bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Theory of spinning band distillation

Just recently encountered this idea for the first time. Wikipedia has a short overview, not hugely informative but enough to at least outline the

concept: http://en.wikipedia.org/wiki/Spinning_band_distillation

Can anyone suggest a reference to some more technical treatment of the topic, that touches on some of the physical chemistry or theoretical basis for

this? It seems to me that there are two effects here: the increased mixing of vapors and condensate, and the increased heat flow to the cooling fluid

as a result of agitation. It seems like it can work pretty well (see e.g. http://homedistiller.org/forum/viewtopic.php?f=17&t=3333) but I'm curious whether the blades have to spin fast enough to create small droplets

of condensate (to maximize surface area), and so on...

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

Looks like one of the numerous chemistry wiki articles that doesn't need to exist. Chemistry seems to be the hardest hit of the three sciences in this

sense.

That is not a new idea at all. It's essentially a Dufton column. There's a good number of different column forms besides Vigreux. One looks identical

to an Allihin condenser, minus the water jacket. Then there are plate columns used for petrochemical work. I'll include pictures of the Dufton and

pear bulb columns available from QuickFit at the end. If high purity is the issue, even QuickFit sell column packing material, which is simply rings

made from glass or ceramic. Then the issue becomes how long is it going to take to heat all that mass and how much material are you willing to loose.

Industrially, there are companies who specialize in making packings for things like petrochemical towers. Here's an example of one, and I'll include a picture of that as well.

For laboratory chemistry, purposefully building turbine rotors into a column is going way over the top. It'd be tricky making bearing surfaces that

were both entirely inert yet also allowed the rotor to spin at a speed that'd centrifugally flick the vapour to the walls and cleaning it is going to

be a major bitch. You can use glass beads or just smash up some glass and pack the column with that. I often have some spare, smashed, borosilicate to

hand. Often not intentionally.

Vigreux columns can cost a fortune. But plain glass columns are dirt cheap and easier to pack.

[Edited on 15-7-2010 by peach]

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Yes, I have a 300mm Hempel column that I packed with little hollow borosilicate cylinders (cut from 6mm glass tubing); it works well for most things.

I suspect that since all of the applications I've seen for spinning band (or even fixed rotor) setups involve a specific task, it's a case where the

parameters only work well for a narrow distillate temperature range or flow rate or both. But that's why I wanted to know more about the theory. There

are a number of possible effects at work: increased path length, creation of small droplets (greater liquid/gas contact surface area), increased rate

of heat transfer... maybe others. Not all of them apply in the case of the Dufton column, which is static (like the distillation column I linked to,

actually).

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by bbartlog  | | It seems to me that there are two effects here: the increased mixing of vapors and condensate, and the increased heat flow to the cooling fluid as a

result of agitation. It seems like it can work pretty well (see e.g. http://homedistiller.org/forum/viewtopic.php?f=17&t=3333) but I'm curious whether the blades have to spin fast enough to create small droplets

of condensate (to maximize surface area), and so on... |

The spinning band in such a column is more properly

called a screw. The original ones had a rather long pitch, from what I recall, and so didn't look much like a screw. It's set up as an Archimedes

screw, and the rotation is set so that the screw forces the liquid phase downward when it gets thicker at the outer surface than the gap between screw

and column. This is one of the reasons for its higher efficiency, that liquid flows downward faster than it would otherwise under the force of

gravity. This effect is more significant for higher-viscosity liquids. It's also the way that spinning band columns limit flooding.

The motion of the screw is necessary for its higher efficiency. The limiting case is where the screw is stationary. In this case the screw acts as an

ordinary packing material with a relatively low surface area. At arbitrarily high speeds, on the other hand, the screw would act like a blower fan,

and create a gas pressure gradient that would limit the vapor pressure at the still head. Somewhere between these two cases there are various optima

of separation and liquid extraction rate.

A fractionating column under steady state conditions has a temperature gradient along its length from the boiling temperature at the bottom to the

condensation temperature at the top. The screw material itself is part of this gradient. As the screw moves, the face of the screw moves to meet the

gas. Assuming adequate rotation speed, this is a faster way of getting gas in contact with a condensable (solid or liquid) surface than relying on gas

diffusion. To get a faster mean time to contact in a packed column, you have to reduce the mean distance to the packing; in the limit, the packed

column has no capacity because it floods constantly.

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

Gas molecules at room temperature move at hundreds of metres per second. Assuming a B24 rotor spinning at 1krpm (which is what Ace glass claim is

optimal), that means the edge of the rotor is moving about 300 times slower than room temperature molecules. So I'm not sure about the idea about it

speeding it up the movement of the gas molecules. Maybe homogenizing the mixture, yes.

I actually think that other guys rotor is a better idea, because the screw is simply going to move gas along it's axis, not outwards very much. If the

idea is to continually and quickly replenish the diffusion gradient between the gas and liquid phase, a more centrifugally based fan design (half way

between the two, like that guys), that flicks the vapour outwards, may be better in terms of homogenizing the mixture.

It may be of benefit to isolate each rotor in it's own little glass compartment, put plates between them essentially. By changing the sizes of the

holes, the blades and the angle they make with the rotor, you could essentially design a small compressor. Such that the final stage produces around 1

bar (the burst pressure of most glass). By elevating the pressure in the stages, it would force more of the contaminants back into the liquid phase.

If the screw is running in a direction that forces the liquid down, any traction it has on the vapour will help push that down as well. But thinking

about it, if it's pushing the liquid phase down the column quicker, I think a bigger effect will be vapour being sucked back up due to the higher rate

the liquid is falling.

I'm, perhaps misguidedly, a little skeptical of this whole idea. There aren't very many people making them. And the petrochemical, liquid air and

other such industries wants every single penny it can squeeze out of the mother liquor. If it worked so well, they'd be all over it. Particularly the

petrochemical industry, as one of this designs supposed claims to fame is distilling high chain lengths.

Also, if you need that kind of purity, chromatography is probably the answer.

I managed to quite spontaneously find that site that discusses the more obscure designs that the vigreux stands like a monolith over, shadowing.

This is it, scroll down until you see pictures of columns.

Again, maybe I'm being stupid, but I think a number of the designs are essentially pointless. If you want higher purity, use finer packing and a

slower distillation rate. If it's flooding, use wider spaced packing.

I expect there must be some design that can eek out some fraction of a percent more purity than that but, yet again, if there was the petro guys would

be onto it; even if it cost a fortune in capital due to the savings they'd make over it's lifespan. And they just go straight for packing.

You know the old saying, you don't get something for nothing. If it's coming out more pure, it's probably going to come out a lot slower. This seems

to be an attempt to squeeze HPLC / GC out of a comparably high rate process.

[Edited on 15-7-2010 by peach]

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

It do be called spinning band (Rotary distillation column)

because —

A. It spins

B. It spins

C. It spins

D. A + B + C

I shelve

Thomas P Carney

Laboratory Fractional Distillation

MacMillian 1949

Who devotes several pages to it.

I would scan it, however, I would probable be criticized

once again by the believers in the 6th Law of

Thermodynamics* here in Mad Science.

*When information is cut and pasted it becomes useless.

I wonder if they believe in spooky action at a distance?

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

As far as i know neither of those two pictures are spinning band apparutus nor any part thereoff, they're just fractionating columns, i mean very nice

and all but not the technique which is quite special.

Edit. Hey, i'm an idiot got spinning band (which was invented in Australia) confused with falling film distillation, now thats special technique.

[Edited on 16-7-2010 by Panache]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

A current vendor of spinning band distillation equipment: http://www.solvent--recycling.com/spinning_band_packed_colum... with their take on why it's good.

Complexity, cost, and compatibility (of the band & spinning mechanism with the material being distilled) are the bad parts.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

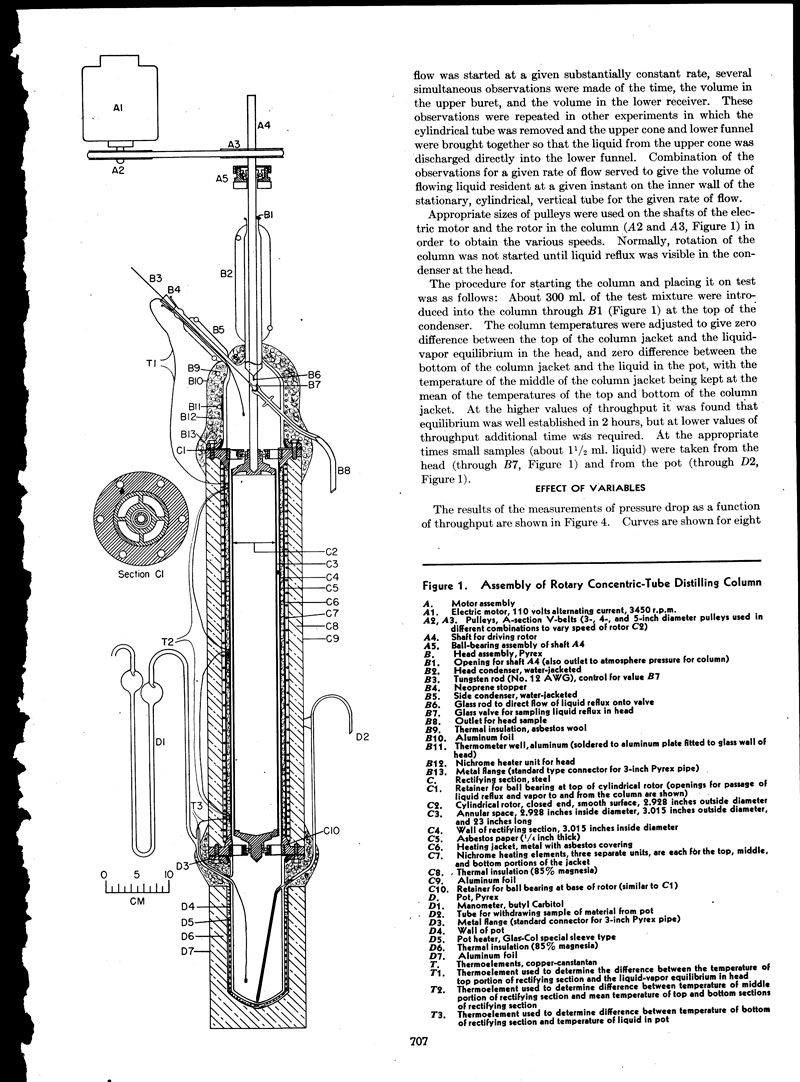

I checked 3 of the reference in Carney that I have at hand.

C.B. Williams & et al

Rotary Concentric-tube Distillation Column

Industrial and Engineering Chemistry 39 [6] 706-712

Is a mechanical marvel.

|

|

|

The WiZard is In

International Hazard

Posts: 1617

Registered: 3-4-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by The WiZard is In  |

I checked 3 of the reference in Carney that I have at hand.

C.B. Williams & et al

Rotary Concentric-tube Distillation Column

Industrial and Engineering Chemistry 39 [6] 706-712

Is a mechanical marvel. |

$29.95 at WallMart

|

|

|

arsphenamine

Hazard to Others

Posts: 236

Registered: 12-8-2010

Location: I smell horses, Maryland, USA

Member Is Offline

Mood: No Mood

|

|

Why, indeed.

The money shot:

A spinning band column permits separation of compounds with close boiling points.

In practice, an experienced technician can effect a separation from mixtures where the compounds of interest have BP's only 0.2C apart.

The spinning band column has very low hold up.

The latter point is very important when distilling small and precious quantities.

Bonus question: Why would anyone make a distillation column as silly-looking as the Podbielniak?

|

|

|

darel

Harmless

Posts: 27

Registered: 12-7-2008

Member Is Offline

Mood: No Mood

|

|

I just bought a B/R spinning band column from a university sale. I believe this is what I got

http://www.brinstrument.com/fractional-distillation/fraction...

I am still lookng for the interface and software to use the thing. Also need an adapter to go from a $50/30 spherical to 24/40, 29/42 or 45/50. Ebay

has given no such luck and I'm still waiting on a response from the company for hard/software. Here is a link to the thing disassembled and some of

the parts.

http://s287.photobucket.com/albums/ll149/darelgreen/Spinning...

|

|

|

Ephoton

Hazard to Others

Posts: 463

Registered: 21-7-2005

Member Is Offline

Mood: trying to figure out why I need a dark room retreat when I live in a forest of wattle.

|

|

the wiz you make me laugh so much

as for spooky action at a distance.

ooh I do I do please cut and past

no crowley he sucks.

he didn't have a nob on the end of his stick.

[Edited on 27-12-2010 by Ephoton]

e3500 console login: root

bash-2.05#

|

|

|

MagicJigPipe

International Hazard

Posts: 1554

Registered: 19-9-2007

Location: USA

Member Is Offline

Mood: Suspicious

|

|

| Quote: | | Looks like one of the numerous chemistry wiki articles that doesn't need to exist. |

Why? Because you don't think it is a good technique?

"There must be no barriers to freedom of inquiry ... There is no place for dogma in science. The scientist is free, and must be free to ask any

question, to doubt any assertion, to seek for any evidence, to correct any errors. ... We know that the only way to avoid error is to detect it and

that the only way to detect it is to be free to inquire. And we know that as long as men are free to ask what they must, free to say what they think,

free to think what they will, freedom can never be lost, and science can never regress." -J. Robert Oppenheimer

|

|

|

NOV:5

Harmless

Posts: 24

Registered: 5-9-2014

Member Is Offline

Mood: Moodless

|

|

Nice!

-jealous-

I'd be happy with one of these though..

[Edited on 11-11-2014 by NOV:5]

Remember, Remember...

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

I hope you realize that post was 4 years ago . . .

|

|

|

NOV:5

Harmless

Posts: 24

Registered: 5-9-2014

Member Is Offline

Mood: Moodless

|

|

Haha no, I didnt...it was in "today's posts" but thanks for pointing that out..

Remember, Remember...

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Has this technology advanced since? Are there available models that could suit a tabletop use? Has anyone actual experience here about using them?

|

|

|