| Pages:

1

2 |

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Activated Carbon and Charcoal (AC)

The 'Activated' word was intriguing, which is why any research was done at all.

What does it Mean ? Why is Activated Carbon (AC) different to plain Carbon ?

There are many references to AC yet very few regarding what the 'Activation' process actually is.

Essentially it means some form of Carbon (usually Charcoal) that has been altered by a process that vastly increases the surface area of the material.

AC can have a surface area of an incredible 1500m<sup>2</sup> per gramme !

https://en.wikipedia.org/wiki/Activated_carbon

Common methods of Activation are a steam process, and more easily achieveable in a home lab, treatment with a CaCl2 solution.

Following the activation process, the AC carbon can be treated with other chemicals to coat this huge surface area with reagents that will

specifically absorb, adsorb or react with the thing you wish the carbon to be 'active' with.

For example, AC can be impregnated with Sulphur to make it an effective filter for Mercury Vapour :-

www.temple.edu/borguet/Publication/Documents/pdf_files/2006-...

For all Activated Carbons, the standard measure is called the Iodine Number (IN).

The Iodine Number can be titrated using the following procedure :-

http://www.mazraehgroup.webs.com/Downloads/ASTM%20D4607-94%2...

(thanks to deltaH for finding that)

Currently i've managed to Buy the reagents, and make the sodium thiosulphate and iodine solutions.

The ASTM source says to wait four days before standardising the thiosulphate solution and this is day 1.

The test subjects are 4 samples that prepared from hardwood charcoal, and a Chinese filter material that was bought as 'Activated Carbon Filter'.

If anyone has the reagents and could perhaps perform the ASTM procedure to dermine the IN of any activated carbon or charcoal they have handy, that'd

be great.

In 4 days, these home made samples will get tested and results posted.

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

I'm really looking forward to your results aga, you are certainly being very thorough!

|

|

|

gatosgr

Hazard to Others

Posts: 237

Registered: 7-4-2015

Member Is Offline

Mood: No Mood

|

|

What method did you use for making the activated carbon foam?

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

What foam ?

I've made activated carbon/charcoal from hardwood charcoal in 3 different ways.

The material is a powder, not a foam.

One sample will be the untreated carbon/charcoal, a 5th sample is some AC filter material off ebay.

If the testing procedure works out OK, i'll try other 'activation' processes and test the results of those too.

Edit :

The samples that i made were produced by treating different grain sizes with CaCl2 as that seemed easiest.

Without a proven testing protocol it seemed silly to try other processes, such as steam, heat treatment, aerofoams etc.

[Edited on 31-7-2015 by aga]

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

I'm curious about the results!

When I was a child I read in a biology textbook how to make activated charcoal. The process was intriguing but never tried since then. Maybe now, that

I know how to compare results I'll give it a go in the winter.

Why winter?

Besides that I'm fairly busy these days the process calls for dry, crushed (few mm particles) walnut husks. These should be impregnated (boiled in)

with ZnCl2, then dried, then heated (dry distilled), then thoroughly washed to remove the ZnCl2 remains.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

ZnCl2 is cited as an 'activation' agent for carbon, so that probably works.

The biggest thing was to find a way to properly Test the AC.

Thanks again to deltaH for finding a freeeeeee version of the ASTM test protocol.

This video is one of the few that 'just' makes activated charcoal.

https://www.youtube.com/watch?v=lN0fT1Uvcsw

Endure the garbage parts, if you can ...

[Edited on 31-7-2015 by aga]

[Edited on 31-7-2015 by aga]

|

|

|

deltaH

Dangerous source of unreferenced speculation

Posts: 1663

Registered: 30-9-2013

Location: South Africa

Member Is Offline

Mood: Heavily protonated

|

|

I'm a bit confused about when/how activation is taking place in that clip. Does it occur in his final oven baking step in 30min? Surely not the 24h

room temperature soak  If so, I am confused why he washes the CaCl2 out before

baking it, if it's not activated by then, then most of it will wash out. Maybe the residual is enough to activate, maybe not. Eitherway, since there's

no reference provided by the demonstrator there, nor test of the resultant carbon, I am not reassured that this would work. If so, I am confused why he washes the CaCl2 out before

baking it, if it's not activated by then, then most of it will wash out. Maybe the residual is enough to activate, maybe not. Eitherway, since there's

no reference provided by the demonstrator there, nor test of the resultant carbon, I am not reassured that this would work.

|

|

|

TGT

Harmless

Posts: 46

Registered: 9-11-2014

Member Is Offline

Mood: No Mood

|

|

I have a huge carbon scrubber that I used for about a year and was wondering if the activated carbon in it could be useful. The scrubber was not used

to filter water. It was used to reduce smell, so could it still be a good source, or being used to filter air could have decreased its uses? Thanks,

I just hate to throw out twenty pounds of activated carbon if it can be used as is or cleaned some how.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Take a sample and subject it to a jet of steam and then oven dry.

I would then test it for its intended purpose.

[Edited on 3-8-2015 by AJKOER]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Some Experimentation

The principle is that the adsorbtion properties of a sample of Activated Charcoal can be determined by measuring how many mg of iodine it can adsorb

per 1g.

This is called the Iodine Number (I.N.), or Iodine Value commonly quoted by sellers. e.g. http://www.suneetacarbons.com/products

In the following experiment parts of the ASTM D4607-94 protocol are used to quantify the I.N. for 5 samples of charcoal subjected to different

processes.

30g of shop-bought hardwood charcoal was ground to a rough powder as the feedstock

2g of the feedstock was added to pots A and B.

The feedstock was further ground down and 2g of this material was added to pot C.

This finer material was sieved though a 90um filter and 2g of this very fine material was added to pot D

A solution was made with 2.52g of CaCl2 and the weight brought up to 10.5g with distilled water.

This solution was distributed between pots B, C and D, then mixed with a glass rod to make a paste.

Each pot was then sealed, then left to stand for 24hrs.

Each sample was filtered and washed 3 times with 30ml of water in a vacuum filtration setup, then left to dry on the filter paper.

A commercial AC filter pad was obtained for comparison.

It was impossible to extract the AC from the pad fibres, so ~2g of pad was cut into small pieces to create sample E.

All were then transferred to individual aluminium containers and weighed before being put into an oven set to 150 C for 3 hours along with a container

of CaCl2 to act as a drying agent.

All samples were also weighed on exiting the oven to determine water content. This failed as there was some spillage, and the range of differences was

only 0.05g which would easily be operator error.

Previously 5 solutions were made according to the ASTM document :-

HCl solution 5 w%

Sodium Thiosulphate 0.1 N

(24.82g sodium thiosulphate + 0.10g sodium carbonate)

Standard Iodine Solution 0.1 N

(12.70g iodine+ 19.10g potassium iodide in 1 litre)

Potassium Iodate Solution 0.1 N

(1.78g potassium iodate in 500ml)

Starch Indicator Solution

The Sodium Thiosulphate solution was standardised by adding 25.0ml of the Potassium Iodate solution to a flask with 2.00g KI and 5.0ml of conc HCl,

then titrating with the Sodium Thiosulphate with the Starch as indicator.

The average of 3 titrations was 0.1018 N (N1)

The Iodine Solution was standardised by titrating 25.0ml with the thiosulphate.

The average of 3 titrations gave 0.0969 N (N2)

According the the ASTM protocol these values are too far out for those solutions to be used, however they are close enough for this amateur

experiment.

Next all samples were tested in the following way :-

Tare a conical flask or beaker.

Add the sample, record the Weight (M)

Add 10ml (H) of 5% HCl. Swirl to wet the sample.

Boil for 30 seconds. Allow to cool.

Add 75ml (I) of Iodine solution. Shake for 30 seconds.

Immediately gravity filter.

Rinse a 25ml pipette with some filtrate, discard rinsings.

Transfer 25.0ml (F) of filtrate to a fresh flask.

Titrate with the Sodium Thiosulphate solution & Starch.

Record burette reading (S)

The Iodine Number (or mg I/g) is given by :

[(12693 N2)-(DF)(126.93 N1)(S)]/M

where DF is (I + H)/F

The results were :-

A 263 (rough, raw)

B 226 (rough, treated)

C 357 (ground, treated)

D 451 (< 90um grain size, treated)

E 341 (commercial filter pad material)

The results indicate that the grain size is a major factor in the activity of charcoal, and that 'activation' by CaCl2 at RT is likely to

be an entirely bogus claim.

Given that the majority of the commercial filter material's weigh was the support fibres, it is likely that the AC used would give a significantly

higher I.N. if just the carbon were tested.

[Edited on 9-8-2015 by aga]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

| Quote: | | According the the ASTM protocol these values are too far out for those solutions to be used, however they are close enough for this amateur

experiment. |

Are you sure it says that? Does it mention tolerances for the 0.1 N normalities? 0.1018 N and 0.0969 N are close enough to 01 N for almost any

purpose, IMO. The point of standardisation is to account for discrepancies between nominal and actual normalities anyway.

Interesting you found no effect of the CaCl2 treatment: I can't really see how that is supposed to affect the IN to begin with...

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

The document actually says that the Iodine solution must be 0.100 N +/- 0.001, not that the thiosulphate must be too.

I guess it can be done to that accuracy if you have an analytical balance down to 1mg, which i don't.

Amazing that some AC must be just finely ground charcoal with an IN of 500 - merely 2x the rating for plain carbon.

Now that the bulls**t CaCl2 yootoob thing is disproven, i'll have a go at baking and steaming to see what they do to the carbon - hopefully

bash it all the way up to 1000 and beyond.

[Edited on 9-8-2015 by aga]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

It does. All kinds of waste materials have been used. I still have a years old jar of pistachio shells black from ZnCl2/HCl awaiting heating. I don't

remember the right temperature but it's not low, and an inert atmosphere is needed, and there are of course fumes. Heating in sand was tried with

mixed results. If you ever want pink sand, this is the way to go.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Would you care to elaborate ?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

aga:

You could also compare to Norit, very OTC:

http://www.drugs.com/uk/norit-200mg-leaflet.html

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Cheers Bloggers.

I think they sell those here as well.

Next step is to actually Activate some Carbon.

Buckyballs and electrozapping or High Heat and Steam or Acid ?

Decisions Decisions ...

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

After an ammonia soak next, this is the next lutefisk. This hitherto untapped resource has the potential to feed nearly a quarter of those who are

starving due to resources being diverted to pistachio plantations.

Or, I'm waiting until I get a vacuum retort before drilling a hole in my box furnace for it. I can't do strange things in the back yard, I can't even

be outside more than 15 seconds anymore before someone is staring at me like I'm TV for as long as I'm outside. If zinc is dissolved in HCl and

pistachio shells are added, they soon turn black and rubbery. The impregnation could be half the activation. The jar has been drained a few times and

it's hard to say if that was chemical or absorbed water.

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

Excellent work aga!

It is not a surprise to me that the CaCl2 failed to activate the carbon, since I don't imagine changing the surface area of something like carbon

would be easy to do at room temperature.

Perhaps you could try adding some CaCl2 to a sample of carbon and popping it in the oven along with the other samples? It's possible that the CaCl2

claim is not entirely bogus, just a little mistranslated.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Oscilllator  |

Perhaps you could try adding some CaCl2 to a sample of carbon and popping it in the oven along with the other samples? It's possible that the CaCl2

claim is not entirely bogus, just a little mistranslated. |

And your very vaguely described experiment will clarify this assumed mistranslation, how, pray tell?

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

It was only an idea. Perhaps the CaCl2 does have an effect on the charcoal but only at high temperatures. If so, then it can be assumed that the

original source got it wrong. Perhaps "mistranslation" was the wrong word to use, but I can't think of a better one.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

As far as i understand it, what's required First is an increase in surface area.

Grinding does that by reducing the particle size.

High temperature steam appears to crack the carbon structure, and also react, randomly removing some of the surface to create a more uneven texture.

Phosphoric acid appears to react with the carbon at elevated temperatures causing the same effect.

CaCl2 is more likely to be simply adsorbed to some extent at RT, and would be unlikely to be removed completely by washing with water.

The traces of CaCl2 would account for some possibility of 'activation' by that method, although the carbon would remain entirely unchanged.

[Edited on 10-8-2015 by aga]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Finally, a year later, having bought more lead for my ball-mill, a pile of charcoal got ground up today, yielding rather a lot of black powder that

makes a huge mess if you spill any.

For further 'normal activation', a.k.a. increase surface area, how about simply mixing it with water, stir a lot to form a paste, then freeze it,

hopefully causing microfractures in those tiny grains of dust ?

A quick google for 'microfracture' brought this up (about rocks) :-

http://www.sciencedirect.com/science/article/pii/S0191814114...

Hence there's a small pot of black mush in the freezer overnight.

For more Sunday diversion, three lots of 5g each of the ground-up charcoal have been boiled up with 2g of NaOH, CaCl2 and MgSO4

respectively, then filtered & washed & dried.

I'm wondering if AC-treated CaCl2 will perform the same, worse or better than straight CaCl2 in absorbing water from a stream of

air.

If nothing goes amiss, tomorrow there'll be some actual scientific data !

|

|

|

Sulaiman

International Hazard

Posts: 3787

Registered: 8-2-2015

Member Is Offline

|

|

I suspect that the CaCl2 activation did not have a significant effect because the Wikipedia article states;

"Prior to carbonization, the raw material is impregnated with certain chemicals"

i.e. not after carbonisation

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Hmm. Makes some kind of sense, kind of.

Impregnate the wood with something, then the organic break-down can't go via a straight gas route to just carbon : basically there's bits in the way,

causing it to end up all fractured.

A bit like mixing wood shavings with gravel, then setting fire to it - the gravel particles get in the way, so it does not end up as a fine dust.

Well spotted Sulaiman, i'll try it.

Perhaps this is what S.C Wack was alluding to with his pistachio nut shells in a bottle of zinc chloride.

[Edited on 1-10-2016 by aga]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

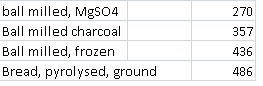

The existing sodium thiosulphate and iodinde solutions were re-standardised and came out +0.0005 N and -0.0008 N, so they were pretty much the same as

earlier.

Some more materials were tested to see if they can up the Iodine Number (I.N.) of home-made activated carbon.

Pyrolysed shop-bought white bread is pretty close to the I.N. of 500 found in the lower-end commercial products, and is the best result yet, despite

it being ground by hand in a pestle and mortar instead of in a ball mill.

Amazing that simply freezing milled charcoal also increases the surface area dramatically.

All-in-all, adding chemicals to milled charcoal seems pointless, unless they are targetted at something specific.

Used up the last if the iodine and sodium thiosulphate solutions doing that and there appears to be no iodine left

Gratuitous lab shot :-

|

|

|

| Pages:

1

2 |