Lion850

National Hazard

Posts: 517

Registered: 7-10-2019

Location: Australia

Member Is Offline

Mood: Great

|

|

Report on trying to make lithium dichromate

When looking online to learn about lithium dichromate I found the below document "Some Properties of Lithium Dichromate BY WINSLOW H. HARTFORD AND

KEITH A. LANE". This was my reference .

Attachment: Some properties of Lithium dichromate.pdf (236kB)

This file has been downloaded 343 times

- 35g CrO3 dissolved in 80ml of water. This dissolved to a dark wine red solution with pH ~1.

- 13g of Li2CO3 was measured out and slowly added. Each addition resulted in vigorous bubbling and the beaker was covered with a paper towel (which

had a yellow circle afterwards showing how much salt get carried off with the bubbling).

- By the time all the lithium carbonate was added the solution was much darker and pH 4-5.

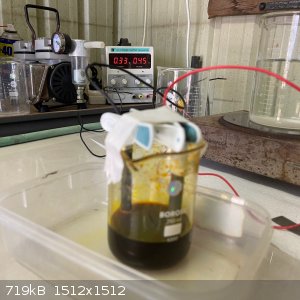

- As per the reference next step was to electrolyze the solution to get it back to a bright orange-red color. The reference mentions lead electrodes,

but I used 2 carbon rods.

- The solution was electrolyzed at 4.5V and 330mA for some 10 hours (spread out over several days). There was some bubbling at the cathode, but

nothing at the anode.

- The solution still appeared dark. I inspected the electrodes, the cathode showed no wear but the anode was being worn away:

- I replaced the anode with a lead sinker and continued the electrolysis.

- After 8 hours more there was some hint of red in the solution. I then increased the voltage to 5V which resulted in a current of 390mA for another 6

hour. By then I saw a lot of red when shining a light into the solution.

- The solution was filtered. The filtrate was red, and there was black sludge left in the beaker and also black powder on the filter paper:

- I added concentrated HCl to the beaker and heated to see if the black sludge would dissolve; the solution turned dark green probably showing some

chromium was present in the sludge but the bulk did not react and was probably carbon from the work electrode?

- I also noticed that the lead anode now had a well formed black layer. What can this be?

- I heated the red filtrate on a steam bath. After many hours it was still liquid with a layer of crystals but the weight stopped decreasing.

- I then heated it on a sand bath with sand temp around 150C, it remained a thick red wet paste without any obvious further drying or decomposition.

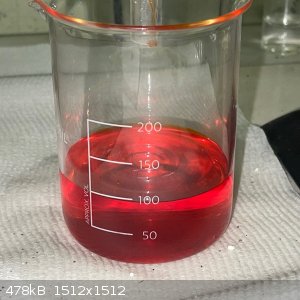

- When the layer of red liquid was poured off, a orange-red paste remains.

- The reference mentions a deliquescent orange-red product and seems that is what I got. If a grain is left exposed it becomes a drop quite quick.

- I decided to keep it in this form - as a wet paste - until I can get more info regarding the decomposition temperature. Being chromium 6 I did not

really want to heat it to max on the sand bath not knowing whether it will decompose, and if it does, how. The below photo, in sunlight, shows the

orange-red product (presumed to be Li2Cr2O7.2H2O) and the red solution it makes.

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

That really is a pretty colour.

[Edit]

I think your anode coating is mostly PbO2.

If it is, and it is strong and robust, this might be an easy route to lead dioxide anodes.

[Edited on 1-10-2021 by j_sum1]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

I don't understand why you need the electrolytic oxidation step when it is simply a neutralisation reaction. If the reagents are pure why is chromium

being reduced? I like the colour of the stuff though!

By the way mixed lithium sodium chromate crystallises beautifully and isn't deliquescent.

|

|

|

woelen

Super Administrator

Posts: 8012

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

This looks really nice. The hassle with the electrolysis indeed was not necessary. It even can do more harm, because at the cathode, some hexavalent

chromium may be reduced to trivalent chromium.

If I look at the color of your product, then I think that you obtained a really pure product (not regarding the water). It really looks nice. Sad that

this stuff is so extremely hygroscopic. I think that the only way to get it dry is drying it in vacuum at moderate heat (e.g. 70 C) , with some

concentrated H2SO4 in a dish, also in the same vacuum.

|

|

|

Lion850

National Hazard

Posts: 517

Registered: 7-10-2019

Location: Australia

Member Is Offline

Mood: Great

|

|

Hi Gents

The initially orange-red solution at first addition of the carbonate was already black prior to starting the electrolysis. The second photo showing

the beaker with carbon electrodes was taken at the very beginning of the electrolysis.

The reference paper does mention that earlier descriptions of this salt mentioned black or brown crystals, probably due to impurities. My chromium

trioxide is technical grade and I suspect very old; the authors of the reference paper also used technical grade and mentions chromium (iii) being one

of the impurities. Maybe a very small presence of impurities has a big effect on the color?

With hindsight I should have filtered the solution prior to electrolysis to see if whatever was causing the black color could be filtered out. It did

however stand for a few hours after the carbonate addition was completed, prior to setting up electrolysis, and nothing settled out.

I forgot to mention that I did pop the very hot evaporating dish (from the sand bath) into a desiccator and then it briefly boil under vacuum. But to

dry it this way I will have to arrive at a setup that is safe in case something implodes and isolated my vacuum pump from the chromium 6 mist.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

No need for a pump or heat if you've got the time...it's not likely to be better at drying than the usual drying agents.

|

|

|

Lion850

National Hazard

Posts: 517

Registered: 7-10-2019

Location: Australia

Member Is Offline

Mood: Great

|

|

It’s now in my desiccator over 98% sulphuric acid. I’ll pull a vacuum a few times a day and see if it dries over time.

|

|

|

Lion850

National Hazard

Posts: 517

Registered: 7-10-2019

Location: Australia

Member Is Offline

Mood: Great

|

|

After 4 days in the desiccator over 98% sulphuric acid the product had a crust that was quite dry but it was still very wet underneath. See photo. I

stopped because my desiccator is not holding vacuum anymore. It is now in a sealed container on a bed of sodium hydroxide. I weighed the whole sealed

container so I can see in future if air is leaking in. If it seals well I will leave it in here for a month or so.

|

|

|

teodor

National Hazard

Posts: 876

Registered: 28-6-2019

Location: Heerenveen

Member Is Offline

|

|

I think the way to solve the problem of "crust" is to add some volatile organic compound which will not be oxidized by Cr (VI) and absorbed by H2SO4.

I already mentioned my usage of butyl acetate to separate dry crystals of chromium sulfate or chloride from water solution. The way how it works is

probably adhering to the surface of crystals and making a barrier with the water solvent. In case of Cr (VI) probably a light petroleum fraction can

work similarly, but in any case please check how is it safe to mix these compounds (I never did that).

But really many organic compounds could be used to protect deliquescent crystals from the moisture. You can try a simple test: put a bit K2CO3 in 2

beakers. In one beaker moist it with some higher alcohol (I know that 2-butanol works well). You will observe the strange phenomenon: the K2CO3 which

has a little alcohol will be perfectly preserved until you have a bit alcohol in it.

[Edited on 7-10-2021 by teodor]

|

|

|

Lion850

National Hazard

Posts: 517

Registered: 7-10-2019

Location: Australia

Member Is Offline

Mood: Great

|

|

After a month in the sealed container with NaOH the product is much drier. But still a bit wet under the crust. I broke it up and sealed it again and

put aside for another month.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

always try removing the water with a solvent such as maybe acetone

oftenly you can get lucky like that, and due to acetones high vapor pressure you can get it out very fast usually

thinking twice about that, the acetone could end up as a reagent.

|

|

|

woelen

Super Administrator

Posts: 8012

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

If you have diethyl ether, use that. Ether dissolves some water, but it is quite inert towards oxidation and it does not dissolve ionic compounds. You

will see that the solid very quickly settles at the bottom and then you can decant the liquid from the solid. The remaining solid then can be easily

dried in a vacuum. Do not dry in contact with air, because that would attract new water and the lowering of the temperature, due to evaporation of the

ether, will attract extra water due to condensation.

|

|

|

Lion850

National Hazard

Posts: 517

Registered: 7-10-2019

Location: Australia

Member Is Offline

Mood: Great

|

|

After almost 5 months in a sealed container on a bed of NaOH i have a orange-red salt of shiny crystals that seems completely dry. 32g bottled.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

KCr2O7 + LiClO4 = KClO4 + Li2Cr2O7

when working with lithium salts, lithium perchlorate is a good starting point

i made lithium bromide as following

Ba(ClO4)2 + LiSO4 = BaSO4 (ppt) + LiClO4

the lithium perchlorate is super hygroscopic, only reason to dry it out would be to measure the weight

LiClO4 + KBr = KClO4 (ppt) + LiBr2

|

|

|