| Pages:

1

2 |

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Inner Sleeve for 1L heating mantle

I recieved an Inner Sleeve for a 1L heating mantle that i ordered.

I wonder how one prepare the sleeve for use, if anyone have done this.

I would guess i use something to put it in like a clay flowerpot or steel bowl and put insulating material between the sleeve and the pot/bowl.

Would glass wool or fiberglass fabric be usable as insulating material?

I plan to drive it with either a variac or more probably i use a PID temp controller with a solid state relay (230VAC) and temp sensor.

I think i can get it working but how do i best prepare the sleeve in a enclosure and insulate the back side so it keep the shape and is usable with

good fit to the 1L flask, this i dont know.

Any good ideas?

Also it would be nice to include a stirring function if doable.

A rotating magnet under the sleeve would work but it would get hot and maybe demagnetize from the high temperature.

Maybe one of those non neodymium magnets have high curie temperature and can be used.

Or maybe an electromagnet but that would be more tricky to get working.

I will search for ideas but it would be interesting to hear if someone done a stirring function using these sleeves.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

https://www.sciencemadness.org/whisper/viewthread.php?tid=13...

About the stirring function, if you use a strong magnet and a non ferrous container, you can add the stirring system under the whole thing, or you can

use a overhead stirrer

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Syn the Sizer

National Hazard

Posts: 600

Registered: 12-11-2019

Location: Canada

Member Is Offline

|

|

In class all we did was set the mantle sleeve on a stirring hotplate with the hotplate function off. The hotplate was placed on a lab jack to lower

and raise the mantle. As Ubya said stirring work through the mantel as long as the vessel you use isn't ferrous. Which usually isn't an issue since

mantle are usually designed for glass round bottoms/

|

|

|

Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

Can you tell me where you bought this?

All the sources I have found so far are asking ridiculous prices.

Also samarium-cobalt magnets can handle temp towards 300 degrees C. Perhaps a little extra shielding with fiberglass can protect the magnets from

heating too much.

These magnets are surprisingly cheap too.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by Belowzero  | Can you tell me where you bought this?

All the sources I have found so far are asking ridiculous prices.

Also samarium-cobalt magnets can handle temp towards 300 degrees C. Perhaps a little extra shielding with fiberglass can protect the magnets from

heating too much.

These magnets are surprisingly cheap too. |

https://www.ebay.com/sch/i.html?_nkw=heating+mantle+sleeve&a...

i bought mine on ebay for less than $10

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

You can buy ones with the nichrome already wound into it.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

all the ones i've seen already have the heating element inside

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Mateo_swe  |

I plan to drive it with either a variac or more probably i use a PID temp controller with a solid state relay (230VAC) and temp sensor.

|

Probably a better idea to use a variac. SSRs are just on/off switches. Heating until at maximum voltage until your reaction mixture heats up to the

set-point would get the heating element very, very hot.

|

|

|

Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

Quote: Originally posted by monolithic  | Quote: Originally posted by Mateo_swe  |

I plan to drive it with either a variac or more probably i use a PID temp controller with a solid state relay (230VAC) and temp sensor.

|

Probably a better idea to use a variac. SSRs are just on/off switches. Heating until at maximum voltage until your reaction mixture heats up to the

set-point would get the heating element very, very hot. |

Another problem with PID is that when no feedback is received from the thermal sensor it will just continue to heat until something blows out.

Molten glass looks cool though.

[Edited on 9-6-2020 by Belowzero]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

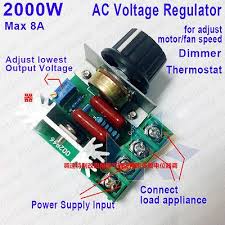

These are awesome for controlling mantles:

AC 50-220V 25A 2000W Adjustable PWM Motor Speed Controller Voltage Regulator

They work great.there basically a $5 variac.dont bother with SSR crap or actual variacs.10/10 definitely recommend.

Type this into Google and pick one from the ebay pics that pop-up: 220v AC 2000w scr thyristor circuit

This is what they look like:

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Thanx for all answers and ideas, very interesting.

The small triac module seems nice.

In the beginning i planned to build a triac control but i cant put a target temp and just turn it on and it heats up to that temp and stays there.

And that is a pretty nice function especially on the larger 2L where the warming up time is longer.

I have seen the PID temp regulator in use on other heating mantles and it seem to work ok.

During the heating up period the heating element will be at high power but i think the heating element can handle this.

I plan to have a temperature measuring element in the bottom of the sleeve, between the flask and the sleeve glass fibers so this spot will never go

over the temp i set in the regulator.

I would guess that is how real heating mantles work that has a temp regulating function.

I could add a thermal fuse for safety in case the temp sensor breaks.

I have to experiment a little and find out a good solution.

Temp regulating with a display would be a nice feature if i can get it to work.

The sleeves with heating wire were bought on ebay for 20Euros (500ml), 27Euros (1L) and 36Euros (2L).

They can probably be found cheaper if one search more.

|

|

|

G-Coupled

Hazard to Others

Posts: 287

Registered: 9-3-2017

Member Is Offline

Mood: Slightly triturated

|

|

Sounds like a nice project that could really benefit from some Arduino or maybe RasPi love.

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Well I could use a microcontroller but i want it finished as soon as possible so i think this temp controller would do it.

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

That pid controller uses relay contacts to control the power,

although the relay should last for a while, and is not too difficult to replace,

a more reliable option would be to get the type with an external zero-crossing SSR.

(it would also produce much less radio frequency interference)

Be aware that the mantle will be at a much higher temperature than the liquid in the rbf due to the poor thermal conductivity of glass.

For a heating mantle I prefer a dimmer controller as shown above - for constant heating power.

(if you were making a hotplate to maintain liquids at some temperature below boiling point then a PID controller with an external thermocouple probe

would be a good choice)

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

ThoughtsIControl

Hazard to Self

Posts: 50

Registered: 13-10-2019

Location: Proxima Centauri

Member Is Offline

Mood: Yin over yang

|

|

So I have a heating mantle that has a magnetic stir but no temperature control. If I open up the box, am I able to attach the "AC 50-220V 25A 2000W

Adjustable PWM Motor Speed Controller Voltage Regulator" to the wires that run to the plate?

I am a total amateur in regard to this..

If I am able to connect a temperature control to my hotplate, what wires do I attach it to? I can upload a picture if anyone would be kind enough to

answer.

"I do not see myself as outside, why enter?"

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by ThoughtsIControl  | So I have a heating mantle that has a magnetic stir but no temperature control. If I open up the box, am I able to attach the "AC 50-220V 25A 2000W

Adjustable PWM Motor Speed Controller Voltage Regulator" to the wires that run to the plate?

I am a total amateur in regard to this..

If I am able to connect a temperature control to my hotplate, what wires do I attach it to? I can upload a picture if anyone would be kind enough to

answer.  |

Yes u can attach it to the nichrome element.jts very easy to wire up I did it on mine and it was easy. if u take the bottom off and take a few

pictures it'll be possible to tell what to do. The only thing I had to do on mine was desolder the pot and solder some wires in between the pot and

board as I wanted it mounted internally. If u don't have a soldering iron that's ok though as a length of wire and a little box is all you'll need to

use it externally

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Maybe it was a bad picture but the temperatire controller is the model for an SSR and dont use a relay. They come in different variants, the one i

ordered is for an SSR.

It doesnt have any built in SSR though so i use an external SSR on a heatsink.

Why would one prefer a dimmer controller i cant really understand.

If one wants to distill a liquid at say 200°C it surely must be better to wait less time until the 200°C is reached. And at 200°C it will regulate

the power so it stays at 200°C.

Only thing that would be different with a dimmer is that you will have to wait longer until it reaches 200°C.

The heating wire isnt a high power one so it still takes some time util it reaches the target temp.

If i want boil water on my stove i dont put it on the 5 setting because its good for the heating element i put it on full setting 10 and dont have to

wait long time until it boils.

If anyone have a good explanation of the benefits of the dimmer driver, i am interested to hear them.

And every mantle get much higher temperature than the liquid in the rbf due to the poor thermal conductivity of glass, regardless of driver.

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

A heating element at reduced voltage won't run as hot. I have a 120V mantle which can hit 400-500 C at full throttle. This puts a lot of stress on

glassware. I run it <90 V which maxes out at around 250 C.

|

|

|

Sulaiman

International Hazard

Posts: 3723

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

At the start of a distillation you can turn a dimmer to any power setting that you wish, including full power.

When the liquid just begins to boil you then manually reduce the power to get the liquid boiling at the rate that you want,

usually limited by either flooding of a reflux column, or condenser efficiency.

Once you have manually adjusted the power for smooth operation you can leave it at that setting for most of the distillation.

The power input will be absolutely constant,

which will create a constant vapour speed in your fractionating column.

IF your PID controller is tuned perfectly then the power will be fairly constant during the distillation,

if not then the power will fluctuate slightly causing fluctuations in the vapour speed in the column,

it does not take much of a fluctuation to upset the equilibrium in a multi-plate column.

So, you can use either a PID controller or a dimmer,

the dimmer is cheaper and guaranteed to not cause problems.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Sulaiman  |

IF your PID controller is tuned perfectly then the power will be fairly constant during the distillation,

if not then the power will fluctuate slightly causing fluctuations in the vapour speed in the column,

it does not take much of a fluctuation to upset the equilibrium in a multi-plate column. |

That's a good point about the PID being tuned perfectly. The PID will likely be on some sort of self-tuning/automatic mode where it adjusts the PID

function coefficients on the fly, so as to maintain a steady temperature without significant oscillation. Most PIDs do this well with a constant mass

reaction mixture but if you're losing mass (i.e. distilling a reaction mixture) then it could fluctuate quite a bit.

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

I understand that driving the heating element at full power is putting more stress on the heating wire but i would guess they can handle this.

There could be some fluctuations in power level if the PID isnt set up good or is of poor construction.

If very stable power levels are needed a PID might not be the best choice.

I see the PID temp controller like a automated dimmer, same as a dimmer that one manually sets on high during heating up and lower the setting as

target temp is reached.

I will try the PID controller and if its not working good i will try the dimmer variant.

I maybe even do one of my sleeves with a dimmer so i can compare the 2 driving options.

|

|

|

Belowzero

Hazard to Others

Posts: 173

Registered: 6-5-2020

Location: Member Is Offline

Member Is Offline

|

|

Quote: Originally posted by Mateo_swe  | I understand that driving the heating element at full power is putting more stress on the heating wire but i would guess they can handle this.

|

Exactly , it will wear down quicker this way.

So if one cares at all about the lifetime of the coil it makes more sense use it at lower throttle , besides full power is rarely ever required since

it is hitting the limits of glass operation temperatures.

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Nicrome and Kanthal wire is cheap so if the sleeve element breaks after some use i can replace it.

I even have some nicrome and kanthal-A1 heating wire of suitable thickness i could use.

However, if it turns out it cant handle more than a few months of use without breaking, i must find another way of driving the sleeve heating element.

A dimmer would be the easiest and cheapest to try out.

Or i build a simple triac driver.

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

Quote: Originally posted by Mateo_swe  | Nicrome and Kanthal wire is cheap so if the sleeve element breaks after some use i can replace it.

I even have some nicrome and kanthal-A1 heating wire of suitable thickness i could use.

However, if it turns out it cant handle more than a few months of use without breaking, i must find another way of driving the sleeve heating element.

A dimmer would be the easiest and cheapest to try out.

Or i build a simple triac driver. |

the heating element is woven inside the glass fibers of the mantle, if it breaks, you replace the whole thing.

[Edited on 12-6-2020 by Ubya]

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Mateo_swe

National Hazard

Posts: 548

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

It would be quite a hassle threading the wire through the glassfibre arrangement so you are probably right about that.

I hope they will last long before needing replacement.

I found something else out about the sleeves.

I tried to shape it so it fitted my 1000ml rb flask as it was flat and dented on arrival.

It went well and i got a nice shape just using my hands.

Later i started get this itch on my fingers, exactly same as when you touch certain cactus areoles who has these microscopic needle thorns (or what

they are called).

It seems the glassfibres are so thin, penetrating the skin and they produce the same itch as those nasty cactus areoles.

I had this itch the rest of the day and it didnt go away by washing my hands so one should be careful hadling the glassfibre sleeves.

|

|

|

| Pages:

1

2 |