| Pages:

1

2 |

RogueRose

International Hazard

Posts: 1592

Registered: 16-6-2014

Member Is Offline

|

|

Ball mill grinding material (making metal balls - ZA-27)

I was looking for the best metal that could be used in casting metal balls for a ball mill. The metal needs to be as hard as possible, as heavy as

possible and have as low a melting point as possible.

Looking at the Brinell hardness chart, it seems that Al can range from 15-120 depending upon the alloy, with the most of the more expensive alloys

being higher like 6000 & 7000 series Al alloys. Most Al foils looks to be 15-25 (but most 15-17).

So I tried to find something that might work better than soft lead and steel that could spark and ZA-27 is what I found to be a possible option. ZA

stands for Zinc Aluminum alloy, which is 25-28% Al, 2-2.5% Cu and the remaining Zinc (with less than .15% other metals found in the metals which are

impurities so they aren't really counted. The density is reported at 5.1g/cc which is a little light for my taste but it has a hardness of 119.

steel 8g/cc

glass 2.4 g/cc

I've made this alloy a number of times and it is very interesting in how melted zinc (at about 800 degrees) can dissolve the Al and Cu (the Cu MP is

1984F!!). I don't' know how it works exactly but it does take a little stirring but it does all dissolve into the zinc - a type of galvanic action

possible? I used cut up pieces of Al cans (and tabs) for the Al or Al wire and then used copper wire (which takes the longest to dissolve). ZA-27

has a MP of 806 F.

I've not tried casting with the ZA-27 in round bullet moulds (which are available from .3" to .69" diameter) yet but I think it should be fine to do

so as the moulds are made of Al.

Has anyone worked with this alloy and/or have any opinions as to the suitability for milling?

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

https://www.dynacast.com/acuzinc5

Acuzinc5 seems to be a better choice. Strength is almost as good with almost 20% higher density. Casting zinc can be problematic, it's usually

pressure cast to ensure good mold filling but I'm sure round balls would be fairly simple to achieve.

Just be aware that the reported hardness can be aged quality, you'll need to look that up. Generally speaking precipitation hardening alloys are first

solution treated by heating at high temperature (say 75% of the MP), then quenched. After that they are aged at moderate temperatures (up to 50% of

the MP) for a few hours. Aging increases yield strength at the cost of reduced ductility. The hardest qualities can be too brittle for your use,

again, you'll have to look that up.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

highpower48

Hazard to Self

Posts: 98

Registered: 30-10-2014

Member Is Offline

Mood: No Mood

|

|

I use hard cast .54 caliber balls. These are soft lead with added tin. I have used the same balls for 10 go around making black powder. No issues with

them....

|

|

|

RogueRose

International Hazard

Posts: 1592

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by Fulmen  | https://www.dynacast.com/acuzinc5

Acuzinc5 seems to be a better choice. Strength is almost as good with almost 20% higher density. Casting zinc can be problematic, it's usually

pressure cast to ensure good mold filling but I'm sure round balls would be fairly simple to achieve.

Just be aware that the reported hardness can be aged quality, you'll need to look that up. Generally speaking precipitation hardening alloys are first

solution treated by heating at high temperature (say 75% of the MP), then quenched. After that they are aged at moderate temperatures (up to 50% of

the MP) for a few hours. Aging increases yield strength at the cost of reduced ductility. The hardest qualities can be too brittle for your use,

again, you'll have to look that up.

|

Thank you kindly for this info. I never really looked into other alloys as once I found this (a low MP castable replacement for cast iron - it has

about 80% of the strength and much less weight from what I remember..) The AcuZinc5 is Brinell Hardness of 115 and a density of 36.5% higher than

ZA-27 so it is about 6.96 g/cc which is pretty darn close to steel and a MP of only 826!!! That is pretty great IMO.

I'm wondering

Lead - 11.34g/cc Brinell - 38-50

Bismuth - 9.78g/cc Brinell - 70-95

Copper - 8.96 g/cc Brinell - 80-85

BUT here is a much different reading on the HB test, less than 50%!!

(but only 35 according to the Wiki Brinell Hardness page...)

I'd like to play around with making some of my own alloys with the highest density, lowest MP to allow casting in Al moulds, and a hardness adequate

for grinding Aluminum, zinc, Mg, charcoal and various salts. I'm thinking a HB rating of 50-60 would be sufficient for these materials but thoughts

and opinions are welcome.

Price is a major factor so the metals need to be relatively inexpensive or available in scrap products like (lino-type, wheel weights, etc).

Are there any other dense metals that might be usable in this?

Finally I'm wondering if anyone knows how to drill semi-spherical holes (a 1/2 sphere on 2 pieces of Al or graphite facing each other to make a

sphere). I have access to Al that is up to 3" thick and 4-18" long, as well as graphite blocks of similar size. IDK if graphite can be used as a

mould for casting lead, zinc or other metals/alloys discussed in this thread. I know that it could be done on a lathe but that isn't available (could

special order I guess). I'm interested in doing anything from 1/2" to 2" spheres for this casting. Any suggestions on how to do this or where to

look for the process. I've looked for spherical pointed drill bits and they don't seem to be "true" spheres - they are similar to pointed flat drill

bits

What I need the moulds to look like after drilling - I'd actually like to have many in a row on one long block instead of a single mould.

Here are the only bits I've found

These are counter-sink bits

Flat, pointed drill bits - forget what they are used for. Supposedly there are semi-circle ones available like this

This is a little closer, and it often used for glass or ceramics

Carbide Tipped Drill Bit for Drilling Natural Stone, Granite, Slate, Ceramic and Glass Tiles - about $20 for a 1/2" bit - not to bad

Undercutting End Mill - about $200 for 1/2"!!! a little pricey

Diamond burrs - 80 grit

20mm-$6.50, 25mm-$8.00, 35mm-$11.50, 40mm-$15, 50mm-$30

The thing I was thinking since these don't have to be perfectly spherical is to use a drill press and drill out the material (using depth stops) and

then remove the remaining material with a Dremel. Many bits available for this - Rotozip bits, cutting discs, sanding drums and then the burrs

directly above would be excellent for removing and smoothing out material left behind from the drill press and then followed up with sanding then

polishing the material.

The last option is to make cylindrical shaped grinding material (1/2" diam x .75 to 1" length, up to 2" diam and 2"-3" length). This would be much

easier to make but IDK how effective this would as grinding material. It might be good for things like salts (KNO3, NH4NO3, charcoal, sulfur, etc)

but for things like metals like Al, Mg, Zinc, having all the weight of the milling ball focused on one point (bottom of sphere) would greatly increase

the PSI applied to the material being milled. Is this correct thinking or am I off in this thinking.

Thanks a lot for all the help guys/gals. I'm going to be making a good how-to for building various size ball mills complete with media one this is

done. The current model is a 5 gal bucket (hence the larger size media).

These below are ceramic insulators for electric fences (found 12 for $2!!). They weigh about 4oz and are very hard. These were mixed with 10mm ball

bearings inside a 1gal paint can (lined with HDPE cut from a paint bucket - works great and doesn't wear through the metal casing anymore!!!) IDK if

these are bad, after about 300 hours, I've lost about 3g of material from the 24 insulators or about 00.12% of the total mass of the material - IDK if

that is bad or unacceptable (for Al & charcoal I don't think this contamination is an issue).

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

You might be able to DIY a spade drill from a round disc, preferably something hardened like a spring washer. I made a half-sphere mill by turning a

piece of rod hemispherical then milling it down to half the thickness. It worked OK in aluminum (made a multi hole mold for 1/2" lead balls). Graphite

will be much easier to machine and should work fine as a mold.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

You could use a pattern to make a split green sand or ceramic mould. You can easily incorporate the runners that way and you will not have to worry

about melting the mould.

Perhaps a one piece mould using a wax (lost wax process) or polystyrene pattern.

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

aga made some ball milling media a while back using a two piece mould drilled with a homemade round bit and it worked great https://www.sciencemadness.org/whisper/viewthread.php?tid=61...

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

I made the balls for my ball mill using a 2oz round fishing sinker mold. It had 5 cavities and made balls ~2cm in diameter. I was casting lead.

The mold itself was cast aluminium. Maybe you could try casting a mold, instead of machining? Or just buy one - they're not expensive.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

RogueRose

International Hazard

Posts: 1592

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by Fulmen  | You might be able to DIY a spade drill from a round disc, preferably something hardened like a spring washer. I made a half-sphere mill by turning a

piece of rod hemispherical then milling it down to half the thickness. It worked OK in aluminum (made a multi hole mold for 1/2" lead balls). Graphite

will be much easier to machine and should work fine as a mold.

|

I was told by a friend that he uses a washer to drill his moulds for large marbles (graphite mould material). This seems like the easiest way to test

and can be done for under $2 for a 2" bit!!! Can't beat that if it works!.

Thanks for the help everyone, I'll post my results!

|

|

|

RogueRose

International Hazard

Posts: 1592

Registered: 16-6-2014

Member Is Offline

|

|

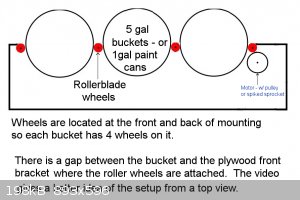

I came across a very interesting idea on how to make a ball mill from a 5 gallon bucket. It uses old rollerblade wheels (2 on each side, one at each

end of bucket) and this is much easier to setup than using cylindrical rollers the length of the bucket (centering the rod in the rollers isn't the

easiest and the wheels makes the much easier).

Here is a short 2 minute video that shows a guy who made a single bucket mill. I'm looking at a similar setup but may make it for 2-3 buckets at

once. One issues is that some say that this works best with some kind of pressure or weight on top of the bucket which helps minimize sound and keeps

it from bouncing when it gets to that point.

Here is a drawing I made which I might try, where 2 buckets can make use of the same wheel and I would need only one driven bucket (as it would drive

each bucket next to it.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

How long are plastic buckets or paint cans going to last?

It obvously depends on what your grinding and the size and material of the balls. I would expect tin cans to fail just from the work hardning from

the flexing and impacts.

My plan is to use an old steel gas bottles. (not good for sparks) Lots of sizes available for example:

Even out of test date high pressure (200bar) bottle are available including smallish alluminium ones (old portable medical oxygen bottles) at my

recycling center.

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

I used a cheap plastic pressure sprayer for a drum. Usually made of fairly thick UHMWPE - so they're tough, inert and wont spark. Get the cheap ones,

as you dont care if the pump and spray nozzle are a pile of crap.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

RogueRose

International Hazard

Posts: 1592

Registered: 16-6-2014

Member Is Offline

|

|

Thanks! That is a good suggestion for the spray container. I've looked at a number of them and they all say polyethylene not UHMWPE, which is a

polyethylene so maybe that is what is meant. Here is a model I was looking at -

https://www.walmart.com/ip/Popular-12L-Hand-Press-Rainmaker-...

Well I started with a standard 1 gallon paint can and that lasted about 100 hours b/4 I has a small fracture (metal got this and slightly broke). I

think it was because I was using these large ceramic insulators as grinding material (see pics above). I then cut a 5 gal bucket and took the sides,

cut it to a rectangle size to fit perfectly inside a new paint can and it seems to work great. The thing is about 5 gallon buckets is they can range

greatly in thickness from 50mils to 100 mils although 90 mils is common for a heavy duty I have also seen 120 mil a few times.

Many 5 gals have very different shapes from one to another (brands/makers). Some have a bottom diameter of 16.5" while others down to 15" and the

taper can very a lot. Finding ones that nest perfectly is awesome when that happens if you need to nest them for a thicker bucket (I'm just not sure

how to bond the two together as they are all made of HDPE and I have yet to find something that will bond/weld/glue two pieces of HDPE together. I'm

great at plastic welding HDPE but I need something for the large inner surface of something like a 5 gallon bucket). Is there any chem I can use to

melt/bond the HDPE layers (doesn't need to be a commercial product just a chem that would work...)

|

|

|

arkoma

Redneck Overlord

Posts: 1761

Registered: 3-2-2014

Location: On a Big Blue Marble hurtling through space

Member Is Offline

Mood: украї́нська

|

|

Pretty good balls can be formed by dropping molten metal into cold water. Great to still see you here Rogue. Used to work at a sand and gravel plant

that used HDPE for dredge pipe, and we used a "fusion" machine to bond pieces together. It was a heat weld. Don't know of a chemical weld for HDPE.

[Edited on 9-26-2017 by arkoma]

"We believe the knowledge and cultural heritage of mankind should be accessible to all people around the world, regardless of their wealth, social

status, nationality, citizenship, etc" z-lib

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

HDPE is one of those problem plastics that nothing sticks to. Very low surface energy, no nice reactive bits dangling off the ends of the polymer

chains. Heat welding is the only bonding method I've heard of used regularly, though I have seen mention of surface treatment using either an

oxidising flame or sulfuric acid as a surface activator to allow epoxy to stick.

One of the things I particularly like about pressure sprayers is the straight sides - they're blow molded, not injection molded which needs a taper

for release. Buckets are also tapered so they can nest-stack for efficient storage.

[Edited on 26-9-2017 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

Last week I made a small furnace and this weekend I made some brass milling media using the lost foam casting method, a couple of the balls turned out

ok but the rest are a bit ugly, they'll work just fine though.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

What did you use as source material for your brass melt? Any issues with Zinc vapors?

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

Hi Bert

When I first built the ball mill I purchased a length of brass round bar and cut it up to used the small cylinders as milling media, I melted those

down plus a few brass fittings I collected, plumbers are the people to talk to if you're after scrap brass, they have old taps etc.

I didn't have any issue with zinc vapors, my garage has a roller door at each end and with them open I get good cross ventilation.

I didn't use any flux for the first melt and ended up with a heap of dross, the second melt I added a table spoon of borax and got almost no dross at

all, when I skimmed the surface of the molten metal all I got was a spoon of stuff that resembles black glass

[Edited on 15-10-2017 by NedsHead]

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

Made a graphite mold today, I copied aga's spherical cutter design to make the mold (washer on the end of a shank) it cut through graphite like

butter.

The first pour I didn't skim the molten metal well enough and some flux messed things up, second pour was better.

Surface finish still isn't perfect, maybe I need to preheat the mold.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I'm always a fan of metal melting and I love reading about these projects, but I wonder why people don't simply buy grinding media? Making your own

would be very time consuming, one ball at a time. I just bought a pound of chrome plated hardened steel 1/4" balls for $25 on eBay.

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

In my case I need a non sparking media, if I could find it for sale it would cost more than I'm willing to pay anyway, this first one was a test, I'll

make up some graphite molds to pour multiple balls at a time

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Heck, learning how to and making your own tools is half the fun- I made my own mill jars and grinding media years ago.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

What did you use for mill jars and grinding media Bert, got any pics?

|

|

|

Twospoons

International Hazard

Posts: 1324

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Quote: Originally posted by Bert  | | Heck, learning how to and making your own tools is half the fun- I made my own mill jars and grinding media years ago. |

This is so true. There are quite a few things I've built from scratch, just because it was more fun (and educational) than going out and buying it.

.... my first and second stereo amplifiers and the speakers, a kayak, a 3d printer, a timber deck, book shelves, a futon bed base, a rabbit hutch,

ball mill and media, and a lot of other stuff I've forgotten.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

RogueRose

International Hazard

Posts: 1592

Registered: 16-6-2014

Member Is Offline

|

|

Is there any reason that multiple size grinding material can't be used, like balls from .25, .5, .75 and 1.25" in diameter mixed together? Would it

be more efficient having different sizes so that they fit together better?

|

|

|

| Pages:

1

2 |