| Pages:

1

..

5

6

7

8

9

10 |

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

That's almost exactly what I made Hennig. Hopefully it'll work well. I'm not a big fan of spreading NC gel on a surface and trying to remove and cut

it to shape.

I was experimenting with raw NC, NC plasticized with acetone and dried on a flat surface and extruded acetone plasticized NC, and controlling for

weight, there is way more carbon left after burning the plasticized material than the raw stuff, and slightly more for the flat than the extruded

flakes. There were air bubbles in the flat stuff not found in the extruded, which have to be removed before use, but perhaps they are part of the

problem, maybe they were just smaller in the extruded stuff. Thoughts?

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I may make an extrusion press yet, but for now the spaghetti press was only $15 delivered. The raw fibrous NC would burn more completely in the open

because it has better access to the oxygen from the air (of course if you used solvent you still will have at least a small amount of solvent left in

the gelatinized propellant as well which is added fuel). I found that pouring the gelatinized propellant out on a piece of wax paper to be extremely

convenient actually. The sheet once mostly dry could be very easily peeled off and then put on a cutting board to be cut up with the rolling cutter. A

mould to control the surface area of the sheet would likely be a good addition. The only problem was regulating particle shape and size which is why I

am trying other things now. The geometry of cylindrical grains is better than flake for larger rifle also.

I haven't had a lot of trouble with air bubbles, but I can see how air bubbles could be added depending on the amount and type of mixing that was

used. I usually just add the NC and solvent to a sealed polypropylene container and leave it overnight or longer to fully gelatinize, I then add the

NG (if used) with slow careful mixing. If air bubbles need to be removed, the container of gelatinized propellant could be put under vacuum, while the

solvent is still in and the propellant soft and with low viscosity, which should remove the bubbles.

[Edited on 9-2-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

I guess I never tried letting it just sit in solvent, I've always constantly stirred it. It seems like sometimes bits of nc gelatinize on the outside

and block access to the inside by the solvent, which is why I've always stirred it. I thought about applying vacuum when still wet with solvent, it'd

be one way to enhance removal of solvent, but I think it'd ultimately decrease density, which may or may not be desirable. I wonder how they would

effect the application of deterrent coatings or nitroguanidine after hardening.

I've not had much luck with cutting the extruding NC cords, unfortunately. It's tough to get the NC dry enough that it doesn't stick to everything

and wet enough to still be workable.

The only thing I don't like about press-cutting the grains is the difficulty in making very many of them, it's a fairly labor costly method. I wanted

to be able to run an ounce of propellant through my extruder cutting flakes in five to ten minutes.

My next though was maybe taking a sheet of Teflon of the desired thickness of my grains and drilling a hundred or so holes of the desired diameter

through it, lay on a solid sheet of Teflon and then scrape the wet NC gel across it, working it into the holes, like putting putty in a nail hole. I

think blowing it with a hair dryer for a few minutes would produce enough of a skin on the NC that the forming plate could be removed and used to make

another set of grains.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

From experience gained in making NC lacquers for pyrotechnic binder:

If you immerse either fibrous NC or most particularly finished NC powder in acetone, dissolution is slowed by the surface gelling and the solids

chunking up- It can take a week or longer to dissolve a fairly small amount of factory made smokeless if you just pour acetone into a jar and let it

sit.

If the solids are thoroughly wetted with ethanol, to the point where grains are an alcohol slurry and the acetone then added with stirring, the

process goes a LOT faster.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thanks Bert, that sounds like a good tip. Do you think that methanol could be substituted for the ethanol?

I guess I do stir some as well, but I wait until the fibrous NC has soaked in acetone for quite some time and has become very soft. I probably only

stir for ten seconds or so, two or three times during the whole dissolution process. I wonder at this point if I am really getting everything

dissolved as well as I should when using the long fibered, fibrous NC. MCNC dissolves much easier and forms translucent solutions with acetone. This

could help explain why the densities of the propellants I made with regular long fibered NC were often so low.

Trotsky, I will need to wait until I try the extrusion method to make comparisons and provide some input. Should be fairly soon.

[Edited on 9-2-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

I have never tried it with straight methanol, but a lot of the paint store solvent grade ethanol used was DENATURED with methanol AFAIK.

I note most ether/alcohol solvent systems for NC in older powder making processes specify ethanol- Don't know if it was solubility or economics

driving that choice.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Just wanted to point out that the DNT used in propellant formulations is not normally pure 2,4 DNT even when it is decribed as such in some cases.

Apparently it is normally a mix of DNT isomers with the largest proportion being 2,4 DNT. I have seen several references indicating this in the last

week or so, but I didn't think to make a note of them at the time.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

How is the flake commonly used in shotguns produced commercially? It looks like it must be incredibly thinly sliced extruded cord, but I can't figure

out how they can process it. When it's still relatively wet it's far too sticky to cut that thinly- it's easy to extrude cord, but trying to process

it that thinly into paper thin flakes is inconceivable to me at this point. Once the cord is dry it's damn near impossible to process it at all.

Obviously there is a process out there, but I can't think of it.

I have spread it in a thin sheet, cut it into .25in x .25in squares, allowed it to finish drying before, but it's performance in a shotgun is not

nearly good enough. It's too slowly burning to develop enough pressure to fire shot at a reasonable velocity. It's also not cleanly burning enough.

I know most shotgun powders are double base, so maybe I should give up trying to make a single base propellant work well enough.

I don't have experience trying to process a double base powder. Are my problems processing it into flakes because I'm working with just NC and not

blending with NG? I would think that a double base propellant would be easier to work with, once the solvent had evaporated I would think that the NG

would keep the now plasticized NC softer and more easily worked. Is there a point when drying that say an 18% NG double base would be soft enough to

cut finely but stiff enough that it wouldn't deform and stick to everything? I work somewhere where we do a good bit of extrusion, so I'm pretty

familiar with a number of industrial extrusion techniques. Our end products are vastly different, but from what I can tell the actual techniques are

pretty similar, it's the post extrusion processing that's completely different. I'm sure when these guys were originally working out the process they

had a lot of raw materials to spend on developing their method so they had the flexibility to make changes on the fly until they had something that

worked, and once they were that far they could simply make small changes to dial the process in to yield a better product in various aspects and to

increase their throughputs.

Whatever process they were going to use had to be one that could be easily scaled up to pump out serious poundage. I don't know what sort of pounds

per hour these plants are expected to produce, but where I am I think the lowest we do for anything (well, lowest accepted, there are always times

when machinery doesn't cooperate to hit standards) is 1800lbs/hr, but virtually everything else is 3-4k though there are some we can run a bit over

9k. I wouldn't expect these places to pump out volumes like that because of the difficulty in producing tens of thousands of pounds of nitrocellulose

that would be needed each day, but I would imagine they do at least a thousand pounds per hour, it'd be hard to make a profit with less, powder isn't

very expensive after all, and the people producing it can't be cheap labor- you're not going to be paying the guy working with large quantities of

nitrocellulose and nitroglycerin 10 bucks an hour, I can only imagine the press's reaction if there were an accident and they found out the plant was

under paying employees. That would be a fun job to have!

I wonder if there are any 'How it's made' sort of shows on YouTube showing smokeless powder manufacture. They'd probably be rather vague about

details for obvious reasons, but I could glean a lot of information just by seeing the process based.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The flakes are likely passed through one or more sets of rollers to flatten them out to their final thickness. Double base propellants are much easier

to work with, or so I have found, since the NG acts as a plasticizer/softener. Plasticizers are often added to propellants with one of the main

reasons being to make processing easier or possible. Also, vibration might work well to remove air bubbles from the propellant before the solvent is

removed. I have found the same thing too; information found is often not very specific with regards to propellant manufacture.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

aj_hazem

Harmless

Posts: 8

Registered: 28-1-2014

Member Is Offline

Mood: No Mood

|

|

Double base and single base propellants are plastic like material witch mean that you need heat and pressure to give it the proper grain size and

shape.

The best practice is to use a twin screw extruder, single screw extruder give inferior quality for the final product.

The using of a solvent help improve the Workability.

Solvents include ketones like acetone and include ethyl acetate, diethyl ether/ethanol the solvent used mostly in industrially is the later.

There is two other methods one for making sheet like propellants, stripes or rings. And the other for making ball powder which uses an emulsion in

inert (water) carrier.

[Edited on 18-2-2015 by aj_hazem]

|

|

|

aj_hazem

Harmless

Posts: 8

Registered: 28-1-2014

Member Is Offline

Mood: No Mood

|

|

Need manufacturing details

Can u please describe the methods used in making that propellant grain the rocket propellant i mean.

|

|

|

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

Yeah I'm familiar with extruder tech, and it seems obvious to me how they make many types, but are these perfectly round flakes, identical in size,

coming from thin sheets and punched, or extruded through holes and cut? In my industry we mostly do the latter, but we don't work with anything that

tiny.

|

|

|

woelen

Super Administrator

Posts: 8082

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

@aj_hazem: This is the third time that you ask for practical information, useful for weaponizing certain compositions without actually showing any

interest in the science behind these things. What are you up to? Bert already put two of your threads about construction of hand-grenades in detritus

and this latter part of this thread could easily end up there as well, together with your account.

Discussing energetic materials is fine, but wo do not want the discussion going towards weaponizing these things.

|

|

|

aj_hazem

Harmless

Posts: 8

Registered: 28-1-2014

Member Is Offline

Mood: No Mood

|

|

Coin-like shaped ballistite ( smokeless powder) are manufactered from ball powder patented by olsen in 1919 if i my memory is still working well ,

the patent describes making an emulsion of NC in ethyl acetate in water with strach then slowly evaporating the solvent while agitation is continued

,small spheres starts to appears and case hardened.

After that the ball is smashed between hot cylinder (roll mill).

|

|

|

aj_hazem

Harmless

Posts: 8

Registered: 28-1-2014

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by woelen  | @aj_hazem: This is the third time that you ask for practical information, useful for weaponizing certain compositions without actually showing any

interest in the science behind these things. What are you up to? Bert already put two of your threads about construction of hand-grenades in detritus

and this latter part of this thread could easily end up there as well, together with your account.

Discussing energetic materials is fine, but wo do not want the discussion going towards weaponizing these things. |

You're an admin you can simply delete my post or even ban me from ever posting. The thing is that i'm already up to make solid grains but i'm facing

the problem of residual solvent remaining traped inside the grain.

I think it's sciences not weaponizing some thing cuz i'm not asking you to give me practical details on rocket systems. Man you are using a twisted

logic here.

|

|

|

aj_hazem

Harmless

Posts: 8

Registered: 28-1-2014

Member Is Offline

Mood: No Mood

|

|

I guess bullet are a projectile fired for weapons!

Shaped charge are devices invented to penetrate steel targets, oil wells and armored car!

Correct me if I'm wrong!

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

There is no point and no need of being offended. Anyone who came new to this forum and asked for help to build a grenade would have had the same

treatment, would have drawn attention to themselves and be looked at with suspicion afterwards for at least a while. Actually, Bert and Woelen have

been incredibly polite about the whole thing (I checked the posts myself). It often depends how things are discussed and what kind of track record the

member has I think. What is appropriate can often be somewhat subjective, but in your case it was very clearly very much against forum rules.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

Hennig, have you experimented with taking acetone-colloided NC (1% Vaseline, <.5% sodium carbonate) and adding it back to water? I hadn't tried it

before, though I had read that it returned the gel to an almost cotton-y like state, so I gave it a shot. It does turn similar to cotton, I suppose,

in a way, but as it dries it's easily turned to a fibrous powder. This material doesn't start as a powder exactly, instead as a fibrous chunk of the

stuff, but as you slowly work it between your fingers, it turns to a fibery powder.This material might be useful as a powder in a .22, I'm not sure

yet. It seems like it's reproducible and pretty homogenous. Particle size is a bit smaller than I want for a shotgun powder, unfortunately, but it

seems pretty close to what I'd want for a .22.

I'm not particularly fond of pressing in sheets and cutting it. While it's not hard to get particle dimensions right (though highly tedious), it is

very difficult getting the sheets proper thickness. It seems that commercial flake powders have the thickness of the plastic film that I remove from

my glassware after the NC gel that I couldn't remove dries on it.

Also, are your NC flakes orange-ish in color? Why is that? Once I add it back to water to make the fibrous powder described above it turns back

white, but let it dry in a sheet of any sort of thickness and it's opaque orange-ish.

Or are you getting your sheets thin enough to end up transparent? That's real thin, but I haven't gotten or really tried to get, sheets that thin.

I'm going to do some more experimentation with turning it back to a fibrous nature by adding it back to water. There are a lot of really tiny

particles produced that are too small to be used, but if properly classified, the primary size I obtained in my first attempt with it was actually

good.

I have done a lot of testing, comparing burn rates and such compared to commercial powders, and comparing the "poof" obtained burning a single

"average sized" particle to a single flake of commercial powder is very similar, and video comparison of the little fireball produced is almost

identical. This is done using a pre-heated hot plate onto which particles are dropped, or placed onto the hot plate and heated until they ignite. I

need to prepare another batch of this sort of material to test burn rates on larger sample sizes, ie: compare burn rates of 100mg and 500mg of my

'fibrocellulose' (I dunno what else to call it) to commercial smokeless powders. I'm thinking that it's going to be very similar based on my early

tests. After that I need to come up with a way to measure burn rates under some sort of pressurized condition. Not sure how to do that as an amateur

yet. Easy to do, but measuring it accurately isn't. Film and watch in slow motion, maybe?

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

No, I haven't tried that. Fibrous propellants, as apposed to colloided propellants, normally produce higher pressures and are much more prone to

accelerate even to detonation when confined and ignited. In comparison to most other calibers, I think you can get away with a lot more with a .22 in

terms of unideal propellants and still get reasonable results and no disaster, but I would still be cautious.

Once you have determined the density of your finished propellant, it is easy to control the thickness by controlling the other two dimensions

(size/area of sheet). An easy way to do this would be using a mould, of appropriate dimensions, that the gelatinized propellant can be poured out

into.

The sulfuric acid I use for nitrations has orange colored dye in it and the fertilizer grade ammonium nitrate also has impurities that can impart a

yellowish color. My NG and NC are often colored a yellowish orange color because of this, however even using pure acids NC in particular can have a

yellowish tint to it, depending on the level of nitration and how it was processed.

From what I have seen and read, the performance of smokeless propellants based on NC or NC & NG is extremely predictable if the composition can be

controlled and the particle size and shape controlled. With the exception of long range marksmanship where each round must perform as close to exactly

the same as the last as possible, it is much easier than we have been led to believe to produce serviceable propellants (in my opinion). Extremely

precise propellants, as are used for getting consistent results for 1000 yard shots for instance, would take much greater attention to detail. It

seems like as with a lot of other things, we can get 80 or 90% of the way there with maybe half or less of the effort.

[Edited on 1-3-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

take a little thick NC-acetone and add it to 70% isopropanol, squish it around a little bit until it's entirely not sticky. I've found that the

isopropanol works a little better than plain water. Once it's good, take it out, use a rolling pin and press it as flat as possible. Let it dry,

break it up a bit and stack it into a pile, then cut into small pieces with a knife. I just keep cutting it as small as I can, then I kind of roll it

between my fingers until it breaks about as fine as I can get it.

It's not truly fibrous but it sort of is, too.

This burns as close to commercial powder as I've gotten to date.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

What you said about needing to test the burn rate under some sort of pressurized condition is important. I am not sure how much useful information can

be had from measuring the burn rate of unconfined smokeless propellants.

The following was taken from "Ammunition General" (TM 9-1900):

"

Burning Action.

Unconfined nitrocellulose propellant burns relatively slowly and smoothly but, when confined, its rate of burning increases with temperature and

pressure. In order not to exceed the permissible chamber pressure of the weapon in which it is to be used, the rate of burning of the propellant has

to be controlled. At any given pressure, the rate of burning is proportional to the propellant surface free to burn. Therefore, propellants are made

into accurate sizes and definite shapes."

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Stabilizers: Diphenylamine and Centralite

I have seen references which indicate that diphenylamine causes hydrolysis of NG and that for double base propellants centralite, typically ethyl or

methyl centralite, is recommended instead. However, I have also seen that double based formulations do often contain diphenylamine and sometimes

diphenylamine and centralite. I now have 500g of diphenylamine, but it looks as though centralite might be more appropriate for double based

propellants. From my experience double base propellants are much cheaper and easier to make than single based and more powerful as well. I can attach

some references shortly.

From "Military Explosives":

"

9-12. Stability. The stability of nitrocellulose, which

was discussed in Chapter 8, is relatively poor. The

stability of nitrocellulose based propellants is

correspondingly poor. The degradation of nitrocellulose

proceeds by two chemical reactions. In the first

degradation reaction, nitrocellulose loses nitrogen

oxides. The loss of nitrogen oxides an intrinsic tendency of the nitrocellulose molecule.

The reaction rate varies with the temperature, but even

at low temperatures the loss of nitrogen oxides occurs.

In the second degradation reaction, which occurs initially

as a result of the first, the nitrogen oxides that are

formed attack the nitrocellulose molecule. The reaction

between the nitrocellulose and nitrogen oxides produces

more nitrogen oxides. The increased number of

nitrogen oxides and increased temperature cause the

reaction rate to accelerate. After a few years the

reaction rate in samples of sufficient size is so fast that

the propellant self-heats above the flame point and will

self-ignite. Nothing can be done to stop the first

degradation reaction. The second degradation reaction

is controlled by two means. The heat of reaction is

dissipated by a suitable heat sink, for example the metal

case of a cartridge is an excellent thermal conductor.

This does not solve the problem totally, however, if the

diameter of the cartridge case exceeds 3 inches. The

second, and most effective, means of controlling the

degradation reaction is to include a chemical stabilizer

in the propellant composition. A stabilizer has a greater

affinity for the nitrogen oxides than nitrocellulose, and

so absorbs them before they can attack the

nitrocellulose molecule. This reduces the rate of

propellant decomposition to about that of the first

degradation reaction. However, the stabilizer is

consumed as it absorbs nitrogen oxides. Therefore the

increase in time the propellant will remain stable is

directly proportional to the amount of stabilizer added.

Some propellants can be stabilized in this manner for 30

or 40 years. Three stabilizers are of interest for military

applications in the United States; diphenylamine (DPA),

ethyl centralite (EC), and the akardites (AK). DPA is

used in single-base propellants but is incompatible with

nitroglycerin and so cannot be used in double-base and

triple-base compositions. EC or 2-NDPA is used for

double and triple-base propellants which use

nitroglycerin as the gelatinizing agent for the

nitrocellulose. Akardites are used in propellants that

contain DEGN rather than nitroglycerin.

a. Diphenylamine, (C6H5)2NH, is an ammonia

derivative in which two of the hydrogens have been

replaced by phenyl groups. Each phenyl ring has three

hydrogens which can be replaced with nitro groups.

Therefore, DPA can be nitrated to the hexanitrate by

absorbing the nitrogen oxides produced during the

decomposition of nitrocellulose. DPA is nitrated

relatively easily and the reaction is not exothermic.

During the decomposition of nitrocellulose, DPA nitrates

to the following compounds in succession.

N-nitrosodiphenylamine

2-nitrodiphenylamine

4-nitrodiphenylamine

N-nitroso-2-nitrodiphenylamine

N-nitroso-4-nitrodiphenylamine

4,4', 2,4', 2,2', and 2,4-dinitrodiphenylamines

N-nitroso-4, 4'-dinitrodiphenylamine

N-nitroso-2, 4'-dinitrodiphenylamine

2, 4, 4' and 2, 2', 4-trinitrodiphenylamines

2,2', 4,4'-tetranitrodiphenylamine

2,2', 4,4', 6-pentanitrodiphenylamine

Hexanitrodiphenylamine

The propellant does not start to become unstable until

most of the diphenylamine has been converted to

hexanitrodiphenylamines. A very accurate test to

measure the remaining safe storage life in a propellant

lot is to analyze the distribution profile of the nitro DPAs.

Only about one percent DPA can be added to a

propellant because its nitrated products change the

ballistic properties.

b. Centralite I (which is also called ethyl centralite

or symmetrical diethyldiphenylurea), OC [N-(C2H5)

(C6H5)]2, was developed in Germany for use in double

base propellants. The compound acts as a stabilizer,

gelatinizer, and waterproofing agent. Unlike

diphenylamine, centralite can be used in relatively large

proportions and some propellant compositions contain

as much as eight percent of this material. Like

diphenylamine, centralite is nitrated by the products of

nitrocellulose decomposition. The following compounds

are formed successively, as many as four being present

simultaneously, as deterioration of the powder proceeds.

4-nitrocentralite

4,4' dinitrocentralite

N-nitroso-N-ethylaniline

N-nitroso-N-ethyl-4-nitraniline

2,4, dinitro-N-ethyl-aniline

Centralite II (which is also called methyl centralite or

symmetrical dimethyl diphenylurea), OC[N(CH3) (C6H5)

]2, also has been used as a stabilizer but is not

considered to be as effective as the ethyl analogue.

9-4. Akardite II is often used in DEGN containing

propellants. c. Three akardites, or acardites, are used to

stabilize propellants. Their structure is shown in figure 9-4. Akardite II is often used in DEGN containing

propellants."

There are many other references as well discouraging the use of diphenylamine in double base propellants, but also some sources suggesting it as well.

[Edited on 20-3-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

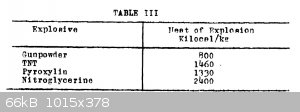

I recently posted the following on page forty of the shaped charge thread. It is probably even more relevant in this thread, so I have included it

here.

Quote: Originally posted by Hennig Brand  | To act as a chemical stabilizer, making the explosive more storage stable. It does also desensitize the explosive to initiation a lot as well, but

that was not what I was commenting on. The following was taken from the Naval Propellants page which has a pdf made of it in the propellants thread,

"Mark I cordite consisted of 37% nitrocellulose (13.1% Nitrogen), 58% nitroglycerine and 5% petroleum jelly. This last ingredient had originally been

used as a lubricant during the manufacturing process, but it was found that it also acted as a stabilizer as its unsaturated hydrocarbons counteracted

the byproducts of the decomposition process."

I wonder if the Vaseline we buy at the drug store is the same as what they were using to make Cordite. Has it been purified and the unsaturated

hydrocarbons been removed for the most part?

|

Here is something else of interest, taken from an old defense document (Powder and Explosives by A. G. Gorst). Comparing the heats of explosion, it is

very clear why double base propellants are normally so much more powerful than single base propellants and also why double base propellants typically

damage barrels at a much higher rate as well.

[Edited on 26-3-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

In at least one place, the manufacture of improvised powder IS regularly done: Khyber pass!

http://www.rimfirecentral.com/forums/showthread.php?p=518568...

Found this posted by a Pakistani of another forum I'm a member of, with pictures of re-manufactured 7.62X39 rounds using spent cases with home made

bullet, primer and POWDER. They are NOT careful reloaders nor accomplished powder makers...

[Edited on 1-11-2015 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

greenlight

National Hazard

Posts: 763

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

What sort of homemade propellant is that? Looks like chopped up tobacco.

Aren't the grains to reload rounds supposed to be of uniform size and shape for loading the correct amounts and for burn rate control? Those look to

be of all sizes and shapes.

[Edited on 1-11-2015 by greenlight]

|

|

|

| Pages:

1

..

5

6

7

8

9

10 |