| Pages:

1

2

3

4 |

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

fan selection for homemade fumehood - help

as stated in a different post i've assembled a homemade fumehood built to handle acid vapors and flammable solvent fumes.

i've read some posts on here, very inspiring, by magpie which without those posts i'd have no idea what to even do. i downloaded some professional

fumehood pdf's, without with i wouldn't even know what the components are.

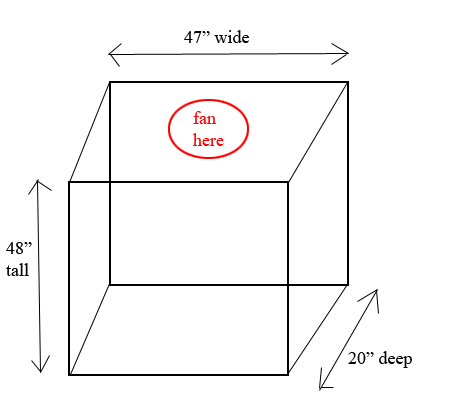

i'm having a difficult time picking out a fan. i attached a picture showing the dimensions of the fumehood, 48" tall / 47" wide / 20" deep is the

work area. i've read i can use a bilge fan or a squirrel cage fan and not have to spend over a couple hundred dollars which is why i'm aiming for.

any specific recommendations as to what i should get that is good for my work area?

i currently have no baffles or sash, just like a box with an open face, i can always add baffles (easy - thanks to magpie's assistance to others) and

a sash (that one's going to be tricky) if need be. will not having those make my current fumehood completely inefficient? which is more important -

a sash or baffles? i'm assuming the baffles only serve for low density vapors to be pulled behind them, out of the work area as opposed to being

pulled straight up. and the sash is just to make the front opening smaller so the vacuum is more effective. the sash, if i build one, will never be

closed entirely as everything i do requires my hands in the work area at the top of flasks (constantly adding, setting driprate, etc)

[Edited on 29-1-2009 by EmmisonJ]

|

|

|

Contrabasso

Hazard to Others

Posts: 277

Registered: 2-4-2008

Member Is Offline

Mood: No Mood

|

|

Depends where you are! The cheapest fans come from surplus shops or demolition skips. The best fans cost a fortune. Consider also where you are going

to send the fumes and how you will connect the ducting.

Maybe some speed control, maybe look for plastic fan blades to minimise corrosion. Good fans have a bifurcated trunking so that the motor is not in

the (acid) gas flow.

The smaller the front opening the smaller the fan flow needed to keep the fumes inside.

|

|

|

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

the fumes will be going out the top of the fumehood to some ducting which will make a 90 degree curve so that it's horizontal and lead outside, it

will be a very short distance, probably like 5 feet.

i never realized just how much of an artform fumehood building really is, it is not an easy thing by any means.

to be honest i'm hoping to just find an entire fan assembly i can slap in the box and go without spending more than a couple hundred dollars. the

problem is, i only vaguely know what to look for so i'm having a hard time looking for a specific fan.

what do you guys here use? like a certain brand, model i can look at then figure out which model i'll need to move air properly in my work space

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

Do not make any abrubt bends in ducting that eventually needs to turn 90*. The airflow will be seriously choked with turbulence and backflow. For

example chimneys with 90* bends don't draw... at all. That out of the way, I've seen small DIY hoods that used computer fans. I'm skeptical. A

bathroon exhaust fan, however, should meet your needs admirably and would be cheap enough. I just installed a 12" exhaust fan with louvers to move my

lab air out of the building. I was looking for a complete change of air every ten minutes so I took the volume of the lab and the cfm rating of the

available fans and specced the fan from there. Most industrial supply catalogs have the specs and from there you can figure out what to look for at

the hardware or surplus bldg. material store. I suspect that Lowes and Home Depot or their equivalents post the fan specs somwhere on their web sites

too.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Do yourself a real favo and get a proper lab fume hood blower, which is driven by a separate motor so the motor never deals with the fumes. See

Nalgene's site. If you work with HCl do not use PVC as it will catch fire with HCl gas.

Sic gorgeamus a los subjectatus nunc.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

If you work with HCl do not use PVC as it will catch fire with HCl gas.

|

Sauron, do you have a reference for that?

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

@Sauron what concentration would do that? My partner was all worried about H2 and ether fumes until I sat down with him and worked through some

scenarios from the real lab world. Sauron has a good point though; a hood is to protect your life, work space and equipment.. don't go cheap (unless

you hold those things to be cheap too...)

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

"PVC as it will catch fire with HCl gas."

Id like personaly to see one my self as I have worked with HCL around PVC alot and never had anysort of a problem..,and Im a Plumber by day . Of couse I try not to get concentrations of anything to high around things that

maybe reactive so I could see how a chlorinated vinyl could react under extream conditions. . Of couse I try not to get concentrations of anything to high around things that

maybe reactive so I could see how a chlorinated vinyl could react under extream conditions.

Ok on topic, I have always found the fans from old heaters to be effective at moving the air out of a homemade fume hood. The motor is seperated from

the blower so as long as precautions are taken one wouldnt have to worry about damage to the motor. These blowers can move ALOT of air, they are

SPARKLESS and shaped in a nice way so that an air duct can be set up to divert the fumes outside.

I do forsee a problem here though with the acids even though alot of the fan constructions are stainless steel I wouldnt put to much faith in pumping

concentrated acid vapors through them although since some air is drawn in from the side also they will dilute in the fan itself.

Possibly a spray coating of teflon would help ease any problems one has with acid damage. Iv always used mine for years now for smelly reactions and

solvent vapors without incedent but Iv always strayed away from strong acids indoors.

|

|

|

gsd

National Hazard

Posts: 847

Registered: 18-8-2005

Member Is Offline

Mood: No Mood

|

|

Flammability of PVC in HCl

| Quote: | Originally posted by Magpie

| Quote: |

If you work with HCl do not use PVC as it will catch fire with HCl gas.

|

Sauron, do you have a reference for that? |

LOL

I have a reference to this, but unfortunately it says the chemical resistance of PVC to HCl upto 10 % concentration is excellent  further it says nothing about fire hazards of this pair. further it says nothing about fire hazards of this pair.

It is a very credible reference: Perry 7th Ed. page 28-49

The entire chapter on MOC is attached herewith.

gsd

Attachment: CE_Handbook_Perry_7ed_Chap28.pdf (638kB)

This file has been downloaded 1903 times

|

|

|

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

unfortunately a proper fume hood blower is out of my league ($1000+) and i don't think the bathroom exhaust fan would last very long would it even i'm

able to find one that moves enough air?

i've been shopping online for bilge fans and they come quite cheap but would need a 12v to 120v adapter for them (no big deal) and squirrel cage fans

but know too little about it to make a proper decision.

considering there is no sash, would 2 of these be suitable (2 x 240cfm = 480cfm)?

http://cgi.ebay.com/ebaymotors/BILGE-BLOWERS-EXHAUST-BLOWERS...

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

using your data:

face velocity = (480ft3/min)(144in2/ft2)(1min/60sec)/[(47in)(48in)] = 0.51 ft/sec

You should have at least 1ft/sec face velocity.

A sash would cut down the face area thereby increasing your face velocity.

Remember, the primary reason for a sash is safety. If you are going to operate without one be sure to always have on eye, face and hand protection in

case something blows up in your face.

From personal experience I can say that I feel much more confident doing unfamiliar reactions in my hood when I have a double pane of safety glass

between my face and the reaction apparatus.

[Edited on 9-2-2009 by Magpie]

|

|

|

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

hm and for the price of ganging up bilge fans i really would be better off finding a sparkless centrifugal fan, plus i read in another thread on here

about a concern with bilge fans not holding up long-term either, that they are meant to only run for a few minutes at a time.

magpie, i saw your fan in another post and am looking for a similar solution that will work with my setup. i like your idea of moving the motor

outside the fume hood so you don't have to worry about it being explosion proof. how would you go about doing that exactly? remove the motor and

mount it outside of the fume hood but have a small opening for the belt? wouldn't that pose as a risk for a leak? also since the motor would be a

further distance away that means you'd have to get a longer belt, wouldn't that put a damper on performance of the fan as well since the belt's longer

it wouldn't turn quite as quickly as a shorter distance belt? or is that performance hit minimal as long as its within a few feet and the motor's

strong enough to begin with

being that my hotplate isn't explosion-proof (again, can't spend thousands) i definitely want to have safety in mind but can't spend more than a

couple hundred dollars on the fan

[Edited on 9-2-2009 by EmmisonJ]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by EmmisonJ

unfortunately a proper fume hood blower is out of my league ($1000+)[...] |

Nonsense. Here's a blower on eBay that took me just a couple of minutes to locate. (There's even points on fan curve in the description.) For about USD 100, you can

have an adequate blower for a modest hood with short exhaust runs. That particular fan would need a plate adapter to seal it up, but if can build a

hood, you can figure out how to get the fan mounted and sealed up.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

When you do not have air-directing baffles, I think a sash is a must, or a lot of contaminants will be swept out of the hood at the upper half of the

opening, where normally the sash would be.

I do not have baffles, but I do have a sash, wich can be opened to a maximum of halfway up. At this height, nothing will get out of the hood, at least

when the motor is at 25% or 50% power. Higher, turbulence steps in, and small amounts leave the hood.

I think a sparkless motor is not an absolute necessary. Flammable vapours are diluted enough before they reach the motor. Ofcourse you should not boil

ether away or something like that. However, you must put your blowers at the end of the duct, if you put it right above the hood, i can't guarantee

vapours are not diluted. As far as I know, everyone on the german forum versuchschemie does not use sparkless blowers, including our member garage

chemist.

A greater problem is corrosion. Make sure the coating of the area where the vapours go through is NOT metal, or HCl and such will make quick work of

it. Mine is plastic coated, except a part in the back, but it doesn't seem like it would hurt much, as it looks to be some kind of armour protecting

the motor.

I bought a blower for 120 EUR, and after months of passing through HNO3, HCl, halogens, solvents, etc, it still works just like when it was brandnew.

And in case it will be destroyed by the vapours sometime, I will just buy a new one, take the destroyed blower out of the duct, and put the new one

into the duct.

https://www.leafman.nl/ruck-rk160l-4standen-buisventilator-p...

This is the one I bought. It's a lot cheaper than those sparkless proof, corrosion proof ones, but may need replacement in a (few) year(s).

This is my hood design:

http://i405.photobucket.com/albums/pp133/Joris12345/P1090889...

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Have you read through the following thread? It seems that most of your questions have been addressed already:

http://www.sciencemadness.org/talk/viewthread.php?tid=11145&...

In that thread I show a manufacturer's picture of my fan. It cost around $260. You can mount this fan anywhere in the exhaust line. I chose to put

it at the very end. This keeps my whole system under slight vacuum when the fan is operating. So small leak paths in the hood and ducting are

inconsequential as air is just entering in very small amounts. No contaminants are escaping.

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

Magpie, I never seen your hood in real action

Can you make a small movie where you generate a large amount of NO2 or smoke, and see how the stuff is sucked at working height ?

|

|

|

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by watson.fawkes

Nonsense. Here's a blower on eBay that took me just a couple of minutes to locate. (There's even points on fan curve in the description.) For about USD 100, you can

have an adequate blower for a modest hood with short exhaust runs. That particular fan would need a plate adapter to seal it up, but if can build a

hood, you can figure out how to get the fan mounted and sealed up. |

thanks for the link! and i apologize for the confusion, i should have been more clear, by 'proper fume hood blower' i meant one with an

explosion-proof motor. i'm assuming that the motor will need to be separated from the blower on all these Dayton and Grainger squirrel cage fans to

keep them away from the fumes. i won't be working with ether, but distilling the likes of nitromethane, xylene, mek, are not out of the question.

i'd hate to buy a fan off ebay to find out that removing the motor isn't going to work for that model, etc, as i have no knowledge on how these fans

differ. perhaps i can get two of them or get by with one and put in a sash

since my hotplate isn't explosion-proof, i'll want to make sure this fan really sucks (can't help myself on that one). some baffles will be going in

similar to magpie's (thanks), and if need be i'll put a sash in just to improve face velocity.

i have read that link you posted, magpie, in fact that's the first link i read when i started thinking about what needed to be done with the fume

hood. i am currently in the process of re-reading it in hopes of picking up on things i may have missed out on the first time i read it since i've

learned some since then (scary concept, but i do apologize for my ignorance on this topic as my knowledge and confidence regarding fans and air flow

is zilch)

[Edited on 9-2-2009 by EmmisonJ]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Jor, I would be glad to do that if I had the technology. I only have a digital camera.

I can say that based on visual flow paths of SO3, NO2, and smoke, and no smell of fugitive ammonia, that the efficiency and flow paths must be good.

This performance does not seem to be affected by position of the sash (I have a constant flow design).

|

|

|

Jor

National Hazard

Posts: 950

Registered: 21-11-2007

Member Is Offline

Mood: No Mood

|

|

A moving sash (hard to make) is not necessary, but at least cover half of the opening of the box with a stationary sash.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

EmmisonJ says:

| Quote: |

i'm assuming that the motor will need to be separated from the blower on all these Dayton and Grainger squirrel cage fans to keep them away from the

fumes.

|

The motor just needs to be out of the flow path. As you can see in the picture of the Grainger (Dayton) blower I posted the motor is out of the flow

path as originally configured, ie, it's on top of the blower. To make my system a little more rugged I simply re-mounted the motor on the same piece

of 3/4" plywood on which I mounted the blower, right next to the blower. I didn't change the spacing, just reused the existing belt. It's not rocket

science.

edit: I'll take a picture and post it later - I have to charge camera battery now.

[Edited on 9-2-2009 by Magpie]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

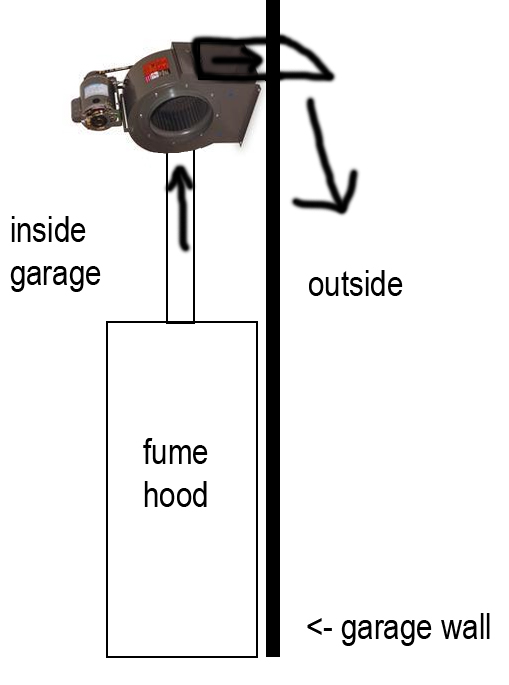

Here's a picture of my blower as installed. As you can see I moved the motor from the top of the blower as supplied by the manufacturer and remounted

it on the same base as the blower. I didn't see why the blower housing should have to support the motor.

|

|

|

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

thanks for the picture! now it's beginning to make a lot more sense. so with your particular model, it wasn't necessary to move the motor as it

appears from the original stock picture ( http://www.grainger.com/Grainger/items/7C651 ) like it's already out of the way of the fumes, you just did so to take that additional weight off

the blower's housing by mounting it the same distance away just on wood instead of the housing.

would the following attached picture be correct? if so then i wouldn't need any bends on the ducting because the blower takes care of the change in

direction itself or at least it appears to be in the manufacturer's stock picture. the picture below isn't completely lined up but hopefully it's

decent enough to show what i'm trying to do. i seriously had no idea what the difference was between centrifugal, inline, or any other design for

that matter. now i'm beginning to understand the differences or at least what to look for. Centrifugal designs are going to change the direction of

airflow which in my case means i won't need any actual bends in the ducting, inline would require for me to put bends eventually equaling 90 degrees

(or a slant of some type so it's more gradual) which is going to decrease airflow considerably as well as the fact that inline fans are going to have

the motor inline with the fumes as well (unless otherwise stated), whereas centrifugal fans i'm looking at have the motor mounted externally, out of

the path of the fumes it seems, and i'd only need to move the motor if i want the weight off the blower itself or if the motor is simply in the way of

how i want to ducting to connect to the blower, etc, then that may be another reason to move it as well.

but getting back to the pre-school style picture i attached, the ducting from the blower to the fume hood would only be about a vertical 1-3' run then

the immediate horizontal outside run of 1-2'. i see the "special plenum to adapt my fan rectangular outlet to the louvred and screened outlet in the

wall of my garage" per http://www.sciencemadness.org/talk/viewthread.php?tid=11145&... and since i don't have a pre-existing outlet in the wall for this i won't need to

get anything special made, i'll just make the hole in the garage's wall to accommodate the blower and put a little outside vent which is what the

little upside-down triangle in the picture is supposed to be. from the outside of the house it will just look like a 2nd dryer vent as it will be

only a few feet away from the actual dryer vent as it will be exiting the side of the house, not the roof.

[Edited on 10-2-2009 by EmmisonJ]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

As you say, my blower configuration does introduce a 90 degree turn in the flowpath.

To do what you propose you would have to mount the blower base in a vertical plane, which is not standard. This would introduce axial stress on the

fan and motor bearings.

I wouldn't do this without consulting with the manufacturer (Dayton) first.

[Edited on 10-2-2009 by Magpie]

|

|

|

EmmisonJ

Hazard to Self

Posts: 89

Registered: 5-1-2009

Member Is Offline

Mood: No Mood

|

|

wow very good point, so if i were to use the example that watson.fawkes provided ( http://cgi.ebay.com/NEW-Dayton-1TDR9-Psc-Blower-463CFM-115V-... ) and it says "Mounting: All Position" would that include a vertical mount like

my picture shows or is what i'm trying to do considered non-standard?

also i see in that ebay example above that it's direct drive unlike magpie's which is belt driven. is that what the "plate adapter" is for, to

separate the blower from the direct drive motor which i guess is something you don't worry about on the belt driven models?

[Edited on 10-2-2009 by EmmisonJ]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

wow very good point, so if i were to use the example that watson.fawkes provided ( http://cgi.ebay.com/NEW-Dayton-1TDR9-Psc-Blower-463CFM-115V-... DVWQQrdZ1QQcmdZViewItem ) and it says "Mounting: All Position" would that include

a vertical mount like my picture shows or is what i'm trying to do considered non-standard?

also i see in that ebay example above that it's direct drive unlike magpie's which is belt driven. is that what the "plate adapter" is for, to

separate the blower from the direct drive motor which i guess is something you don't worry about on the belt driven models?

|

I'm not sure that "Mounting: All Position" would include a mounting that places axial stress on the fan bearings. Although I have seen motors

mounted that way. Perhaps someone else on the forum can comment on that.

In answer to your second question: yes.

|

|

|

| Pages:

1

2

3

4 |