| Pages:

1

2 |

hodges

National Hazard

Posts: 525

Registered: 17-12-2003

Location: Midwest

Member Is Offline

|

|

H2O2 By Electrolysis

I read that (at one time) hydrogen peroxide was produced commercially by "electrolysis of ammonium bisulphate". That sounds pretty easy to

do at home; certainly ammonium bisulphate would be easy enough to make. I searched and didn't see any mention of this technique here - has

anyone tried it?

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

IIRC, this method produces mainly ammoniumpersulfate and/or persulfuric acid.

I'm not sure how you could make hydrogen peroxide from that, but I think I remember reading that somewhere too.

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

t_Pyro

Hazard to Others

Posts: 120

Registered: 7-2-2004

Location: India

Member Is Offline

Mood: Volatile

|

|

Persulfuric acid reacts with water to give hydrogen peroxide. It is possible that persulfuric acid is formed during electolysis of ammonium

hydrogensulfate.

Earlier, hydrogen peroxide used to be produced commercially by electrolysing sulfuric acid aith a high current density at the anode, thus producing

persulfuric acid, and then diluting it with water to get hydrogen peroxide.

The only difficult part would be to maintain a high current density without wearing out the anode.

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

Has anyone else tried this? - i read totally different in patent number 5643437 - cogeneration of ammonium bisulfate and h2o2 -- they spoke of a molar

solution of ammonium sulfate and sulfuric along with an exchange barrier between the two electrodes of platinum/titanium - seems like it would be

pretty nasty with the acids but possible to do in an improvised setting. I couldnt understand much else.

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

noone has any interest in this? I would love to know how to make high grade peroxide at home - platinum and titanium arent too hard to come by along

with the rest of the materials

[Edited on 22-1-2005 by jimmyboy]

|

|

|

Pommie

Hazard to Self

Posts: 70

Registered: 6-2-2005

Location: Australia

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by jimmyboy

Has anyone else tried this? - i read totally different in patent number 5643437 - cogeneration of ammonium bisulfate and h2o2 -- they spoke of a molar

solution of ammonium sulfate and sulfuric along with an exchange barrier between the two electrodes of platinum/titanium - seems like it would be

pretty nasty with the acids but possible to do in an improvised setting. I couldnt understand much else. |

Jimmyboy (or any one else),

Do you have a link to the patent. It sure sounds interesting.

Mike.

|

|

|

chloric1

International Hazard

Posts: 1141

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

What IS easier

You are going to purchase platinium coated titanium anode to make H2O2?? The

35% H2O2 is easy to get at "green" organic food suppliers. Also, a quick search on google will turn up the same type of suppliers that will

sell almost any volume. It is one of the few chemicals that is actually being praised for its environmental freindliness as opposed to the panic that

is risen about many other reagents. The

35% H2O2 is easy to get at "green" organic food suppliers. Also, a quick search on google will turn up the same type of suppliers that will

sell almost any volume. It is one of the few chemicals that is actually being praised for its environmental freindliness as opposed to the panic that

is risen about many other reagents.

Fellow molecular manipulator

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

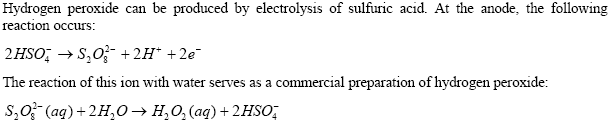

Hydrogen peroxide from sulfuric acid (aq) electrolysis

The attached image is from some PDF file (don't ask for it as it has no other reference to this than what is shown). The acid is not consumed,

and is in water. Anyone care to suggest how this can be turned into a practical procedure? I'd like to try to create a small amount of 90% for

monopropellant experiments. Would I need split cell with a salt bridge; is temperature very important; is there a specific voltage range I must use,

likewise for current density; what electrode materials are appropriate?

Edit: using graphite electrodes in a single pre-chilled cell with 10% H2SO4 and a supply of DC 12 V @ 5 A, very little bubbling at the cathode, and

lots of bubbling at the anode; fast heating and production of nasty corrosive vapours (the vapours corroded the alligator clips holding the

electrodes); contamination with grahite particles. So the simple guess doesn't work. The question is, how do I get it to work.

BTW, I diluted the acid with 35% H2O2 instead of water as I'm trying to get more than 35% concentration, so I might as well start from there.

[Edited on 3-3-2005 by Quince]

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

I found this floating on the web as well - so electrolyzing a sulfuric acid solution would be a fairly easy way to go -- but now how do you separate

it? vacuum distilling H2O2 is bad -- good way to blow yourself up - maybe it would be safe if you heavily dilute the acid/peroxide mix then distill -

then you could sparge and concentrate - i was also thinking about freezing? nah -- or maybe even a hydroxide to neutralize the acid but would it react

with the peroxide as well - you would also have to watch the heat - peroxide decomposes at what around 86 degrees C ? any suggestions?

Yet another way i have found (no electrolysis involved) is to introduce ozone directly into water - im not sure if uv light would be needed in this

reaction but ozone can be made by lightly heating manganese heptoxide

PRODUCTION METHODS OF HYDROGEN PEROXIDE

There are at least three ways to make hydrogen peroxide by electroysis.

The first is to electrolyse a 50% solution of sulfuric acid. This forms persulfuric acid H2S2O8. On (vacuum) distillation, it reacts with water to

form permonosulfuric acid, H2SO5 which then further reacts with water to give hydrogen peroxide and H2SO4.

The second is to electrolyse a solution of ammonium sulfate in sufuric acid. This gives ammonium persulfate which is then reactied with K2SO4 to give

potassium persulfate K2SO8. This is then distilled under low pressure with sulfuric acid to give a solution of hydrogen peroxide that can be

concentrated by fractional distillation.

Lastly, if oxygen under pressure is bubbled under a cathode from which hydrogen is being evolved by electrolysis, hydrogen peroxide is formed.

[Edited on 10-10-2005 by jimmyboy]

|

|

|

khlor

Hazard to Self

Posts: 95

Registered: 4-1-2014

Location: Who knows, really...

Member Is Offline

Mood: No Mood

|

|

So, I remember I tried this(by electrolysis) I had some sucess, but I don't remember what I used in my electrolyte. but, any way... since this can be

made of sulphuric acid, I was wondering how do we separete the acid from the hydrogen peroxide?

|

|

|

huegene

Harmless

Posts: 8

Registered: 1-12-2015

Member Is Offline

Mood: No Mood

|

|

as far as i remember you distill the h2o2 (at low pressure ?) off.

Jerry: YOU TRY TO RELAX!!! HAVE YOU EVER TRIED TO RELAX!?! IT IS A PARADOX!!!

|

|

|

MeshPL

Hazard to Others

Posts: 329

Registered: 20-4-2015

Location: Universe

Member Is Offline

Mood: No Mood

|

|

Technically, electrolysing a solution of some kind of quinone will yield SOME H2O2. Because Quinones can be reduced on cathode and will likely undergo

autooxidation with O2 produced on anode, what yields H2O2. I'm not sure about eventual decomposition products and about anodical, direct oxidation of

quinone. In industry catalytical hydrogenation and oxidation with atmosferic oxygen is used.

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

I don't want to open a new thread to discuss the same topic

I am just curious, any success story to synthesis H2O2 by electrolysis?

I even can't find any video that explain this process in details.

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

A Dictionary of Applied Chemistry Vol. III, 1921 - Thorpe:

| Quote: | When air at atmospheric pressure is led through the cathode compartment of an electrolytic cell containing 1 p.c. sulphuric acid hydrogen peroxide is

formed at the cathode. With oxygen the amount is increased and is also increased by increasing the pressure of oxygen. Working with a potential of 2

volts, a current density of 2 amps. per sq. dcm. and a pressure of 100 atmos., a 2.7 p.c. peroxide solution can be obtained. 300-400 grams of hydrogen

peroxide can be obtained for each kilowatt-hout....

3. Hydrogen peroxide has also been conveniently, but not so cheaply, prepared by treating sodium peroxide with hydrofluoric or hydrochloric acids

(...); and by treating persulphates, percarbonates, and perborates, obtained by electrolysis of the ordinary acids with dillute acids (...).

To obtain hydrogen peroxide from persulphates, acid solutions of persulphates, obtained by electrolysis, or by treating solid persulphates with

sulphuric acid, are converted on warming into monopersulphuric acid:

H2S2O8 + H2O = H2SO5 + H2SO4

and this into hydrogen peroxide:

H2SO5 + H2O = H2SO4 + H2O2

The solutions must contain a high concentration of sulphuric acid (circa 40 p.c.) in order that h2S2O8 may be converted into H2SO5. The concentration

must not be too great since the action is reversible; in solutions containing over 58 p.c. H2SO4 the H2O2 reforms H2SO5. A certain strength of

sulphuric acid is neede to obtain a concentrated distillate at a fairly rapid rate. The general conditions affecting the stability of hydrogen

peroxide must be observed. The solution must not contain salts of copper, iron, manganese, and must be free from dust of organic matter.

Traces of platinum derived from electrodes catalyse the decomposition of H2O2 in presence of H2SO5

H2SO5 + H2O5 = H2SO4 + H2O + O2

Teuchner (Eng. Pat. 24507, 1905) removes these traces of platinum by adding aluminium, the salt of which have no catalytic influence....

Persulphates (of potassium and ammonium) are distilled with sulphuric acid, giving H2O2 of high concentration:

K2S2O8 + H2SO4 = K2S2O7 + H2SO5

H2SO4 + H2O = H2O2 + H2SO4

Water is sintroduced and the H2O2 is distilled as fast as formed at a high concentration. By this means 96 p.c. of the theoretical yield of H2O2 from

K2S2O8 may be obtained as a 20 p.c. solution. On the large scale 1 kilo of ammonium persulphate is said to be produced by 2.5 kilowatt-hour.

Hydrogen peroxide is produced by Cobellis (US apt 1195560) by heating a solution of ammonium persulphate and bisulphate. The process i smade

continuous by electrolyzing a slution of ammonium sulphate at comparatively low temperature to form the per-salt, heating under pressure to form

sulphate and hydrogen peroxide which is subsuquently distilled off undert diminished pressure in current of inert gas (Reports of the Progress of

Applied Chemistry, 1917, II, 192). |

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

Thx for the reply.

I found many steps online but I search for something practical that someone else tried and worked with him.

I don't want to put a lot of effort then realize that nothing work

do you know any verified steps ?

|

|

|

Jstuyfzand

Hazard to Others

Posts: 166

Registered: 16-1-2016

Location: Netherlands

Member Is Offline

Mood: Learning, Sorta.

|

|

Very interesting, an awesome (Theoretical) yield of 400 grams of H2O2 for 1 kwh.

I am just left wondering what would be suitable for the electrodes, it seems like almost anything decomposes the H2O2.

Platinum is mentioned, but that is not very budget friendly.

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

Graphite, PbO2.

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

Quote: Originally posted by Jstuyfzand  | Very interesting, an awesome (Theoretical) yield of 400 grams of H2O2 for 1 kwh.

I am just left wondering what would be suitable for the electrodes, it seems like almost anything decomposes the H2O2.

Platinum is mentioned, but that is not very budget friendly. |

budget?

did you notice the pressure needed ? it is 100 atmos this is the complex part.

|

|

|

Jstuyfzand

Hazard to Others

Posts: 166

Registered: 16-1-2016

Location: Netherlands

Member Is Offline

Mood: Learning, Sorta.

|

|

Quote: Originally posted by ecos  | Quote: Originally posted by Jstuyfzand  | Very interesting, an awesome (Theoretical) yield of 400 grams of H2O2 for 1 kwh.

I am just left wondering what would be suitable for the electrodes, it seems like almost anything decomposes the H2O2.

Platinum is mentioned, but that is not very budget friendly. |

budget?

did you notice the pressure needed ? it is 100 atmos this is the complex part. |

I was looking at the "When air at atmospheric pressure" part.

Dreams are crushed.....

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

100atm isn't that much, but 316L ss isn't too cheap.

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

do you have an idea how to make a system that can stand this pressure?

|

|

|

Jstuyfzand

Hazard to Others

Posts: 166

Registered: 16-1-2016

Location: Netherlands

Member Is Offline

Mood: Learning, Sorta.

|

|

I do wonder, what does the pressure do in this process?

As far as I know, Which is not alot though, pressure speeds up reactions between gasses.

Maybe the pressure is not necessary, it might improve the efficiency.

That would be a big requirement to perform this process gone, it seems (Kind of) straight forward.

"Making H2O2 by electrolyzing Sulphuric acid and Bisulfates"

Anyone....?

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

one could be engineered, most off the shelf materials will handle it, just comes down to material compatibility.

first you'd need to make a process diagram, then from there select materials for the feed stocks then tot he reactor vessel.

then do you want a batch system or a flow through system, batch system need less pressure regulators then with a flow through.

100atm is just under 1500psi, in terms of materials that is nothing as nitrogen tanks and scuba is all at 1300psi.

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

this setup can't be made at home

I can reach 100 psi at home using metal vessel but not 1300 psi !

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

depends on the persons home I guess lol but it all starts with a clear process flow and sorry I am not interested enough to start from the dead ground

up on this some one works out all that stuff I'll toss in a few hours on the system.

ATM I am making a molten salt electrolyser for sodium and potassium

just an fyi SS pipe at 3/8 is rated for 1500 psi operating as is swag lock fittings, to handle, the reactor vessel can be made in some schedule 80 ss

pipe of suitable size with brazed ends utilizing 45% silver material.

then just need suitable rated valves and regulaters

To get the required pressure you can cheat by using compressed Nitrogen rather then a compressor. But when dealing with such a system it will be

expensive to buy the parts if you lack the fabrication ability more so for some one to assemble it.

Compressed gasses are uniquely dangerous as when a rupture occurs it can toss shrapnel Vs a burst liquid system where it just rips, so you need more

robust safeties and fail safe mechanisms

Personally it is cheaper and easier to buy it, and where necessary get the tickets/licenses to buy it! then it is making it dead scratch

[Edited on 28-8-2016 by XeonTheMGPony]

|

|

|

| Pages:

1

2 |