Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

barium hydroxide [Ba(OH)2]

S.C. Wack has discussed preparation of barium compounds under the ferrate thread. But I think that barium hydroxide is important enough to merit its

own thread.

I needed to prepare a few grams of barium hydroxide. The starting compound I have is BaCO3, readily availabe from pottery suppliers.

I tried 2 methods: (1) ignition w/carbon at 1100C to form BaO, and (2) formation of Ba(NO3)2 w/HNO3 then ignition at 500C to BaO. Addition of water

to BaO gives Ba(OH)2 or a hydrate thereof. Here is a summary of my results:

1. Ignition of BaCO3 to BaO with finely ground carbon seemed to be successful. Heated to 1025C (highest my muffle furnace will do) for 1 hour.

Weight loss was 24.4% vs theoretical 26.8%.

2. Conversion of BaO to Ba(OH)2 not successful due to considerable absorbtion of CO2 from the atmosphere.

3. Conversion of BaCO3 to Ba(NO3)2 using HNO3 was successful using the theoretical amount of HNO3. Yield was 99.6%.

4. Ignition of Ba(NO3)2 to BaO was not successful. The crucible contents frothed over the edge. A glassine material formed in the bottom of the

crucibles. Since my furnace temperature indicator doesn't seem to be accurate in the 500C area I heated the furnace until it just stared to show

redness (meter indication: 700C).

So, in playing around with the compounds I found that Ba(OH)2 agressively goes after the CO2 in the air. Everything I tested fritzed CO2 when treated

w/10%HCl.

My next attempt will be to convert the BaCO3 to BaCl2 and then convert this to Ba(OH)2 using NaOH per the method in Henderson & Fernelius (our

library). This includes some steps to prevent absorption of atmospheric CO2.

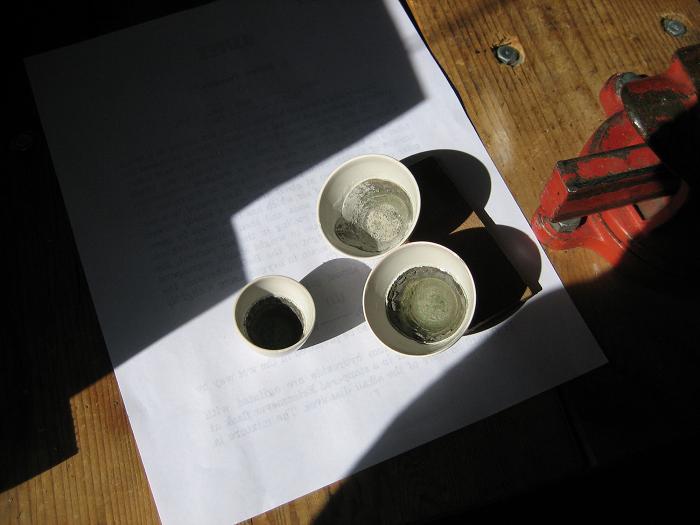

The attached photo shows the BaO formed after igniting the BaCO3 at 1025C for an hour.

[Edited on 12-3-2006 by Magpie]

[Edited on 12-3-2006 by Magpie]

[Edited on 12-3-2006 by Magpie]

[Edited on 30-1-2007 by chemoleo]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

It's the strongest alkaline earth, no? Beware of glass and porcelain, it'll probably tend to dissolve things, aqueous or glassy state. (Barium is a

strong flux, though not much used for toxicity reasons.)

Tim

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes, it chewed into my porcelain crucibles fairly well. I had a feeling it was fluxing with the wall but thanks for the confirmation. You can see

this in the photo.

The Ba(NO3)2 glassine product won't come out of the crucibles. One became brittle and broke when I was cleaning it - this is getting expensive!

This will be a big advantage of the next method - no ignition.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

BromicAcid

International Hazard

Posts: 3266

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

You can easily precipitate the hydrated form of barium peroxide from a solution of barium chloride with a concentrated

H<sub>2</sub>O<sub>2</sub> solution. The peroxide could then be heated to decompose the peroxide to the oxide and

subsequently hydrated. Although I think the peroxide is still somewhat resistant to thermal decomposition with respect to many other peroxides.

There is a preparation around here for barium peroxide and I have additional properties if you decide to act on this possible method of preparation.

|

|

|

mantis

Harmless

Posts: 38

Registered: 17-7-2005

Member Is Offline

Mood: No Mood

|

|

| Quote: |

You can easily precipitate the hydrated form of barium peroxide from a solution of barium chloride with a concentrated H2O2 solution.

|

yes, but only in a alkaline solution.

|

|

|

BromicAcid

International Hazard

Posts: 3266

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Yes, indeed. Hence my reference to finding the procedure that states such a thing. I intended for the statement to be made as an overview, that's

all. Additionally it should be noted that trying to pyrolyze barium peroxide might turn into quite the mess, wouldn't it be quite corrosive at high

temperatures.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

In reference to the glassine product left in the crucibles after igniting the Ba(NO3)2: It completely softened and turned white after I left it

covered in water overnight. So I believe that the glassine material was BaO. What I found today was likely Ba(OH)2*8H2O.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

BaO is converted to a less reactive form at high temperatures, due to the particles fusing together. This BaO reacts only slowly with water.

A solution of Ba(OH)2 becomes turbid in air in a matter of minutes, due to CO2 being absorbed. You should filter it to get out the barium carbonate.

|

|

|

turd

National Hazard

Posts: 800

Registered: 5-3-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | | A solution of Ba(OH)2 becomes turbid in air in a matter of minutes, due to CO2 being absorbed. You should filter it to get out the barium carbonate.

|

Tell me about it.  When I filter my Ba(OH)2 solutions they develop a carbonate

layer on top in a matter of *seconds*. Thankfully I'm reacting them with stronger acids than H2CO3, so it shouldn' t matter a lot... When I filter my Ba(OH)2 solutions they develop a carbonate

layer on top in a matter of *seconds*. Thankfully I'm reacting them with stronger acids than H2CO3, so it shouldn' t matter a lot...

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Making Ba(OH)2*8H20 from BaCl2 according to the method in Henderson & Fernelius worked well and I ended up with some nice looking, but wet,

crystals. Not able to leave well enough alone I tried to dry these by wrapping them in a paper towel for 24 hours (per another book in our library,

Walton IIRC). This didn't work out too well as about half of the crystals effloresced. They also fizzed with 10%HCl whereas the non-effloresced

crystals did not. (I thought about separating the crystals by hand then quickly decided that was a bad idea.)

The Henderson & Fernelius procedure for final drying of Ba(OH)2*8H20 to Ba(OH)2 was to place it in a dessicator with - you guessed it -

effloresced Ba(OH)2!

Overall, I'd have to say that working with barium salts kicked my ass. My BaCO3 and Ba(NO3)2 ignitions weren't too practical. And when I did get

Ba(OH)2 I had to use air purification and sealing to prevent absorbtion of CO2. Although I now think that just working quickly would have worked just

as well. But there is more to it than that. The Ba(OH)2 adheres something fierce to all glassware. Then when it absorbs the CO2 you have white

stubborn stains. This was removeable with H2SO4 cleaning solution, however.

[Edited on 18-3-2006 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

chloric1

International Hazard

Posts: 1159

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Huge swing in BaOH2 in water

I am pretty sure I mentioned this elsewhere on this forum, but BaOH2 is like 100 times more soluble in boiling water than cold water. Boil water to

dissolve barium hydroxide, filter out carbonate, then cool to crystallize octahydrate. Crystals remind me of marble.

Fellow molecular manipulator

|

|

|

nezza

Hazard to Others

Posts: 324

Registered: 17-4-2011

Location: UK

Member Is Offline

Mood: phosphorescent

|

|

I have had trouble with making barium hydroxide by decomposing carbonate/nitrate. The best method I found was double decomposition with carbonate free

alkali. This gives a hydroxide precipitate which will still absorb CO2 pretty rapidly. Dissolve the precipitate in hot water, filter and cool. Most of

the hydroxide will precipitate out.

If you're not part of the solution, you're part of the precipitate.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I made some barium hydroxide from barium carbonate using an idea posted by clearly_not_atara (who probably did not intend using impure pottery grade

starting materials). He suggested making barium hydroxide by dissolving barium carbonate in dilute acetic acid and then adding sodium hydroxide.

I simply extracted an excess of barium carbonate with 1L of 5% household vinegar in a well-ventilated area, filtered, and precipitated barium

hydroxide with sodium hydroxide. Then I heated the mixture to boiling, causing the barium hydroxide to dissolve and did a hot filtration through a

coffee filter on top of a cotton ball, placing the flask in a boiling water bath and guiding the steam around the funnel with aluminum foil. At times

I used a heat gun to make the mixture in the funnel boil.

Once the filtration was complete, I chilled the filtrate in the refrigerator and then vacuum filtered. The mixture wasn't easy to filter, and to make

sure things stayed cold, I dropped a couple of ice cubes in the filter funnel. I also covered it with plastic wrap to keep out carbon dioxide to a

large extent. I washed the filter cake a few times with ice cold water.

Here is a picture of the crude product. It is contaminated with a little bit of an extremely fine, brown, silty material that passes through the

filter paper (perhaps sulfur?).

The yield I'm sure is not very good, and it will be even worse once I recrystallize, but I'm looking forward to having some barium hydroxide on hand

for tests and experiments.

|

|

|

Deathunter88

National Hazard

Posts: 544

Registered: 20-2-2015

Location: Beijing, China

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Magpie  | Yes, it chewed into my porcelain crucibles fairly well. I had a feeling it was fluxing with the wall but thanks for the confirmation. You can see

this in the photo.

The Ba(NO3)2 glassine product won't come out of the crucibles. One became brittle and broke when I was cleaning it - this is getting expensive!

This will be a big advantage of the next method - no ignition.

|

It might be better to consider ceramic crucibles as single use, disposable. They are cheap to buy in bulk and not worth the effort to clean. Platinum

ones on the other hand...

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

After researching the matter, I think the brown, silty material is most likely iron pyrite. Who knows for sure... I'm thinking about trying the

synthesis again on larger scale with hydrochloric acid in a 5-gallon bucket outside.

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

I'd be surprised if the pottery grade material doesn't contain at least some Strontium which has very similar chemistry. It also precipitates its

hydroxide as the octahyrate from water, but it has lower solubility than barium. So, any impurities are likely concentrated through this method.

Strontium nitrate on the other hand, is way more soluble than Barium Nitrate. Perhaps the nitrate can be recrystallized as a precursor to the

hydroxide.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Wouldn't a hot filtration remove most of the strontium hydroxide?

|

|

|

nezza

Hazard to Others

Posts: 324

Registered: 17-4-2011

Location: UK

Member Is Offline

Mood: phosphorescent

|

|

Ignition of Barium salts (carbonate or nitrate) requires very high temperatures and is not at all easy. I have found that the best method is to add

carbonate free caustic alkali to a solution of a soluble barium salt and filter the precipitate off. It can be washed or recrystallised to purify it.

Carbonate free alkali can be prepared by dissolving sodium or preferably potassium hydroxide in alcohol and allowing to settle. Any chloride or

carbonate will not dissolve. This can then be added to boiled out water to give carbonate free alkali.

If you're not part of the solution, you're part of the precipitate.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

It is possible to differentiate qualitatively between barium hydroxide and strontium hydroxide with flame testing. There's also a test based on

rhodizonic acid, which can be made by nitric acid oxidation of inositol.

(I should probably mention that in the procedure above I boiled down the solution/mixture a couple of times.)

[Edited on 4-9-2018 by JJay]

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

Quote: Originally posted by 12AX7  | It's the strongest alkaline earth, no? Beware of glass and porcelain, it'll probably tend to dissolve things, aqueous or glassy state. (Barium is a

strong flux, though not much used for toxicity reasons.)

Tim |

Just recently I blurred my plastic juice jug all over just because of handling it into an acidic barium salt batch!

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Hi Magpie,

Are you in the US?

I have maybe 75 or 100 g of BaO. You can have whatever you need for the cost of postage.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Metallus

Hazard to Others

Posts: 116

Registered: 16-5-2013

Member Is Offline

Mood: No Mood

|

|

Off topic:

Was it barium chromate that had that disgusting yellow/green coloration reminishing of snot?

|

|

|

Poppy

Hazard to Others

Posts: 294

Registered: 3-11-2011

Member Is Offline

Mood: † chemical zombie

|

|

No thats iron phosphate lol

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

BTW it is said the nitrate requires 900C for some hours, then crushing and reheating.

|

|

|