hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

Iron Photochemistry

I read about using organic iron (III) salts to produce photographic prints. Under the influence of light, iron (III) is reduced to iron(II), and the

iron(II) will then react as a reducing agent with various other substances to produce an image. I decided to give it a try.

I made some ferric oxalate as follows. I added an oxalic acid solution to a ferrous sulfate solution. The result was a precipitate of insoluable

ferrous oxalate. After decanting and washing the precipitate several times, I added more oxalic acid solution. I then added 30% hydrogen peroxide

slowly until all the ferrous oxalate dissolved (ferric oxalate is soluable whereas ferrous oxalate is not). The result was a pale yellow-green

solution containing somewhere around 20% ferric oxalate by weight. I mixed equal volumes of this solution and 10% silver nitrate solution. I painted

this on paper. When dry, I exposed to strong light from a fluorescent bulb a few inches away for 30 minutes. The image of the objects I had sitting

on the paper clearly showed up. I used sodium acetate solution to wash the image to get rid of the unreacted salts.

I tried a second way of making an image. Instead of using silver nitrate I used potassium ferricyanide. This substance produces a dark blue in the

presence of iron(II). Unfortunately, I found that the solution would always turn blue after a few minutes even without exposure to light. Using a

very dilute solution and exposing it before the paper had dried completely allowed me to produce a poor-quality print, but clearly the second reaction

didn't work the way it was supposed to.

Although photography books call for ferric oxalate for printing with silver nitrate, they call for ferric ammonium oxalate for printing with potassium

ferricyanide. Any idea why it would work with one and not the other? Using ferric oxalate and potassium ferricyanide, something must be getting

reduced even without light. Since this is not a problem using silver nitrate I assume the potassium ferricyanide is what is getting reduced (to

ferrocyanide, which is also blue in the presence of iron (III)). But why would a double salt work differently, given that they would both contain the

oxalate ion?

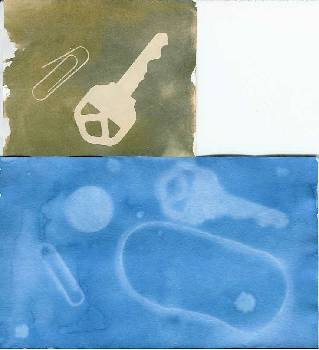

Here are the two images I produced (scanned in).

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

That appears to be basically the same process as blueprinting, which has been superseded by the use of laser printers/copiers. It involves the

production, in the areas to show up in drawings, of Prussian blue, ferric ferrocyanide, Fe4[Fe(CN)6]3, by reacting ferrocyanic acid or a ferrocyanide

with Fe(III). It is also used as a paint pigment, but not as good as copper or cobalt blue pigments. There is also Turnbull's blue, ferrous

ferricyanide.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

You can be conned by putting objects on the paper directly if not careful with heat and electrochemistry interfering with the image production. Ive

made this mistake based on an idea about permanganates.

For general information, second to none is,

http://www.mikeware.demon.co.uk/

Silver nitrate itself will of course darken on exposure to light, so using both seems a little redundant.

If the solution is going green or blue out of contact with light there is a reduciong agent somewhere. As Mike says the paper itself is fairly

crucial to good results, impure paper reducing the iron salt itself.

The cyanotype process, and iron(III) generally is more sensitive to deep blue/UV IIRC.

I'm bothered by the oxidation of the ferrous salt with hydrogen peroxide for a few reasons. I tried precipitating iron(III) hydroxide from

ferric chloride and then adding oxalic acid but I was after pyrophoric iron, not photographic grade.

Prussian blue and Turnbull's blue are exactly the same compound just for reference.

[Edited on 5-4-2005 by Marvin]

|

|

|

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

Okay, thanks Marvin for the link.

I read some of the site. I concluded that the reason that ferric ammonium citrate is used instead of ferric citrate has to do with the physical

properties of the salt. The ammonium double salt tends to attract a bit of water and thus allows some reaction to occur while the print is being

exposed, instead of just when it is developed in water afterwards. This helps in monitoring progress during exposure.

I was able to get better results. I made a new batch of ferric oxalate, this time being careful not to add too much oxalic acid the second time (I

think I ended up with an excess before). Between this, and using a more dilute solution, I was able to get the unexposed part of the paper to remain

almost completely white. The solution itself still turned blue after a few hours, but the dried paper did not turn until exposed to light. I have

read that it is best to mix the solution right before use, so apparently when wet it does react on its own somewhat.

I did find that some papers did not work, as was mentioned. HP inkjet paper caused the solution to turn blue immediately, and with silver nitrate

caused it to turn brown immediately. I had the best results using index cards - they don't seem to be treated with chemicals the way other

papers are.

As far as using ferric oxalate along with the silver nitrate, I got much better results this way than by simply using silver nitrate on a paper

previously coated with salt. Exposure time a few inches from a fluorescent bulb was a few minutes with the iron oxalate vs. hours with the silver

chloride. I have yet to try other salts of silver alone without the iron oxalate. Supposedly the bromate and iodide are more sensitive - this would

make sense given that bromine and iodine are more easily oxidised than chlorine. I will give that a try sometime.

The web site mentions using expensive salts of rare metals such as gold and platinum in place of silver nitrate. Apparently they give a superior

color. I'm guessing that a mercury salt would work too since mercury is pretty easily reduced. I may give this a try.

I ordered some ferric ammonium oxalate, as well as ferric ammonium citrate and sodium ferricyanide to experiment with. That was before I got my

homemade ferric oxalate blueprint process working. If I had known I would get it to work I would not have necessarily ordered anything else. The

amounts needed are truly tiny. I used around 2.5 grams of ferrous sulfate, 2g total of oxalic acid, and 1g of potassium ferricyanide. This makes two

10ml solutions which are mixed and right before application. Even then the image I am posting had this solution diluted about 3 to 1 with water, and

then less than 1ml was needed to cover the whole index card (which I only used half of for this image).

|

|

|

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

Silver Bromide

Slightly different from the original topic, but I was able to get a homemade silver compound to produce a recognizable picture.

I mixed 2 grams of AgNO3 with 10ml of distilled water. In a second test tube, I mixed 2 grams of Knox clear gelatin (from the supermarket) and 1.2

grams of NaBr (from hottub supply) in 10ml of hot water. In darkness, I mixed the two solutions and then chilled in the refrigerator until the

gelatin hardened. I then washed the gelatin mixture by squeezing it through my fingers (with gloves on) several times in ice-cold water. This was to

remove the NaBr.

I then melted the washed gelatin again and coated it onto a blank index card with a pipette and small paint brush. When dry, I exposed it for 15

seconds using an old box camera (f/8) in bright sunshine. I developed using standard paper developer from Kodak.

I then scanned this negative image into my computer with a regular scanner, took the negative image of it, and adjusted the brightness slightly.

The ASA for the photographic emulsion I made works out to be about 0.05, or about 1/100 the speed of normal photo paper.

[Edited on 10-5-2005 by chemoleo]

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

This is very impressive!

I remember playing with a box camera, and I know that the light intensity hitting the plate is quite low - I am impressed you got it to work with

under 'amateur' conditions.

Anyway - could you please (for reference, and for myself) state the reactions that are happening?

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

When making the emulsion:

AgNO3 + NaBr ---> AgBr + NaNO3

The AgBr is insoluable and remains with the gelatin. Washing the gelatin helps get rid of the soluable NaNO3, which is somewhat hygroscopic and

decreases the quality of the image produced.

When exposed to light, silver bromide decomposes into silver and free bromine

2AgBr + light ---> 2Ag + Br2

Now, when the silver bromide precipitates it forms tiny crystals. When two photons with sufficient energy hit two nearby AgBr molecules, two atoms of

silver are formed. As we know, exposing silver bromide (or any silver halide) to light for a long period of time causes it to change color from white

to black. The black is tiny silver particles.

If only a small amount of light hits the silver bromide, there will be no visible change (not even with a microscope). However, the crystals that

have been hit with light each contain a tiny piece of silver. When exposed to a reducing agent (the developer), the crystals that already have free

silver atoms are reduced to silver much faster than those that are still pure silver bromide. Thus the developer amplifies the effect of the light by

many orders of magnitude.

The sensitivity of the emulsion to light depends on the size of the AgBr crystals. The larger the crystals are, the more silver produced by the

developer and thus the easier to see it. Larger crystals are also more likely to be struck by two photons of light than smaller crystals. In film

photography films with a higher speed rating contain larger crystals of silver halide. Unfortunately the larger crystals also make the image more

"grainy" when developed, as is noticable when using high-speed films.

The strength of the bonds between silver and a halide varies with the halide. The bond between silver and chlorine is the strongest. As a result, it

take a high energy photon to affect silver chloride. Only ultraviolet light is effective for this. I was able to get an image using silver chloride

in sunlight, but the exposure times were even longer. Silver-bromine bonds have medium strength. Thus visible light can affect it, although red

light has too little energy to do so. I did all my mixing and coating in a room lit only by a photographic red light. Silver iodide is sensitive

even to red light. I tried making a silver iodide emulsion with potassium iodide and silver nitrate, and found that paper coated with it developed as

exposed (turned all black) even before I took a picture. Apparently the red light I used while preparing the solution exposed it (or else some other

factor such as impurities started a reduction).

The developer is an organic reducing agent. I don't know the equations for the reduction or even the exact composition of the developer.

Supposedly 150 years ago photographs were developed in gallic acid, which is also a reducing agent. I don't have any gallic acid so I

couldn't try this. I heard that iron (II) sulfate was sometimes used. I tried this with no success on either my homemade emulsion on on regular

photographic paper. I've also read that ascorbic acid can be used as a developer but have not yet tried this.

|

|

|

Darkblade48

Hazard to Others

Posts: 411

Registered: 27-3-2005

Location: Canada

Member Is Offline

Mood: No Mood

|

|

I'm well aware that this is an old topic (and yes, I'm dragging out an old topic)

Anyways, given that you have an organic Iron (III) salt that will reduce to Iron (II) under light, does it matter what iron (III) salt is used?

i.e. hodges mentionned using ferrous sulphate, mixing it with oxalic acid, then oxidizing it up with hydrogen peroxide. Would the same process be

possible if I were to say use iron (II) chloride, mix it with oxalic acid, and then oxidize it up with the peroxide?

Alternatively, would it be possible to skip the entire oxidizing step by starting off with an iron (III) salt (i.e. FeCl3) and then mixing it with

oxalic acid?

|

|

|

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

I believe you should be able to user iron (II) chloride instead of iron (II) sulfate. However, you will need to go through the iron (II) oxalate

stage because iron (II) oxalate is insoluable and thus can be purified by washing. If you start with iron (III) chloride, you will not have a way of

removing the chloride ion since both iron chloride and iron oxalate are soluable.

|

|

|

Darkblade48

Hazard to Others

Posts: 411

Registered: 27-3-2005

Location: Canada

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by hodges

That was before I got my homemade ferric oxalate blueprint process working. If I had known I would get it to work I would not have necessarily

ordered anything else. The amounts needed are truly tiny. I used around 2.5 grams of ferrous sulfate, 2g total of oxalic acid, and 1g of potassium

ferricyanide. This makes two 10ml solutions which are mixed and right before application. |

So from this, you used 2.5 g ferrous sulfate, added 2 g oxalic acid to precipitate out the ferrous oxalate. After decanting and washing several times,

you oxidize up to ferric oxalate via H2O2.

You say that you used 30% H2O2, but if I don't have access to this and only to the 3% stuff, I would (obviously) end up with a lot more than 10

mL of this mixture (I presume the other mixture is just 1 gram of potassium ferricyanide mixed into 10 mL of distilled water).

How would this affect my results? I.e. would I end up having something like 100 mL of the ferrous oxalate solution and only 10 mL of the potassium

ferricyanide?

Edit: Another question, why does the oxalic acid displace the sulfate from the ferrous sulfate to precipitate out the ferrous oxalate?

[Edited on 24-10-2005 by Darkblade48]

|

|

|

Darkblade48

Hazard to Others

Posts: 411

Registered: 27-3-2005

Location: Canada

Member Is Offline

Mood: No Mood

|

|

Darn, can't edit my previous post, forcing me to bump this thread.

I made some iron (II) chloride by throwing in some steel wool into HCl, and after filtering out all the junk, I get my green FeCl2 solution.

However, when I tested this on a semi microscale, I found that mixing in a solution of oxalic acid to the ferrous chloride solution had no effect

(i.e. no precipitate was formed)

Does anyone know why a precipitate is formed with ferrous sulfate but not with ferrous chloride?

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Likely because you had a large excess of HCl remaining from dissolving your steel wool in HCl.

[Edited on 29-10-2005 by rogue chemist]

|

|

|

Darkblade48

Hazard to Others

Posts: 411

Registered: 27-3-2005

Location: Canada

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by rogue chemist

Likely because you had a large excess of HCl remaining from dissolving your steel wool in HCl.

|

Ah yes, I checked the CRC after this and noticed that ferrous oxalate is soluble in acids.

Is there any way to perhaps get rid of the acid so that FeCl2 is usable to precipitate out the ferrous oxalate, or is it necessary to use ferrous

sulfate (which does not form an acidic solution)

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Use a stoichiometric ammount of acid and steel wool, filter out the blac carbon junk floating in there, add a very small ammount of NaOH slowly until

the first precipitation of iron hyroxide is visible, then filter out the ppt and you are left with a pretty much neutral iron(II) chloride solution

with a very small NaCl contamination. Then react with oxalic acid to get the ferrous oxalate you want.

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Alternately, you could boil your acidic FeCl<sub>2</sub> solution down. HCl should come off with water vapor, leaving a pure

FeCl<sub>2</sub> solution.

|

|

|

Texium

|

Thread Moved

19-11-2023 at 10:48 |