| Pages:

1

2

3

4 |

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Mine platinum from the dust next to highways

6.8g Pt/ton of dirt next to the highway is a pretty impressive grade!

https://www.youtube.com/watch?v=v5GPWJPLcHg

Damn, I wish I lived in a country were catalytic converters were mandatory

|

|

|

Zephyr

Hazard to Others

Posts: 341

Registered: 30-8-2013

Location: Seattle, WA

Member Is Offline

|

|

Wow, thanks for sharing this very cool video. Maybe highway dust will become a valuable commodity one day...

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Pleasure! Mind you, the dirt immediately on the down stream side of the road could be pretty rich as the road dust would wash over to there from

rainfall, unless there are gullies and storm drains

[Edited on 29-5-2016 by deltaH]

|

|

|

ficolas

Hazard to Others

Posts: 146

Registered: 14-5-2016

Member Is Offline

Mood: No Mood

|

|

6.8g/ton isnt probably the amount, he suposed the whole beat was platinum.

In what country arent catalytoc concerters mandatory?

It doesnt seem fair that some countries are able to pollute more than others, but politics are politics, they should be imposed everywhere

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Sounds like fun !

$214 for collecting/processing a ton of road-dust sounds less attractive.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

wow, that much? ... and I get to do chemistry? I'll take it

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  |

Sounds like fun !

$214 for collecting/processing a ton of road-dust sounds less attractive. |

Possibly more attractive than processing a ton of platinum ore.

Occurrence in the earth's crust is something like 4 or 5 mg/ ton.

It would be interesting to know if there are valuable amounts of other metals- like Cu and Pb in road dust.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

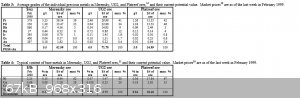

Actually its a little more than what's found in Platinum ore. South Africa has the largest reserves of platinum in the world. This is from one of our

platinum mining companies:

Source: http://www.mintek.co.za/Pyromet/Platinum/Platinum.htm

So as you can see, there's more in this road dust than platinum ore and you don't have to blast, dig and mill it!

[Edited on 29-5-2016 by deltaH]

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Yes, but I don't think you will be able to extract lots of nickel, cobalt etc from road dust to cover most of the cost.

|

|

|

MeshPL

Hazard to Others

Posts: 329

Registered: 20-4-2015

Location: Universe

Member Is Offline

Mood: No Mood

|

|

http://www.telegraph.co.uk/news/uknews/2976623/Road-dust-can...

Cody wasn't the first one to think about it.

Here's a paper on a subject:

http://www.ncbi.nlm.nih.gov/pubmed/15050388

But it is 12 years old and since that amount of platinum in exhaust catalysts may have increased.

Sewage also contains precious metals:

http://www.telegraph.co.uk/news/newstopics/howaboutthat/1199...

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

So, how much roadway do you need to vacuum up dust from to get, say, 100,000 tonnes (2000 troy ounces of Pt*) and what would be the cost of doing so?

Three things make a mine: an ore body of sufficient concentration, an ore body that is accessible, and an ore body that is large enough to payback the

cost of opening the mine with profit.

The road-dust only satisfies the first part. Low concentration ores can be mined for profit only because they can be extracted in bulk at a low cost.

*This is way insufficient to open a processing operation, really. A reliable source of one million tons would probably be needed to get even a second

look.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Ore is much easier to get in kiloton quantities.

Dust is harder to catch.

Edit:

Perhaps people who live in high-density cities would donate their used hankies ?

plantinum-from-snot.com is born.

[Edited on 29-5-2016 by aga]

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

I would think that if you are sweeping the streets anyway then a lot of the donkey-work is done. All that is required is to divert the sweepings to a

processing facility. I think that there are a lot of harder ways of getting a viable ore.

The idea has merit. Especially for urban areas.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

What might be profitable is to sweep up the dust (roads get swept anyway), sieve it to remove most of the stuff that nobody wants, (maybe roast it to

remove rubber dust- just to save weight) and then sell it to an existing platinum mine to chuck in with their beneficated ore before the smelting

process.

Much less investment in equipment- albeit at some considerable transport cost.

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Added to that idea...

Most cities of amy size have a rail lin. It is common for more goods to go into a city than come out. So filling a railcar or two with dust and

transporting it out could be reasonably cost-efficient. If the sweeping, the infrastructure, and the processing are already in existence then it is

largely a logistics exercise.

Sounds like a sensible course of action to me.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Recycling the PGM would also be more environmentally friendly: Pt etc are toxic

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Depending on rainfall, getting your hands on the dust might be economically viable.

Rain washes stuff into the sewers/storm drains.

Periodically these need to have the silt cleaned out, which is a service that the town council generally pay for, as the waste (in the UK at least) is

classified as 'contaminated' due to the oils & tars from the tarmac.

The waste companies have to pay to dispose of the silt.

If you could work out how to profitably process the silt (and dispose of the residues) you'd simply offer a free disposal service to the waste

companies, and they'd collect/transport the silt to your facility for free.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

The nice thing about ordinary PGM ore is that the value metals are associated with sulphide minerals that can easily be concentrated out of the waste

powdered rock (called gangue in the industry) by the cheap process of flotation.

During flotation, air is bubbled through the stirred slurry of ore, water and the sulphides, being naturally hydrophobic, stick to the rising air

bubbles. At the top, you get a grey froth which spills over a weir and is then vacuum filtered continuously in drum filters.

The concentrate is then sent straight to the smelter if I remember correctly.

Now with this road dirt, the PGM metals in the catalyst is supported over inert oxides like silica and titania, which unfortunately is chemically

similar to gangue, so difficult to concentrate it by flotation as these materials are hydrophilic.

The fire assay that Cody used in the clip was a neat trick, but not feasible because of the enormous amounts of lead used and wasted.

It would really be ideal to have some kind of simple physical method of concentrating the dirt, but I can't think of any just now.

As far as wet chemistry is concerned, leaching out all the metals with acid and oxidant is probably the most accessible, but not a very good method

cost-wise.

Time for vinegar, air and salt again

I'm glad some people are starting to toy with the idea, I agree that mines are more feasible economically, but unfortunately I don't own one. Does

anyone care to donate a platinum mine? I'd even settle for rights to the ore body, see I'm not greedy

[Edited on 30-5-2016 by deltaH]

|

|

|

100PercentChemistry

Hazard to Others

Posts: 117

Registered: 21-8-2015

Location: On the island of stability

Member Is Offline

Mood: No Mood

|

|

Sound like a lot of work but sounds fun!

I'm assuming it's from the converter or is it from the asphalt itself?

[Edited on 5-30-2016 by 100PercentChemistry]

[Edited on 5-30-2016 by 100PercentChemistry]

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

From the converter.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Any vinegar salt and air notions regarding Pt dissolution ?

Perhaps add pepper (chilli) ?

What the hell ! go organometallic !

[Edited on 31-5-2016 by aga]

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by deltaH  | The nice thing about ordinary PGM ore is that the value metals are associated with sulphide minerals that can easily be concentrated out of the waste

powdered rock (called gangue in the industry) by the cheap process of flotation.

...

The concentrate is then sent straight to the smelter if I remember correctly.

...

[Edited on 30-5-2016 by deltaH] |

I suspect that, give the tonnage of material put through a smelter, adding a few tons of road dirt to the "concentrate" wouldn't be a problem. The

"concentrate" from flotation still has gangue in it. You would be adding a little more dross, but quite a lot more Pt.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Quote: Originally posted by aga  | Any vinegar salt and air notions regarding Pt dissolution ?

Perhaps add pepper (chilli) ?

What the hell ! go organometallic !

[Edited on 31-5-2016 by aga] |

If you had very thin platinum plating on some electronic components, I suspect you could well leach it using a solution of salt, vinegar and hydrogen

peroxide, as we did with gold. In this case you would form chloroplatinic acid which is analogous to chloroauric acid.

HOWEVER, here we have platinum supported over extremely high surface area catalyst support. This is not just ordinary silica or titania, it's fumed

silica and titania (typically) with specific surface area's of 300+ m^2/g and ~50m^2/g, respectively. These are powerful adsorbents because of those

large surface areas, much like activated carbon adsorbs things like crazy. So even if you did oxidise the precious metal here, those

chloroplatinic acid ions would probably still stick like mad to the silica.

In fact, you prepare these catalysts by impregnating this carriers/supports with a solution of chloroplatinic acid and they adsorb on.

This is the problem. Leaching these things off is not a favourable equilibrium, which necessitates multiple washings and concentrating the resulting

very dilute solution. All this makes it extremely impractical.

[Edited on 2-6-2016 by deltaH]

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

Quote: Originally posted by unionised  | Quote: Originally posted by deltaH  | The nice thing about ordinary PGM ore is that the value metals are associated with sulphide minerals that can easily be concentrated out of the waste

powdered rock (called gangue in the industry) by the cheap process of flotation.

...

The concentrate is then sent straight to the smelter if I remember correctly.

...

[Edited on 30-5-2016 by deltaH] |

I suspect that, give the tonnage of material put through a smelter, adding a few tons of road dirt to the "concentrate" wouldn't be a problem. The

"concentrate" from flotation still has gangue in it. You would be adding a little more dross, but quite a lot more Pt. |

I quite agree with you, I don't see any other economical way to recovering this beside smelting. Only high temperatures can negate the strong

adsorption of metal on these catalyst supports.

High temperature sinters the material which destroys the very high specific surface area of the support and also sinters the metal nanoparticles into

larger particles that can coalesce even further.

Ideally though, it would be nice if some process could be found to pre-concentrate the dirt so that you don't have to smelt such a low grade.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

I do have an idea as to how to pre-concentrate the dirt before smelting.

Since the catalyst support consist typically of fumed silica/titania/zirconia etc. nanomaterial with very high specific surface area, one can use

surface chemistry to one's advantage.

In a solution of high pH, these inorganic oxides charge up like crazy and you form colloidal solutions of them. Sand doesn't do that because there

isn't enough surface area to significantly charge up, so the electrostatic repulsion between sand particles due to this surface charging is

negligible, but not for silica nanoparticles.

In fact, such colloidal silica and such are sold commercially, e.g. brand name Ludox (if it still exists).

If anyone is wondering how the pH causes the surface to charge, the surface of these inorganic oxides typically contain lots of hydroxyl groups and

these can be deprotonated at high pH. In fact, it is these surface hydroxyl groups that make these materials very hydrophilic.

So perhaps all one has to do is prepare a slurry (aka thick mud) of the dirt, add cheap caustic soda to raise the pH, then tumble the dirt for some

time (cement mixer?) to mechanically assist the conglomerated catalyst particles to break up into colloidal particles that enter into solution.

Finally filter and boil down the filtrate and then smelt the resulting dark solids. You aught to have a high grade concentrate consisting of a mixture

of sodium silicates, PGMs and silica gel and other metal contaminants.

If you want to save on energy and have lots of liquor containing the colloidal materials to process, simply dig a very shallow hole over a wide area,

buy cheap thick black plastic sheeting used by builders to protect floors while painting, lay it in the hole and pour your filtrate into that to

evaporate in he sun, taking care to only have a few cm's depth in the sheet plastic or you might develop holes and leaks by the pressure exerted onto

the plastic and dirt/twigs beneath. Obviously summertime is best.

Heck, all you really need to start is a pick-up truck, cement mixer, brooms and shovels, some cheap labour, plastic sheeting and water.

If you want to smelt it yourself, you'd need to buy a furnace, $$$

Better would be to assay the concentrate and then sell it on ebay for spot price of PGM content minus some x percent to make it attractive and make

the real hard work somebody else's problem

[Edited on 2-6-2016 by deltaH]

|

|

|

| Pages:

1

2

3

4 |