| Pages:

1

2

3 |

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

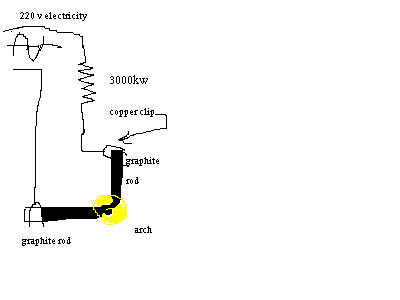

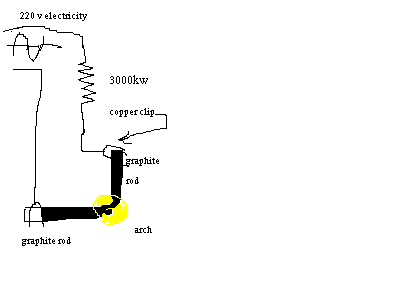

DIY 3000'C homemade electric Arc-for P,... production

very dangerous.be very careful and if you don`t know it completely,simply forget it.do it in your own risk.

all electric wires must be capable of at least 3kw,20Amper.

here i want to explain you how to have an easy homebuilt high temperature source of heat for your needs ver 3000 degree:eletric arch,without need of transformer: ver 3000 degree:eletric arch,without need of transformer:

it can be used for regular preparation of Phosphorus, calcium carbide, silicon carbide,...

100% practial and tested.

you should just buy an nichrome[nikel-chromium alloy] 3000Watts coil[like the one used in hot plates,heaters,...] and u should secure it on a fire

clay frame or base and then in serie you should connect two clips that keep the

graphite rods therefore when u just touch the graphite rods its like that electricity is passing simply through nichrome wire but when u take rods

back,electricity current get disconnected.in practice i used 220V and i did

not do that with 110V but it seems to me that it should work too but little bit weaker.

all the copper wiring should be from thick wires to be able to work with high current otherwise they get warm then insulator will burn and shortcut!!!

how to run it:simply connect the rods,it sparks,then gradually take it back,electric arch will be formed.don`t watch to arch with naked eyes.use

UV-lens or very-dark eye glasses,wear gloves!!!electric shock!!!

mixtures like phosphorus making mixture(C+Ca3(PO4)2+SiO2)contain C and are conductor.therefore if put the rods inside the retort made of fire

clay-fire cement,...in contact with each other,after some seconds they have spark then the mixture get warmed then rod contacts will be cut but

electricity will run through carbon content of mixture then because of created high temperature,mixture melts and pass electricity much better till

all the mixture is liquid.

i used this simple device for melting silver(100Gr),palladium ,platinum and even rhodium although not easily about the latter.

it can be used simply for preparation of sulphides from sulfate and charcoal too!!!

=============

before i had a powerful transformer and powerful diode(high amper)[can be made by paralleling diodes with lower current limit and making a rectifier]

and i used 50v electricity as DC for electric arch making with graphite rods and i melted NaCl and made Na althogh i did it in open air and it burnt

with yellow flame but some of its globules were surronded

inside salt and i made metallic sodium when i was just 14!

==============

a question:I want to use the reference&Whimsy

section of this forum but it is restricted.how i can access them?i couldn`t find any access method mentioned in site.thx

[Edited on 24-9-2009 by halogenstruck]

[Edited on 25-9-2009 by halogenstruck]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by halogenstruck  | you should just buy an nichrome[nikel-chromium alloy] 3000Watts coil[like the one used in hot plates,heaters,...] and u should secure it on a fire

clay frame or base and then in serie you should connect two clips that keep the

graphite rods therefore when u just touch the graphite rods its like that electricity is passing simply through nichrome wire but when u take rods

back,electricity current get disconnected.in practice i used 220V and i did |

Please explain that part better...

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Blogfast25, I think it's about wasting 3kilowatts per hour in order to get some resistive heating or arcing going in a fire-clay pot, and doing it in

a way that will surely set fire to your house and home. . .

It sounds too dangerous and inefficient to be of any use.

[Edited on 24-9-2009 by hissingnoise]

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

it uses less than 3kw for sure as in direct contact it is 3kw but when we have arch,it`s less than that.

if u don`t serie a resistor,then your home fuse box cut the electricity as a huge current want to pass.in fact it limits electricity current.

i did it many many times.

i tried to illustrate it on a jpg pic.sorry for low quality design.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Even so, it sounds wasteful, at best.

A welding transformer would be better. . .surely?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Thanks for the clarification, Halogenstruck. The 3 kW resistor reduces current strength and if you can safely (by insulating yourself) manipulate the

graphite electrodes, this should be relatively safe to use for an AC arc. Max. current about 14 A.

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

you are welcome blogfast25.

in fact in practice you should put the arch on a heat resistant board.in past i fixed one rod inside the crucible from clay and just moved one

electrode.i used glove and well insulated plier[handle had a thick plastic insulator][600v safe].the distance between electrodes can rich between

1-2cm i think.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Well, it's all heat, so it's all 100% inefficient. But maybe you count heat as efficiency? In which case, it's 100% efficient. Well, not with the

resistive ballast, then maybe only 50% tops, but hey, it's cheap as hell, and it's not going to be running for days, who cares.

FYI, "arch" is an architectural feature. "Arc" is a thermoelectric discharge. ("Spark" is either a short duration arc, or an ionizing discharge not

at thermal equilibrium.)

Tim

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

If hes speaking of what I think he is(Hard to tell due to the confusing opening post) I have also done something simular using an old electric stove

top burner as the resistor. This is nothing more then a thin piece of Nichrome wraped in ceramic, wraped in a metal sheth. It prevents blowing the

breaker but I always found it hard to sustain an arc. I only toyed with it for a while but Im sure I could get something up and running if I continued

to work with it.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

thx for correcting me,u r absolutely right.arc

the resistor element does not emit hit a lot,it`s only there to avoid shortcut and power out,when we have arc then R of arc is much higher than

nichrome wire 3KW as arc is a 1 cm distance of air,therefore heat loss from 3kw coil is low

|

|

|

barbs09

Hazard to Others

Posts: 113

Registered: 22-1-2009

Location: Australia

Member Is Offline

Mood: No Mood

|

|

Well arc furnaces (and arc lights) have been around for a while and may still have a place in a DIY lab for making Phosphorus or carbide. The link to

the old article below is a good read. For a resistive load they use a conductive solution. Perhaps their method of striking an arc is better/safer

than using pliers and gloves.

http://blog.modernmechanix.com/2007/08/02/arc-furnace-incase...

Another

http://blog.modernmechanix.com/2007/03/19/experimental-arc-f...

The guy in the above article can't have any eyes left!!

Lots of other good stuff an the Modern Mechanics web site as well

Halogenstruck once the arc is struck do you have to constantly move the electrode in to make up for carbon erosion? I guess gouging rods are adequate

since they are designed to withstand high-temperature arcs?

[Edited on 25-9-2009 by barbs09]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Phosphorus from phosphate, silica and carbon needs just 1500°C and is therefore one of the least temperature-demanding applications of an arc

furnace. Temperatures above 2000°C are needed e.g. for calcium carbide production and melting down alumina for abrasives production.

Go to 4:20 to see alumina being melted and poured:

http://www.youtube.com/watch?v=fopD-QA1YY0

Using an inductive current limiter is a good improvement over a resistor, as it doesn't waste power and limits the current just as well. A transformer

that produces about 40-60V secondary would be even better- it's mostly the current in the arc that decides how powerful the furnace is.

The difficulty in building such a furnace lies in catching the phosphorus vapor. The whole thing must be gastight and the outer shell must be kept

above 280°C to avoid the phosphorus condensing in the furnace.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

barbs09 and garage chemist:

Thanks for the links. Now I know all about hot dogs too and am even less inclined to eat them!

I suppose the carbon electrodes used in most ordinary batteries are out of the question, huh? I imagine these to fritter away in record time. What

type of carbon to use and where to get it?

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

The carbon "gouging rods" for arc welding would probably be a good choice here, as they are specially made to be used as arc electrodes.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Ace Hardware has gouging rods.

http://www.sciencemadness.org/talk/viewthread.php?tid=2680&a...

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

graphite rod inside spent dry cells work well.yes as arc run graphite rod burn very very slowly and evaporate,for some period electricity still keep

the arc running as distance grows but after sometime you need to aproach them a little bit,but in practice when arc starts it create heat then mixture

melts and by conductivity heat is made in following.in fact mostly arc is needed till mixture melt then molten lava conduct electricity and create

enough heat to stay molten and warm up even more as for sure they conduct electricity better than hot air.

in fact if container is insulated very well smallest heat can keep the temperature constant just to compensate lost heat from insulant.because of this

fact,even with a nichrome wire coil alone you can make a 1000'c furnace and even 2000 if use a very good insulator but in fact over 1000 it melts and

does not work and u need SiC resistor.

for leakage you can simply put an inert stream of neutral gas like CO2 or burnt gas from a gas burner.

for inductive oven,u can use a reactor or retort made from mixture of fire clay and graphite powder inside a microwave.as graphite absorb

electromagtetic waves it warms up and get red.

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

yes possibly if u use strong electrodes and in an inert atmosphere,it should work the best.

an idea:

how if we make a coil from thick copper and at end we connect it to graphite road and put it inside microwave.

first electricity get induced on coil and makes arc then mixture is getting warm and melt.when melted and red,it`s conductor and absorb

electromagnetic waves directly from microwave and stays warm and melted and no need to arc anymore.therefore don`t care to move rods anymore.just as

an innitiator[like catalyst!!]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by halogenstruck  |

before i had a powerful transformer and powerful diode(high amper)[can be made by paralleling diodes with lower current limit and making a rectifier]

and i used 50v electricity as DC for electric arch making with graphite rods and i melted NaCl and made Na althogh i did it in open air and it burnt

with yellow flame but some of its globules were surronded

inside salt and i made metallic sodium when i was just 14!

|

And you made sodium with an arc, how?

Oh, I see: DC arc! (must get those reading glasses...)

[Edited on 25-9-2009 by blogfast25]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

And I thought that the rhodium, etc. would be the most questionable part.

It's all out there, from dead people I trust a little more.

http://books.google.com/books?id=H_RUAAAAMAAJ

http://books.google.com/books?id=WDUKAAAAIAAJ

http://books.google.com/books?id=ah9DAAAAIAAJ

http://books.google.com/books?id=Lx9DAAAAIAAJ

http://pubs.acs.org/search/advanced

title search furnace, or don't.

|

|

|

User

Hazard to Others

Posts: 339

Registered: 7-11-2008

Location: Earth

Member Is Offline

Mood: Passionate

|

|

@halogenstruck

It's some nice DIY stuff.

Can you explain to me how you constructed the heat transfer between the arc and the reactor.

And do you have pictures of youre device.

I have 2 neon trans. laying around doing nothing.

It is quite easy to draw long and hot sparks with it.

Might be uesfull stuff.

What a fine day for chemistry this is.

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

in fact i did the arc in a graphite crucible or in normal crucible.

in case of silver i fixed one rod inside crucible in contact with silver powder and arced between graphite rods.i arced between rods many times to

melt it.in case of Rh i melted around 1 or 2 gr with some difficulties as its melting point is very high.

in case of salt i did it on the brick.u can do it inside a normal crucible.

i think if u use a graphite crucible as - electrode,cathode and a rod as anode and use CO2 current around it when u work u can prepare good amount of

Na especially if u use NaOH.

i did not use it for P preparation but surely it`s the commercial process for making P and works very well.

in P case like many other cases u don`t need arc always,remember, ARC IS NEEDED FIRST WHEN THE MIXTURE IS COLD,AFTER ARC

MELTED A LITTLE BIT OF MIXTURE,THEN CURRENT WILL PASS THROUGH THE MELT AND CREATE ENOUGH HEAT EVEN MORE THAN ARC TO MELT WHOLE MIX AND KEEP IT IN

MOLTEN STATUS.

sorrily it was a long time ago and i did not take any picture that time.it`s a simple thing u can master it easily but be a little careful and regard

safety issues like goggle/glove/mask/heat insulators/don`t allow wires even with insulator touch each other as they warm up then insulator may melt

and a shortcut is possible.

|

|

|

halogenstruck

Hazard to Self

Posts: 61

Registered: 24-9-2009

Member Is Offline

Mood: No Mood

|

|

about neon trans i don`t know it exactly but it think it won`t work in this way as it increase the voltage but u don`t need it.u need only current.

|

|

|

chloric1

International Hazard

Posts: 1140

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Quote: Originally posted by User  | @halogenstruck

It's some nice DIY stuff.

Can you explain to me how you constructed the heat transfer between the arc and the reactor.

And do you have pictures of youre device.

I have 2 neon trans. laying around doing nothing.

It is quite easy to draw long and hot sparks with it.

Might be uesfull stuff. |

Neon sign tranformers are better designed for building Tesla Coils not arc furnaces. There are several books on building thoughs. What you ideally

need is a step down transformer. One that produces 30 to 40 volts and 50 to 80 amps. This way it can run off a 115V. It is the same as a 115V stick

welder.

Fellow molecular manipulator

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Here is an old paper from my website. It was published in an old science magazine known as The experimentor and it talks about making

something just like this only with one major difference that I feel is better then the nichrome resistor mentioned here.

In this article they use a salt water bath for the resistor where the depth of the electrode and the concentration of salt can change the desired

current to what ever one desires. Just though I would track this down for ya'll as I read it sometime ago and knew I had to have it uploaded already.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

The suggestion of an electric welding apparatus for this sort of work is probably the best idea. For example, a used 115V (input) 50A (output) welder

is for sale locally for $US 35. I looked on the Internet for about 30 seconds to find that one. Not free, but much safer than any direct connection to

the mains!!!! For more money one can get 100s of amperes at 10-50V AC or DC.

The big advantages of the welder are (a) isolated from mains (b) knob to adjust current (and some have a knob for voltage too) and (c) big thick

cables and big thick power cord and big thick electrode clamps already attached. The case, wires, and clamps alone are worth paying for if you believe

in safety or convenience. I believe that the older units use an adjustable series inductor to limit current; more modern ones use semiconductor

inverters with current limiting.

For arcs or resistance heating the cheapest ancient electric welder will work very well and save a great deal of trouble and electric cost.

Besides, if you don't want it any more you can sell it, as opposed to an improvised apparatus.

[Edited on 27-9-2009 by densest]

|

|

|

| Pages:

1

2

3 |