| Pages:

1

2 |

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

Pressure cooker regulator weight help...

I am not good at math so I am asking for some help. I have a small pressure cooker designed to run at an internal pressure of 15psi at sea level. I

live at an altitude of 3445ft. above sea level (1050m). The pressure cooker lid has a vent tube with an ID of 3/16" OR 4.7625mm.

I want to know how heavy a new regulator weight needs to be to run the pot here at my altitude with an internal pressure of 15 psi? I can simply

add some additional weight to my existing regulator weight once I know how much the new total weight is. Thanks a lot for helping. Regards moray

james.

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

The vent diameter is not needed to solve the problem. The weight counteracts the pressure, so if the pressure must be 12% higher, the weight to

counteract it must be 12% more.

Which also means 12% more than the thing was designed to run at. Might work, or might be above the rating of the safety valve.

[Edited on 22-9-2016 by Maroboduus]

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

The unit was designed to run at 15 PSI at sea level. I just happen to live well above sea level. So if my regulator is fitted with 12% more weight

the pot will now run at 15 psi just at a higher altitude. Is there a conflict and am I missing something?

Thank you very much for the help. Regards moray james.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Assuming you mean 15 psig (psi gage) where you live makes no difference. The size of the weight establishes the gage pressure.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

I re weighed the original weight it was 2.7 oz total weight I added a third of an ounce to it and it now weighs 3 ounces even. Does that all sound

correct?

The person who gave me the pot said it was a 15 psi pot but I was just looking and do not see any markings of any kind except the name and a date

(can't find a thing on line about the pot or the maker) which says it was built in 2004.

So just to be sure would a 2.7 ounce regulator weight be correct for 15 psi at sea level? I would like to be sure as you said there is a safety

valve and I want to know that is a 15 psi unit before I run the pot up to 15 psi with the extra weight on the regulator. Pressure pots make me nervous

at the best of times. Thank you very much for the help Maroboduus.

[Edited on 23-9-2016 by moray james]

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

I think he wants the same absolute pressure as sea level. That would be about 90mm more pressure than he's gonna get at 3500 feet since the weight of

the original weight will determine the gauge pressure at 760mm. So his 11% heavier weight will give him 83mm more. Close enough and I'd rather be a

little low than a little high.

Magpie, I'd be glad to hear your opinion on this, since I'm telling him how much extra weight to apply to a pressure vessel and I obviously don't want

to steer him wrong. I've already made a couple of dumb posts here on this site, but I think I'm on solid ground with this one.

Moray James, am I correct that you want the same ABSOLUTE pressure as at sea level? Because if you just want the same GAUGE pressure, then I agree

with Magpie 100%.

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

Yes Maroboduus I simply want to be able to use the cooker here with an internal pressure of 15 psi so the internal pot temperature will be the same as

if it were being used at sea level. Internal pressure and temperature are the goal.

Does the factory stock regulator weight of 1.7 ounces translate into 15 pounds at sea level? If so then I can be assured that this pot has a 15

pound safety valve. As I said I cannot find any info on line about this unit. This unit has no pressure gage just a rocker regulator (weight).

Thank you all very much for helping out. I have really started to appreciate cooking with a pressure cooker. Regards moray james.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I'm glad to try and help here.

Manufacturers and sellers of home pressure cookers don't deal in absolute pressure and indeed there is no need to. When they say the cooker is rated

for "15 psi" I take it to mean a gage pressure, or in an engineer's parlance 15 psig.

The ambient pressure is irrelevant as it cancels itself out by being applied to both the inside and the outside of the cooker walls.

So I think that the OP wants a gage pressure of 15 psig. In this case he doesn't have to change anything, just put the weight on the vent.

If he indeed wants a 15 psia (15 psi absolute) then the ambient pressure would have to be included. No matter where he is he will have to reduce the

size of the weight unless he exists in a vacuum.

I'm not sure what he really wants.

[Edited on 23-9-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

I think he really wants an absolute internal pressure of 30 psi, which would be the same absolute pressure you'd get at sea level with 15PSIG. This

would require getting about 16.5 PSIG at his altitude. (3500 feet)

His concern seems to be that at his higher altitude the pressure cooker will develop a lower temperature at 15 PSIG because it's the absolute pressure

in the pot, not the difference between the pot's pressure and the exterior pressure which determines the temperature in the pot. [Just as a pot of

water boiling (open pot, 0 PSIG) at his altitude isn't as hot as it is down at sea level.]

When he says 15 PSI I believe he means The equivalent absolute pressure of a sea level pressure cooker cooking at 15 PSIG.

He just wants the cooking times to be correct for recipes designed at sea level.

Re read his 18:31 post. The key phrase is, "so the internal pot temperature will be the same as if it were being used at sea level".

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes, I agree. I should have read more closely. He probably knows from experience that it takes longer to cook at 3500'.

We don't know how finely designed the cooker is. But I would think it could easily take a 11% overpressure.

My cooker that I use for a steam generator only has a soft metal plug that melts at a high temperature. I don't think it bursts on high pressure as

that is what the weight is for.

edit: I read on Wiki that the soft plug can also be a pressure relief port. So it is likely that there are many variations in safety features,

depending on make and model.

[Edited on 23-9-2016 by Magpie]

[Edited on 23-9-2016 by Magpie]

[Edited on 23-9-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

Moray James, We have agreement! The extra 11% weight you added to the weight should do the trick. We had some confusion because of the difference

between absolute pressure and gauge pressure, but it's okay. I just wanted to be sure Magpie said it was right because he's got engineering

knowledge far beyond mine and I didn't want to lead you wrong if some one more expert was willing to help.

Hope the food comes out good, or whatever else you're cooking.

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

Thank you everyone. Sorry that I was part of the confusion. The temperature and so the cooking time has been the issue for me. All the same using

this cooker is so much faster than regular stove top cooking. I may even experiment with some canning. Your kind help will allow me to cook faster and

feel safe while doing so. Regards moray james.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Anytime you tell someone they can exceed normal operation you should have a sound basis for that. I don't have such a basis, only a gut feeling that

a pressure cooker likely has a hefty safety factor.

As a caveat I show here an excerpt from the Wiki on pressure cookers:

"Use as an autoclave

Pressure cookers have been used effectively as makeshift medical autoclaves in rural countries where there is no electrical infrastructure and where

the cost of such a piece of equipment would otherwise be prohibitive. Although working on the same principle there are several operational differences

such as professional autoclaves having purging ability to remove air before sterilization and having programmable control over the sterilization

cycle. Education on usage is very important as the sterilization cycle is often much longer due to the presence of air in the cooker and most

pressure cookers require modification to reach sufficient sterilization temperature which although within the capabilities of most pressure cookers,

is still risky. "

The underlining is mine.

Here's an inquiry on pressure cooker design that mentions the safety factor:

http://engineering.stackexchange.com/questions/8511/can-anyo...

At work we had to test our piping systems at 1.5 times the intended use pressure. This was an ANSI requirement.

[Edited on 23-9-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

I had made the unjustified assumption that modern pressure cookers were all fitted with safety blow-off valves set a few PSI above the working

temperature (as mine is). I can see that one with a fusible plug wouldn't provide the same assurance of safety at high altitudes.

Al though I still feel it would be okay to increase the working gauge pressure 10% anyway, I'd feel a lot better if I had determined just how his

cooker operates before I was so free with my novice's opinion. I'll try not to make such assumptions about the design of potentially dangerous

appliances in future.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

A test could be performed to help assure that the modification of the weight is safe:

1. Prepare a weight that is 1.5 times the normal weight.

2. Using this weight heat the pressure cooker containing some water using an electric hotplate located in an unoccupied room, say the garage. Heat

it until it relieves steam for a few minutes.

3. Cut the power to the hotplate using a circuit breaker in another room.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Sulaiman

International Hazard

Posts: 3696

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Online

|

|

moray james,

as you asked your question in Sciencemadness Discussion Board » Special topics » Technochemistry

certain assumptions are made,

when you tell that you intend to do a lot of domestic cooking in close proximity to the pressure cooker,

those assumptions become invalid.

Thinking through risks is part of a hobby,

domestic cooking requires greater safety margins,

so follow the manufacturer's instructions.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

I believe that I understand the concern for liability when providing advice that may or may not be correct. Please allow me to ask a few specific

questions.

First of all I did ask but never got an answer about my stock factory regulator weight of 2.7 ounces and if that would be a standard weight for a

regulator for the operation of a pressure pot at sea level to achieve an internal pot pressure of 15 psig? The regulator weight for all pressure

cookers operating at sea level sea for a given psig should all be the same? Is that correct?

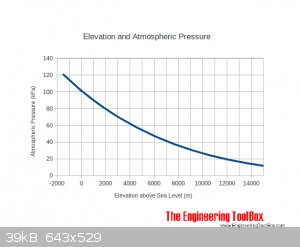

Second, if the pot runs at 15 pisg at sea level with a 2.7 ounce regulator weight and as it was suggested that the atmospheric pressure at 3445 ft

above sea level would be 12% lower than at sea level then I would need to increase or add 12% more weight to the stock regulator weight increasing it

to 3 ounces so the pot could reach an internal pressure of about 15psig? Will or can the pot reach an internal pressure of 15psig at my altitude?

Is there things that I am not understanding or that I am overlooking here? Is the pot strong enough to function at 15 psig at 3445ft above sea

level where there is 12% less external pressure on it?

I realize that I initially forgot to consider the decrease in the external atmospheric pressure on the pot if it were operating at 15 psig at my

altitude, there will be 12% less external pressure holding the pot together! For safety sake the pot would need to be stronger by some amount? I

suspect there is a lot more to this than I initially thought. I do not have the training and I do not know enough to establish if what I want to do is

even possible or safe.

So if the pressure cooker pot can reach an internal pressure of 15psig at my altitude would the internal pot temperature be the same as it would be

at sea level (250F)?

I realize that do not understand the concept of "differential pressure" Perhaps this is where I should have started. I think that I jumped the gun

and made a bunch of assumptions. Thank you all very much for your concern and and your assistance in getting to the bottom of this. Regards moray

james.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by moray james  | I believe that I understand the concern for liability when providing advice that may or may not be correct. Please allow me to ask a few specific

questions.

First of all I did ask but never got an answer about my stock factory regulator weight of 2.7 ounces and if that would be a standard weight for a

regulator for the operation of a pressure pot at sea level to achieve an internal pot pressure of 15 psig? The regulator weight for all pressure

cookers operating at sea level sea for a given psig should all be the same? Is that correct?

Second, if the pot runs at 15 pisg at sea level with a 2.7 ounce regulator weight and as it was suggested that the atmospheric pressure at 3445 ft

above sea level would be 12% lower than at sea level then I would need to increase or add 12% more weight to the stock regulator weight increasing it

to 3 ounces so the pot could reach an internal pressure of about 15psig? Will or can the pot reach an internal pressure of 15psig at my altitude?

Is there things that I am not understanding or that I am overlooking here? Is the pot strong enough to function at 15 psig at 3445ft above sea

level where there is 12% less external pressure on it?

I realize that I initially forgot to consider the decrease in the external atmospheric pressure on the pot if it were operating at 15 psig at my

altitude, there will be 12% less external pressure holding the pot together! For safety sake the pot would need to be stronger by some amount? I

suspect there is a lot more to this than I initially thought. I do not have the training and I do not know enough to establish if what I want to do is

even possible or safe.

So if the pressure cooker pot can reach an internal pressure of 15psig at my altitude would the internal pot temperature be the same as it would be

at sea level (250F)?

I realize that do not understand the concept of "differential pressure" Perhaps this is where I should have started. I think that I jumped the gun

and made a bunch of assumptions. Thank you all very much for your concern and and your assistance in getting to the bottom of this. Regards moray

james. |

Its difficult to impossible to say whether your regulator weight is correct because weights may vary between different pressure cookers and although

you gave the internal diameter of the vent pipe its actually the diameter of the exit hole that is closed by the weight that effects the internal

pressure. In addition although one atmosphere (relative pressure) is common there are probably variations between manufactures.

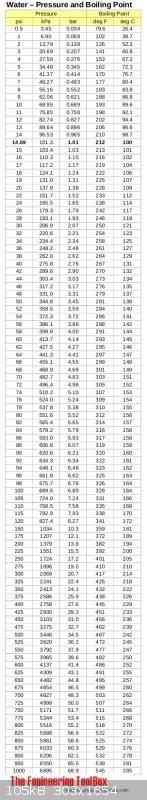

Assuming an exit hole diameter of 4.76mm and mass of 2.7 oz the increase pot pressure would be 0.45 atmospheres above the external pressure. I

checked the mass of the weight on my pressure cooker and it is 2.67oz. Its difficult to determine the exit hole diameter on my pot lid but it looks

less than 5mm.

The internal temperature (hence cooking time) is determined by the internal absolute pressure of your pot which is determined by mass of the weight +

the external absolute pressure. So you could increase the mass of the weight to compensate for the reduced external pressure. So reiterating the

advice of others. Given how short cooking times are in a pressure cooker the risk associated with messing with the weight seems unwarranted unless you

have special cooking requirements.

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

WG48: thank you for your explanation. So you pot has a very similar vent hole size and regulator weight? Is you pot then a 15 psig rated pot? I agree

that a longer cooking time is the way to go. If I was running your pot at my location (3445ft above sea level) what would the internal temperature of

the pot be? Regards moray james.

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

While I was typing my last post I decided to run a test with the pot using the extra weight on the regulator. I filled the pot about 25% full with

water and brought it up to temp and let it steam vent for three minutes like I usually do and then put the now slightly heavier regulator weight on. I

ran up the temperature in steps on my largest element for five minutes at a time per step on the dial. I ran the pot for 45 minutes ending up on a

setting of 8 (out of ten) for ten minutes total time at that temperature (much higher than I ever use) and I never saw the safety vent release. My

pressure pot has one of those spring loaded safety vents.

So to recap the stock regulator weight is 2.7 ounces which I increased to exactly three ounces. At no time or at any setting up to eight on my

element did the safety vent release. The regulator either rocked or sat still but the whole time it vented steam. I started at a setting of three

which produced steam venting from the regulator (but no rocking). Dose this sound like thinks are ok? Thanks moray james.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by moray james  | | WG48: thank you for your explanation. So you pot has a very similar vent hole size and regulator weight? Is you pot then a 15 psig rated pot? I agree

that a longer cooking time is the way to go. If I was running your pot at my location (3445ft above sea level) what would the internal temperature of

the pot be? Regards moray james. |

I don't know if my Premier stainless steel pot is an extra 15psi pot, irritatingly Premier do not give that info. I picked it up from someone's

trash but it has no gasket so I can not run it up and measure the temperature. I got it to cook up sodium silicate from sand and sodium hydroxide.

I general trawl on the web suggests pots are between 13.5 to 15psi extra pressure. Today I found the following spec for Tower T9 series pots. I was

beginning to think it was an industrial secret. I guess cooks don't look at specs.

This pot is adjustable I assume P2 is the highest pressure.

"2. Under the pressure limit, the temperature of the

boiling water is 120°C"

.

"TECHNICAL PARAMETERS

Working Pressure: 80 P1:60kPa P2:100kPa

Safety Pressure: 130-200 kPa

Destroy Pressure: > 500kPa

Pressure inside the cooker under the condition

that the cover has not been closed to its

correct position: > 5kPa

Pressure in the cover when the indicating

valve is locked: > 4 kPa"

( I like the 500kPa destroy pressure nice safety margin)

I estimate if my pot is a 15psi pot at 1km up its temperature would be 116C and 120C at sea level assuming I am not in the middle of a hurricane

. .

|

|

|

Texium

|

Thread Moved

24-9-2016 at 13:04 |

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

Thanks wg48 so the up shot here at my altitude is that even with the additional weight I am using is that the pot is probably reaching just over

12psi. The graph are very informative. Thank you very much for taking the time to provide this most useful information. Regards moray james.

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Online

Mood: Bored

|

|

Let's recap.

The pressure cooker is designed for a pressure difference of 15psi at sea level. In other words it operates at 30psi (absolute pressure). At 3500feet

the air pressure should be about 13psi, meaning that the cooker operates at 28psi. In order to achieve 30psi the pressure difference must be increased

to 17psi, so the mass of the weight must be increased by 17/15=13%.

As for the safety I hesitate to say anything absolute. I don't know the safety factor for these devices, but I would be surprised if it was below 2.

If so, a cooker in good conditions should handle the extra pressure. Still, unless I was sure it had a design safety factor of at least 3 I personally

wouldn't do it.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I wasn't' going to say anymore but this is too interesting.

If you really want to make a science project out of this, I suggest the following:

1. Fill the pot with water (lid off) and boil it for 2-3 minutes to expel the dissolved air. Place lid on and secure.

2. Rig up a hand water pump with pressure gage to the vent hole.

3. Slowly pump up the pressure until the spring-loaded pressure relief valve opens. Note the pressure at valve opening.

Now you can calculate a new safety factor for your larger weight use.

This is a hydraulic test and is much safer than a pneumatic test. Never do the latter.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

moray james

Harmless

Posts: 11

Registered: 22-9-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Fulmen  | Let's recap.

The pressure cooker is designed for a pressure difference of 15psi at sea level. In other words it operates at 30psi (absolute pressure). At 3500feet

the air pressure should be about 13psi, meaning that the cooker operates at 28psi. In order to achieve 30psi the pressure difference must be increased

to 17psi, so the mass of the weight must be increased by 17/15=13%.

As for the safety I hesitate to say anything absolute. I don't know the safety factor for these devices, but I would be surprised if it was below 2.

If so, a cooker in good conditions should handle the extra pressure. Still, unless I was sure it had a design safety factor of at least 3 I personally

wouldn't do it. |

Thank you. So given your explanation if the regulator weight were increased by 13% what would the resulting internal pot temperature be?

|

|

|

| Pages:

1

2 |