| Pages:

1

2 |

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Preparation of Phenol from Salicylic Acid

A practical and quantified method for the preparation of phenol from inexpensive, readily accessible starting materials is something that, to the best

of my knowledge, does not yet exist on this forum. Methods such as the cumene process or direct oxidation of benzene require specialized catalysts and

conditions that are not amenable to amateur experimentation. Diazotisation of aniline yields phenol upon warming the solution of diazonium salt, but

aniline is itself a difficult to acquire or tedious to make chemical. Fusion of benzenesulfonates with molten alkali hydroxides furnishes phenol, but

benzenesulfonic acid is typically prepared with oleum and the alkali fusion is unpleasant at best.

Anyone who has heated salicylic acid knows that it decarboxylates to phenol, as is evident from its powerful smell. However, conversion is far from

quantitative through brief heating, so more controlled conditions are required for an isolatable yield. One such procedure comes from another amateur

experimentation forum, versuchschemie.de Suspecting that the stated 40% yield could be improved, I did some of my own experimentation.

The salicylic acid used was prepared from acetylsalicylic acid (aspirin) recrystallized from acetone. The one-pot cleavage of the phenyl acetate ester

and crystallization of the product was carried out in the following manner:

Conversion of Aspirin to Salicylic Acid

A 1L RBF is charged with a stirbar, 45.04g of acetylsalicylic acid (250mmol), 600ml of distilled water, and 10ml of 31.45% hydrochloric acid. A

vertical condenser is attached and the reaction mixture heated to reflux. After 30 minutes (This may be excessive, but I know it works), heating is

stopped and stirring turned off. The solution, which should be a clear, colorless liquid, is very nearly saturated with salicylic acid and after

cooling for a few minutes should be agitated to induce crystallization or seeded with a small quantity of salicylic acid crystals. The flask is left

to stand undisturbed for several hours while crystallization occurs. Solubility at 20oC is nearly negligible (~2g/L), and cooling in an ice

bath is unnecessary. The product is a mass of small, white needle-like crystals that fill the solution. The solution is agitated to break up the

fragile crystal mass and vacuum filtered. A clean stopper is used to press the "fluffy" mass of crystals to aid in removal of the mother liquor. This

cake is washed with two 50ml portions of distilled water. The product can be dried in a dessicator, at room temp, or at mildly elevated temperatures.

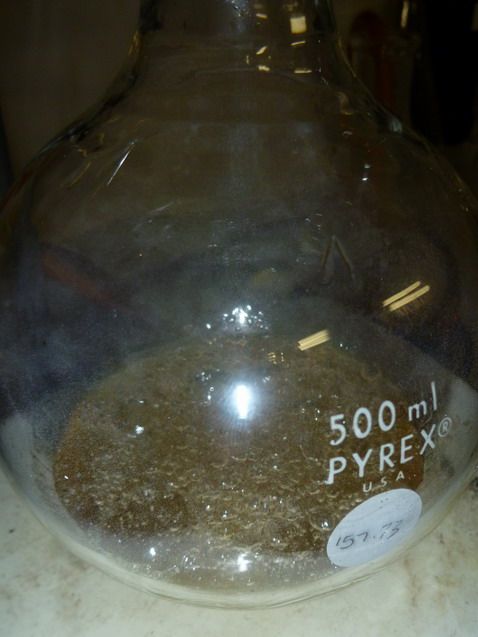

The yield of salicylic acid is roughly 95% of the theoretical as glittering white needles melting at 156-157.5oC (uncorr, lit m.p.

158.6oC)

The filtrate can be reused several times to hydrolyze additional batches of salicylic acid. Discard 100ml of liquid, add 1-2ml of 31.45% hydrochloric

acid, and an additional 45.04g of aspirin. The reflux procedure is repeated and the product collected may be obtained in nearly quantitative yield, as

solubility losses are minimized and the only limiting factors are the purity of the aspirin and mechanical losses.

Thermal Decarboxylation of Salicylic Acid to Phenol

A 500ml RBF is charged with 69.06g (500mmol) of salicylic acid and a few boiling stones. A short path distillation head with thermometer is mounted

atop this flask, though there is no reason that a normal 3-way adapter couldn’t be used. Since the product distilling is phenol (m.p.

40oC) it is prudent to maintain the condenser water at ~45oC. As I am working in an unheated lab, I found that the easiest way

to do this was to load the condenser with hot water and not cycle it. The distilling phenol dissipates enough heat into the small condenser to keep

the water at the desired temperature.

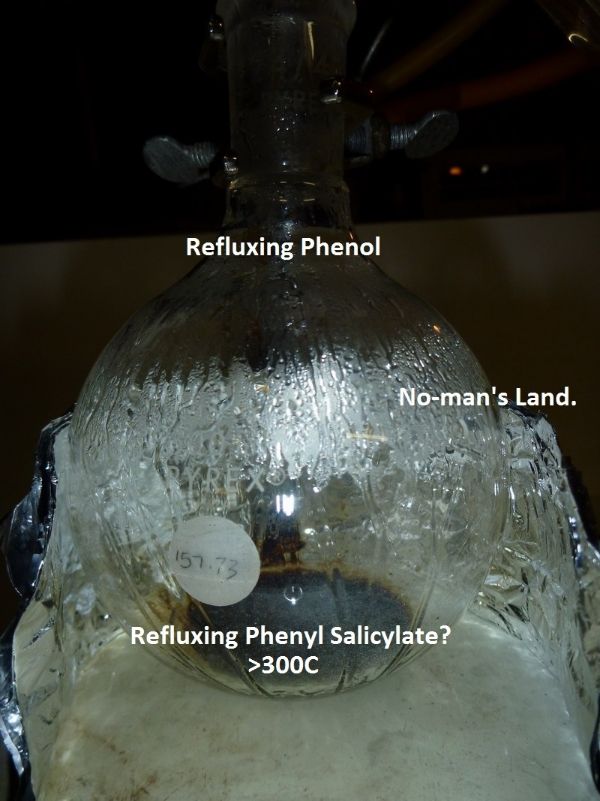

The flask is strongly heated with a hotplate and the salicylic acid melts into a bubbling liquid. Some fine crystals of salicylic acid will probably

deposit on the roof of the flask but should not make it into the stillhead. After a few minutes, a vapor front of phenol/water will rise up the walls

and knock down any crystals that have formed. If this does not make it into the stillhead and begin a slow distillation after several minutes,

increase the heat supplied to the flask or add insulation.

Distillate should slowly pass over at the stillhead. It will initially be milky and biphasic from small quantities of water, but the stillhead

temperature will rise and it will become monophasic dry phenol. Do not allow the stillhead to exceed 165oC. The formation of carbon dioxide

by decarboxylating salicylic acid serves to “blow” phenol vapor into the condenser below its normal boiling point. Increasing the stillhead

temperature will only serve to carry additional vaporized salicylic acid over as well (some is inevitable). No crystals should form in the condenser.

For the duration of the experiment, phenol passed over from 145oC to 165oC and collected as a clear, colorless to very faintly

yellow, supercooled liquid in the receiving flask.

Heating will need to be increased eventually to maintain a reasonable distillation rate and the whole process may take a few hours. At the very end, a

second liquid, suspected of being phenyl salicylate (and possibly xanthone per, Org. Synth. 1927, 7, 84) may begin

refluxing in the lower part of the distillation flask.

The residue is tarry and brown and consists of unreacted salicylic acid, polycondensed crap, and what is likely a reasonable amount of phenyl

salicylate/xanthone. The crude product formed a slushy crystalline mass on standing and weighed 37.55g.

To purify the crude product, vacuum distillation is employed, though it should be possible to do it without vacuum. At ~30torr, phenol distills from

85-90oC With vigorous stirring under vacuum the product is first distilled until the stillhead reaches 85oC. At around

30oC, water passes over, and a small amount of phenol is lost in the 30-85oC range, but ensures the product will be dry. No

cooling is necessary for this stage. If operating without vacuum, distill until the stillhead reaches 181oC

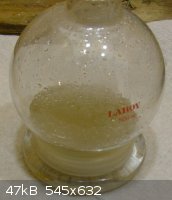

The vacuum is broken and the stillhead, condenser, and reciever are cleaned and dried. The phenol is then distilled utilizing a similar condenser

setup as the initial distillation and passes over as a monophasic colorless clear liquid, freezing in the receiving flask. When product ceases to

distill in the appropriate temperature window (though there may be liquid or even solid in the stillpot), heating is stopped. The stillpot residue

freezes into a solid mass well above phenol’s melting point and consists largely of salicylic acid. The product weighs 31.45g, a 66.8% yield from

salicylic acid.

(Note: This image is of a previous smaller run, but the product is visually identical to that of the 500mmol scale.)

Smaller scale experiments using 20g of salicylic acid gave 57% and 71% yields of phenol, so 60-70% is probably a reasonable expectation of yield.

Notes:

-Attempts to convert all of the salicylic acid to phenol through extended reflux failed. After an hour and a half, roughly 30% was converted as

determined by decrease in mass from CO2 evolution. As the refluxing phenol lowers the melt’s temperature significantly, the rate of

decarboxylation slows to a crawl, as indicated by a mineral oil bubbler.

-Attempts to catalyze the decarboxylation using copper chromite catalyst failed. Conversion based on loss of mass was identical to that of the

uncatalyzed reaction after 1 ½ hour reflux. This therefore rules out copper powder and copper oxide as other likely catalysts. While using quinoline

as a reaction medium may promote decarboxylation with these catalysts, this is not viable for as simple a compound as phenol with inexpensive starting

material where uncatalyzed decarboxylation is fairly effective.

-No attempt was made to work up the tar from the initial distillation for its suspected phenyl salicylate content. If you wish to do so, I suggest

adding in the stillpot residue from the vacuum distillation and dissolving everything you can into toluene, washing with bicarbonate solution to

remove salicylic acid, and vacuum distilling after stripping the solvent. Any forerun will likely be phenol and if there is phenyl salicylate present,

it should distill over near 200oC at 30 torr. (lit. 172-173oC at 12torr) Xanthone, boiling at 351oC at atmospheric

pressure may complicate this isolation, or may prove to be the major product.

[Edited on 12-1-13 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Boffis

International Hazard

Posts: 1897

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Nice work UC! An interesting thought on your final paragraph; The distillation of phenyl salicylate at atmospheric pressure yields phenol and

xanthone. The latter compound only distills at about 350-360 C. The detailed preparation is covered in Org Synth Coll. Vol. 1 p552 (attached).

Attachment: CV1P0552.pdf (119kB)

This file has been downloaded 2424 times

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by Boffis  | | Nice work UC! An interesting thought on your final paragraph; The distillation of phenyl salicylate at atmospheric pressure yields phenol and

xanthone. The latter compound only distills at about 350-360 C. The detailed preparation is covered in Org Synth Coll. Vol. 1 p552 (attached).

|

Very cool. Since I had the heat cranked all the way and the only thing keeping it from getting to the hotplate's surface temp of nearly 500C was

reflux, I bet that conversion did happen, at least to an extent. When washing the stillhead out after the initial distillation, a smell similar to

benzoate/salicylate esters was noted, but quite weak and somewhat with a more "plastic" character than the fruity/mintyness of the normal esters. This

is the main reason why I jumped to phenyl salicylate as a conclusion. I've edited the original post to reflect this information.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Phenol from acetylsalicylic acid - it is insanity......

Commercial salicylic acid is really cheap (~10 euros/kg), so phenol prepared in this way is not very expensive, however much more expensive than

commercial one. But for experiment, why not.

Oxidation of benzoic acid to phenol can be conducted via (thermal) decomposition of its Cu(II) salt but your preparation seems to be better solution.

Слава Україні !

Героям слава !

|

|

|

ParadoxChem126

Hazard to Others

Posts: 104

Registered: 5-4-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

A similar method of making phenol from acetylsalicylic acid was discussed here:

http://www.sciencemadness.org/talk/viewthread.php?tid=23930

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Perhaps, but I see no info on characterization info to suggest that your product is phenol of any appreciable purity, though you claim 95-98% somehow,

nor do you give a yield. Dissolving in DCM will not separate phenol and salicylic acid. In fact, water would be a far better choice, as salicylic acid

is nearly insoluble and the phenol can be isolated by distilling from the aqueous solution, where it passes over with steam.

Additionally, you simply heat salicylic acid in a flask. The reaction temperature (and rate) is limited by the phenol content, as I found with my

reflux experiments. If vigorously boiling for an hour and a half converted only 30% of my salicylic acid, why would 10-15 minutes of on and off

boiling with a torch convert all of it?

[Edited on 12-1-13 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

ParadoxChem126

Hazard to Others

Posts: 104

Registered: 5-4-2013

Location: USA

Member Is Offline

Mood: No Mood

|

|

I did not formulate this idea, I got it from page 128-129 of this book:

http://books.google.com/books?id=y5mZrW1KB_AC&pg=PA129&a...

This method is likely to be very ineffective compared to the method you have suggested; distillation would seem to give a much purer product as well

as a higher yield. Additionally, due to phenol's volatility, a good portion of the product would vaporize and be lost without any means to

re-condense the vapors. This would subtract from the already low yield.

I believe that your method is a much better way to prepare phenol.

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Oh look, a Ledgard publication. I suggest you disregard anything he says ever. It's not for nothing that another of his books is discussed in the

first few posts of one of our threads, before it degrades into religious shit-flinging of course: The WORST BOOKS Ever Written!

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Do you have no heat transfer agent between your plate and flask? Like sand bath or...?

Or was it removed for photos?

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

None. I only use them when I have particular need of very stable reaction temperatures. I used one for the 170C reaction temp called for in my recent

(failed) attempt at ethylene carbonate. In this case, it is desirable that the temperature of the stillpot rises as high as possible while the

stillhead remains at an appropriate temperature and maintains a slow, steady takeoff of phenol.

I use sheets of aluminium foil or fiberglass cloth to insulate the vessel when necessary. I find an air bath sufficient for most things. It would

likely be advantageous to use one during the vacuum distillation of the phenol, though.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

barley81

Hazard to Others

Posts: 481

Registered: 9-5-2011

Member Is Offline

Mood: No Mood

|

|

Great work!

By the way, on the Russian Hyperlab forum, there are some people who used calcium hydroxide as a catalyst for the decarboxylation, citing a 1949 US

patent. They claim 85% yield. I have attached a text copy of the webpage and a pdf of the patent. Google Translate does ok in getting the main idea

across.

Attachment: russian phenol.html (43kB)

This file has been downloaded 1580 times

Attachment: US2488472__Phenol.pdf (1.4MB)

This file has been downloaded 1719 times

|

|

|

BlackDragon2712

Hazard to Others

Posts: 124

Registered: 22-12-2012

Location: Everywhere

Member Is Offline

Mood: Sleepy

|

|

around 20 dolars for the kilogram of salicilyc acid. convertion of a 70 percent. the kilogram of phenol costs like 220 dolars so 700 grams would have

a price of 154 dollars giving us a profit of 134 dollars O:!!!

nicely done btw, mister UnintentionalChaos I really apreciate your work

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by BlackDragon2712  | around 20 dolars for the kilogram of salicilyc acid. convertion of a 70 percent. the kilogram of phenol costs like 220 dolars so 700 grams would have

a price of 154 dollars giving us a profit of 134 dollars O:!!!

nicely done btw, mister UnintentionalChaos I really apreciate your work |

Don't get ahead of yourself there. 70% yield of phenol from a kilo of salicylic acid is 477g. I think you may also be comparing different grades or

reagents there... Salicylic acid is made from phenol industrially so the starting phenol in any sane universe should cost less. That being said, you

may not be able to buy it at that price point.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by UnintentionalChaos  | | Salicylic acid is made from phenol industrially so the starting phenol in any sane universe should cost less. That being said, you may not be able to

buy it at that price point. |

Most phenol is produced by the cumene process, more than 95% of world production according to Kirk-Othmer. Starting materials are benzene and propylene. Reaction conditions in

the first step are 30 bar and 250 °C, not particularly amenable to amateur production. It helps a lot to own an oil refinery.

More amenable to amateur production is the toluene - benzoic acid process, at 4% of world production per K-O. But since that's taking things off-topic

for this thread, those interested should just go look it up.

<hr/>bfesser moderator expellendus est

|

|

|

BlackDragon2712

Hazard to Others

Posts: 124

Registered: 22-12-2012

Location: Everywhere

Member Is Offline

Mood: Sleepy

|

|

Quote: Originally posted by UnintentionalChaos  | Quote: Originally posted by BlackDragon2712  | around 20 dolars for the kilogram of salicilyc acid. convertion of a 70 percent. the kilogram of phenol costs like 220 dolars so 700 grams would have

a price of 154 dollars giving us a profit of 134 dollars O:!!!

nicely done btw, mister UnintentionalChaos I really apreciate your work |

Don't get ahead of yourself there. 70% yield of phenol from a kilo of salicylic acid is 477g. I think you may also be comparing different grades or

reagents there... Salicylic acid is made from phenol industrially so the starting phenol in any sane universe should cost less. That being said, you

may not be able to buy it at that price point. |

damn! I got excited too quickly.

btw here where I live I swear god phenol is way more expensive than salicylic acid and I'm still getting a 84 dollars profit ahahah

[Edited on 06/11/2013 by BlackDragon2712]

|

|

|

Natures Natrium

Hazard to Others

Posts: 163

Registered: 22-12-2004

Member Is Offline

Mood: No Mood

|

|

Well, now I am regretting not documenting my experiments more closely. Inspired by the Pyridine decarboxylation thread, I have been dabbling in this

particular subject.

I would like to report some success, using copper chromite catalysts. The catalyst was prepared according to UnintentionalChaos's methodology, i.e.

no barium involved, with some modifications. No ammonium dichromate was available, so sodium chromate was taken up in aqueous solution, acidified to

an orange color with sulfuric acid, and an equimolar volume of ammonium chloride was added. This solution was used in place of the straight ammonium

dichromate solution, and appeared to perform identically.

Yields at this time can only be estimated because the product is still in its crude form, as pictured below. The crude product there is the result of

using 195g of salicylic acid.

I also redistilled the phenol product from the reaction flask, as UC did with the pyridine procedure, so I am unsure of any potential product loss

there. It seems as though the product contained less water before the redistillation, as it solidified continuously as the reaction proceeded, and

had to be warmed above its melting point (which took a surprising long time and a lot of heat) to be poured back into the reaction flask for

redistillation. After redistillation I obtained a slush of needles in what is presumed to be water saturated with phenol, as reported by UC and

pictured below.

I did the 195g in two separate reactions, one using a propane fueled bunsen burner and one using a hotplate brought slowly up to temp. I did not

observe any qualitative difference between the two heating methods. I used an unusual short path set up (flask -> distilling adapter -> claisen

adapter (used as an air cooled condenser) -> vacuum adapter -> receiving flask). This set up required constant close attention with a heat gun

to prevent phenol from clogging the vacuum adapter, and thus was far from ideal.

I also attempted the decarboxylation of salicylic acid using an equal weight mixture of sodium hydroxide and calcium hydroxide, in a retort of iron

pipe, and heated by a propane bunsen burner flame. On mixing the three reagents, they heated up considerably, which implies to me that quite a bit of

moisture was present. The product from this was mostly water with oily droplets of phenol floating about. It was discarded.

\"The man who does not read good books has no advantage over the man who cannot read them.\" - Mark Twain (1835-1910)

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by Natures Natrium  | Well, now I am regretting not documenting my experiments more closely. Inspired by the Pyridine decarboxylation thread, I have been dabbling in this

particular subject.

I would like to report some success, using copper chromite catalysts. |

I did a bit of reading for this and then decided to test chromite anyway and it's my understanding that the decarboxylation using copper catalysts

requires pyridine-type ligands to be present to form the active catalyst. Normally the decarboxylations are done in quinoline, but apparently an inert

solvent with things like 2,2'-bipyridine added can work as well. In the case of pyridine preparation, the nicotinic acid supplies its own ligands, but

salicylic acid doesn't. I took my failed catalyzed reflux experiment (so as to not waste it) and subjected it to slow distillation (with the catalyst

still present). This is the one mentioned to have gotten 71% yield. I chalk the 57% uncatalyzed yield up to sloppy technique as this was my first

attempt, and the 71% is probably not significantly different than the large scale prep.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Natures Natrium

Hazard to Others

Posts: 163

Registered: 22-12-2004

Member Is Offline

Mood: No Mood

|

|

Hmm, interesting info. I was aware that quinoline was often used in decarboxylations, but I did not realize it was fulfilling a necessary role as a

ligand. Further experimentation would clarify, but your deduction sounds reasonable to me.

Even if the copper catalyst is having some effect, it may be that the small increase in yield does not justify using it.

As an aside, I processed the aspirin in the following way. Refluxed briefly in a solution of 3x molar sodium hydroxide, precipitated with

hydrochloric acid to pH 2. Filtered, and washed the filtrate with 3x 100 mL ice cold dH20. Dried on a glass plate on a hot plate set to barely warm.

\"The man who does not read good books has no advantage over the man who cannot read them.\" - Mark Twain (1835-1910)

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by Natures Natrium  |

As an aside, I processed the aspirin in the following way. Refluxed briefly in a solution of 3x molar sodium hydroxide, precipitated with

hydrochloric acid to pH 2. Filtered, and washed the filtrate with 3x 100 mL ice cold dH20. Dried on a glass plate on a hot plate set to barely warm.

|

I used to do it that way years ago. The material comes out off-white and smells slightly of phenol in my experience. The acid approach I worked out

for this produces perfectly white odorless material, not that it should matter for the intended use. The lower reagent usage is nice though.

In fact, about 13g of the SA to go into the 500mmol batch was old base-hydrolysis material with roughly the same m.p. The melt should initially have

less color than it does in my pictures if using only acid hydrolysis SA.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

HeYBrO

Hazard to Others

Posts: 289

Registered: 6-12-2013

Location: 'straya

Member Is Offline

Mood:

|

|

any recommendations on clean up and disposal? MSDS of phenyl salicylate makes it seem pretty innocuous, xanthone not so much. Great write up,

hopefully will be trying this soon.

|

|

|

papaya

National Hazard

Posts: 615

Registered: 4-4-2013

Member Is Offline

Mood: reactive

|

|

Quote: Originally posted by UnintentionalChaos  | Quote: Originally posted by Natures Natrium  |

As an aside, I processed the aspirin in the following way. Refluxed briefly in a solution of 3x molar sodium hydroxide, precipitated with

hydrochloric acid to pH 2. Filtered, and washed the filtrate with 3x 100 mL ice cold dH20. Dried on a glass plate on a hot plate set to barely warm.

|

I used to do it that way years ago. The material comes out off-white and smells slightly of phenol in my experience. The acid approach I worked out

for this produces perfectly white odorless material, not that it should matter for the intended use. The lower reagent usage is nice though.

In fact, about 13g of the SA to go into the 500mmol batch was old base-hydrolysis material with roughly the same m.p. The melt should initially have

less color than it does in my pictures if using only acid hydrolysis SA. |

Do you discuss here production of salicylic acid from ASA or phenol directly from ASA? Is it possible to decarboxylate SA (or even ASA in one pot

way) in water solution with excess NaOH under reflux (getting Na2CO3 and Na phenolate), then acidify solution and distill phenol-water mixture?

|

|

|

papaya

National Hazard

Posts: 615

Registered: 4-4-2013

Member Is Offline

Mood: reactive

|

|

Another variation of what UC did is described in this patent, claiming 96% yield :O

http://www.google.com/patents/US3061651

|

|

|

thebean

Hazard to Others

Posts: 116

Registered: 26-9-2013

Location: Minnesota

Member Is Offline

Mood: Deprotonated

|

|

Out of curiosity UC, how was the odor? I've heard that's rather indescribable but is sometimes equated to the smell of rotting fish.

"You need a little bit of insanity to do great things."

-Henry Rollins

|

|

|

DraconicAcid

International Hazard

Posts: 4412

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Quote: Originally posted by thebean  | | Out of curiosity UC, how was the odor? I've heard that's rather indescribable but is sometimes equated to the smell of rotting fish.

|

That sounds more like pyridine than phenol.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Phenol is sweet and mediciney. If you know a diabetic ask them to smell a few drops of their insulin. It usually contains phenol as a preservative and

is easy to smell.

|

|

|

| Pages:

1

2 |