elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Spot Welder

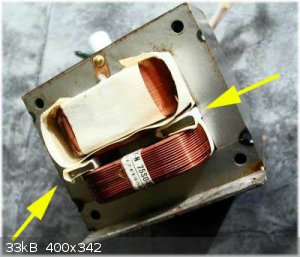

So, in my quest to assemble a metal reactor for high-temperature distillation, I noticed that I really needed a welder of some sort if I

wanted this thing to hold up. With that aim in mind, I began constructing a spot welder. It's heavily based off of Grant Thompson's (aka the King of

Random) version from a microwave oven transformer, with two safety switches, a plug, and of course the new secondary and solid copper tubing added to

the transformer itself.

http://www.instructables.com/id/How-to-Make-a-Spot-Welder-fo...

However, upon testing my prior iteration, I found that the transformer had somehow managed to spontaneously stop working between yesterday and this

morning. Go figure. I've got a new transformer now, but I just want to make absolutely sure I've got the theory right. So, could someone check over my

setup and make sure I've got it right, at least from a theoretical standpoint?

-The live (black) wire leading from the plug goes through two safety switches (both rated for high current and voltage), before connecting to one of

the primary coil's terminals.

-The neutral (white) wire goes to the other terminal on the primary coil.

-The ground (green) wire connects to the transformer block itself.

[Edited on 10-2-2016 by elementcollector1]

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

Microwave oven transformers are very simple in construction and quite robust, so it is unlikely that one just broke on you. Check that the safety

switches aren't burned out and that the insulation isn't melted.

Your wiring sounds correct. It makes no difference which wire (live/neutral) is attached to either end of the primary coil. I assume the primary coil

in this case is the one with more turns to it?

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by Oscilllator  | Microwave oven transformers are very simple in construction and quite robust, so it is unlikely that one just broke on you. Check that the safety

switches aren't burned out and that the insulation isn't melted.

Your wiring sounds correct. It makes no difference which wire (live/neutral) is attached to either end of the primary coil. I assume the primary coil

in this case is the one with more turns to it? |

The primary coil is the one with less turns on it... I think. Either that, or I've made a horrible mistake with which coil I decided to

dremel into oblivion.

I checked with the multimeter, all the switches work perfectly. The transformer I used previously may not have been a MOT, as it had four output wires

at each coil. No idea what that was about, but I had figured out which wires weren't connected to each other and assumed those were the 'terminals'.

Well, if nobody else steps in saying "Halt! You've forgotten such-and-such!" then I'm going to go ahead and wire this thing up again. Hopefully this

time I'll also remember to make it look safe, as the staff at think[box] were none too happy to see my strange contraption plugged in.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

When looking at an unmodified MOT, the primary will have fewer turns of relatively thick wire while the secondary will have more turns of relatively

thinner diameter wire. This is contrary to what you'll typically find in other transformer because the MOT is a step up transformer.

The winding that must be hacked away is the more turns/thinner wire one (the secondary). Also, if you're using copper tube with no insulation, you're

probably shorting out the secondary. Buy a few feet of 6 or 8 gauge THHN wire from your nearest big box store and experiment with # of turns you need

for the secondary. As a very rough guide, you can expect around 1V/turn (open circuit) but that will drop under load.

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by m1tanker78  | When looking at an unmodified MOT, the primary will have fewer turns of relatively thick wire while the secondary will have more turns of relatively

thinner diameter wire. This is contrary to what you'll typically find in other transformer because the MOT is a step up transformer.

The winding that must be hacked away is the more turns/thinner wire one (the secondary). Also, if you're using copper tube with no insulation, you're

probably shorting out the secondary. Buy a few feet of 6 or 8 gauge THHN wire from your nearest big box store and experiment with # of turns you need

for the secondary. As a very rough guide, you can expect around 1V/turn (open circuit) but that will drop under load. |

Oh, thank goodness. That was indeed the one I completely destroyed.

Don't worry, the secondary's insulated. In fact, I wish it was insulated just a little less, because it's rather hard to form into the transformer

coil. Oh well.

Schoolwork's picking up again, so I may have to slow down on this project until the weekend. Hopefully some pictures will be posted soon!

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

It works! Just welded together two washers. It also tripped the circuit breaker every time I used it, but that's an easy fix.

Now let's see how well it works on steel pipes...

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

BTW - if you want to try copper tubing as a super-heavy conductor, slip it into polyethylene tubing for an insulator.

About that which we cannot speak, we must remain silent.

-Wittgenstein

Some things can never be spoken

Some things cannot be pronounced

That word does not exist in any language

It will never be uttered by a human mouth

- The Talking Heads

|

|

|

violet sin

International Hazard

Posts: 1480

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

Don't weld titanium for more than a moment, and wear safety glasses  it will

tack quickly in air with no flux, or eject burning metal if left going too long. Good mechanically and electrically. About 1 second max with the MOT

core and new 1.5 turn secondary. Used large braided copper wire; Red, white, black +ground main box supply line for homes. Just strip the three

shielded wires (+ bare ground) and twist all four together on each end for a decent equivelant single braided copper cable. it will

tack quickly in air with no flux, or eject burning metal if left going too long. Good mechanically and electrically. About 1 second max with the MOT

core and new 1.5 turn secondary. Used large braided copper wire; Red, white, black +ground main box supply line for homes. Just strip the three

shielded wires (+ bare ground) and twist all four together on each end for a decent equivelant single braided copper cable.

At least that was my experience. also note it was poor for tacking 5 cent nickels together even with borax flux(around edges of overlap, not between)

. Though never tried with zinc chloride. They were weak mechanically, never got a decent electrode made as they kept separating.

I stopped experimenting when it became apparent good pressure helps alot. Couldnt allocate time to make a suitable lever press. Was hoping to make

something akin to a hand press bottle capper ( think rootbeer). It was fun though, and I have a nice fiberglass rod ~1" dia. been saving for lever

arm... One of these days

|

|

|

Sulaiman

International Hazard

Posts: 3697

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Online

|

|

elementcollector1

" It also tripped the circuit breaker every time I used it, but that's an easy fix."

when you modify a MOT

if you knock out the magnetic shunts, current is limited only by resistances,

so it is easy to pop a breaker.

if you leave the shunts in, then there is automatic current limiting,

the breaker pops less often.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Is the shunt a part of the MOT itself?

About that which we cannot speak, we must remain silent.

-Wittgenstein

Some things can never be spoken

Some things cannot be pronounced

That word does not exist in any language

It will never be uttered by a human mouth

- The Talking Heads

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

We're not banging rocks together here. We know how to put a man back together.

|

|

|