Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

n-amyl alcohol

I recently finished a protracted synthesis of n-amyl alcohol. This utilized a Grignard reaction with n-butylMgBr acting as Grignard reagent and

gaseous formaldehyde acting as substrate.

n-butylMgBr + CH2O --> Grignard adduct

Grignard adduct + H2O --> n-amyl alcohol + MgBrOH

1. Reaction of the Grignard Reagent with CH2O

My basis was 0.5 mole of the Grignard reagent, the preparation of which is documented here: link1 The reactor vessel was a 3-neck 500ml RBF. Gaseous CH2O was produced by depolymerizing 24g (0.27 mole) of trioxane camp fuel using a

supported H3PO4 catalyst in a tube furnace kept at 220°C. The solid trioxane was boiled in a 3-neck RBF heated in a 140°C oil bath and carried into

the furnace as a gas using 1SCFH argon. This technology is documented here: link2. The dry CH2O was sparged into the 500ml reactor over a period of 3 hours.

Trioxane feed system picture

Tube furnace with 1” quartz tube containing the H3PO4 catalyst

Reactor system

Paraformaldehyde formed in the 10mm ID sparge tube (slightly submerged) and had to be unplugged with a wooden dowel, once. Paraformaldehyde also

formed in the outlet tubing of the reactor, which included a reflux condenser topped with a CaCl2 guard tube w/cotton plugs and a rubber hose leading

to an inverted funnel over water. The only place total pluggage was noted was at the end of the sparge tube.

About half way through the run I noted that the liquid level of boiling trioxane was not dropping as fast as I expected. Although this was not

visible I suspect the 4-5mm outlet of a ground glass fitting w/tublature was partially plugged with recrystalized trioxane. The argon supply fitting

on the 100ml RBF neck was popping now and then after the boil-off rate was increased.

The 500ml reactor with the reaction product was sealed and set aside for 3 days while I dealt with an electrical problem with my hood/hood light.

2. Workup (hydrolysis)

The day before yesterday the product was dumped onto about 200ml of crushed ice in a 600mL beaker. This was followed by the addition of 6M HCl. I

added the acid until the opaque white mix turned clear. This required ~100ml (0.6 mole). There was only a small layer of oily yellow liquid floating

on top of the aqueous layer. Although I realized that most all of the 200ml of ether had been evaporated, the thinness of this layer was not a good

sign.

I split the 350mL batch in two and extracted each portion with 25ml of ether. The aqueous layer was discarded. The combined ether layers was placed

over anhydrous Na2SO4 overnight to dry.

Yesterday the ether was removed by simple distillation.

Today, the paltry product, a golden liquid, was transferred to a 25ml RBF and distilled. A few drops came over early but most came over at

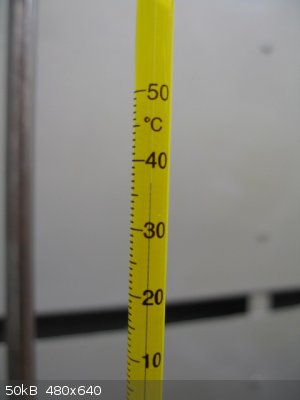

133°-140°C. The Wiki bp value for n-amyl alcohol is 137°-139°C.

Boiling point of the product

Picture of n-amyl alcohol product

3. Yield

The yield was 3.4g, for a %yield of 7.7%.

4. Discussion & Conclusions

This is the completion of a long-held fantasy, ie, making a normal alcohol via Grignard synthesis.

This was an extremely complex system due to the fact that there were 3 reactions occurring simultaneously. There were nine separate requirements for

electrical power. Also, ether and gaseous formaldehyde were being handled.

Proof that CH2O entering the reactor is truly anhydrous would be good to have.

Prevention or amelioration of the trioxane and paraformaldehyde plugging occurring throughout the gas train would facilitate an increase in yield.

Because I was wary of the exothermic heat that would be generated during the formation of the adduct I did not heat the reactor until the last hour of

the gassing. Thereafter I kept it at a gentle boil. Heating throughout the run would likely increase yield.

5. References

1. Organic Syntheses, 1983, 61, 65, “2-HYDROXYMETHYL-2-CYCLOPENTENONE”

2. A Textbook of Practical Organic Chemistry, by A.I. Vogel, 3rd Edition, p.253, “n-Hexyl Alcohol”

Questions, comments, and suggestions are welcomed.

[Edited on 27-2-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

I find it rather interesting that every intro organic textbook uses formaldehyde in the grignard discussion when such a transformation is extremely

impractical. It would make a particularly good tool to shatter their expectations when later steering them toward awareness of competing reactions and

more practical synthetic approaches.

I haven't read the whole thing (and it _is_ Tett Lett so there's a chance it's crap), but I did see this. Benzyloxymethyl chloride can presumably be

prepared from HCl, trioxane, and benzyl alcohol. Hydrogenolysis of the reaction product would afford the 1-carbon homologated alcohol without

intermediacy of free formaldehyde.

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2701705/

|

|

|

Delta

Harmless

Posts: 11

Registered: 23-2-2016

Member Is Offline

Mood: No Mood

|

|

According to this grant proposal (http://www.google.com/patents/US3169840) the formaldehyde can be passed through DMSO "between 20-120°C but preferably between 50-100°C" to

remove water, and then you could definitely be reassured that it is anhydrous. Can you dissolve formaldehyde in anhydrous ethers to make a solution

that could be used at a later date?

|

|

|

Dr.Bob

International Hazard

Posts: 2734

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

If you ever try this again, it would be interesting to see if you could react any of your sublimed trioxane directly with the Grignard. That even

makes me think that just subliming the trioxane from the fuel pellets might provide pure enough material without the complexity. I have used

paraformaldehyde (trioxane) several times for reductive aminations without any cracking of it. But that was in methanol, which likely creates an

equilibrium of formaldehyde and paraformaldehyde in situ. Just a thought, however, as a quartz tube furnace is not a common household item. (I

don't even have one, so that is pretty rare.)

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by UC235  | | I find it rather interesting that every intro organic textbook uses formaldehyde in the grignard discussion when such a transformation is extremely

impractical. |

My particular method is tough to do. Vogel's 3rd (p. 252) uses solid dewatered (mostly) paraformaldehyde to make cyclo-hexylcarbinol. In my reference

1 above OrgSyn uses gaseous formaldehyde.

Quote: Originally posted by Delta  | | Can you dissolve formaldehyde in anhydrous ethers to make a solution that could be used at a later date? |

I would be surprised if it was not soluble. But to an extent to be practical would be another question.

Quote: Originally posted by Dr.Bob  | | Just a thought, however, as a quartz tube furnace is not a common household item. (I don't even have one, so that is pretty rare.)

|

I don't know why ordinary borosilicate couldn't be used unless the hot (but dry) H3PO4 would attack it at 220°C. I only used quartz as it was the

only glass tube I had.

[Edited on 27-2-2016 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by UC235  | | I find it rather interesting that every intro organic textbook uses formaldehyde in the grignard discussion when such a transformation is extremely

impractical. |

Quote: Originally posted by Magpie  |

Quote: Originally posted by Delta  | | Can you dissolve formaldehyde in anhydrous ethers to make a solution that could be used at a later date? |

I would be surprised if it was not soluble. But to an extent to be practical would be another question.

|

I posted a Synlett paper in Magpie's thread on anhydrous formaldehyde(?) where paraformaldehyde is depolymerised with acid catalysis and the resulting

formaldehyde co-distils with THF to yield a ca 0.7 M solution suitable for use in reactions where anhydrous formaldehyde is required.

[Edited on 28-2-2016 by DJF90]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I took the 3.4g of n-amyl alcohol and made n-amyl acetate using the procedurel in Pavia for iso-pentyl acetate. Boiling range of the product was

139-144°C compared to the Wiki value of 139°C. The yield was 55.3%. It has a nice banana smell.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|