyketide synthase family, which condenses three acetate units from malonyl CoA with one p-coumaric acid to form

chalcone. Stilbene synthase (STS), EC 2.3.1.146, is another member of the polyketide synthase family, which condenses three acetate units from malonyl

CoA with one p-coumaric acid to form stilbene (Zheng et al 2001). The polyketide synthase family is described in detail in Schroder 1999

(Comprehensive natural products chemistry vol 1: polyketides and other secondary metabolites includingfatty acids and their derivatives [U. Sankawa

Ed] pp 749-771).

CHS is part of another part of the phenylpropanod pathway, which converts phenylalanine into naringenin chalcone and its derivatives (Weisshaar and

Jenkins 1998; Hwang et al 2003). This part of the phenylpropanoid pathway involves the following enzymes: phenylalanne ammonia Iyase (PAL),

cinnamate-4-hydroxylase (C4H), 4-coumarate:coenzyme A ligase (4CL) and chalcone synthase (CHS).

As a first step phenylalanine Is deamnated to yield cinnamic acid by the action of PAL. Cinnamic acid is hydroxylatcd by C4H to 4-coumaric acid.

4-coumaric acid is activated to 4-coumaryl-coenzymeA (CoA) by the action of 4CL. CHS catalyses the stepwise condensation of three acetate units from

malonylCoA with 4-coumaryl CoA to yield nanngenin chalcone (which is a precursor for some flavonoids). Naringenin chalcone is converted to naringenin

by chalcone isomerase (CHI) or naringemn chalcone spontaneously converts to naringenn.

Evidence for the relation between BAS and CHS is provided by BorejszaWysocki and Hrazdna (1994 and 1996). Borejsza-Wysocki and Hrazdina (1994) show

that the timing of BAS activity parallels CHS activity. In addition, Borejsza-Wysock and Hrazdina (1996) show that CHS and BAS co-purify, and seem to

react with the same antisera. However, CHS and BAS activity in the same enzyme preparation showed a different response to treatments with, for

instance, 2-mercaptoethanol and ethylene glycol. Also, CHS activity and BAS activity showed different induction patterns upon treatment of raspberry

cell cultures with yeast extract, suggesting that these enzymes are not one and the same molecule.

Soluble enzymes catalysing the reduction of a double bond using NADPH, for example benzalacetone

reductase (BAR), are classified by the International Union of Biochemistry and Molecular Biology as belonging to enzymatic class EC 1.3.1.X. For

instance, an enzyme annotated as EC 1.3.1. 11 from Arthrobacter sp. was reported to remove a double bond from coumarate (Levi and Weinstein,

1964). However, no gene has been identified in connection to this enzymatic activity. Other enzymes In the enzymatic class EC 1.3.1.X are orotate

reductase, 2-hexadecenal reductase,

cholestenone 5 alpha-reductase etc. for which genes are known. However, none of these enzymes was reported to have benzalacetone reductase (BAR)

activity. It is known from literature that 4-hydroxybenzalacetone can be transformed to raspberry ketone by fungi or yeasts such as Pichia,

Saccharomyces, Beauveria, Kloeckera, Aureobasidium, Cladosporium Geotrichum, Mucor and Candida spp. (Fuganti and Zucchi, 1998). However, no gene has

been identified in connection to this enzymatic activity. Also, to our knowledge, no such activity has been reported for bacteria, neither gram

negative nor gram positive.

Attempts to biosynthesise raspberry ketone have been described. Hugueny et al (1995, Boflavour 95

pp 269-273) teach a biotechnological method for producing raspberry ketone. This method comprises culturing a microorganism which has a secondary

alcoholdehydrogenase (ADH), such as Candida boidinii, and adding the precursor betulosde to the culture medium. In this cellular environment the

secondary ADH dehydrogenatates betuligenol into raspberry ketone.

Various studies have been carried out to determine the role of polyketide synthase genes in the production of flavonoids using E cold transformed with

a raspberry CHS gene (see Zheng et al 2001; Kumar and Ellis 2003), a Glycyrrhiza echinata CHS gene (Hwang et al, 2003) or a Arabidopsis thaliana CHS

gene (Watts et al 2004). However these studies teach the in vitro or in vivo synthesis of naringenin.

These studies do not teach the in vivo synthesis of benzalacetone or raspberry ketone.

Abe et al (2001) teach the cloning of rhubarb BAS, expression of the gene in E colt, purification of the recombinant BAS protein and the in vitro

synthesis of benzalacetone. However this study does not teach the in vivo synthesis of benzalacetone or raspberry ketone.

SUMMARY OF THE INVENTION

According to a first aspect of the present invention, we provide a host cell comprising a chalcone synthase (CHS) polypeptide sequence and a

4coumarate:CoA 1igase (4CL) sequence in which one or both of the CHS polypeptide sequence and the 4CL sequence is heterologous to thc host cell.

Preferably, the CHS polypeptide sequence is derived from one of the following: raspberry, petunia, grape, Medicago sativa, Arabidopsis thaliana,

Antirrhinum majus, Zea mais and Petroselinum crispum, preferably a raspberry CHS sequence. Preferably, the CHS sequence is selected from the group

consisting of: accession number AF292367, accession number AF400567, accession number X04080, accession number X76892, accession number L02902,

accession number AF112086, accession number X0371O, accession number X60204, accession number V01538, a sequence shown in SEQ ID NO: 2, and a sequence

having at least 75% sequence homology thereto.

Preferably, the 4CL sequence is a tobacco 4CL sequence.

Preferably, the 4CL sequence is a sequence having an accession number U50846 or a sequence shown in SEQ ID NO: 3.

Preferably, the host cell is transformed with an expression vector encoding the chalcone synthase (CHS) polypeptide sequence and an expression vector

encoding the 4-coumarate:CoA ligase (4CL) sequence, or an expression vector encoding both sequences.

Preferably, the host cell is a microbial host cell selected from the group consisting of F,scherichia spp, Saccharomyces spp, Pichia spp, Beauveria

spp, Candida spp, Aspergillus spp, Bacillus spp, Pseudomonas spp, Hansenula spp, Klayveromyces spp, Schizosaccharomyces spp, Streptomyces spp,

Lactococcus spp, Lactobacillus spp, Pediococcus spp, Kloeckera spp, Aureobasidium spp, and Streptococcus spp, preferably an E. colt, preferably strain

BL21, or a Saccharomyces cerevisiae, preferably strain YPH 499, or a Bacillus subtilis host cell.

Preferably, a polypeptide expressed from the CHS polypeptide sequence has benzal acetone synthase (B AS) acti vity.

Preferably, the host cell is capable of producing benzalacetone when supplied with a precursor of benzalacetone, preferably p-coumaric acid or a

source of p coumarc acid.

Preferably, the host cell has benzalacetone reductase (BAR) activity, preferably inherent benzalacetone reductase (BAR) activity.

Preferably, the host cell further comprises a benzalacetone reductase (BAR) sequence, preferably a heterologous BAR sequence, preferably shown as SEQ

ID NO: 5.

Preferably, the host cell is capable of producing raspberry ketone when supplied with a precursor of raspberry ketone, preferably benzalacetone or a

source of benzalacetone. Preferably, the host cell is capable of producing raspberry ketone when supplied with a precursor of raspberry ketone,

preferably p-coumaric acid or a source of p-coumaric acid.

Preferably, the host cell further comprises a cinnamate-4-hydroxylase (C4H) sequence.

Preferably, the host cell Is capable of producing benzalacetone or raspberry ketone, or both, when supplied with cinnamic acid or a source of cinnamic

acid.

Chemistry is our Covalent Bond

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

Reference Information

Cation-exchanged montmorillonite-catalyzed facile Friedel-crafts alkylation of hydroxy and methoxy aromatics with 4-hydroxybutan-2-one to

produce raspberry ketone and some pharmaceutically active compounds.

Tateiwa, J.-I., Horiuchi, H., Hashimoto, K., Yamauchi, T., and Uemura, S.

J. Org. Chem. 59:5901-5904., 1994

Abstract

The Friedel-Crafts alkylation of hydroxy and methoxy aromatics with 4-hydroxybutan-2-one (y- KB) in the presence of a cation-exchanged

montmorillonite (Mn+-mont; Mn+ = Z++, N3+, Fe3+, and Zn2+) was investigated. Phenol was C-alkylated regiospecifically with y-KB in the presence of

Z1A+-, A13+-, or Fe3+-mont to produce 4-(4-hydroxyphenyl)butan-2-one (raspberry ketone) in 31-35% GLC

yield. Anisole, 2-methoxynaphthalene, and 1-methoxynaphthalene were regiospecifically C- alkylated to produce 4-(4-methoxyphenyl)butan-2-one,

4-(2-methoxy-l-naphthyl)butan-2-one (phar- maceutically active), and 4-(4-methoxy-l-naphthyl)butan-2-one, respectively. N3+- and Fe3+-mont

were the most effective catalysts in these cases (13-58% isolated yield). y-KB could be used as an alkylating agent instead of the highly toxic

3-buten-2-one (MVK) which also polymerizes easily.

Attachment: Cation-Exchanged Montmorillonite-Catalyzed Facile Friedel-Crafts Alkylation of Hydroxy and Methoxy Aromatics with 4-Hydr (553kB)

This file has been downloaded 1981 times

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

Reference Information

Amberlyst-15 Catalyzed Addition of Phenols to agr,b.beta-Unsaturated Ketones

Richard A. Bunce a; Henry D. Reeves

Synthetic Communications Volume 19, Issue 5 & 6 March 1989 , pages 1109 - 1117

Abstract

Amberlyst-15 has been used to catalyze regioselective additions of phenols to agr,b.beta-unsaturated ketones in yields of 20-90%. The reaction is

superior to the analogous reaction employing concentrated sulfuric acid in affording greater yields and purer products with a minimum of laboratory

operations.

[Edited on 25-12-2007 by solo]

Attachment: Amberlyst-15 Catalyzed Addition of Phenols to agr,b.beta-Unsaturated Ketones.pdf (417kB)

This file has been downloaded 2598 times

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Thanks for all thoses articles!

I've just realized that there seems to be some confusion in the litterature on the exact nature of the so-called "raspberry ketone": in two of my

org.chem books, and in some articles on the net, it is said to be the branched p-hydroxyphenylbutanone, the phenyl ring being attached to the

third carbon of the chain, alpha to the carbonyl. See here: Smell Database

But in all the articles/patents you guys have kindly provided, it is said to be the straight-chained isomer.

To my eyes, the linear isomer 4-(para-hydroxyphenyl)butanone seems easier to synth, especially through the p-hydroxybenzaldehyde pathways.

A crossed aldol with acetone is easy and well documented, basic conditions would be more effective here I guess, the benzalacetone should be easy

to isolate and purify, and I guess a CTH could reduce the double bond, or NaBH4 even if the carbonyl gets reduced, it could easily be re-oxydized.

US4414417 deals with a CTH using Rhodium and Iridium catalysts that yield the saturated ketone; this could be applied to other catalyst/donors.

The FC option seems equally interesting, but not possessing any b-hydroxybutanone, it doesn't seem readily obtained from MEK or other

accesible reagents.

p-hydroxybenzaldehyde could be obtained through a Riemmer-Tiemann as mentionned in the review Solo provided, I remember ready about performing the

reaction in alcoholic medium to preveil the para-formylation.

I have ~30g of phenol left, so this could be enough on a small scale, though I want to give the o-formylation a try using Mg(OCH3)2/paraformaldehyde

a try again. Maybe a bayer-villiger oxydation on benzaldehyde could give workable yields of phenol. I don't want to melt any benzenesulfonic acid with

NaOH  . .

Well, I guess I'm going to keep busy for a while  thanks for the help! thanks for the help!

|

|

|

LSD25

Hazard to Others

Posts: 239

Registered: 29-11-2007

Member Is Offline

Mood: Psychotic (Who said that? I know you're there...)

|

|

Klute,

I just found this whilst looking for zingerone (fuck knows why I was looking for that, but...)

http://www.apc.titech.ac.jp/~tikariya/mito/teaching/2005/tex...

Seems like a nice, simple route

I reckon I could even practice the yeast reduction on the zingerone - although that rhodium catalyst makes ones mouth water eh?

Whhhoooppps, that sure didn't work

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

Reference Information

Rheosmin (“Raspberry Ketone”) and Zingerone, and Their Preparation by

Crossed Aldol-Catalytic Hydrogenation Sequences

LEVERETT R. SMITH

THE C H EMICAL EDUCATOR VOL . 1 , N O . 3

Introduction

Preparations of the two closely-related natural products rheosmin (“raspberry ketone”, 4-(4'-hydroxyphenyl)- 2-butanone) and zingerone

(4-(4'-hydroxy-3'-

methoxyphenyl)-2-butanone), are well-suited for the introductory organic laboratory. The crossed-aldol condensation of 4-hydroxybenzaldehyde with

acetone gives an adduct (4-(4'-hydroxyphenyl)-3-buten-2-one), which is hydrogenated

cleanly over rhodium on alumina to form rheosmin. Condensation of vanillin with acetone gives 4-(4'-hydroxy-3'- methoxyphenyl)-3-buten-2-one, which is

hydrogenated to zingerone. The article includes background information on the

target compounds and the synthetic methods used, along with experimental procedures and IR and NMR data on the compounds encountered.

[Edited on 1-1-2008 by solo]

Attachment: Rheosmin (“Raspberr Ketone”) and Zingerone,and Their Preparation.pdf (99kB)

This file has been downloaded 2764 times

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Thanks alot for those two last papers, especially your Solo, just what I need.

I think i will ratehr try a NaBH4 reduction of the unsaturated ketone though, as I don't plan on aquiring any rhodium catalyst, and Pd/C would

surely give the same result as NaBH4, or a mixture of the saturated alcohol and ketone. I might try it with some recylced catalyst at a small scale,

as per Solo's document.

I will surely try making zingerone first, trying the aldol condensation and see how the reduction goes, I've encountered a few mishabs with the

Mg(OMe)2 / (H2CO)n formylation, although the reaction seems to proceed well. Left the acidifyed mixture stir too long, resulting in a f**king

polymeric sludge (excess paraformaldehdye). It's just a lot of work, along with the preparation and drying of the reagents. Does seem more interesting

than the Riemmer Tiemann though.

|

|

|

pantone159

National Hazard

Posts: 590

Registered: 27-6-2006

Location: Austin, TX, USA

Member Is Offline

Mood: desperate for shade

|

|

Thanks also to solo for the last paper... Also thanks for pointing out 'The Chemical Educator', a journal that I wasn't aware of. Perhaps this is

akin to the Journal of Chemical Education(?) which I like a lot.

Klute - Let us know how the NaBH4 reduction goes, that would be easier for me to try then the hydrogenation.

|

|

|

stoichiometric_steve

National Hazard

Posts: 827

Registered: 14-12-2005

Member Is Offline

Mood: satyric

|

|

klute: Pd/C-CTH does generally NOT reduce carbonyl functions.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

From the document Solo has just posted:

"Literature reports appear of palladium and Raney nickel giving significant over-hydrogenation to give alcohols as byproducts, in 15–20%

yield, which complicates cleanup and isolation of pure ketone products [30,

36, 47].

30. Mannich, C.; Merz, K. W. Archiv d. Pharm. 1927, 265, 15.

36. Pabst, A.; Barron, D.; Adda, J.; Schreiber, P. Phytochemistry 1990, 29, 3853.

47. Banno, K.; Mukaiyama, T. Bull. Chem. Soc. Japan 1976, 49, 1453."

I might try a microscale experiment with recycled Pd/C, both by CTH and catalytic hydrogenation as per the article, if I have enough time. But if

NaBH4 reduction works as cleanly and effeciently as I hope it will, and oxydation with either H2O2/Fe3+ or some HOCl source works nicely, it could

come out cheaper/more practical than getting some Rh/Alumina, of which I won't have any immediate use elsewhere.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Thanks to Nicodem, who kindly retreived European Journal of Organic Chemistry 9,(2000) 1793-1797, dealing with the use of

NaBH4/CoCl2 system in either MeOH or aq. medium for reduction of 4 unsaturated ketone, including benzylideneacetone, the unsubstitued derivative of

the two unsaturated ketones mentionned further up, to afford either:

-the unsaturated alcohol by using straight NaBH4 in protic medium

-the saturated ketone by using NaBH4/CoCl2, giving 86% of 1-phenylbutan3-one when using a Sub/NABH4/CoCl2 ratio

of 1/3.5/3

-the saturated alcohol, by doing a two-step one-pot procedure, first reducing the carbonyl then the double bond, or vice versa.

So this really is a key article for this synth, no need of catalytic hydrogenations, or multiple steps to obtain the ketone. Aldol, reduction,

voilà. Mild conditions, easy workup.

I will try out the zingerone synthesis as soon as I get my vanillin, and then start working on get that para-hydroxybenzaldehyde... Any ideas

apart from the Riemmer Tiemann, which isn't really para-selective, and would yield o mixture of o- and p-isomers?

BTW, NiCl2 can be used aswell with similar results. I will also report back on the Mg(OMe)2/(CH2O)n formylation once everything is done.

EDIT: I read the wrong colum in the tables, actually the best yield of the 1-phenylbutan-3-one is 86%, when using a solution of Sodium

Dodecylsulfate..

[Edited on 7-1-2008 by Klute]

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

I don't know about purity, but to get some vanillin on the cheap, go buy the cheapest bottle of clear artificial vanilla extract that you can

(essentially containing vanillin, ethanol, and water) and place it in a flask with air excluded (such as by a piece of aluminum foil with a small hole

in it) and heat until ethanol stops boiling off (I did this a looooong time ago before I had much experience or a decent thermometer and remember that

the solution suddenly changed boiling pattern when this happens..I was also checking the flammability of the vapors). You may have a second phase

seperate. This is liquid vanillin or perhaps liquid vanillin with water dissolved in it (mp. vanillin 81-83C). Add water and heat to dissolve if this

occurs. Chill the solution (which may be a pale amber color from oxidation/polymerization products. Using aluminum foil and allowing water/alcohol

vapor to form a protective atmosphere minimizes this) Vanillin crystallizes out as long, thin, pale yellow/cream colored needles. I got 13g from an

8oz bottle ($7 US) I'm sure most here can improve on this method though.

[Edited on 1-6-08 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

UnintentionalChaos, thanks for the advice, but I think I will be getting my vanillin from a flavoring supplier, which offers it in >99% purity for

a reasonable price. But I might give it a try with the flavorings at the local supermarket, as the minium is 500g, and I wouldn't know what to do with

so much vanillin, even if using it for baking cakes and stuff

As I only screened quickly through the article yesterday, I mixed up some entries, and the fact that the only way of obtaining good yields of pure

phenylbutanone is to use a 0.1mol.L solution of Sodium Dodecylsulfate (SDS), which I don't currently have at hand, as a reagent anyway. Apparently,

Tetrabutylammonium Bromide can't be a good substitute as it doesn't form micellar emuslions, which apparently "protect" the ketone from reduction by

BH4-; it's the formed H2 which is the true reducing agent, catalysed by the formed metal boride. I could try using benzylalkylammonium chlorides, in

C10-C12, which would form micellar emuslions and might act similarily. It's starnge as they have a few entries were using MeOH and H2O as solvants

give 77% et 51% yield respectively, but latter state that:

"The preparation of pure product 3c [1-PhButanone] was not possible in either MeOH or water, and only use of aqueous solutions of SDS afforded it in

good yield (entry 10). It seems that this surfactant ‘‘protects’’ the micellar-bound substrate

from attack by the reactive anion BH4 –, the main reduction

pathway being, therefore, the one carried out by H2."

I guess the product is contaminated by saturated alcohol, and that the 2 must be hard to seperate. A light oxydation could convert any over-reduced

material back to the ketone, but could also make more impurities, and give a complex mixture of products. Let's try it one pot.

So if the benzalkonium (pool supply) doesn't work out nicely, I was thinking about generating before-hand the metal boride with stoechimetric

amounts of borohydride and the chloride, in the appropriate solvant, and then adding the substrate and performing a atmospheric catalytic

hydrogenation. Wouldn't it basicly proceed the same way as in-situ formed H2? I think it is molecular hydrogen that is evolved and not nascent, but

don't take my word on this. Can anyone can help me out here? This way, no need of using expensive Rhodium catalyst.

EDIT:I've been kindly given ~30g of reagent-grade vanillin, so I will be able to perform the aldol condensation this weekend.

I've decided on trying a simple atmospheric catalytic hydrogenation with preformed CoB catlyst (from CoCl2 and stoechiometric NaBH4), as I've

realized I've only got a couple grams of CoCl2 and no NiCl2... We will see how it turns out. I'm still undecided concerning the amount of catalyst to

use... Any advice would be welcome.

[Edited on 10-1-2008 by Klute]

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Solo kindly retreived two more article on the catalytic hydrogenation of unsaturated ketones:

Colloidal nickel boride on rare earth oxides for hydrogenation of olefins

Yu-Lin Jiang, Xue-Yun Wei, Shou-Ping Tang and Liu-Bin Yuan

Catalysis Letters; 34, (1995) 19-22

This deals with the use of colloidal NiB catalyst, mixed with rare earth oxides in some cases, to afford a highly active catalyst, prepared from the

metal salt, and alcoholic NaBH4 in presence of PEG. The hydrogenation of p-hydroxyphenylbut-3-en-2-one to Rheosmin "raspberry ketone" is covered. The

preperation of the "simple" catalyt is straight forward. They claim a 96% isolated yield of rheosmin when using Ni2B, in 170min, and the hydrogen

uptake rate and thus reaction is much quicker when the catalyst is made as described with PEG and Nd2O3.

Another particluary interesting thing is that they compared the activity of this catalyst with Pd/C, and claim a 96% isolated yield of Rheosmin in

160min! This is pretty contradictory with the Chem.Educ. article.

At first reflexion, I would rather trust the Chem. Educ. article, as the reactions were reviewed for use in academic labs by students, although it

is not explicity claimed that the Pd/C hydrogenation was. But then again, when presenting a new catalyst, the authors of the Cat. Today would have

highlighted the strong superiority of their catalyst towards product isolation if they had obtained bad yields when using Pd/C. Although dishonest,

claiming higher yields with the object of their article would seem more logical than claiming high yields (although longer reaction times) with such a

widely used catalyst. In any case, this inspires me at trying it.

The other good news is that with both catalyst atmospheric hydrogenation seems to give very good yields, so no need of pressurized hydrogen.

Selective hydrogenation of 4-(6-methoxy-2-naphtyl)-3-buten-2-one to Nabumetone®

Nicoletta Ravasio, Federica Zaccheria, Pietro Allegrini and Mauro Ercoli

Catalysis Today, Volume 121, Issues 1-2, 15 March 2007, Pages 2-5

This article describs the use of reuseable, easily prepared SiO2-supported Cu catalyst for hydrogenation of unsaturated ketones.

Highly-loaded catalyst promotes complete reduction to the saturated alcohol. But 8% Cu/SiO2 apparently gives good yields when reducing the titled

compound, derivative of benzalacetone were the phenyl ring is replaced by a substitued naphtyl ring. Both compounds should behave similarily I guess.

No isolated yields are mentionned, only high selectivities, which can be unclear towards to true efficienty of the reaction. High selectivites but

low conversions can be usefull for industrials when the substarte can easily be recycled.

Once again, >98% selectivites are mentionned for 5% Pd/C. It is also mentionned that adding ~5% K2CO3 to a Pd/C hydrogenation minimizes the

formation of the saturated alcohol, which is a good find.

Even if the catalyst can easily be prepared before introduction of the substarte, the problem is that changes in the quality of the silica can

cause drastic changes in the products, especially with aliphatic unsaturated ketones. Conjugated aromatic unsaturated ketones appear more resitant to

this change in chemioselectivity. But as I personally make my silica gel from soduim silicate solution and HCl, the quality varies enormously, and I

don't really have means of controlling porosity, surface/gram and other caracteristics that seem to play a important role here.

But the simplicity of the procedure still makes this a interesting experiment. Cu-based catalyst are said to be more selective to carbonyl reduction

than double-bonds, and if reprocuble results can be obtained with home-made catalyst, this could have other applications for different compounds, and

thus make cheap, available hydrogenation catalyts for the home chemist, compared to other mostly expensive ones.

I'm finding this subject more and more interesting. What started as a simple weekend-occupation subject is turning into my major center of interest

actually. I'm very lucky that there some interesting litterature on the subject, and incredibly helpfull members here that provided these articles as

I can't access any libraries at the moment. Again, thanks a million.

|

|

|

LSD25

Hazard to Others

Posts: 239

Registered: 29-11-2007

Member Is Offline

Mood: Psychotic (Who said that? I know you're there...)

|

|

Solo,

Thanks for J.Chem Ed article - I'd seen the abstract to that before and have long wanted to read it....

Whhhoooppps, that sure didn't work

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

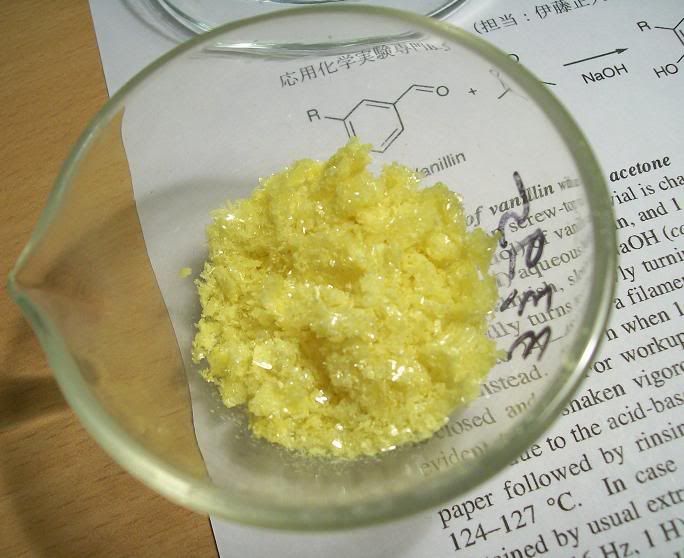

Synthesis of 1-(4-hydroxy-3-methoxyphenyl)but-1-en-3-one by basic crossed-aldol condensation of vanillin and acetone.

Finally started this very easy reaction. I just scaled up 20x the L. R. SMITHChem. Educ. 1(3) "short" synthesis, and plan on

leaving it 48h at room temp.

Synthesis

5g (33 mmol) of reagent-grade vanillin [Picture 1] were weighed, and dissolved in 20mL (~280 mmol) of

technical acetone, giving a totally limpid solution, in a 100mL capped bottle containing a stir bar [picture 2].

2g (50 mmol) of technical NaOH were dissolved in 20mL dH2O (10% w/v, 2.5 mol/L), and the warm solution was cooled under a stream of cold

water. Once at room temp, the solution was slowly poored into the acetone solution with steady stirring. This immediately caused the solution to turn

yellow and warm up somewhat [picture 3]. The color gradually darkened, becoming dark orange after 5min, and the bottle cooled down

gently [picture 4]. This will be stirred at RT for 48h, then worked up as per the article: addition of 100mL of 3M HCl, filteration

and washing of the resulting solids, recrystallization with EtOH/H2O, and caracterisation of the product.

This unsaturated ketone will then be hydrogenated over 10% Pd/C to the corresponding ketone, 1-(4-hydroxy-3-methoxyphenyl)butan-3-one, or

Zingerone. Hydrogenation over preformed Co2B might also be tried.

Picture 1

Picture 2

Picture 3

Picture 4

Sorry if the pics are big, I didn't find how to just post a "icon" to the large pictures for display on another window. If this causes too much

problems for uploading this thread, I'll diminish the size...

EDIT:

12h later, the mixture is now dark cherry red. I will post a picture tomorow as I don't have the time right now.

[Edited on 17-1-2008 by Klute]

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Synthesis of 1-(4-hydroxy-3-methoxyphenyl)but-1-en-3-one - Continued

After 48h stirring at RT [Picture 1], the dark red/black mixture was transfered to a 250mL beaker, and 100mL 10% HCl poored in with

magnetic stirring. A black oil crashes out, giving a black heterogenous mixture [Picture 2]. After 2min stirring, a fine yellow solid

started precipitating [Picture 3]. Black droplets were still present at the bottom.

After another 5min stirring , the suspension was filtered, care taken of decanting the heavy, dark granules present at the bottom of the beaker.

The fine suspension gave a greenish crystalline powder [Picture 4], which was washed with a little water, dried with suction on the

buchner, and transfered to a small beaker.

The dark crystalline granules were equally washed, filtered and dried [Picture 5]. They did not agglomerate, and were very easy to

collect in a seperate beaker.

The two crops were recrystallized with hot 10mL EtOH, followed by gradual addition of 5-8mL water, and left to cool. The first crop gave a clear,

greenish solution, the second gave a dark brown, but limpid solution. The first crop crystallized very quickly. It was filtered, briefly washed with

water, and dried on the buchner [Picture 6], giving beautifull canary-yellow crystalline flakes [Picture 7] .

The second crop crysatllized much less, not enough water had been added. The formed crystals were filtered, the filtrate replaced in the beaker, and

the cake sparingly washed with water and dried. The crystals formed, although larger than the first crop, were of a more darker yellow

[Picture 8].

The two crops of crystals were left to dry in the dessicator, and finally weighed exactly 2.53g each!

The final weight was 5.06g (26.35 mmol), representing a yield of 79.86%. Not bad.

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

Picture 6

Picture 7

Picture 8

Hydrogenation will hopefully be performed next weekend.

|

|

|

tinydantzler

Harmless

Posts: 1

Registered: 20-1-2008

Member Is Offline

Mood: No Mood

|

|

I was wondering if someone could help me out with something regarding this synthesis of zingerone.

I am currently in a beginner-ish orgo chem lab in college, and I need to propose a 3 step synthesis of a compound of some interest. As far as I can

tell, the synthesis of zingerone from vanillin is only a 2 step (the vanillin and acetone with NaOH and the hydrogenation), and I'm having trouble

coming up with a possible third step either at the beginning or end.

I mean, I can sort of see some compounds I could possibly synthesize vanillin out of, but they seem to be unimportant things that would not be readily

purchasable.

I read that zingerone is produced by heating gingerol through a retro aldol reaction. Now, mind me if I say something stupefying as I do not have much

practical lab experience, but would an aldol reaction of zingerone and what appears would be an aldehyde be at all feasible?

If anyone could help out, I'd really appreciate it. I have a backup plan if I cannot figure something out with zingerone, but this seems more

interesting.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

You could make the vanillin from eugenol, that's a common academic synthesis IIRC, using KMnO4. I'll have a look to see if I can't find a protocol at

home. Or there some news ways of making vanillin from lignin.

Maybe you could reduce the unsaturated ketone all the way to the saturated alcohol (NaBH4/CoCl2 2 steps-one pot, see the article mentionned earlier

in the thread, or better LiAlH4 if they let you handle that) and then oxydize to the saturated ketone.

You could try the rheosmin synthesis, making the p-hydroxybenzaldehyde, although I haven't found a practical way with the chems I can acces for now.

It seems the Riemmer Tiemann formylation would essentially yield salicylaldehyde, with only small amouts of p-isomer.

Good luck, please keep us posted on what you decide on doing, and how it goes.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

@Tinydantzler: Vanillin can also be done by formylating guiacol (2-methoxyphenol) - a cheap and readily available chemical. This can be done by the

Reimer Tiemann reaction in the presence of cyclodextrin or tertiary amines (they change the regioselectivity of the reaction thus allowing for the

para formylation). Other published methods include the condensation with glyoxalic acid in basic media following by the oxidation of the intermediate

mandelic acid to vanillin (but these are two steps). One Japonese patent also describes the Vilsmeier-Haack formylation of guiacol using DMF/POCl3 at

120°C. This last is probably the most suitable for lab scale.

@Klute: Nice work.

Edit: Wrote glycolic acid instead of glyoxalic...

[Edited on 22/1/2008 by Nicodem]

|

|

|

LSD25

Hazard to Others

Posts: 239

Registered: 29-11-2007

Member Is Offline

Mood: Psychotic (Who said that? I know you're there...)

|

|

Or you could oxidise the ketone to the cinnamic acid... Ferulic acid:

http://en.wikipedia.org/wiki/Ferulic_acid

Alternatively, I think Solo (here or elsewhere) came up with a 1-step procedure for benzaldehyde from phenylalanine - this might hold true for

tyrosine (p-hydroxyphenylalanine) then you have the p-hydroxybenzaldehyde. From that rheosmin synthesis could be acheived in the remaining two steps.

If yields ain't important - the Strecker degradation of tyrosine with glyoxal or potassium peroxodisulfate:

http://www.cazv.cz/attachments/3-Adamiec.pdf

Will give crap yields of the benzaldehyde, but like I said, if yield ain't important. If however you use diazomethane some very interesting methyl

ketones might result.

Whhhoooppps, that sure didn't work

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Nicodem: does that tertiary amine trick work in general, or is this only related to vanilin? I don't remember ready about this before, IIRC the

Riemmer Tiemann review (haven't got the ref on hand, but it was made available here) doesn't mention it, but I haven't got the document at hand so

can't confirm this. If you've got a ref or two, I'd be delighted to give them a look.

LSD25, smart idea from the tyrosine, but indeed seperating the vast amount of byproducts would be time-costly, and for minimal yields. But both

products (tyrosine and S2O82-) are pretty available. I'll have a look for Solo's idea, or ask him directly if I can't find anything.

|

|

|

| Pages:

1

2

3

4 |

|