| Pages:

1

..

7

8

9

10

11

..

13 |

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

I mistook my wife today for a hat, but apart from that my mind is OK.

Some more patents

4028215 is a patent that gives a description of Electroplating MnO2 and thermally decomposing painted on Mn Nitrate in alternat layers. They brush off

excess MnO2.

Pat. also uses DTO. This patent has been on the board before AFAIK.

Also 4,267,025 is a patent that mixes Platinum group Oxides with Tin Oxide for Perchlorate production.

J.P. Smith (are you still reading!!!!!!!!) was wondering (a long time ago) wheather or not Pt Oxides would make Perchlorate. They do, (along with Tin

Oxide), according to this patent. Perhaps this was discussed here before and I missed it (or plain forgot).

Take a look at the bottom of this page. It states that the electrodeposited MnO2 is Gamma, heating gives Beta (what we want).

http://www.geocities.com/CapeCanaveral/Campus/5361/chlorate/...

A study of Manganese Dioxide electrodes for Perchlorate production was covered in:

Howard H.C.,Trans. Am. Electrochem. Soc., 43, 51-53 (1923)

Is this article available do yiz think?

Dann2

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by dann2

A study of Manganese Dioxide electrodes for Perchlorate production was covered in:

Howard H.C.,Trans. Am. Electrochem. Soc., 43, 51-53 (1923)

Is this article available do yiz think?

Dann2 |

Couldn't find that online , only in libraries old collections , and on microfilm . That's the older journal name before ECS ,

which is available online only from 1948 to present .

From what I have found it looks like unmodified , undoped

MnO2 won't do the job efficiently or have much endurance in a chlorate or perchlorate cell because it evolves oxygen preferentially . So there is a

need for mixing it with other

oxides in a baked coatings scheme to change the selectivity

to evolve chlorine and to raise the oxygen overvoltage for perchlorate . That probably means doping with cobalt

for the chlorate and/or doping with bismuth for chlorate / perchlorate . And Tin needs to be there in the mix .

The MnO2 can perhaps be omitted entirely , as the BTO may very well do what was hoped that ATO would do but doesn't , produce chlorate and perchlorate

directly from

a DTO which can function as a baked working coating itself .

Here's what I mean . And this is using nitrates precursors ,

or nitrates with some chlorides in oxygen balanced mixture .

Ti or TiH2 / Co2O3(1 or 2 coats) or

..................Co2O3-Ni2O3 (1 or 2 coats)/

..................SnO2(1 or 2 coats)/

..................SnO2-Bi2O3(many coats)

The first coating would probably also work okay and perhaps better with the spinel dopant nitrates ~6%-8% mixed with the tin nitrate . Maybe three or

four coats of that mixture and then follow with the Bi doped SnO2 the same way .

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

| Quote: | A study of Manganese Dioxide electrodes for Perchlorate production was covered in:

Howard H.C.,Trans. Am. Electrochem. Soc., 43, 51-53 (1923)

Is this article available do yiz think? |

My local Uni has this - I will have a copy of the article later today to share with everyone. Hopefully it is useful!

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

So I went and copied the pages out of that 1923 article, which is actually not about MnO2, although it does mention it..

http://www.apcforum.net/files/DSCN7227.JPG

http://www.apcforum.net/files/DSCN7228.JPG

http://www.apcforum.net/files/DSCN7229.JPG

I did look in the index of journals 21-41 for any references perchlorate and did not see anything. I'm sick as a dog and was illegally parked so I

couldn't look through other indexes.

[Edited on 27-2-2008 by tentacles]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Thanks for that Tentacles, hope you get OK.

My mistake I guess.

Cheers,

Dann2

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

No big deal really, it was fun checking out the science library. I think we'd need to find newer research on doped MnO2, if anyone has tried?

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I need to edit my above post , but the editing time limit has expired , I put down the formula wrong for the spinel

component . It should read

Ti or TiH2 / Co3O4(1 or 2 coats) or

..................Co3O4-Ni3O4 (1 or 2 coats)/

..................SnO2(1 or 2 coats)/

..................SnO2-Bi2O3(many coats)

Also in the antimony tin nitrate thread I found an excerpt

from a paper posted by not_important which tends to confirm what I have been thinking is probably the case concerning stannic nitrate being neglected

as a precursor ,

not for any undesirability or unworkability really , but for

its being considered to be an "exotic" precursor , for its unavailability from suppliers due to its short storage life ,

requiring it to be made by the end user . It is then

a matter of convenience which has motivated the use

of alternatives , not necessarily any technical superiority for those alternatives .

I think a bit of ferric nitrate might serve as a stabilizer ,

and reportedy NH4NO3 is a stabilizer although it could be problematic . Acetic acid is another possibility .

One thing I like about the idea of using a stannic nitrate composition as a dip and bake , is the rapidity with which the dipped coating should gel

when heat hits it . It should produce very even coatings staying put long before it

is dried out completely and baked . Its tendency to

vitrify on dehydration instead of dusting is also a desirable

characteristic .

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

anomalously soluble stannic oxalate

There was a mention of this patent US4924017 material about six months ago in the PbO2 thead , but the patent was not attached then . http://www.sciencemadness.org/talk/viewthread.php?goto=lastp...

This particular organotin derivative should be noted because of its relatively easy synthesis , and that it is reportedly possible to use bismuth as a

dopant in this system , as well as other dopants . This is a non-volatile precursor which can develop hard high quality films on baking , and it

*may* also be compatable in mixture with nitrates based precursor

mixtures at low pH . Some additional information on the formation of nitrates and mixed nitrates with chlorides of tin

has been posted in the antimony tin nitrate thread .

http://www.sciencemadness.org/talk/viewthread.php?goto=lastp...

The old tin mordants used by dyers to deposit adherent residues of tin oxide upon cloth for securely binding colorants

to the fiber , is curiously similar technology in several respects with our own efforts at producing doped tin oxide

adherent coatings on titanium . This is precisely the reason

for my recent interest in those old dyers formulations for tin mordants , looking for those compositions which may have value in both arts because of

that similarity . That ancient dyers art is very pertinent and parallel to the present work .

[Edited on 1-3-2008 by Rosco Bodine]

Attachment: US4924017 Stannic_acid_anhydride from oxalate and H2O2.pdf (155kB)

This file has been downloaded 930 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by tentacles

No big deal really, it was fun checking out the science library. I think we'd need to find newer research on doped MnO2, if anyone has tried?

|

Xenoid has the inside track on the patents which are relevant there . Cobalt is definitely a dopant which seems to successfully change the

selectivity from oxygen to chlorine and raise the oxygen overvoltage for MnO2 , and reportedly Bi doping moves things in the same direction and

further ,

which gives the performance required for a perchlorate anode . MnO2 seems to behave similarly as SnO2 in response to both dopants , the usefulness

of MnO2 seems to be that it is a much more conductive material for use as

a solvent oxide for the dopants , and in the combination of

MnO2/SnO2 behaves as a "hybrid SnO2" solvent oxide "eutectic" or cosolvent of a sort for the dopants like

Co and/or Bi . But it is the dopants , the Co and/or Bi , which

are the essential materials which provide activity for chlorate and/or perchlorate .

What that would mean for Xenoids experiments where plural

coatings of MnO2 alone were baked on top of plural coatings

of Co3O4 , and an anode resulted which for however long it lasted did produce chlorate and perchlorate , is explained

in terms of the Co which diffused upward into the MnO2 and

functioned as a dopant to give that MnO2 the activity it revealed . MnO2 could likely have been substituted with

MnO2/SnO2 , or perhaps MnO2 could have been omitted entirely and SnO2 or Co doped SnO2 may have resulted in

similar activity at least for chlorate .....proving that it was the Co which had more to do with the activity of the anode ,

than was the MnO2 alone .

I would have to go back and reread the thread to see if Xenoid even tried it , but mixing in 5%(or more) Co with the Mn would probably have resulted

in a tougher and longer lasting MnO2 coating after baking while the activity of the coating should have increased also . And similarly some added

SnO2 would have made the coating more durable

but probably all of the activity of the MnO2 for chlorate and/or perchlorate is attributable to the Co .

[Edited on 2-3-2008 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

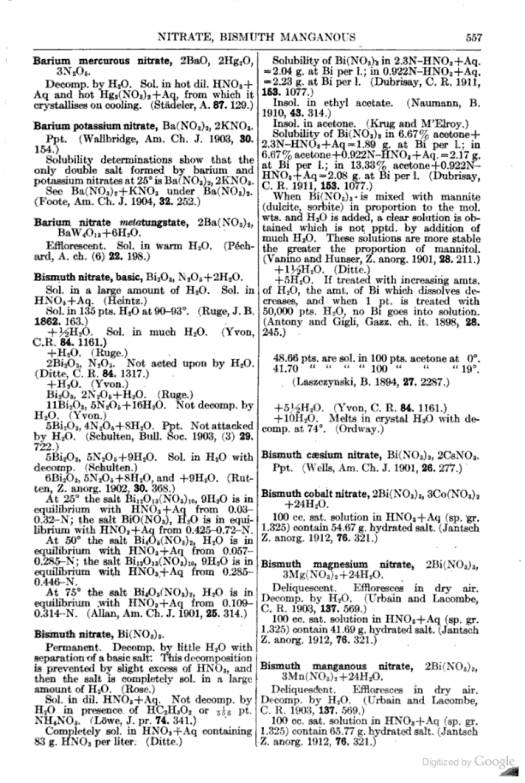

bismuth compounds solubility

Some of the following references differ from one source and another . But a few interesting things have been found concerning bismuth salts which

reveal anomalous solubility .

Mannitol forms an addition compound with Bismuth Nitrate ,

sorbitol and dulcitol are mentioned also , as well as ordinary glycerin , and the usual hydrolysis of Bi(NO3)3 - 5H2O upon dilution is inhibited

greatly for these mixtures . All of these materials are polyhydric alcohols and the anomalous solubility may possibly be due to formation of a bismuth

alcoholate or "alcoholoxide" substituted hydroxide sol .

Also a citrate salt of bismuth may be gotten from boiling the subnitrate in suspension in citric acid , and the precipitated bismuth citrate rinsed

and filtered . This material acts as a monoacid towards ammonia and when neutralized is freely soluble in H2O so long as the solution is neutral to

very slightly basic with ammonia . A bismuth acetate crystallizes from the double decomposition of lead acetate and Bi(NO3)3 solutions . A bismuth

oxalate can be precipitated from a nitric acid solution of Bi(NO3)3 on boiling with oxalic acid ,

and I could find no information specific to the formation of

a possible peroxalic anhydride derivative with H2O2 as is reported for the stannic anhydride sol , but this seems a good possibility . At the bottom

left corner of the attached image the Lowe reference is interesting concerning the

hydrolysis inhibiting effect of acetic acid or 1/300 part of

ammonium nitrate . NH4NO3 was also mentioned in

connection with the citrate in an obscure early pharmaceutical text , as having been used to form more concentrated solutions of Bismuth Ammonium

Citrate , but

that older formulation was obsoleted and I could find nothing

further concerning the use of ammonium nitrate for stabilizing bismuth in solutions .

[Edited on 4-3-2008 by Rosco Bodine]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

Total Failure

My latest perchlorate anode was my most sophisticated attempt to date, and utilised UMLT* and featured NTT**.

I applied 2 coats of Co3O4, baked at 410 oC to an etched Ti rod.

This was in turn coated with 4 layers baked at 380 oC. These 4 layers each comprised 1 dip 'n dry Co3O4, 5 dip 'n dry MnO2 and 1 dip 'n dry Bi2O3

layers!

After this I considered that the Co and Bi levels might be a "bit" high, so I overcoated all this with another 4 baked layers as above but with about

10 dip 'n dry MnO2 layers!

On top of all this I added another 8 layers each baked at 380 oC. of MnO2 which was doped with Co and Bi.

Total layers was about 88......

The anode lasted about 48 hours in a perchlorate cell. The cell was a dark permanganate colour at the end (it put "Purple Haze" to shame) there was

also black MnO2 on the bottom of the cell.

The cell started at 4.4 volts, 2 amps (60mA/cm^2) the voltage dropped to 4.2 volts as the cell warmed up and then steadily rose to 6 volts as the

anode passivated and was switched off.

The idea for this anode was based on the concept that if you put on enough layers of variable composition, somewhere in there will be a layer that is

"just right". Rosco alluded to this some time ago.

Interestingly, when I did the the first bake with the Bi(NO3)3 dip (I actually did two dip 'n dries, not the one in the "ideal" sequence above) shiny,

metallic Bismuth was produced on the outside of the anode (that's why it was reduced to one dip 'n dry). Hints of metallic Bi also appeared in some of

the later sequences.

Even with this extensive pyrolytic coating, it was still possible to see deep scratches in the underlying Ti rod, this suggests the coating is still

only, what, 50 - 100 um thick! It is difficult to see how this type of anode can compete with a plated on layer of PbO2 which can be millimetres

thick, and also more catalytically active for perchlorate. A plated coating would also appear to be a lot easier to apply than 88 pyrolytic coats

which took me about 1.5 days to do.

*UMLT - Ultra Multi Layer Techniques

**NTT - No Tin Technology

UMLT and NTT are registered trademarks of the Anode Division - Xenoid Chlorate - Perchlorate Corporation.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello Xenoid,

It's no wonder you were not posting for a while!!! (PHEW). You put us all to shame.

I attempted to coat LD (Alpha from a Lead Tartrate bath) on top of Cobalt Oxide spinel (Ti substrate). It plated for a few hours untill my 'set up'

went up in smoke. The bench caugh fire (smouldered away), beaker tipped over etc. Luckily that is all that happened before I got to it. The LD is very

soft and very easy to scrape off.

I have since purchased a magnetic stirrer hot plate and may have another go.

My LD anode is giving very poor CE. Have tried lowering temp. from 55 to approx. 22. CE went up from 20 to 24%.

Lowered CD on anode, temperature approx 32C. Still 20% CE.

So I have not had my head in the clouds either.

I am currently running at very low CD, will measure CE. Then I intend to run at a large CD (300mA per square cm) and keep temperature low by putting

cell in large bucket of water and measure CE.

I keep thinking it may be the cathodes (Ti) but that has to be bullshit. I could attach some mild steel to them easily (then measure CE) to put my

mind (what left of it) at rest.

Will run cell to end (low Chlorate conc.) and start a pure Perchlorate cell.

Hashashan has gotten around 50% CE (Chlorate stage). It was estimated by the time it took the cell to start forming Perchlorate.

I am doing titrations.

Am also setting up a Magnetite anode cell. Last time I tried it I ran the anode at far too high CD which was not a fair test of the Magnetite.

Dann2

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

xenoid: I've gotten thickness increases out of successive layers, but maybe that just means I'm laying it on too thick? I do wipe between dip n bakes,

though - I always figure if I get more than a token smudge that I need to thin the solution (and do). Perhaps your dry but unbaked coats are

redissolving when you dip again? That would probably be quite visible however.

It sucks the MnO2-BiO3 doesn't seem to want to work. I will be making up some Bi(NO3)3 tommorow as well as some stannic nitrate via Rosco's method

from SnCl2. I think I even have some SnCl2 that is dry, or at least damp to start with a known quantity. I can dope with ~10% Bi by adding with the

stannic oxohydroxide when I neutralize with nitric acid.

The plan is to work on this tommorow, or possibly tonight.

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by tentacles

Perhaps your dry but unbaked coats are redissolving when you dip again? That would probably be quite visible however.

I will be making up some Bi(NO3)3 tommorow as well as some stannic nitrate via Rosco's method from SnCl2. |

Yes, to some extent the "dried" coats were redissolving, this was evidenced by the Mn solution getting darker from Co solution contamination, the Bi

solution also took on a slight pink hue as well. It was not possible to obtain a completely "dry" coat in a reasonable time frame, usually they were

slightly "gummy". Even if all the coats were perfect and intact the "build up" is still only going to be a few hundred microns at the most (ie. tenths

of a mm.) whereas plating can quickley build up coats of a few mm.

Unfortunately my procedures were not very quantitative but at least I expected something that would last longer in a perchlorate cell than just the

"straight" MnO2 coating, this was not the case however!

Good luck with the Sn, I had a third attempt at tin nitrate, but just got the same cloudy solution and ppt. as previously. That's why I used NTT ....

Bismuth nitrate solution was no problem, I used about a thumbnail pile of crystals, in a test tube, a few drops of nitric acid and diluted with water

up to halfway, this was enough solution to "dip my rod in"....

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

*Mixed* metal oxide = "doped" (including tin) oxide

Doing the math ......

NTT (no tin technology) = SOL (shit outta luck)

Really , there's probably no getting around the SnO2 .

As for your Mn(NO3)2 becoming cross contaminated with

Co(NO3)2 ......well that's a good thing , and it would probably help the MnO2 to deliberately mix in about 5%

of the Co precursor . The MnO2 without the Co3O4 is an oxygen selective anode coating , and it is only the diffusion which you have been getting from

the Co3O4 in underlying layers which has allowed the MnO2 to make chlorate and perchlorate , if the literature which I have seen is correct on this

point , as MnO2 alone makes only oxygen and at too low a voltage for chlorate or perchlorate . Tin shifts the selectivity in the right direction also

, and both tin and cobalt

toughen the MnO2 mechanically . SnO2 and MnO2 and Co3O4 are all solvent oxides towards each other so they diffuse freely on baking . But there are

desirable proportions

which will make for a mixture which sinters to a tough film better than some different proportions .

That old 1857 Chemical Gazette article by Ordway which describes the formation of stable mixtures of tin nitrate and tin chlorides is enlightening .

The existence of a mixed valency tin oxide , a "sesquioxide" , and a series of salts

derived from it is something which I have have suspected could be useful in anode precursor mixtures . There seems

to be a niche condition for stable solutions where the higher and lower valency species tend to buffer each other and the result is anomalous

solubility and stability for the sol or solution . This should facilitate mixing with precursors for

the dopant materials . Anyway the Ordway article is significant , and I am attaching a cleaned up file which can

be read and printed better than the first attached file I put

in the antimony and tin nitrate thread .

There have been identified several thermally decomposable

precursors for stannic oxide which are highly loaded solutions or sols that are stable across a range of pH values which should make possible mixtures

with various dopant precursors . What mixture is best I'm not sure , but I am

pretty certain a *mixture* of the precursors is definitely going to be required to achieve the best MMO end result , as

diffusion alone will be too variable and produce not nearly so intimate a mixture as can be gotten from mixing the precursors before baking .

As an example of compatable pH , what I was thinking for

the Bi doping is using "ammonium stannate" ( ammonia peptized alpha stannic oxyhydroxide sol ) which is alkaline

with the Bismuth Ammonium Citrate which is highly soluble

in alkaline medium ....hoping the two don't immediately react preferentially to precipitate Bismuth Stannate

For a highly acidic compatable pH , what I was thinking for

Bi doping is the Bismuth Oxalate or perhaps the Bi Nitrate ,

along with the peroxalic "stannic anhydride" of the patent

US4924017 and related US4873352 . Glacial acetic acid is

also a solvent for Bi(NO3)3 compatable with a low pH mixture .

For a more neutral pH system like some of the Tin Nitrate

mixed valency compositions described by Ordway in 1857 ,

possibly using the anomalously soluble Bi(NO3)3 addition compound with a polyol like glycerin or mannitol would be

workable . Bi(NO3)3 is also reported soluble in acetone ,

but the reports are conflicting concerning the pH useful ,

so this might be workable either in the middle pH or low pH

mixtures , depending on how that reported acetone solubility sorts out .

And beyond these possible schemes there are always the

alcoholate derivatives , of which those polyol addition compounds are a type . The chemistries involved for

Tin , Bismuth and Antimony are similar , so there should

be possible some reasonably stable mixtures of precursors

useful for dip coating .

Anyway , there are possible mixtures across the entire pH range for dopants useful with SnO2 , so the issue becomes

which combination will produce the best quality , most adherent film on baking . There's really not a lot of help

in the literature in the way of predicting what is best .

One more thing , regarding the sesquioxide of tin in solution as the chloride . This still has a reducing properties , but

it is less reducing than SnCl2 . So this mixture might possibly have usefulness as an oxidative soak deposition precursor ,

as it is already "halfway there" ....it might not attack a spinel

in the same way as does SnCl2 . But really I think a more likely to succeed mixture would be cobalt nitrate or chloride

mixed directly with one of stannic oxide precursors would be better , or a single or double coating of spinel alone , followed by the stannic oxide or

cobalt doped stannic oxide

precursor mixture . Getting some Bi doping in that interface

mixture too would be ideal . The goal would be to get the

SnO2 lattice of the interface layer as close to saturation as possible with Bi doping , without phase separation . That

would create the oxygen migration barrier needed for protection of the substrate . The Co3O4 doping would

provide conductivity and toughening also . If Sb doping is added as a grain modifier , it should be held to 1/2 % .

Guessing on the proportions of Co and Bi , I would try 4% Co

and 6% Bi ...the rest Sn .

Edit: Reminder that the terminology of the year 1857 differed in its meaning for "equivalents" than is the usage of the term today , due to chemists

misidentification of molecular versus atomic weights for gases like chlorine and hydrogen ,

in which case stannous chloride would be mistakenly identified as SnCl instead of SnCl2 , and stannic chloride would be misidentified as SnCl2 instead

of SnCl4 , and water

would be mistakenly identified as HO instead of HOH , ect.

Also I suspect the term "equivalents" may sometimes simply be equal parts by weight without any strict reference to molecular weights be they correct

or incorrect , so some

interpretation and verification must be applied to these older texts in order to revise and correct the equations for the described reactions so they

are accurate using the modern formulas . Experiments should clarify the meaning for proportions that may be unclear from these old texts .

[Edited on 9-3-2008 by Rosco Bodine]

Attachment: Tin Nitrate stable solutions Ordway (Chemical Gazette 1857) legible printable.pdf (489kB)

This file has been downloaded 800 times

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

Xenoid: did you try making the SnCl2 > stannic oxyhydroxide > stannic nitrate or the cold dissolution of tin in 28% nitric acid with a dash of

HCl?

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There are definitely intriguing possible reactions which would be generally aligned

with Ordway and Pytlewskis observations .

I was wondering if cobalt carbonate , manganese carbonate , or bismuth carbonate , and/or their nitrates might react in the same way as lead nitrate

and lead carbonate was described by Ordway , as reacting with the mixture of SnCl2 and SnCl4 which was made from "tin crystals" (SnCl2) . The K ion

and/or KCl from the KClO3

may or may not be simply spectator ions in the reaction Ordway described , as stannic salts do form double salts

with both K and Ammonium chlorides . For our uses the

ammonium salt would be better , if a double salt being present is essential to the stability of the system .

Instead of using KClO3 plus SnCl2 and then reacting with lead nitrate or a different nitrate , it might work similarly

to simply treat the SnCl2 solution with a little NH4Cl and a quantity of HNO3 insufficient for its complete oxidation to

the mixed stannic salts , and then treat the resultant mixture with a carbonate ....perhaps just until a thickening

occurs and then "back titrate" with a little more HCl ,

or perhaps acetic acid to thin it back out again , if it is reversible .

Whatever is the mixture used , it is likely going to have the

electrostatic and wetting properties of the Pytlewski polymer . The subsequent coating of something like

the ammonium stannate sol would be electrostatically opposite to the Ordway-Pytlewski precursors mixture ,

and alternating these differing characteristic mixtures could lead to a highly dense coating with good wetting out

since they should undergo an in situ electrophoresis ....

like a sort of "powder coating" scheme at a nano particulate level , sticking to each other like magnets .

The coatings thickness could build at a rate several times

what the usual sequence of the same precursor builds ,

absent that electrostatic attraction . A tenfold increase

in the coatings thickness build rate would not be unreasonable .

Eight coats of electrostatically enhanced

deposition could be as thick as eighty without it .

[Edited on 8-3-2008 by Rosco Bodine]

|

|

|

Ioxoi

Harmless

Posts: 20

Registered: 24-9-2007

Location: Upstate NY

Member Is Offline

Mood: Pensieve

|

|

Using dichromate

First and unrelated is that Xenoid is my savior now. I've run a sodium chlorate cell with gouging rods and gotten tons of KCLO3 from adding KCl, but

it's so messy it's crazy. Seeing pictures of your cobalt oxide substrate + betaMnO2 anodes (purple haze, etc) work perfectly gladdens my heart. I so

want to make an MnO2 anode now! You are awesome.

Second, and on topic: have you tried using K2Cr2O7 with your MnO2 anodes? I know that dichromate is terribly bad for PbO2 anodes, but what about your

MnO2 anodes? You should see whether dichromate improves chlorate-making efficiency using your MnO2 anodes, or drastically reduces it.

Chuck Norris does not uphold laws. He is the law.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Chromium and Vanadium both have been high on my

list of suspects as likely catalysts for perchlorate ,

because each have the ability to form transiently stable

peroxidized forms which are very active oxidizers .

These are definitely candidates for experimenting in combination with MnO2 and SnO2 .

But it would be better to use the ammonium salt like

dichromate , or to use chromium nitrate , than to use

the potassium salt , since you need to keep potassium out of the composition after sintering .

Really if you are using MnO2 , it should be doped with

a second material like these , or cobalt , nickel , or some other dopant which produces an altered selectivity for

the mixture favoring evolution of chlorine . Whether

the chromium would achieve that I'm not sure , but it

is a definite possibilty . Chromium is also interesting because

it reportedly forms that anomalously soluble metastannic acid

mixture which is dervied form the nitrates of chromium and tin , as a concentrated hydrosol , so it would be a very intimately dispersable dopant with

SnO2 and likely also with MnO2 as a tertiary mixed oxides coating . This could be one of the easier mixtures to use , among some of the other

combinations which are contemplated .

[Edited on 13-3-2008 by Rosco Bodine]

|

|

|

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

| Quote: | Originally posted by Ioxoi

Second, and on topic: have you tried using K2Cr2O7 with your MnO2 anodes? I know that dichromate is terribly bad for PbO2 anodes, but what about your

MnO2 anodes? You should see whether dichromate improves chlorate-making efficiency using your MnO2 anodes, or drastically reduces it.

|

@ Rosco - I think Ioxoi is meaning adding potassium dichromate to the cell solution!

No, I haven't tried it!

Actually I never got around to posting a footnote to "Hubert" and "Purple Haze" the final yield of KClO3 was 945g, (recrystallised, dried and clean).

I used 2299 amp hours and the efficiency was 53.9% - not too bad.

What would be desirable is if the dichromate extended the lifetime of the anode!

Sorry for not posting for a while, but after my last disasterous attempt at an anode I thought I would have a break for a while! I'll wait for someone

to make a breakthrough....

Image shows dried KClO3 from "Purple Haze" in roasting dish.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

MnO2 (or Co Oxide) in Diaphram cell

Well OK,

Here is my break through

Rosco, a long time ago posted a patent for making Perchlorate using Graphite in a cell that had a diaphram. It is an old patent but probably perfectly

workable.

Would it work with MnO2 anode (instead of Graphite)?? That would allow MnO2 to make Perchlorate and not erode???

What do ya's think.

Patent attached:

Dann2

Attachment: us1279593.pdf (173kB)

This file has been downloaded 684 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@Xenoid

Yeah it could be good for dichromate in the electrolyte too .

It may work via similar mechanism wherever it is in the system , but in the electrolyte it could have effect at the cathode also .

@dann2

Hmmm , I'm not sure , but it seems simpler to work out a coating scheme that doesn't need a divided cell . I think the MnO2 will toughen up with

added SnO2 , Co3O4 , Bi2O3 .

Time for my diva fix

http://www.youtube.com/watch?v=zo5n0HwaRmQ&feature=relat...

http://www.youtube.com/watch?v=rh-q8RNLr3Q&feature=relat...

http://www.youtube.com/watch?v=nDVgb4pJMdI&NR=1

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

@Dann2: Is that divided cell idea something you plan on trying? If it works with graphite maybe it will work with MMO anodes too?

I wonder what kind of diaphram material would be suitable for a cell like that?

Anyway, it's not exactly clear to me what's going on with the cathodes in the cell depicted in that patent...are they cups filled with electrolyte?

And what's the "hydroxid solution" [sic] they're talking about...are they're just referring to the OH generated at the cathode as the cell operates?

@Rosco: Wouldn't this be more appropriate for you:

http://www.youtube.com/watch?v=2IlHgbOWj4o

|

|

|

chloric1

International Hazard

Posts: 1141

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Xenoid is not posting on this thread and jpsmith resurfaces from the abyss of ambiquity??  What happened here? What happened here?

@jpsmith-They stated porous cup many times in that patent which basically means unglazed pottery. If kilnless like myself, find one of those outfits

that lets you fire your wares and simply make your own "cups". I have wanted to do that but not sure what the best clay is yet.

@rosco-Well, I do not think the divided cell idea is too difficult. The main disadvantage is using higher voltage to drive the current needed. I was

a little suspect of the patent becuase they mention perbromates as if they can be whipped up by the kilo. AFAIK perbromates where not successfully

isolated until at least 50 years after this patent was published and that was done via fluorine oxidation. So, I wonder if this design is not some

electrochemist's wetdream scribbled on a coffeehouse napkin.

Fellow molecular manipulator

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Chloric1 I see mention of a "porous cup", yes, and if that means/includes unglazed pottery, that's fine with me; it just would have been nice if

they'd given some specific examples of such suitable porous materials.

In any case, the statement that has me a little confused is this one (@100):

"As the current passes the usual cathode reactions take place in the hydroxid solution 6, provided of course, such a solution surrounds the cathodes

4;"

The "hydroxide solution" whatever it is, is optional? WTF are they talking about?

|

|

|

| Pages:

1

..

7

8

9

10

11

..

13 |