| Pages:

1

2

3

..

8 |

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

homebuilt fume hood

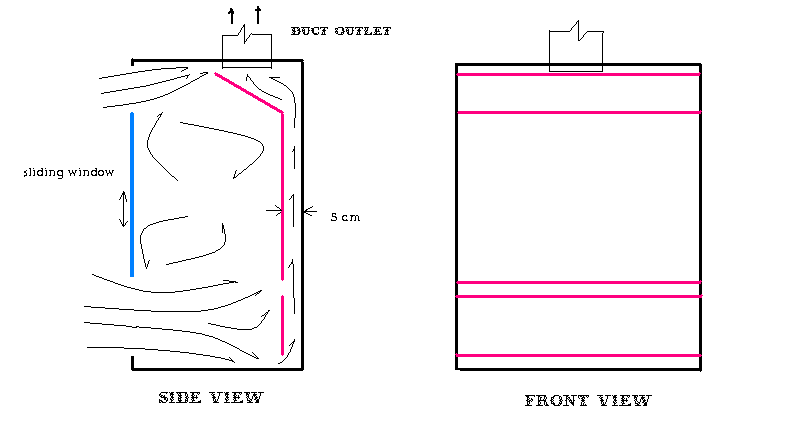

Sideview of fumehood

Like this?

the 5cm from the back of the hood you were mentioning.

Do you mean 5cm space between the baffle and the backwall or do you mean around the edges?

Frontview

I was bored and I made another one just for clarity and practising my paint skills.

[Edited on 2-9-2008 by DNA]

[Edited on 2-9-2008 by DNA]

[Edited on 2-9-2008 by DNA]

[Edited on 9-9-2008 by Polverone]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

Do you mean 5cm space between the baffle and the backwall or do you mean around the edges?

|

The backwall. The baffles are tight up to the edges.

I will prepare a couple sketches to show you what I mean. I need to learn how to use "paint" I guess. I'm a troglodyte and don't even know if I

have that capability on my computer.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

[Edited on 2-9-2008 by Magpie]

Oops! Somehow during my edit I lost the text to my message. I reconstruct as:

Here is the sketch of the hood baffles. Keep in mind that the baffles do not in themselves create suction. They are there to direct air

flow. Adequate suction requires a sufficiently large blower and duct size to provide sufficient airflow. Sufficient airflow in turn gives

sufficient "face velocity," previously defined.

If you have any further questions let me know.

[Edited on 2-9-2008 by Magpie]

[Edited on 2-9-2008 by Magpie]

[Edited on 2-9-2008 by Magpie]

|

|

|

Picric-A

National Hazard

Posts: 796

Registered: 1-5-2008

Location: England

Member Is Offline

Mood: Fuming

|

|

ozone labs, what do you use your nitrogen for? a inert gas?

On my home built fume hood it doesnt extract the gas well, i often find it pushes it back at me,

will those air foils stop that?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

On my home built fume hood it doesnt extract the gas well, i often find it pushes it back at me, will those air foils stop that?

|

A fume hood shouldn't do that - that defeats the purpose of the hood.

Whether baffles will solve this problem or not is hard to say without knowing your configuration in detail. They might.

I would take a look at the configurations shown on the Kewaunee Scientific Corporation website (and others). See if you can modify to their designs.

At least you might get some ideas for improving your air flow pattern.

[Edited on 2-9-2008 by Magpie]

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

I found a table for airsuction in fumehoods after searching for a while.

It might be useful for the people that already made a fumehood and ofcourse the people planning on making one. The information below is for the

industry and university's in The Netherlands as defined by the law.

Standard fume hood:

Cabinet width 100 cm: 450 - 630 m3/h

Cabinet width 120 cm: 540 - 756 m3/h

Cabinet width 150 cm: 675 - 945 m3/h

For all above mentioned sizes with the sash opened for 50cm there should be a flow of 0,25 - 0,45 m/sec.

If one has cupboards below the fumehood then that room should be refreshed 20 times (8,5 m3/h) an hour by

the suction in the fume hood.

The fan should not make more noice then 45 dB(A).

I looked back to what my fan does...*shame* 88.3 m3/h

WAY too little so I'll be getting myself an  expensive squirrel-cage fan but hey

look at the positive side of it, I'll probably keep living expensive squirrel-cage fan but hey

look at the positive side of it, I'll probably keep living

[Edited on 3-9-2008 by DNA]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

Standard fume hood:

Cabinet width 100 cm: 450 - 630 m3/h

Cabinet width 120 cm: 540 - 756 m3/h

Cabinet width 150 cm: 675 - 945 m3/h

For all above mentioned sizes with the sash opened for 50cm there should be a flow of 0,25 - 0,45 m/sec.

|

That's some good information DNA. For US usage I converted the figures for the 120cm (47.2 inches) width hood:

flow: 317 - 441 ft3/min

face velocity: 0.82 - 1.46 ft/sec

There really is no substitute for an adequate flow.

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

Just got myself a 1000 m3/h "squirrel-cage" fan 8" (20cm diameter) for 80 euro's (new price 208 euro).

Did you attach the fan at the beginning (above the hood) or at the end of the ducting (exhaust pipe)?

Has anyone got an idea to measure the airflow in m/sec. at the sash opening?

Also leave enough space between the hood and yourself so that you don't obstruct the airflow going inwords.

Do mind that little bobble at around your stomach hight, this is quite important for the airflow.

In understanding url you can see a animated picture of airflow of a new and a old fumehood.

The text says that with the new fumehood when opening/closing the window the vortex is not disrupted, while as you click the button you see the vortex

being disrupted of the "old" fumehood.

I tried to make a drawing of the baffles of the new one:

http://www.splusb.nl/sb2003/ZK_product/zk_werking.asp?link=0...

[Edited on 4-9-2008 by DNA]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

Just got myself a 1000 m3/h "squirrel-cage" fan 8" (20cm diameter) for 80 euro's (new price 208 euro).

Did you attach the fan at the beginning (above the hood) or at the end of the ducting (exhaust pipe)?

|

Wow! That's quite some blower, and for a good price too.

You could vent a 5 ft (150cm) wide hood with that!

I placed my blower at the end of the duct. Commercial applications usually do this by placing the blower on the roof. Mine is just inside the garage

attic wall. You can see it in the rafters in one of my pictures early in this thread. For air movement I don't think it matters where the blower is

placed. However, having it at the end keeps the ducting under suction. This is better for any small duct joint leaks,etc, I think. Edit: Also,

it gets the blower noise as far away from you as possible. Although I have read that most of the noise is just due to the air rushing through the

ducting.

Your sketches show a hood with variable opening. By changing this opening you will change the face velocity. This is something you should give some

thought: Do you want a varable area opening or a fixed area opening? I have a fixed area opening. My face velocity is constant no matter where I

place my sliding window.

Edit:

That seems to be a high capacity blower for a 20cm opening. What is the blower rpm? Also, is the inlet to the blower on one side only, or both

sides? If on both sides I suppose you will have to blank off one side somehow. Or construct a huge inlet plenum. I hope you don't have to do that.

[Edited on 4-9-2008 by Magpie]

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

I have the option on two fans I will show them below and their specs.

Left: 90 euro, brand: FMV "lamel", type is C180x180, 800 m3/h, speed is adjustable.

Right, 80 euro, 1000 m3/h @ 50 Pa, 2550 rpm, speed not adjustable.

What do you mean with a varable area or fixed area opening, when you have a slide window I thought it was varable and when your window cannot slide it

is fixed or do you mean something else?

What fan would you prefer?

About the right one it says "can be placed horizontally and vertically in ducts" So I'm afraid this one has two openings where a tube needs to be

attached.

Right fan:

http://img175.imageshack.us/img175/4114/afb024ic0.jpg

http://img66.imageshack.us/img66/1393/afb025ev4.jpg

http://img98.imageshack.us/img98/764/afb026aat7.jpg

Left fan:

http://img360.imageshack.us/img360/9241/dsc00477fj9.jpg

http://img352.imageshack.us/img352/1019/dsc00478wj6.jpg

http://img156.imageshack.us/img156/2875/dsc00479km4.jpg

Magpie could you look at what one I need I think I need the left fan as it is adjustable in speed and it is an actual squirel cage fan and the right

one well...I don't know it is 1000 m3/h which is a lot I also don't want powders being sucked up from the working floor of the fumehood into the

fan...and it needs to be placed inside a tube and the other one more looks like commercial suction of fumehoods.

[Edited on 5-9-2008 by DNA]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

DNA I am concerned that neither of those blowers may be good for a lab fume hood.

1. My first concern is the placement of the motor. In the one on the right it is definitely right in the path of the vapors. I wouldn't recommend

this for chemical and solvent fumes. I'm not sure about the one on the left but its motor also looks like it may be exposed to the fumes.

2. I am also concerned about the 50 Pa pressure drop. This equates to 0.20 inches of water static pressure. My blower is rated at 475 ft3/min at

0.75 inches of water static pressure. So your 50 Pa blower may be good for moving a lot of air but only at a low duct resistance.

In the following thread I explain more fully the difference between a fixed hood opening area and a variable hood opening area, and their effect on

face velocity. Also I show a picture of my blower. As you can see it is belt driven. This removes the motor from the path of the fumes. Also, what

you can't see is that the back side of the blower is blanked off, so it sucks air only on the front face of the squirrel cage. This makes it easy to

attach to the end of the duct.

http://sciencemadness.org/talk/viewthread.php?tid=10425&...

Please understand that I am not trying to discourage you from getting a blower, quite the contrary. I just don't want to see you spend a lot of money

for one that will not do the job.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Magpie

2. I am also concerned about the 50 Pa pressure drop. This equates to 0.20 inches of water static pressure. My blower is rated at 475 ft3/min at

0.75 inches of water static pressure. So your 50 Pa blower may be good for moving a lot of air but only at a low duct resistance.

|

The full rating for a motor includes a graph relating volume flow vs. static pressure. Many times a vendor

will only quote a single point on this graph (and typically on one of the axes, an unrealistic operating point). It may be that this fan is just fine

for you, but you need some idea what the static pressure is. There are tables all over the HVAC world for such estimation. The main parameters are

diameter of duct, length of straight runs, and the number and geometry of bends and joins.

There's something of a risk of specifying a fan that's too strong for a hood. When face velocity gets too high, that itself creates eddy currents and

diminishes containment (which is, after all, the actual goal). If you fear that might be the case, install a damper in the duct line or a

variable-frequency drive on the fan motor.

Finally, allocate a little extra static pressure at the outlet. This prevents outside winds from temporarily blocking or even reversing the air flow

through the duct.

|

|

|

tapira1

Hazard to Others

Posts: 168

Registered: 9-10-2006

Location: Here!!!

Member Is Offline

Mood:

|

|

Hood

In order to be able to have any opening in the window of the hood, I have added a couple of counterweights linked to the window through steel cables

and running through a poley (at both sides); the counterweighs weigh as much as the whole window. The window stays at the exact position where you

leave it; there is no risk of moving down "accidentally"

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

I found the datasheet of pressures of the right fan.

The left one I will look for but for so far the right one.

http://rapidshare.com/files/143588026/ck_grafiek.pdf.html

It's the 200 model.

[Edited on 8-9-2008 by DNA]

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

Would it be unreasonable to ask that the hood/blower conversation become a new thread so that this one can remain on topic?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

homebuilt fume hood

As suggested I have started this thread for the discussion of design and construction of homebuilt fume hoods.

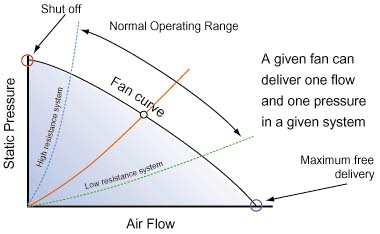

As indicated by watson.fawkes selection of an appropriate blower (or fan) should be based not only on the characteristics of the blower but on those

of the ducting as well. The ducting will provide a certain static pressure resistance to a given flow. The blower will be able to deliver a certain

airflow at a given static pressure resistance. This is shown in the diagram below.

The resistance curve is in red, and the fan curve is in black. Where these two curves intersect is the "operating point." This determines the fume

hood airflow.

Fan curves can be obtained from the fan manufacturer. Determining the duct resistance curve is trickier. As watson.fawkes has indicated this must be

calculated based on duct ID, duct length, number and type of elbows, reducers, increasers, duct smoothness, etc, and airflow.

I calculated my duct resistance to be about 0.75 inches of H2O at 475 ft3/min airflow. This matched a point on my fan curve. On this basis I judged

my hood/duct design and blower selection to be acceptable. Ideally all of this design work is done before any procurement of materials is started.

If all these calculations seem overwhelming then you are left with making fan and duct design selections based on the successful experience of others.

Using some good judgement you will likely do OK.

Here is some of the text that came with the diagram below:

"The governing principle in fan selection is that any given fan can only deliver one flow at one pressure in a particular system. This "operating

point" is determined by the intersection of the fan static pressure curve and the system pressure curve. Figure 3 illustrates the operating points of

both high and low resistance systems. It is best to select a fan that will give an operating point being toward the high flow, low pressure end of the

performance curve to maintain propeller efficiency and to avoid propeller stall. Each particular electronic packaging system should be analyzed for

possible reduction in the overall resistance to airflow. Other considerations, such as available space and power, noise, reliability, and operating

environment should also be brought to bear on fan choice."

|

|

|

jarynth

Hazard to Self

Posts: 76

Registered: 12-8-2008

Member Is Offline

Mood: No Mood

|

|

First of all, congratulations on your beautiful fume hood, perfect construction skills and an overall efficient lab. I believe appropriate apparatus

is mandatory for successful amateur science. In chemistry, sometimes even more so than purity of reagents.

Unfortunately most of my lab is still boxed, but I do have a thin long centrifugal fan at hand, bought for the explicit purpose of building a hood but

never used. It's very quiet, hence probably too weak (I don't have the data with me) even for a midget-sized hood. It looks almost like this one:

http://www.eol.ucar.edu/lidar/real/ncar_cell/squirrel_cage.J...

The intention was to have a laminar flow window as in professional applications. That would have probably required another exhaust fan. Well, I was

just a confused teenager

Furthermore, I gleaned from the discussion in the 'Tour My Lab' thread that the fan should be placed as far as possible from the hood, for best

suction. Can you still envision a way I can salvage my fan and still build a fume hood for the more benign reactions, or at least a chemical closet?

Best of luck with your projects and keep up the good work!

[Edited on 8-9-2008 by jarynth]

[Edited on 8-9-2008 by jarynth]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Jarynth thanks for the kind comments.

| Quote: |

Furthermore, I gleaned from the discussion in the 'Tour My Lab' thread that the fan should be placed as far as possible from the hood, for best

suction.

|

No, this is not quite what I meant. I don't think the suction will necessarily be affected. But by having the fan at the end of the duct you keep

the duct under a slight suction. If you place the fan right at the hood the duct would be under a slight pressure. From a containment perspective it

seems better to keep the duct under a slight vacuum.

I have never seen a blower (fan) like that in your picture file. I would love to see its fan curve.  I couldn't comment on its use without seeing the curve. Also I'm prejudiced against any blower that has its motor in

the path of the fumes. I couldn't comment on its use without seeing the curve. Also I'm prejudiced against any blower that has its motor in

the path of the fumes.

|

|

|

497

National Hazard

Posts: 778

Registered: 6-10-2007

Member Is Offline

Mood: HSbF6

|

|

I am considering building a small fume hood some time in the near future. The biggest hurdle now is finding a good place to put it...

I found a pretty nice squirrel cage fan in an old high powered microwave I found in the dump. IIRC the motor draws at least 250 watts, it seems to

move a lot of air, I don't know the actual number of cubic feet though. I doubt it can do a lot of suction so hopefully my duct path will be very

short. It has plastic blades and housings (there's one on each side of the motor) and I think with a little modification the motor could be pretty

well protected from fumes. I think it would hold up well, except to a few solvents possibly. But I shouldn't be needing to vent large quantities of

any solvent. I guess I'll just have to test it and see how well it works. Anyway, just wanted to say that trashed microwaves are probably a good

source of fans. They're probably not ideal, but hey, they're free!

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

I found the datasheet of pressures of the right fan.

The left one I will look for but for so far the right one.

http://rapidshare.com/files/143588026/ck_grafiek.pdf.html

It's the 200 model.

Here a screenshot of the pdf.

This fan is the one that needs to be placed within a duct.

It has classifications IP44, isolationclass B special impregnated against humidty and moisture. And important the motor is outside the tube so fumes

will not atack the motor...

Still looking for the left one...

[Edited on 9-9-2008 by DNA]

[Edited on 9-9-2008 by DNA]

[Edited on 9-9-2008 by DNA]

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Magpie has already made a new thread.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by jarynth

Unfortunately most of my lab is still boxed, but I do have a thin long centrifugal fan at hand, bought for the explicit purpose of building a hood but

never used. It's very quiet, hence probably too weak (I don't have the data with me) even for a midget-sized hood. |

You're right, it doesn't look anywhere near strong enough to provide adequate face velocity. It could, however, make a reasonable

fan for an air curtain. This is an air flow blowing gently down over the operator. It's placed in front of the fume hood, about a foot over head

height. The flow should be gentle enough not to feel drafty. Air curtains improve the consistency of flow through the face of the fume hood. They

also provide better isolation of breathing air.

| Quote: | | Furthermore, I gleaned from the discussion in the 'Tour My Lab' thread that the fan should be placed as far as possible from the hood, for best

suction. Can you still envision a way I can salvage my fan and still build a fume hood for the more benign reactions, or at least a chemical closet?

|

A weak fan just won't exhaust fumes thoroughly enough. The problem is that in an enclosed room,

contaminants will build up over time. There's just no substitute for an adequate rate of air exchange, and that requires an adequate fan.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Magpie

But by having the fan at the end of the duct you keep the duct under a slight suction. If you place the fan right at the hood the duct would be under

a slight pressure. From a containment perspective it seems better to keep the duct under a slight vacuum. |

What matters is the pressure difference between the face of the hood and the outlet of the hood to its exhaust duct. Any method you

can use to create that pressure difference (at its required value) will move air. You can put a fan at the exhaust port to the outside. You can put

a fan at the hood outlet. You could even make a well-sealed room and use a fan at the inlet to pressurize the entire room. This technique used, for

example, to protect immunosuppressed patients, where you also want the room at positive pressure (with respect to ambient) to ensure that all incoming

air is well-filtered. There's plenty of room for creativity here. The situation of a fume hood inside a laboratory, though, implies that you can

only control the exhaust air, so that's the side where the fan goes.

The best reason to put the fan at the exhaust port is noise control. Moving the fan away from the hood is the first step in controlling fan noise.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by 497

I found a pretty nice squirrel cage fan in an old high powered microwave I found in the dump. IIRC the motor draws at least 250 watts, it seems to

move a lot of air, I don't know the actual number of cubic feet though. I doubt it can do a lot of suction so hopefully my duct path will be very

short. [...] Anyway, just wanted to say that trashed microwaves are probably a good source of fans. |

With a microwave oven fan you might be able to make a hood the size of a microwave oven. If it's strong enough, that is. Which I

doubt, since that fan provides cooling air for the magnetron, not exchange air for a volume of space.

|

|

|

DNA

Hazard to Others

Posts: 191

Registered: 11-6-2003

Location: @moon

Member Is Offline

Mood: Experimenting

|

|

Here is the other one the squirrel cage one...

|

|

|

| Pages:

1

2

3

..

8 |