condennnsa

Hazard to Others

Posts: 217

Registered: 20-4-2010

Location: Romania

Member Is Offline

Mood: No Mood

|

|

bluing steel

I have some steel parts that i want to blue, but i have never done this. I googled and found dozens of procedures from boiling the part in KNO3 and

NaOH solution , to enclosing the part together with concentrated nitric acid or HCl, and letting the acid vapor work for about 12 hours. I've also

seen one guy who seems to be using a molten bath of KNO3...

Does anyone here have any experience with bluing?

What is the difference between these procedures? And what is the role of the sodium hydroxide in the first method? thanks

|

|

|

Justin

Hazard to Self

Posts: 84

Registered: 6-5-2010

Member Is Offline

Mood: No Mood

|

|

Talk to a gunsmith, i've blued a few gun barrels but i always just bought the little "kit" they sell at walmart. I actually have one here infront of

me. It uses the "cold blue method" One bottle has "cocoa soap" which is the metal cleaner and the other one has "Selenous acid, hydrochloric acid and

copper sulfate" which is the gun blue. Is it a gun barrel that your wanting to blue or re-blue or something else?

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

usually steel of decent carbon content or stainless (hardened or tool steel)can be "blued" in a boiling solution of KNO3 and NaOH. it only works on

ferrous metals. note that it is a limited process and will wear off mechanically over time. the parts still have to be oiled to stop rust. the acid

methods are referred to as a cold process and are even less effective than the boiling alkalai bath. there are other methods but this is one i was

taught in metal shop when i was a kid. you can confirm this process on wiki:

http://en.wikipedia.org/wiki/Bluing_(steel)

it takes an experienced hand to get it right. several tries may be necessary so don't be discouraged but also don't use any piece you want to keep

until you get a feel for it. different concentrations of alkalai and nitrate will play into your result as will the exact composition of your steel.

it's sort of a black art.

i own several firearms that need constant care despite the bluing. in humid or salty (coastal) areas corrosion can be even worse so inspect your parts

regularly and keep them oiled. hopps 9 is usually excellent for protection of parts and lubricates well but if you intend to expose your parts to

chemical reactions think twice about any protectant you use and how it may affect or be effected bo your chemicals.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

If you're in the US, get a copy of the Brownell's catalog. They're the major supplier of gunsmithing supplies. They've got pages and pages of bluing

chemical and equipment. It's very easy to become a gunsmith; just start being one.

|

|

|

condennnsa

Hazard to Others

Posts: 217

Registered: 20-4-2010

Location: Romania

Member Is Offline

Mood: No Mood

|

|

No, I have nothing to to with gunsmithing, I have never touched a gun , though sometimes i wish i had one  . .

They are parts and fixtures for machine tools, so i can't use paint to affect the accuracy, and i don't want them to be oily all the time either.

I have read one time on the internet, can't remember where now, of a guy that just used a blow torch to blue small parts . And this process really

made the parts of a very nice blue color, not the usual "black" bluing. I'm not sure how the long-term corrosion resistance of such a process is

though.

Regarding hot oxidiser solutions, will any oxidiser work, for example KClO3, KClO4 or KMnO4 ?

And still, why the hydroxide there? does it have a particular purpose?

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Me - the analogue guy again. If you want to expand your horizons

and be a true do-it-your-self'r I recommend :—

R Hughes and M Rowe

The Colouring, Bronzing and Patination of Metals

Watson-Guptill Publications

1982

Absolutely nothing in it on steel, however ..... $53.55 @

Amazon.com

For convenience I would go with the Brownells.com suggestion.

djh

----

Blazonry-

It will be observed that the description

of the field is first set down, the blazoner

giving its plain tincture or describing it

as burely, party, paly, or barry, as

powdered or sown with roses, crosslets,

or fleurs-de-lis.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Justin  | | Talk to a gunsmith, i've blued a few gun barrels but i always just bought the little "kit" they sell at walmart. I actually have one here infront of

me. It uses the "cold blue method" One bottle has "cocoa soap" which is the metal cleaner and the other one has "Selenous acid, hydrochloric acid and

copper sulfate" which is the gun blue. Is it a gun barrel that your wanting to blue or re-blue or something else? |

Selenous acid as in H2SeO3? Blimey...

|

|

|

ScienceSquirrel

International Hazard

Posts: 1863

Registered: 18-6-2008

Location: Brittany

Member Is Offline

Mood: Dogs are pets but cats are little furry humans with four feet and self determination!

|

|

I would recommend one of the kits if you just want to do a small amount.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

I would also mention —

RH Angier

Firearm Blueing and Browning

Stackpole 1936

There is a revised edition. Thirteen and change. You can

preview it either at Amazon.com or Google.com/books both

previews appear to be the same.

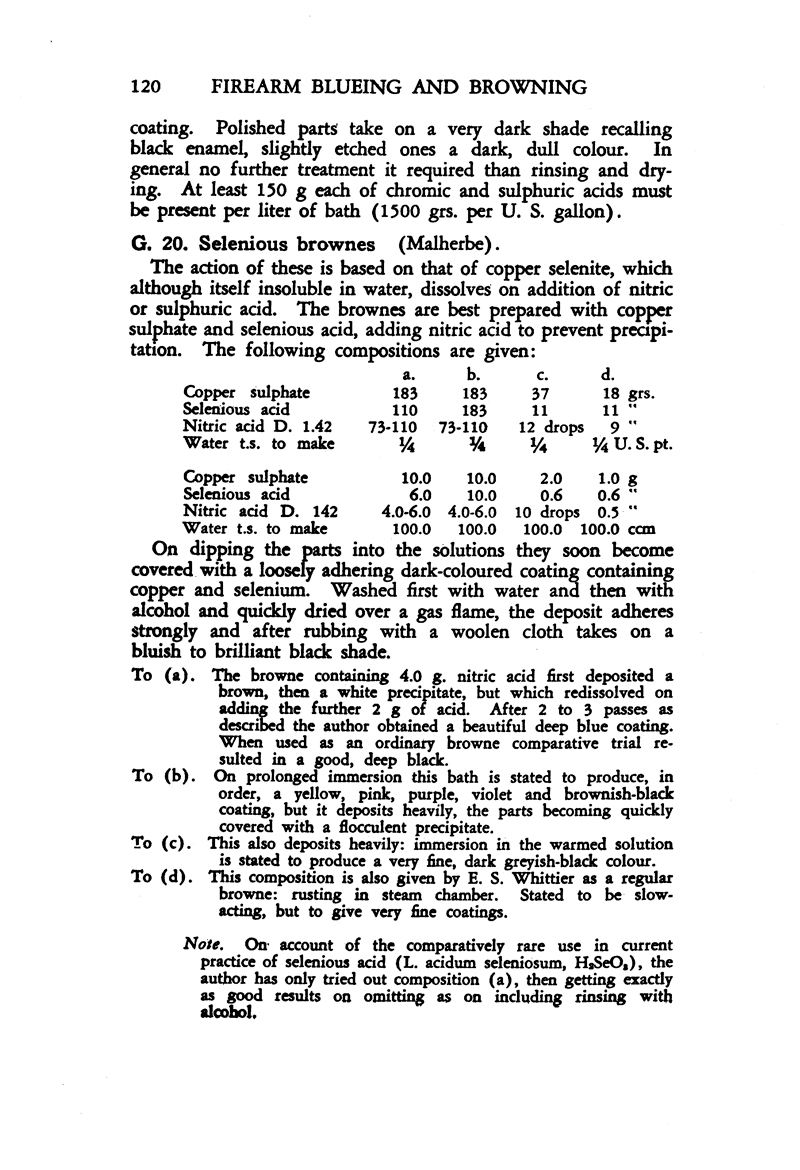

Anbier cites selenious browning formula from the

periodical Metallarbeiter, Wein. Presumable —

Journal für Metallarbeiter jeder Gattung, namentlich für ...

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

you can "color" steel with heat alone but this is a process more akin to tempering and i'm not certain if it adds any anti-corrosion properties at

all. over tempering will make it very brittle. i have accidentally shattered steel parts learning this technique and it is also very difficult to do

evenly on larger parts. upon heating it will go through color ranges from gold to a pinkish color then violet through blue. at that point you remove

from heat and quench. you can quench in used motor oil to increase the carbon content if desired.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  | | you can "color" steel with heat alone but this is a process more akin to tempering and i'm not certain if it adds any anti-corrosion properties at

all. over tempering will make it very brittle. i have accidentally shattered steel parts learning this technique and it is also very difficult to do

evenly on larger parts. upon heating it will go through color ranges from gold to a pinkish color then violet through blue. at that point you remove

from heat and quench. you can quench in used motor oil to increase the carbon content if desired. |

How steel is hardened is specific to the alloy being treated. The

temperature to which it is heated - how it is quenched, e.g.,

oil-water-air are all alloy specific. Of up most importance is

that after quenching it be annealed to reduce it hardness or as you

discovered — it can be friable as glass. I had a file made in India's

sunny clime - that when it fell off the bench onto my shops cement

floor — broke into 3-pieces.

I strongly recommend a little book —

Gentry and Westbury

Hardening and Tempering Engineers' Tools

Model & Allied Publications

Hertfordshire, England

89 pages.

I shelve the 3rd ed. 1977. You can find copies for sale ca. US $10.00.

For a more complete description of the various methods of hardening steel I shelve —

Palmer, Luerssen and Pendleton, Jr.

Tool Steel Simplified

Chilton Company

4th ed. 1978

535 pages

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Why do you need to blue these parts? What do you hope to achieve?

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

No. Oil is used as it has a high boiling point and more

importanlty is viscous insuring good contact with the hot metal for

rapid cooling. Ditto for brine.

If you want to carbonize steel/iron molten sodium cyanide works

wonders - I have use it with great success on coat hanger wire.

The less adventurous use bone black or commercial products

such as Kasenit.

There is extensive literature on case hardening and nitriding steel.

Also treatment with LN2.

The Brownwells catalogue has quick description on how to make

flat or "V" springs, P. 327 in catalog #61. I did not find it on-line.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

when i was in 11th grade i forged a four foot broad sword using a gas forge, cross pean hammer and 100 lb. anvil by hand. i hardened the steel with an

oil bath after the final heat treatment. took me two years to finish since i only got an hour a day. i think that method worked pretty well. the blade

was incredibly strong and quite rigid and held an edge for years without having to file or grind it. yes water is the best for hardening but it also

lends to distortion and cracking. the oil bath is after the quench and is used to toughen the steel. your metal should be bathed in oil and heated

around 250C to help avoid cracking and distortion.

this is why i call it a "black art". there are many techniques and they are all dependent on the composition of the metal and to some extent the

smith. if anyone were truly a master we would not have lost the true technique of producing legendary damascus steel .

[Edited on 11-10-2010 by Rogeryermaw]

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  |

when i was in 11th grade i forged a four foot broad sword using a gas forge, cross pean hammer and 100 lb. anvil by hand. i hardened the steel with an

oil bath after the final heat treatment. took me two years to finish since i only got an hour a day. i think that method worked pretty well. the blade

was incredibly strong and quite rigid and held an edge for years without having to file or grind it. yes water is the best for hardening but it also

lends to distortion and cracking. the oil bath is after the quench and is used to toughen the steel. your metal should be bathed in oil and heated

around 250C to help avoid cracking and distortion.

this is why i call it a "black art". there are many techniques and they are all dependent on the composition of the metal and to some extent the

smith. if anyone were truly a master we would not have lost the true technique of producing legendary damascus steel . |

Sigh. There is O1 steel tobe oil hardened and W1 steel to be

water (brine) hardened. Their composition is optimized for

their hardening method which also determines the temperature

- time they are annealed at.

I chose these URL's as I am pressed for time. You could fill a

library w/ books on tool steel.

http://www.mcmaster.com/#oil-hardened-tool-steel/=98gsn6

http://www.mcmaster.com/#88645kac/=98guc1

djh

----

Black-footed ferrets are beautiful little mustelids, like pine

martins, with black masks and feet. They feed on prairie

dogs, with ground-living rodents of the American prairie. By

1979, they were though extinct, but then a small colony

turned up in Wyoming. After a few setbacks including a near

wipe-out by canine distemper, they were rescued by heroic

captive breeding. In 1991, they were released.

In Prairie Night, Brian Miller, Richard Reading, and Steve

Forrest tell their tale. So is this another heroic triumph for

modern aggressive conservation a story to match the

Arabian onyx and the Hawaiian goose? Almost, but not quite,

For the modern US is more beleaguered by bureaucracy

than Mandarin China. While one agency strives to maintain

the newly wild ferrets, another offers grants to eliminate the

prairie dogs that form their sole diet.

New Scientist

26 October 1996

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

ok, i concede. arguing will not yield any results. some sciences are perfected out of the book such as engine tuning and calculus. engine tuning is

easy. a mix of stoichiometry, ignition timing and maximizing port design by flow bench testing. rules of mathematics are rather rigid(except

accounting) and well documented. some are more artistic and can not be mastered without years of study at the hands of a true master. some examples

are body work, transmission tuning and, believe it or not, metalworking. all the years i have spent working metal including machine work and welding

professionally, and foundry as a hobby have given me some good ideas what works and what does not but also has reinforced the knowledge that i have a

long way to go. i suspect no one here is a true metallurgical master or genius by any stretch of the imagination. no offense if you are but the man

that thinks he has nothing more to learn has only succeeded in failure.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rogeryermaw  | | . some are more artistic and can not be mastered without years of study at the hands of a true master. some examples are [snip]

|

----

Traditional Japanese swords.

Damascus steel.

djh

-----

In Italy for thirty years under the Borgias they had warfare,

terror, murder, bloodshed — and they produced

Michelangelo, Leonardo da Vinci and the Resaissance. In

Switzerland they had brotherly love, five hundred years of

democracy and peace, and what did they produce?

The cuckoo clock!

(George) Orson Wells, 1915-1985

Speech added to Graham Greene's script for

The Third Man, 1949

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

parkerizing is far far superior to blueing IMO

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Yeabut -- it ain't pretty like bluing. Military small arms are

usually parkerized.

|

|

|

condennnsa

Hazard to Others

Posts: 217

Registered: 20-4-2010

Location: Romania

Member Is Offline

Mood: No Mood

|

|

Panache, thanks for the suggestion, do you have experience with parkerizing?

I have phosphoric acid, a little MnO2 ,ZnO and ZnSO4. I did a little reading in the patents cited in wikipedia on parkerizing and it really sounds

easier as the bubbling of the part signals the end of the process, better corrosion resistance and bath temperatures of only 50-60 C with some

recipes.

I'll try and see if i get anything. i just hate rust.

|

|

|

bquirky

Hazard to Others

Posts: 316

Registered: 22-10-2008

Location: Perth Western Australia

Member Is Offline

Mood: No Mood

|

|

as i know zero about guns this is a possibly retarded question but why not plate it with nickel ?

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

yes, i parkerize everything that rusts in the lab (and is steel) like retort bases clamps etc. The US military developed it because blueing failed too

often, i quite like the finish of parkerizing, those swedish tools you can get with the matt dk grey/black finish, thats parkerizing.

Honestly i only found out about it because i ended up with some 20L of the parkerizing concentrate that you dilute tenfold or so, so as far as make

your own goes i have no experience. if you live in Aus i'll happily try to send you a litre or so. Treatment time is 30min at 80C or 8hrs at 45 C or

any range between (assume linear). It quite easily evidenced (when treatment is complete) by the absence of surface bublbing. Stainless is inertish to

it so you can just do it in a stainless pot. I find sandblasted stuff works great although i have had good, yet inconsistent results with rusted

surfaces also.

edit this is the msds off the concentrate i use.

[Edited on 13-10-2010 by Panache]

Attachment: parkerizing 200.pdf (47kB)

This file has been downloaded 937 times

|

|

|

condennnsa

Hazard to Others

Posts: 217

Registered: 20-4-2010

Location: Romania

Member Is Offline

Mood: No Mood

|

|

bquirky, that would affect the accuracy . Among the parts i'm talking about there are 2 beautiful parallels ground to 0.0001 " .

From what i've read bluing does not affect accuracy at all, but I find that hard to believe.

About parkerizing I don't know.

Panache , i'm on the other side of the world unfortunately

Thanks for the msds as it contains the ingredients also the percentages.

|

|

|