flaminglasrswrd

Harmless

Posts: 9

Registered: 17-9-2019

Member Is Offline

|

|

PET to Terephthalic Acid with Ethaline: 60% yield; 79% conversion

Hey everyone! Long time lurker, first time poster. Just thought I would share a small success.

I've been doing some research with Deep Eutectic Solvents lately. They are remarkable substances with wide ranging applicability. They are especially

suitable for the amateur because they can act as solvent and catalyst while being environmentally friendly, cheap, and safe to handle. They are

successors to Ionic Liquids, but are safer to handle, more stable, and easier to make.

In this particular instance, I was attempting the hydrolysis of PET to terephthalic acid with future plans to produce benzene. This is a continuation

of the work with ILs shown here and here.

The DES I used for this reaction is called Ethaline: A one to two molar ratio of Choline Chloride and Ethylene Glycol. Simply combine the two, heat to

about 70C for a few hours with mixing, and you have your DES. I chose Ethaline because the hydrolysis of PET should liberate EG that won't contaminate

the DES.

So I started the experiment by grinding recycled PET in a blender (two egg and one strawberry carton). From the literature, it seems that the

solubility of PET in the DES is the limiting factor, so I attempted to make it as fine as possible. I stopped when it was approximately the size of

play sand because my blender was overheating. The total PET used was 105.42g.

The PET was added to a 1L flask along with 139.62g Choline Chlorine and 62g ethylene glycol. This wasn't enough to fully cover the PET so I added some

previously made Ethaline (same ratio). Total volume was about 450ml.

I had intended to heat the mix to 160-180C for 12 hours, but was interrupted part way through. So I just kind of guessed when the mix was done and

turned off the heating. All told, the flask was heated to 160C for 4 hours, turned off for 9 hours, heated to 170C for 6 hours and then 180C for 4

hours. If you are going to repeat this procedure, just heat the flask to 180C for 10-12 hours.

After everything was cooled, about 200ml of water was added to precipitate the TPA. The whole thing was filtered and rinsed several times with water.

Then two moles (overkill) of sodium hydroxide as a solution was added to dissolve the TPA as the disodium salt. The solution was filtered again to

remove the unreacted PET and contaminants. The solution was left overnight.

In the morning a small amount of brown precipitate had formed so I filtered again to yield 1L of pale yellow-brown solution. I'm unsure if this

contaminant is from the PET or the DES.

Since I plan on taking this synth all the way to benzene, I only took a small sample to judge yield and left the rest. Upon precipitation with ~2ml of

31% hydrochloric acid, the 9.9ml sample produced 0.55g of dry, fluffy, white TPA. So the entire 1L batch should contain about 55g of recoverable TPA.

The unconverted PET was dried to give a sand-like mix. Total weight: 24.34g.

So of the 105g (0.55mol) PET, 55g (0.33mol) TPA was produced with 24.34g leftover: A yield of 60% and conversion of 79%.

In the future I plan on reusing the Ethaline and unreacted PET for another run and converting the TPA to benzene using a different DES. Also, a

replication of this process using a urea based DES instead might give higher yields.

There are some notes on my website if you don't mind reading something so unorganized. I also have some notes on a successful test run for decarboxylating niacin with

Ethaline as well.

Anyway, just thought you guys would appreciate my work. More to come...

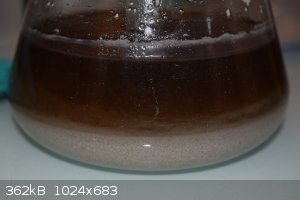

Image 1: The flask after the reaction has finished before water addition.

Image 2: Filtering the precipitated TPA and unreacted PET

Image 3: Unreacted PET and contaminants

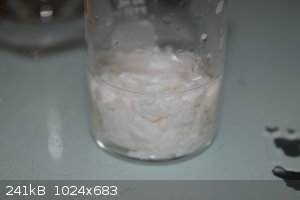

Image 4: Precipitated sample of TPA

Image 5: Dried sample of TPA

|

|

|

Pumukli

National Hazard

Posts: 699

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Flaminglasrswrd, as a "friend" of PET and aromatic carboxylic acids in general, I very much appreciate your work!

Keep up and keep us posted!

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

Very cool project.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Nice work. very interesting. I'm a big fan of work in this area.good to see I'm not the only one

|

|

|

RedDwarf

Hazard to Others

Posts: 166

Registered: 16-2-2019

Location: UK (North West)

Member Is Offline

Mood: Variable

|

|

Do you have a cheap/easily available source of Choline Chloride, and are you aware of any DESs that use something more easily available than Choline

Chloride?

|

|

|

Ubya

International Hazard

Posts: 1247

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

what is the advandage of using ethaline instead of plain ethylene glycol as it's usually done?

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

Welcome, flaminglasrswrd, and great work; you'll fit right in here.

I am very interested in your plan to use DES to convert plastics to benzene. There are several papers I have seen where raw plastic was pyrolyzed in a

quartz tube and the distillate analyzed. In many cases the benzene content is very high. Some kind of steel container with a condenser stuffed with

plastic waste sitting on a campfire will yield a wealth of aromatic products. The only real challenge is separating them effectively.

https://www.hindawi.com/journals/jpe/2013/987568/

"the maximum yield of total gas obtained at 800°C from HDPE pyrolysis is 94.5% with the following composition: 20% methane, 3.8% ethane, 37%

ethylene, 0.2% propane, 4.7% propylene, 0.3% butane, 0.4% butylenes, 2.2% pentane, 24% benzene, 2.1% toluene, 0.01% acetylene, and

0.02% xylenes and styrene"

Note that the majority of the distillate is gaseous at room temperature; therefore the majority of the liquid collected will be BTX at greater than

89% benzene and might be quite separable with an efficient packed column.

I am very interested to see if a new route to benzene using a DES might have a >24% total yield.

[Edited on 24-9-2019 by Praxichys]

|

|

|

flaminglasrswrd

Harmless

Posts: 9

Registered: 17-9-2019

Member Is Offline

|

|

Quote: Originally posted by RedDwarf  | | Do you have a cheap/easily available source of Choline Chloride, and are you aware of any DESs that use something more easily available than Choline

Chloride? |

I buy choline chloride on ebay. 500g for $30.

There are quite a few DES's that are worth looking into. None of them are as extensively studied as Ethaline, however, which is why I started with it.

ChCl is produced industrially as a feed additive, so I imagine the price could come way down if there is more demand.

Quote: Originally posted by Ubya  | | what is the advandage of using ethaline instead of plain ethylene glycol as it's usually done? |

DES's are catalysts as well as solvents. The original procedure by CHROMIUM requires a steel container because of the NaOH etching problem. This

method can be done with standard glassware. Plus the molar excess of NaOH has to be neutralized for recovery. Ethaline should be able to be reused

multiple times after a quick filter and drying.

I hope with future research, I can reduce the temperature required and provide an easier workup. The original base-acid procedure was mostly for

determining yield and conversion. Since the goal is benzene, workup for terephthalic acid should be unecessary. I'm looking into either urea or zinc

chloride as possible hydrogen bond acceptors in the future.

|

|

|