math

Hazard to Others

Posts: 101

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Iron bar bending force (physics question)

hello everyone,

I've got this physics related problem banging in my head and I don't know how it could be calculated/answered.

Given an iron bar, of round cross-section, fixed by its extremities

(bar measures 152 mm in length and 4.8 mm in diameter),

a weight of 88.5 kgs is hung from its middle, bending it at least

90 degrees.

How much weight/force would be needed to bend another

bar of the same material and size, but of hexagonal or square

section?

I guess the answer relies on calculus skills I'm not aware or lacking of  , maybe

that's why I find this real-life problem that interesting , maybe

that's why I find this real-life problem that interesting  . .

Thank you all in advance

|

|

|

ScienceGeek

Hazard to Others

Posts: 151

Registered: 22-1-2008

Location: Norway

Member Is Offline

|

|

I hate myself right now! I just HAD to read this question, and now as I don't have an answer to it, it will be bugging me until someone is able to

answer it.

It is a very good question, nonetheless. Very good indeed. I am not sure you need calculus to solve it, though. I can't think of any way that you

would...

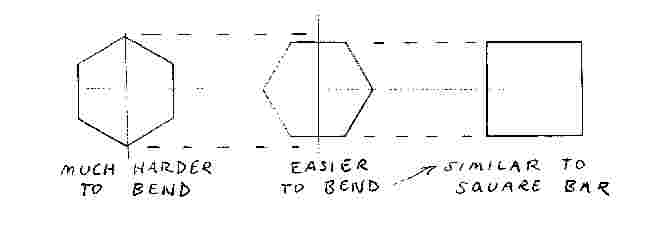

Structurally, a square or hexagonal bar would have different properties compared to a round one. As you bend it, the material will compress and

stretch differently at different "corners", of which I have no idea how to calculate.

Also, a square bar would behave quite differently from a hexagonally formed bar because the hexagonal bar allows itself to be compressed at the point

of bending more easily than the square one. This is because of the shape of a hexagon.

I hope someone is able to figure this one out!

Sorry I couldn't help you more than this

|

|

|

math

Hazard to Others

Posts: 101

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Thank you for spending some time to reply

yes actually the only real life-supposition I can do

is that a bar of same size and material, is more

likely to bend the more "sides" its cross-section has.

For example a round bar takes less force to bend than

an hexagonal one, and in turn that bar takes less force

to bend than a square one...with the above list

ending with a bar of triangular cross-section.

Hope some guru will enlighten us on this subject

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I can't solve this problem but remember from my strength of materials class that a pipe of the same unit mass is much stronger than a rod of the same

unit mass, in bending.

I suspect that the math required to prove the answers to your question would be quite complex and difficult.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

The question is not nearly well enough specified. What are the properties of this iron bar? "Iron" often refers to gray cast iron, which doesn't

bend at all. Some alloys (admittedly, none(?) of them iron alloys) can be bent much tighter than this while in elastic deformation. Pure, annealed

iron will undergo considerable plastic deformation, while spring hard chromium steel will retain considerable elastic force (probably retaining some

plastic deformation).

This question does not specify if the endpoints are allowed to slide or if the bar is rigidly clamped in place. If so, it must be stretching a

considerable amount -- at least 40%, which is more ductile than most alloys!

If the problem were well specified, the complete analytical answer lies somewhere in tensor calculus, because stress and strain can be expressed by a

tensor. Some tensors here:

http://mysite.du.edu/~jcalvert/phys/physhom.htm

Tim

|

|

|

pantone159

National Hazard

Posts: 590

Registered: 27-6-2006

Location: Austin, TX, USA

Member Is Offline

Mood: desperate for shade

|

|

I think the bending involved is so large that permanent deformation is occurring, which makes things 1) far more complicated, and 2) probably

incompletely specified.

When elastic deformation is involved, there are beam equations that can be used, differential equations of some kind, I forget, although I did take a

class in this. (Kind of fun math.) If you are willing to change 'at least 90 degrees' to 'at least 0.9 degrees' then you can make progress.

|

|

|

math

Hazard to Others

Posts: 101

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

thank you for your points 12AXT.

Actually, the question is quite specific and abstract, as it doesn't consider material specifically, costants etc, but rather the DIFFERENCE in

bending forces between two bars of same material and size but different cross-section shape, given the strength of a round one;

so it would have been the same if we'd have considered aluminum bars, zinc bars etc...I wouldn't point out this material issue that much.

Well to be realistic, yes, consider the bar sliding and not stretching of course

Thanks to a friend of mine, I've got two real-life info about iron bar bending (allegedly middle-steel), they could be used to make a percentage

proportion, still usable but not as satisfying as the answer we're searching for:

152 x 4.8mm round section (61.3 kg to bend)

152 x 4.8mm square section (95.3 kg to bend)

178 x 6.4mm round section (108.9 kg to bend)

178 x 6.4mm square section (172.4 kg to bend)

|

|

|

pantone159

National Hazard

Posts: 590

Registered: 27-6-2006

Location: Austin, TX, USA

Member Is Offline

Mood: desperate for shade

|

|

| Quote: | Originally posted by math

Actually, the question is quite specific and abstract, as it doesn't consider material specifically, costants etc, but rather the DIFFERENCE in

bending forces between two bars of same material and size but different cross-section shape, given the strength of a round one;

so it would have been the same if we'd have considered aluminum bars, zinc bars etc...I wouldn't point out this material issue that much.

|

For such a large amount of bending, the specific material will be very important and not neglectable. You are past the point where the material

behaves like a spring and the crystal structure is being permanently changed, and the particular crystal involved will matter very much.

Are you really interested in such a large amount of deformation? That vastly complicates your question.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

I think that the particular material may be irrelevant depending on the exact focus of the question. I am not well versed in engineering, but it

seems like there would be two equations for solid vs tubular, where the metal identity's property would be a constant in each equation, and when

comparing the two that these would cancel out making the exact identity of the metal irrelevant.

Kind of like a physics question in which an object falls to the ground from a certain height in a certain time, find the time it takes to hit the

ground from another height, in which the mass of the object is constant between the two, so one does not need to know it.

Of course the metal bar question is going to involve some much more heavy duty math than my example.

|

|

|

tumadre

Hazard to Others

Posts: 172

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

The material properties matter in this case, because if you notice, the inside edges of a square/rectangular bar can bend outward in permanent

deformation, while the bulk of the bar remains elastic and or plastic.

I have never seen this with a round bar.

if you were to bend the bar back straight, maybe repeat once more, most alloys will break along this inside corner.

but some aluminum alloys will break along the outside, when bending to 90degrees the second time.

A while back a friend of mine and i concluded this is best left to empirical formulas, even though we had access to matlab and a few "educated"

professors.

edit:

152 x 4.8mm round section (61.3 kg to bend)

152 x 4.8mm square section (95.3 kg to bend)

178 x 6.4mm round section (108.9 kg to bend)

178 x 6.4mm square section (172.4 kg to bend)

I find it interesting, that the ratio between the two forces is very close to the ratio of cross sectional area squared. .785^2 = .616

[Edited on 15-6-2008 by tumadre]

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

For a start, this problem is one of "squaring the circle"! Firstly, one has to calculate the lengths of the cross-sections of each side of a square

and of a hexagon with the same cross-sectional area as the circular-sectioned bar. These are simple exercises in geometry.

But after that, the fun starts. One has to calculate the stress required for the permanent deformation of the circular bar, which is reasonably

straightforward from the standard formula for the bending moment. The required stress on bending a square-sectioned bar of the same material can then

be calculated from the bending-moment formula for a square bar, although it is not stated whether the bending of it is parallel to two of the faces or

diagonally, for which there are two different mending-moment formulas. There must be similar bending-moment formulas somewhere for the bending of a

hexagonal bar either at right angles to two faces or diagonally. References such as the "Mechanical Engineer's Handbook", "Mechanical Engineering

Handbook", "Mechanical Engineer's Reference Book", and "Machinery's Handbook" should have these formulas; I will see about finding uploads of them, or

uploading them for the References section.

[Edited on 16-6-08 by JohnWW]

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

This is not a hard question, I'm sure there are standard engineering formulas that can be

applied. The answer will vary depending on the orientation of the bar to the applied

bending force. It's been to long since I took strength of materials to be of further help.

You may also try posting to an appropriate forum here _ http://www.eng-tips.com

|

|

|

Geomancer

Hazard to Others

Posts: 228

Registered: 21-12-2003

Member Is Offline

Mood: No Mood

|

|

[NB: I started writing this last evening, before many of the posts now present were made. Those posts address many of the same issues.]

Generally when materials deform continuously under force they are assumed to behave in a certain way. Up to a point (the "elastic limit") they

behave as springs: the amount they stretch is reversible and directly proportional to the strength of the force. This is the "elastic deformation"

12AX7 was referring to. Beyond the elastic limit they continue to deform, however the amount of force doesn't increase (ideally), and the deformation

is not reversible ("plastic deformation"). So, as 12AX7 noted, the nature of your solution will depend on to what degree you exceed the elastic limit

of your material. If, upon removing the load, the beam springs back to its original shape then you're in luck: you can be certain the deformation was

entirely elastic.

One can easily calculate the degree of bending in a beam if one knows how much plastic deformation has occurred. For example, for pure elastic

deformation the amount of bending force needed to produce a given amount of bending ("flexural stiffness") is proportional to the moment of inertia of

the (symmetric) beam cross section about the axis perpendicular to the applied force, i.e. the integral of the square of the distance (in the

direction of the applied force) to the center of gravity, taken over the entire cross section with respect to area. (The derivation of this is simple

enough: imagine the beam as being composed of parallel fibers. If it's bent into an arc, how much does each fiber need to stretch, and how does this

contribute to the overall bending force ("moment")?) One can find the force required for completely plastic deformation (i.e. plastic throughout the

entire cross section) similarly.

To wit, the moment of inertia of a circle of radius 1 is pi/4 (a somewhat hairy integral to do directly, use the "perpendicular axis theorem"),

whereas that of a square of the same cross sectional area along the axis parallel/perpendicular to the flats is (pi)^2/12, if I haven't screwed

anything up. Thus, for bars of equal length and weight the square bar is stiffer by a factor of pi/3, with the load applied along the flats, and so

the required load for the same (elastic) deflection will be approximately 92.7kg (the assumption being that the deflection is due primarily to

bending). Approximate solutions can be found similarly for the other cross sections. If plastic deformation is occurring, then I suspect that the

desired ratio will be somewhere between the elastic ratio, as above, and the ratio of force for completely plastic deformation (to get this,

approximately, use absolute value instead of the square in the formula for the moment of inertia).

|

|

|

math

Hazard to Others

Posts: 101

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

thinking again, it may be needed a second moment of inertia

defined as

picture

where the area is perpendicular to the axis of bending. The bigger this moment of inertia is, the harder it is to bend or deform the beam, so one can

use proportion to find what is needed.

However it may not be that simple, as it would be too nice to consider that a circle of D diameter has an area that's 78.5% the one of a square with

same diameter, and hence the force required to bending one is 78.5% the one required to bend the other.

[Edited on 30-6-2008 by math]

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

No there is no direct relation. In fact the cross sectional area of the material

can be reduced by for example fluting and the stiffness would be increased,

the principal reason for H and I beam forms. Similarly in building construction,

a segmented beam ( a sandwich of 2 X 12 individual planks interfaces oriented

vertically ) has greater bearing strength than the equivalent monolithic beam.

.

|

|

|

tumadre

Hazard to Others

Posts: 172

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by math

However it may not be that simple, as it would be too nice to consider that a circle of D diameter has an area that's 78.5% the one of a square with

same diameter, and hence the force required to bending one is 78.5% the one required to bend the other.

[Edited on 30-6-2008 by math] |

"The ratio between the two forces is very close to the ratio of cross sectional area squared. .785^2 = .616" (i said that in the ninth post)

(Your data was 64.3 and 63.1% circle vs. square)

It's just a second order relationship. ignoring the differences in geometry. Comparing two circles would be closer to the square of the area ratio.

[Edited on 2-7-2008 by tumadre]

|

|

|