| Pages:

1

..

5

6

7

8 |

Brightthermite

Hazard to Others

Posts: 127

Registered: 26-6-2019

Member Is Offline

|

|

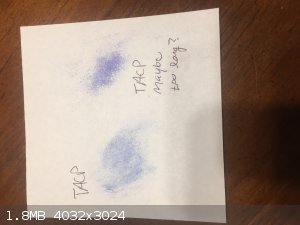

I made some TACP the other day using 10g AP, 33g Ammonium Hydroxide, and a bundle of 22 gauge wire as well as a piece of 12 gauge wire. I reacted the

mix in a jar with a small hole, on a ball mill for 1 hour. The product I got was a deep blue and performed well.

I tired again using 20g AP, 66g ammonium hydroxide and the same sections of wire. I allowed this to react for 2 hours. This product came out an almost

violet purple color, no where close to the deep blue it should be. The color difference can be seen in the smears on white paper.

Aside from the color difference it seems to perform well. My guess is it has copper oxides in it. I think my wire gauge is too small and when left to

react longer then I did in my first run, it produced to much oxide. Any input?

Also when converting this to CHP, the AP and hexamine are mixed in under ammonium hydroxide. Would it be possible to use the hydroxide solution left

over from filtering the TACP or should fresh hydroxide be used?

[Edited on 29-11-2020 by Brightthermite]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

CHP

"Also when converting this to CHP, the AP and hexamine are mixed in under ammonium hydroxide. Would it be possible to use the hydroxide solution left

over from filtering the TACP or should fresh hydroxide be used?"

Sentence should by : Also when converting this to CHP, the AP and hexamine AND TACP are mixed in under ammonium hydroxide. Would it be possible to use

the hydroxide solution left over from filtering the TACP or should fresh hydroxide be used?

Yes. If you are deficient in ammonium water (NH4OH), is possible it to use for mixing to porridge for create CHP. However, a new ammonia water 25%

is better. Old water contents impurities. Adding AP ( at create CHP) is changed mixture on positive oxygen balance, which is very important for good

properties of final material. CHP66 has OB + 2,44. Hexamine is fuel. Hexamine and AP create sensitive ingredients for easy DDT, but decrease

brizancion. Their necessary content is 12%. The concentration NH4OH during the process in Liptakov converter drops to 20 - 12 %. (time, teperature)

For create porridge is this water enough, becaouse is used only a few drops. Exact color of dry TACP from converter is not so crucial. Yes, during

longer process can arises oxychlorides, which change color on light blue - grey. This is a sign of a lack of NH4CLO4 in the solution. Or low

concentrations of NH4OH. Or too much air during process. Copper is still oxidized, but does not react with NH4ClO4. Copper oxychloride, which has a

lihgt blue color, is probably formed. The is insoluble in water, or ammonia water. During preparation of CHP, thus adding AP 6% is copper oxychloride

transferred and create form him TACP again. Partially, or entire. Sometimes, is final color dry TACP very dark blue, almost black. Black is surplus

CuO. Which usually create at deficiency air in converter. However, important is his final properties of CHP, for example in alu foil confinement

heating...

[Edited on 29-11-2020 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Brightthermite

Hazard to Others

Posts: 127

Registered: 26-6-2019

Member Is Offline

|

|

Thank you for the information! Answered all my question LL

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

TACP

It seems, that 8. October 2020 Scientific work on TACP has been published. Czech Republic, University of Pardubice https://onlinelibrary.wiley.com/doi/full/10.1002/prep.202000...

Unfortunately, The whole text is charged.

Fortunately for us, we all know minimal 4 years, what he can do TACP.

Is there describe VoD 3230 m/s . At density 0,9g/cm3.

In amateur conditions was reached density 1,91g/cm3 And VoD about 7500 m/s. Detonation pressure 25 GPa...

(ETN wiki: At cast density 1,7g /cm3 VoD 8030 m/s, detonation pressure 30 GPa.)

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

B(a)P

International Hazard

Posts: 1130

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Here is the full paper.

They don't reference your work LL.

Attachment: TACP.pdf (706kB)

This file has been downloaded 552 times

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Thank you. With the exception of sensitivity, we didn't find out much. Because VoD at a density of 0.9g / cm3 is of course relatively low.

Interestingly, the critical diameter is less than 2 mm even at such a low density of 0.9. Of course, TACP can be easily compressed to a density of 1.9

g / cm 3. At such a density, its brisance approaches ETN. There is not a word about that in the document.

Comparisons of sensitivities: Mercury Fulminate has impact energy (for 50% explosions) 0.62 Joules. PETN 3.9 and TACP 2.6. The compressive force for

standardized friction is: Mercury fulminate 0.53 Kg, PETN 7.5 Kg,

TACP 9.3 Kg. That friction is good news. TACP is less sensitive to friction than PETN. Thanks Again, B(a)P....

----------------------------------------------

I'm not angry that there's not a word about LL research. They are professionals.It is a higher league. We can be glad that we know at least something

from professionals on the topic of TACP. Such data is possible use a like relevant values. Sometimes in future.

[Edited on 16-12-2020 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

B(a)P

International Hazard

Posts: 1130

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

It seems strange to me that they did not explore density vs VoD.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Is it only partially study.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Uriel

Harmless

Posts: 14

Registered: 28-1-2017

Member Is Offline

Mood: No Mood

|

|

Dear LL,

I'm really thankful for your job

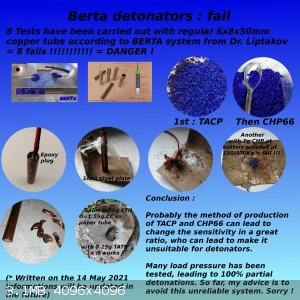

BUT after a ten of try : 100% fails with TACP and CHP66.

I put this picture for illustration.

I don't intend to push anybody to use dangerous primary like me, but a failed detonator can be really dangerous in some applications.

So, I would like to aware anybody about the risk of fail for the Berta system.

Maybe it is my fault, in drying operation, I puted in a regulated controled plate at 50°C during long time like 2 hours until the cristals are dry

and the ammonia smell very low.

But if something sensitive like humidity can make difference between fail and success, it is strongly hazardous...

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Uriel: In your last research you are used a like primary TATP. posted on 21-10-2018 at 13:14. http://www.sciencemadness.org/talk/viewthread.php?tid=10575&...

And you need talking about dangerous about CHP?.....

Next, you can try drying TATP at 50 C during 2 hours.....

Maybe will results better.....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

BauArf56

Hazard to Self

Posts: 68

Registered: 22-8-2019

Location: between the moon and the sun

Member Is Offline

Mood: energetic

|

|

would it be possible to make this by adding flash powder from a firecracker (which usually is al + kclo4) to tetramminecopper? I don't have any pure

perchlorate

|

|

|

Uriel

Harmless

Posts: 14

Registered: 28-1-2017

Member Is Offline

Mood: No Mood

|

|

@LL

Thank you for your "Argumentum ad hominem"

Maybe you haven't read the picture ? I was speaking of too low sensitivity.

And I mentioned TATP in the same picture doc, but you probably haven't read it ...

The subject was the low sensitivity of TACP/CHP who can lead to fail your detonator system, and that point is dangerous in my view.

@BauArf56

About flash powder, in most countries, flash was banned in firecrakers, usually it is just "slow flash" with KNO3/Al/S.

I've made some try with TACP + Flash 70/30 (KClO4/Dark German) but the TACP was not set off in paper tube, maybe in copper tube it could works, but

as far as Al particles could react with TACP (possibly, not a certitude) , I think it is a bad idea, and I won't try.

[Edited on 16-5-2021 by Uriel]

[Edited on 16-5-2021 by Uriel]

|

|

|

Brightthermite

Hazard to Others

Posts: 127

Registered: 26-6-2019

Member Is Offline

|

|

Quote: Originally posted by Uriel  | @LL

Thank you for your "Argumentum ad hominem"

Maybe you haven't read the picture ? I was speaking of too low sensitivity.

And I mentioned TATP in the same picture doc, but you probably haven't read it ...

The subject was the low sensitivity of TACP/CHP who can lead to fail your detonator system, and that point is dangerous in my view.

@BauArf56

About flash powder, in most countries, flash was banned in firecrakers, usually it is just "slow flash" with KNO3/Al/S.

I've made some try with TACP + Flash 70/30 (KClO4/Dark German) but the TACP was not set off in paper tube, maybe in copper tube it could works, but

as far as Al particles could react with TACP (possibly, not a certitude) , I think it is a bad idea, and I won't try.

[Edited on 16-5-2021 by Uriel]

[Edited on 16-5-2021 by Uriel] |

I encourage to keep trying to get CHP66 to work, once you do you wont go back.

I believe you are making an error somewhere either with manufacture of the CHP or building the detonator itself. It was touch and go for me but once I

got it right I have a 100 percent detonation rate with 20 caps. Caps are copper 1/4 inch tubing cut to 2 1/4 inches long and filled with .7 grams of

CHP. The CHP does not even need to be pressed if it is the consistency of fine sand.

I live in a humid area and have had no problems with it affecting my product.

Tip I always had poor results when I dried the product over heat, once I just left it to air dry it preformed much better. Are you using a ball mill

during the reaction? Also try a smaller tube diameter, I found better results with that.

All this being said I have had similar instances were I was not able to replicate someone's good results (ETN yields over 75 percent) its very

frustrating but hopefully you are able to get it to work.

|

|

|

dangerous amateur

Hazard to Others

Posts: 148

Registered: 8-7-2011

Member Is Offline

Mood: No Mood

|

|

Have you ever considered the purity of electrical wiring copper?

What kind of contamination can be expected typically?

| Quote: |

Caps are copper 1/4 inch tubing cut to 2 1/4 |

Are 1/4 inches the inner or the outer diameter?

How thick was the tube?

And how did you ignite it?

[Edited on 28-5-2021 by dangerous amateur]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Basic compound of CHP is tetraamine, which is stable. But slightly wet TACP contain Octo Amine. Is it part molecule of wet tetraamine. Octo Amine has

a weak bond. After long drying stays only tetraamine, which has weaker DDT. Even very wet TACP has easy DDT. But very dry TACP not. Hexamine decrease

trouble with DDT.

Typical CHP contains 6% hexamine. Is it abbreviation that has been used as a standard designation for several years. For Tetraamine Copper di

perchlorate - hexamine clathrate. But more exactly should Octoamine Copper di Perchlorate - hexamine clathrate. Something a like OCPH. Typical

mixture CHP is 88% TACP + 6% hexamine + 6% NH4ClO4. Therefore CHP 66.

[Edited on 1-6-2021 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Uriel

Harmless

Posts: 14

Registered: 28-1-2017

Member Is Offline

Mood: No Mood

|

|

Thank you Brightthermite,

An error during the fabrication ? Difficult to believe because my TACP is working and CHP66 too but just partial detonation each time in copper tube.

But it's violent and total in low powder, unconfined.

The very probable issue is the very dry final powder. As for me a smell of NH3 = danger, I make it dry properly but it seems to decrease a lot the

sensitivity...

So if the detonator need to get a powder with an unknown percent of water to make it functioning properly, it is unreachable for a non-laboratory.

And it make it unrealiable.

But many other user get good results ... So...

I've tested a standard bloc of 30mm diameter ID containing 30grams of CHP66 presed at 1.41g/CC +/-0.03 against a 5mm standard steel plate (S235)

underground and the result is quite good.

(set off by non-TACP detonator ! haha !)

it seems near 5500~6000m/sec, what do you think ?

|

|

|

MineMan

National Hazard

Posts: 998

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I am surprised it did not punch through.

|

|

|

dangerous amateur

Hazard to Others

Posts: 148

Registered: 8-7-2011

Member Is Offline

Mood: No Mood

|

|

| Quote: |

it seems near 5500~6000m/sec, what do you think ? |

2500-3000m/sec

|

|

|

Brightthermite

Hazard to Others

Posts: 127

Registered: 26-6-2019

Member Is Offline

|

|

Quote: Originally posted by dangerous amateur  | Have you ever considered the purity of electrical wiring copper?

What kind of contamination can be expected typically?

| Quote: |

Caps are copper 1/4 inch tubing cut to 2 1/4 |

Are 1/4 inches the inner or the outer diameter?

How thick was the tube?

And how did you ignite it?

[Edited on 28-5-2021 by dangerous amateur] |

Maybe 1mm thickness, the outer diameter is 1/4 inch. Just standard 1/4 copper tube you can pick up at Lowes or home depot. I use fuse. Rap about an

inch of electrical tape around the fuse to increase the diameter, place in the tube, and crimp one side with plyers.

|

|

|

Brightthermite

Hazard to Others

Posts: 127

Registered: 26-6-2019

Member Is Offline

|

|

Quote: Originally posted by Uriel  | Thank you Brightthermite,

The very probable issue is the very dry final powder. As for me a smell of NH3 = danger, I make it dry properly but it seems to decrease a lot the

sensitivity...

|

This could be the issue. When allowed to air dry (you can tell its dry bc the product is able to be crushed without caking up) the stuff still reeks

of NH3 which should be fine. The container I store it in has a heavy ammonia smell when the lid is removed, not nearly as strong as concentrated

ammonia hydroxide but more like heavy duty cleaner.

Maybe when you are drying it over heat you some of the product itself is being destoryed?

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

| Quote: |

For low density (DDT part) is best grain 2x2 mm. Minimal 1x1 mm. And pressing on 1 - 5 Kg. Why invent a wheel? When Nobel patents always use 2x2 or

even 2 x 4 mm grain? |

I don't think the exact dimensions are so critical as long as the charge has a lot of voids, like a rocket engine designed to CATO.

Anyway, cant somebody tell me where these figures came from?

US5,385,098 says

| Quote: |

Granule weight average sizes between 10 and 2000 microns and preferably between 100 and 500 microns are suitable. |

That's for PETN of course.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

I previously cited my weak results on creating a product per the reaction of dilute aqueous tetra-amine-copper hydroxide acting on magnesium nitrate

(which seemingly works well forming Mg(OH)2 and a hydrated version of tetra-amine-copper nitrate, TACN).

However, for the record largely aqueous routes are not the only path (or even perhaps the best way) as there are many reports via natural occurring

corrosion (galvanic chemistry) of the unwanted creation of related salts of interest in moist conditions. To quote, as an example, this source at https://www.resourcesregulator.nsw.gov.au/__data/assets/pdf_... :

"TACN is formed when air, moisture, ammonia, copper and electrical currents combine. It is a deep purple, as opposed to the blues and greens of copper

nitrates. If copper nitrates are exposed to air, the purple TACN will begin to form underneath. The photos below (Image 1) show TACN formation on a

brass locking lever of a cam-lock fitting..."

My take on the associated chemistry, adding warming as likely necessary, a reaction serving as a source of ammonia and H+ :

NH4+ = NH3 + H+

Next, in the presence of copper, ammonia, oxygen and moisture:

2 Cu + 4 NH3 + 1/2 O2 + H2O --> 2 [Cu(NH3)2]OH

2 [Cu(NH3)2]OH + 4 NH3 + 1/2 O2 + H2O --> 2 [Cu(NH3)4](OH)2

Cu + [Cu(NH3)4](OH)2 <---> 2 [Cu(NH3)2]OH

Reference: "Kinetics and Mechanism of Copper Dissolution In Aqueous Ammonia", at https://www.google.com/url?sa=t&source=web&rct=j&...

So, I suspect, in the presence of say NH4ClO4, the following last step in the corrosion process:

[Cu(NH3)2]OH + NH4ClO4 -> [Cu(NH3)2]ClO4 + NH3 (g) + H2O (g)

with the possible creation of yet again a problematic energetic dry salt, but this time, as a targeted product.

An interesting important electrochemical point here, use a solid piece (or large pieces) of copper as Cu is the anode (in this anodic corrosion) and

the speed of this reaction is accelerated if the relative surface area of the anode (Cu) to the Cathode (O2) is small.

[Edited on 31-8-2021 by AJKOER]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

But of course it works very well. Use a Cu pan. Put 1 g NH4ClO4 on the pan. Pour 10g NH4OH 25% aq. And stir with a copper spoon. You can get your

first TACP in 10 minutes. If you stir for several hours (at 10 - 15 C) you will get almost pure TACP. But it is a very stinking and slow method...

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | But of course it works very well. Use a Cu pan. Put 1 g NH4ClO4 on the pan. Pour 10g NH4OH 25% aq. And stir with a copper spoon. You can get your

first TACP in 10 minutes. If you stir for several hours (at 10 - 15 C) you will get almost pure TACP. But it is a very stinking and slow method... |

What if you employ an inert pan (say glassware) instead and kept the small copper spoon as is and also injected air/O2 via an air pump into the

aqueous NH4ClO4 and NH3(aq) ?

Likely faster is my opinion!

The path you suggested was not likely from anyone acquainted with the electrochemical aspects of the reaction. Further, even try employing dilute

aqueous ammonia, but with the aeration, you will have to add more during the course of the reaction.

[Edited on 3-9-2021 by AJKOER]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1352

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

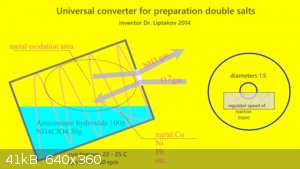

The efficient and simplest way to prepare TACP. Which is made during a 2 hours. (TACN during a 4 hours) Rotaring converter from a glass to cucumbers.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

| Pages:

1

..

5

6

7

8 |