Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Anthracene

A member recently asked me whether anthracene can be prepared from napthalene and I had no immediate answer. A few moments with my old pal Merck and

this thread is my answer.

Very pure anthracene can be prepared from synthetic anthraquinone. See citation.

Anthraquinone is prepared industrially from phthalic anhydride and benzene in presence of AlCl3 (Friedel-Crafts acylation).

Merck on phenanthrene

" Isomeric with anthracene. Occurs in coal tar. Isoln: Ostermayer, Fittig, Ber. 5, 933 (1872); Glaser, ibid. 982. Purification (from contaminating

carba zole and anthracene): Clar, Ber. 65, 852 (1932). Formation from toluene, bibenzil, 9-methylfluorene or stilbene by pas sage through red-hot

tube: Graebe, Ber. 7, 48 (1874); Ann. 167, 161 (1879); Ber. 37, 4145 (1904). Also from coumar one and benzene: Kraemer, Spilker, Ber. 23, 85 (1890).

Pschorr syn thesis from o- nitrobenzaldehyde and phenyl acetic acid: Ber. 29, 500 (1896). From diphenylethylene: Cook, Hewett, J. Chem. Soc. 1933,

1098. Diene synthesis from 1-vinylnaph thalene and maleic anhydride: Cohen, Warren, ibid. 1937, 1315. From o- phenylbenzoic acid: Schoumlnberg,

Warren, Chem. and Ind. (London) 58, 199 (1939). By irradiation of stilbene: Mallory et al., J. Am. Chem. Soc. 84, 4361 (1962). Synthesis by double

succinoylation of benzene: Rahman et al., J. Org. Chem. 28, 3571 (1963). Structure: Trotter, Acta Cryst. 16, 605 (1963).'

Phthalic anhydride can be obtained by oxidation of napthalene.

So the answer, at least superficially, is Yes, in two steps.

Napthalene -> phthalic anhydride

Phthalic anhydride + Benzene -> Anthracene

It will take a little more time to get the details, where the devil always hides.

"Obtained from coal tar: Dumas, Laurent, Ann. 5, 10 (1833); Laurent, Ann. 34, 287 (1840); Anderson, Ann. 122, 294 (1862); J. Chem. Soc. 15, 44 (1862);

Auerbach, Das Anthracen und seine Derivate (Braunschweig, 1880); Perkin, J. Soc. Arts 27, 572 (1879); Lunge, Coal Tar and Ammonia (1916); Barnett,

Anthracene and Anthraquinone (London, 1921); Nanson, Textile Colorist 48, 605, 678, 751 (1926); 49, 19, 246, 557, 593 (1927); Houben, Fischer, Das

Anthracen und die Anthrachinone (Leipzig, 1929); Borrmann, Der Teer (Leipzig, 1940); Schumann, Kokereiteer (Stuttgart, 1940). Extensive patent

literature on purification. Prepn of very pure anthracene from synthetic anthraquinone: Clar, Ber. 72, 1645 (1939). Review: E. Clar,

Polycyclic Hydrocarbons 2 vols. (Academic Press, New York, 1964)."

Purification of anthracene from coal-tar is apparently a matter of some technical difficulty.

Here's Merck on anthraquinone:

: Produced industrially from phthalic anydride and benzene in the presence of aluminum chloride by a Friedel-Crafts reaction: Klip stein, Ind. Eng.

Chem. 18, 1327 (1926). From anthra cene with vanadium pentoxide, sodium chlorate, glacial ace tic and sulfuric acids: Org. Syn. coll. vol. II, 554

(1943). Convenient lab procedure: L. F. Fieser, Organic Experi ments (Heath and Co., Boston, 1964) pp 195-200. Reviews: de Barry, Barnett, Anthracene

and Anthraquinone (London, 1921); Phillips, Chem. Rev. 6, 157 (1929); Houben, Fischer, Das Anthracen und die Anthrachinone (Leipzig, 1929); R. H.

Chung in Kirk-Othmer Encyclopedia of Chemical Technology, Vol. 2 (Wiley-Interscience, New York, 3rd ed., 1978) pp 700-707."

[Edited on 11-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

sparkgap

International Hazard

Posts: 1234

Registered: 16-1-2005

Location: not where you think

Member Is Offline

Mood: chaotropic

|

|

It fluoresces a nice blue, but back when I was working with anthracene, my real target was preparing triptycene (anthracene + a suitable benzyne

precursor like diazotized anthranilic acid). Fun.

sparky (~_~)

"What's UTFSE? I keep hearing about it, but I can't be arsed to search for the answer..."

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Sauron, I believe he mass U2U'd us, or at least U2U'd several members. I got the same question as well as one about what to do with trichloroethylene.

Industrially, the production of phthalic anhydride is done by catalytic oxidation of naphthalene with oxygen gas. I haven't done a thorough search,

but I get the feeling a lab scale version of this procedure would be highly impractical and cracking an aromatic ring open by oxidation is probably

not too easy to do. Phthalic acid and it's anhydride are large scale industrial chemicals and should be procurable without too much hassle. IIRC,

there have been some experiments on mass-extraction of plasticizer from shower curtains and subsequent hydrolysis to yield the free acid on this

forum. I seem to recall it was fairly cheap and straightforward.

[Edited on 11-11-08 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

yES, PHTHALIC ANHYDRIDE IS FILTHY CHEAP, AND YES, THE OXIDATION FROM NAPTHALENE MIGHT BE A MESS ON BENCH SCALE. tHAT IS WHAT i MEANT BY THE

SUPERFICIALITY REMARK AND THE DEVIL BEING IN THE DETAILS. Sorry about the all caps. I accidentally hit the caps lock and did not notice. No intention

to shout!

Here is the take from Ullmann's:

3. Production

Four processes are used in the industrial production of anthraquinone today:

1) Oxidation of anthracene with chromic acid

2) Vapor-phase oxidation of anthracene with air

3) Naphthalene process

4) Synthesis from phthalic anhydride and benzene

Anthraquinone is produced from anthracene, where this is available from coal tar, either by oxidation with chromic acid in 48 % sulfuric acid or by

oxidation with air in the vapor phase. The oxidation with chromic acid is competitive, provided that the chromium(III) sulfate lye formed can be

processed to tanning agents. Anthracene with purity of ² 94 % is required for both oxidation processes; crude anthracene from coal tar must be

purified by recrystallization.

About 85 % of world production today is based on the oxidation of anthracene. Since the mid-1970s, anthracene production has fallen continuously,

creating a supply shortage. Therefore, the complex naphthalene process is gaining in importance. There is an adequate supply of naphthalene in coal

tar. If necessary, additional naphthalene can be isolated from the residual oils of gasoline reforming, a process common in the United States.

In the new naphthalene processes developed in Japan by Kawasaki and in Europe by Bayer anthraquinone is synthesized in three steps: Naphthoquinone is

prepared by vapor-phase oxidation with air. Butadiene is added to this naphthoquinone in a Diels-Alder reaction. The tetrahydroanthraquinone formed is

oxydehydrogenated. In this naphthalene process a significant amount of phthalic anhydride byproduct is produced.

In the synthesis of anthraquinone from phthalic anhydride and benzene approximately 1.4 t of aluminum chloride and 4 – 6 t of sulfuric acid per ton

of anthraquinone are used. This procedure is used in areas where anthracene is not available in sufficient amounts from coal tar. It may become

important again, as a result of the shortage of anthracene. Phthalic anhydride has become available at low prices and in sufficient quantities

following the introduction of the economical oxidation of naphthalene or o-xylene with air.

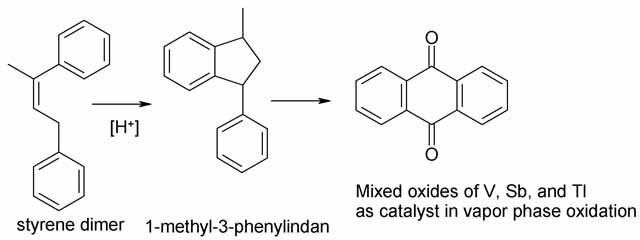

In the early 1970s another interesting anthraquinone process was developed by BASF. Styrene is first dimerized to 1-methyl-3-phenylindane in the

presence of an acid catalyst, which is then converted to anthraquinone in the vapor phase by oxidation with air.

(Sections 3.1 and 3.2 are ommited as they are concerned with anthracene -> anthraquinone. -Sauron)

3.3. Naphthalene Process

The naphthalene process developed by Kawasaki Kasei Chemicals [9] consists of three steps. In the first step naphthalene is oxidized in the gas phase

with air on a vanadium pentoxide catalyst to produce the relatively unstable naphthoquinone (4). Large amounts of phthalic anhydride form at the same

time. Because most of the naphthalene reacts, recycling of unreacted naphthaline is not necessary [10][11][12][13].

.

The hot reaction mixture is precooled in a gas cooler and then quenched and washed with water in a tower. The naphthoquinone is obtained mixed with

phthalic acid anhydride (or phthalic acid) as a suspension in water. The naphthoquinone is extracted with an aromatic solvent, for example xylene or

tetrahydroanthraquinone, to separate it from the phthalic acid. The small residue of acid is carefully removed by washing with dilute alkali

[14][15][16].

In the second step the naphthoquinone is reacted with butadiene in a Diels-Alder reaction to give 1,4,4 a,10 a-tetrahydroanthraquinone (5). The

Diels-Alder product is separated from unreacted naphthoquinone by extraction with aqueous alkali, which converts the quinone into a water-soluble

alkali-metal salt. The organic phase, which contains naphthoquinone, is recycled to the first step [10] , [11] , [17].

In the third step the aqueous tetrahydroanthraquinone solution is reacted with air. The anthraquinone that forms is insoluble in aqueous alkali and

can be isolated by filtration. The aqueous alkali is recycled into the tetrahydroanthraquinone extraction step [18]. The anthraquinone can be purified

further by vacuum distillation [9].

Phthalic acid is isolated from the aqueous phthalic acid solution by crystallization and filtration. It is heated to convert it to phthalic acid

anhydride. The phthalic acid anhydride can be further purified by distillation.

Kawasaki Kasei Chemicals operates a plant based on the naphthalene process that produces 3000 t/a. The plant has been in operation since 1980.

In Bayer's variation of the naphthalene process, naphthalene is oxidized with a mixture of air and recycled reaction gas on a vanadium pentoxide

catalyst to give naphthoquinone, phthalic acid anhydride and unreacted naphthalene [19][20][21]. The products of the oxidation along with unreacted

naphthalene are quenched and condensed into a liquid reaction mixture, which is reacted without purification with butadiene [22] , [23]. The

Diels-Alder product mixture that contains tetrahydroanthraquinone is reacted with air. The tetrahydroanthraquinone is oxydehydrogenated to give

anthraquinone. The naphthalene is removed by distillation [23][24][25]. The two end products, anthraquinone and phthalic acid anhydride, are separated

by fractional distillation [26].

3.4. Synthesis from Phthalic Anhydride and Benzene

In the first step o-benzoylbenzoic acid (6) is prepared from phthalic anhydride and benzene by a Friedel-Crafts reaction. In the second step

the o-benzoylbenzoic acid is cyclized to anthraquinone by heating with concentrated sulfuric acid. The primary product of the Friedel-Crafts reaction

is an aluminum chloride complex of the o-benzoylbenzoic acid, which can harden easily to form a compact mass in the reaction vessel. Several methods

have been proposed to overcome this problem. Based on a process described by G. HELLER already in 1906, condensation is carried out in excess benzene

to give yields of more than 95 %. Patents issued to Klipstein & Sons and the I. G. Farbenindustrie from 1923 to 1927 describe a solvent-free

process carried out in ball mills. The problem posed by the reaction mixture's baking can be reduced by adding ethylene glycol or 1,4-butanediol,

which causes a reduction in the necessary excess benzene or makes a solvent-free process possible. For both processes batch processing is used even

today.

Phthalic anhydride, benzene, and aluminum chloride in a molar ratio of 1 : 1 : 2 are allowed to react below 45 °C in iron ball mills fitted

with hollow axles for the addition of benzene and the removal of the hydrogen chloride formed during the reaction, or in a vessel equipped with a

strong horizontal agitator, possibly propelled from the bottom. The reaction mass, which is heterogeneous at first, liquefies, then gradually becomes

viscous as hydrogen chloride is continuously lost, and eventually forms a powder. During the reaction there is extensive foaming, producing several

times the original volume, a fact that must be considered when the charge is measured out. The reaction is complete after 1 mol of hydrogen chloride

per mol phthalic anhydride has been evolved. The reaction product is placed into dilute acid. The precipitated o-benzoylbenzoic acid is separated,

washed, and dried, providing a yield of more than 95 %.

3.5. Styrene Process

This process was developed in pilot by BASF.

Styrene dimerizes in the presence of acid catalysts, such as sulfuric acid [27] , [28] , phosphoric acid, or boric acid [29] , yielding primarily

1,3-diphenyl-2-butene, which cyclizes further on the same catalyst to 1-methyl-3-phenylindane [6416-39-3]. The yields obtained in this step are 85 –

90 %.

1-Methyl-3-phenylindane is converted directly to anthraquinone by oxidation with air in the vapor phase [30].

Basically, the same catalysts are used as those employed in the gas-phase oxidation of anthracene with air, i.e., vanadium compounds, primarily

vanadium pentoxide in combination with other oxides, such as thallium oxide and antimony oxide [31].

Yields of » 77 % are obtained in the oxidation stage. Byproducts are still attached to the precipitated reaction product, and further purification is

necessary.

8. References

ï [9] Kawasaki Kasei Chemicals Ltd., Research and Development in Japan awarded the Okochi Memorial Price, 1980, Okochi Memorial Foundation.

ï [10] Kawasaki, JP 5108256, 1974.

ï [11] Kawasaki, JP 5108257, 1974.

ï [12] Kawasaki, JP 5322559, 1978.

ï [13] Kawasaki, DE 3033341, 1980.

ï [14] Kawasaki, JP 5251356, 1975.

ï [15] Kawasaki, GB 2039897, 1978.

ï [16] Kawasaki, JP 5422246, 1979.

ï [17] Kawasaki, US 4412954, 1981.

ï [18] Kawasaki, JP 5652434, 1981.

ï [19] Bayer, DE 2532422, 1975.

ï [20] Bayer, DE 2453232, 1974.

ï [21] Bayer, DE 2532365, 1975.

ï [22] Bayer, DE 2532388, 1975.

ï [23] Bayer, DE 2218316, 1972.

ï [24] Bayer, DE 2245555, 1972.

ï [25] Bayer, US 4284576, 1975.

ï [26] Bayer, DE 2532450, 1975.

ï [27] J. Risi, D. Gauvin, Can. J. Res. Sect. B. 14 (1936) 255.

ï [28] P. E. Spoerri, M. J. Rosen, J. Am. Chem. Soc. 72 (1950) 4918.

ï [29] BASF, DE 2064099, 1970.

ï [30] BASF, DE 1934063, 1969.

ï [31] BASF, DE 2135421, 1971.

ï

[Edited on 11-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

In the last post I emphasized in bold the phthalic acid -> o-benzoylbenzoic acid -> anthraquinone route simply because it appears to be the most

practical to do in a home lab.

So the problem devolves to:

a) Do we try to get to phthalic anhydride from napthalene? Or

b) Do we just buy it or prepare it from, say, o-xylene?

I seem to recall that "Fundamental Processes of Dye Chemistry" has prep of phthalic anhydride.

It is also a good time to look for bench scale preps of o-benzoylbenzoic acid.

And it is appropriate to see what is entailed in that Clar, Ber. 72 1645 (1939) reference from Merck for anthraquinone -> anthracene.

I would also like to know why the member who mass-PM'd the rest of us about this failed to take these simple and obvious steps himself?

Three pages from "Fundamental Processes of Dye Chemistry" detail the lab prep of phthalic anhydride by air oxidation of napthalene vapor over V2O5 on

pumice at 450 C. It is stated that 20 g can be obtained if the proper temperature and throughput is maintained and that if so the product is

chemically pure.

Several of us have commercial tube furnaces and several others have built their own and posted about it. 450 C is not an onerous temperature

requirement. V2O5 is not hard to get and pumice support is commonly available in a variety of sizes. Here 3mm is preferred. The rest of the apparatus

is well described and illustrated. So making phthalic anhydride in the lab from napthalened is perfectly possible. Personally I'd just buy it, but

never mind. That part of the question has been answered.

Now let us ferret out the gremlins in the anthraquinone prep and the anthracene prep from that.

I will go get the Ber. citation and DOI for that paper and request from References.

[Edited on 11-11-2008 by Sauron]

Attachment: Pages from fundamental_processes_of_dye_chemistry.pdf (190kB)

This file has been downloaded 1036 times

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Org.Syn. Collective Volume 1 has two preps by the great Louis Fieser, the first of p-toluyl-o-benzoic acid, from phthalic anhydride and toluene with

AlCl3; the second treating that with hot fuming H2SO4 to obtain 2-methylanthroquinone.

These amply illustrate the identical reactions with benzene rather than toluene to yield 2-benzophenonecarboxylic acid (benzoyl-o-benzoic acid) and

from it, anthroquinone.

Now we only need to await the Clar paper from Ber. detailing the Zn reduction of anthraquinone to anthracene.

If no demons pop up, this tale will have been told.

I have combined the pair of Org.Syn.writeups into a single PDF for convenience and to keep vulture from flexing his talons at me for multiple

postings.

[Edited on 11-11-2008 by Sauron]

Attachment: CV1P0353.pdf (298kB)

This file has been downloaded 1643 times

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

We did not have a long wait for the Ber. paper thanks to vovan79.

Paper is attached. The zinkstaubschmelze = zinc dust melt. This is prepared from one equivalent of the anthraquinone, 1 equivalent NaCl, 5 equivalents

AnCl2, and 1 equivalent Zn dust in a melt at 210 C. Details on page 1647 at top. Anthracene is separated by sublimation and freed from a small

contaimnant of condensation product by recrystallization.

So that concludes this little adventure into polycyclic hydrocarbon land.

Napthalene -> phthalic anhydride

phthalic anhydride -> o-benzoylbenzoic acid

o-benzoyl benzoic acid -> anthraquinone

anthraquinone -> anthracene

All on your lab bench.

No really outre equipment, nor really exotic reagents.

I doubt it is going to get any easier than this. You can save yourself some bother by buying the phthalic anhydride. But the rest is rather

straightforward.

Have fun!

[Edited on 11-11-2008 by Sauron]

Attachment: Clar_Ber72_1645.pdf (360kB)

This file has been downloaded 950 times

Sic gorgeamus a los subjectatus nunc.

|

|

|

kazaa81

Hazard to Others

Posts: 368

Registered: 30-4-2004

Member Is Offline

Mood: ok

|

|

| Quote: | Originally posted by sparkgap

It fluoresces a nice blue, but back when I was working with anthracene, my real target was preparing triptycene (anthracene + a suitable benzyne

precursor like diazotized anthranilic acid). Fun.

sparky (~_~) |

yes but it seems to photodimerize under UV light, changing in physical properties; wiki says it can be reverted with UV below 300nm, though

sublimation could revert it as well if I'm right.

picture

@Sauron: thank you, I agree there couldn't be a simpler procedure.

[Edited on by kazaa81]

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

@kazaa81

You are welcome. Anytime.

Sic gorgeamus a los subjectatus nunc.

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Perhaps I should explain why I selected the phthalic acid route to anthracene for amatuer purposes, and rejected the two alternatives, i.e.,

napthoquinone and styrene dimerization respectively.

The napthoquinone method starts off much like the phthalic acid route with air oxidation of napthalene vaport over V2O5 on pumice support. The

differene is that throughput is increased to optimize for napthoquinone, although lots of phthalic acid is still produced and must be removed. That

seperation is objection No.1. Objection No.2 is the next step: Diels Alder with butadiene. Well, you could buy a cylinder of butadiene or you could

make your own using an apparatus essentially identical to a ketene lamp, q.v. in Org.Syn. The question is whether or not you would want to in a home

lab.

From that point themethod looks reasonably tame.

The styrene process takes a different long way round to get to anthroquinone, and has no apparent advantage over the others. The real objection from

my point of view is that the air oxidation to anthraquinone employs thallium oxide in addition to vanadium and antimony oxides, and I think thallium

oxide is simply too toxic to much around with in a home lab. Furthermore the product is impure and requires further workup before it can be reduced to

anthracene.

So proceeding from phthalic acid (DIY or commercial) is shorter. The Friedel-Crafts step in about quantitative. The cyclization requires 20% fuming

H2SO4 (20% SO3) but the lit says conc H2SO4 can be used with longer reaction times and lower yields.

[Edited on 13-11-2008 by Sauron]

Sic gorgeamus a los subjectatus nunc.

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

I made some anthracene from benzene and phthalic anhydride. The phthalic anhydride can be obtained off of Ebay. The aluminum chloride is the problem.

This will have to be purchased from a chemical supplier. Alfa Aesar around $30 for a kilogram. The benzene will have to be made or purchased. I

recommend this lab to any one who is serious about amateur organic chemistry. Drain cleaner grade sulfuric acid can be used in the cyclization step.

The procedure is available for a gram scale synthesis in the williamson organic lab book. Sodium dithionate for the reduction step can be produced by

reducing sodium metabisulfite in an alkaline solution with zinc dust. Most of these chemicals can be obtained off of Ebay.

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

I am planning on repeating part of this experiment soon. I have around 30 grams of o-benzoylbenzoic acid and some anthraquinone synthesized from the

benzoylbenzoic acid. Using the procedure in the Williamson textbook I plan to reduce the anthraquinone to anthrone with tin (II) chloride and then use

the zinc dust reduction to produce the anthracene. I synthesized the o-benzoylbenzoic acid from benzene and phthalic anhydride using an aluminum

chloride catalyst. I then used 92% sulfuric acid to close the ring to produce the anthraquinone. After adding water, the anthraquinone precipitates as

a light yellow-brown powder. I will be posting more information as I work on this experiment.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Nice work! Please do give us more deatails when possible!

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

Outer

Harmless

Posts: 38

Registered: 24-11-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by benzylchloride1

Using the procedure in the Williamson textbook I plan to reduce the anthraquinone to anthrone with tin (II) chloride and then use the zinc dust

reduction to produce the anthracene. |

I think, that one-step reducing of antraquinone by zinc/HCl (without tin (II) chloride) also must be possible.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

It certainly would not be selective for Anthracene, but does anyone have thoughts on just cooking toluene with AlCl3?

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Just refluxing AlCl3 in toluene does nothing. Refluxing AlCl3 in toluene with prior saturation with HCl gas is supposed to lead toward Friedel-Crafts

transmethylation (methyl groups disproportionation) yielding xylenes and benzene, but I have yet to find a paper describing this. There are several

papers describing Friedel-Crafts transethylation and other transalkylations from ethylbenzene and other alkylbenzenes respectively (using HAlCl4,

HAlBr4 or HBF4 as acids), but the ethyl, isopropyl, not to even mention benzyl or t-butyl groups, transalkylate so very, very much easier

than the methyl. Therefore I have some doubts that toluene can even be transmethylated at all.

By the way, what does treating toluene with acids have to do with anthracene?

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

Outer

Harmless

Posts: 38

Registered: 24-11-2008

Member Is Offline

Mood: No Mood

|

|

May be, he mean the possibility of oxidative dimerization of toluene (like benzyl chloride) to 9,10-dihydro-anthracene, and then to anthracene.

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

I just ran the entire reaction from O-benzoylbenzoic acid to anthracene. The yield of anthraquinone from the O-benzoylbenzoic acid was around 45% due

to the acid being the monohydrate and the sulfuric acid was only 92%. Next time I plan on recrystallizing the acid from water and placing the dry

product in my rotovap and pulling a vacuum and heating the flask in a boiling water bath until the solid has a constant weight. The O-benzoylbenzoic

acid crystallizes as a monohydrate. The reduction from anthraquinone to anthrone went fairly well. The anthrone was obtained with a yield of about

82%. The reduction has to be followed exactly as stated in the Williamson textbook or else the anthraquinone will not be reduced completely by the tin

(II) chloride. I do not have sodium dithionate and so I did not use the dithionate reduction method. I think that the dithionate reduction would be

better because glacial acetic acid would not be required due to its expense. The reduction of the anthrone to anthracene worked well. The anthracene

was obtained as a yellowish crystalline solid that melted at 216 c, the literature value for anthracene. The yeild was around 50%, but I am still

working up the residual toluene that was used for cystallization. I just got my rotary evaporator to work and it has been a major help with this

experiment. I plan to use the anthracene to trap benzyne generated from anthranillic acid and isopropyl nitrite to produce the interesting cage

structured hydrocarbon, trypticene using the procedure in the Williamson textbook.

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

I came across a reference to Anthracene/Phenanthrene a few years ago whilst researching organic semiconductors.

At that time i had no idea of the Complexities involved, and followed a suggestion that it could be a component of 'partially oxidised organic

material', so i burnt some dry weeds in a metal bucket with some tinfoil (about 4" x 4") hanging from the bucket lid, which was put on after the weeds

caught fire.

After about 1 hour in the smouldering bucket, surprisingly i found a voltage of around 0.3V between the aluminium foil and two points on the tarry

coating in strong sunlight.

Unscientific i know, but it impressed me at the time.

|

|

|

Polverone

Now celebrating 21 years of madness

|

Thread Split

15-11-2014 at 12:55 |

|