| Pages:

1

..

5

6

7

8

9 |

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Half an hour ago I've mixed TCCA and NaOH in water while keeping the mixture cool, then I added a few drops of acetone and the mixture became

cloudy.

The I smelled the reaction mix and was greeted with the lovely smell of chloroform!

A new, high- yielding OTC method of making CHCl3!

No large amounts of bleach needed!

TCCA contains LOTS of chlorine and this reaction converts it ALL to chloroform!

I will elaborate a complete synthesis of chloroform from TCCA.

If anyone's interested, I can write it down when I'm ready.

|

|

|

UhhKaipShaltaBlet

Harmless

Posts: 11

Registered: 23-1-2005

Member Is Offline

Mood: Shalta Blet ...

|

|

Excuse me of my ignorace ,but what's "TCCA"?

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Trichloroisocyanuric acid, a common pool chlorinating chemical.

|

|

|

chloric1

International Hazard

Posts: 1142

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

| Quote: | Originally posted by garage chemist

Half an hour ago I've mixed TCCA and NaOH in water while keeping the mixture cool, then I added a few drops of acetone and the mixture became

cloudy.

The I smelled the reaction mix and was greeted with the lovely smell of chloroform!

A new, high- yielding OTC method of making CHCl3!

No large amounts of bleach needed!

TCCA contains LOTS of chlorine and this reaction converts it ALL to chloroform!

I will elaborate a complete synthesis of chloroform from TCCA.

If anyone's interested, I can write it down when I'm ready. |

That is awesome! I would like to try the TCCA & NaOH mixture on ammonia mixed with acetone or methylethyl ketone. A little gelatin wouldn't

hurt for cautionary measure. I just need to find TCCA in a container small enough to be economical. How well does TCCA dissolve in water and in

alkali anyway?

Fellow molecular manipulator

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I'm sorry, I wasn't able to produce significant amounts of chloroform from TCCA and, to be honest, I stopped the research because a supplier

started carrying chloroform and I bought 500ml for 10€.

That's more than I will ever use...

But it's still possible to make lots of chloroform from TCCA by adding HCl and bubbling the resulting chlorine gas into ice-cold dilute NaOH.

This produces NaOCl in a concentration depending on the starting concentration of NaOH. Up to 20% NaOCl are possible. Upon reacting this with acetone,

chloroform will be had in high yield.

This method converts ALL chlorine from the TCCA into chloroform.

Making NaOCl from chlorine + NaOH would also be highly advisable for hydrazine production, because my chloroform attempts directly from TCCA failed

and this indicates insufficient NaOCl concentration in the TCCA + NaOH mixture.

Don't try to make hydrazine with that!

Instead, build a fume hood / get a gas mask / work outside when its windy, produce chlorine from TCCA and HCl and bubble it into cold NaOH. The

resulting NaOCl solution is most likely much purer than the storebought pool chlorinator, this can improve yields with hydrazine production

considerably.

|

|

|

chloric1

International Hazard

Posts: 1142

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Wait a minute!

Now I know pool suppliers also sell sodium dichloroisocyanurate. Would this be your reagent from TCCA and NaOH? Or maybe its not that simple. Maybe

the alkali hydrolysizes the TCCA to release free NaOCl. I am not familiar with the oxidizing species involved here though. I once tried a Sodium

Dichlor oxidation of sodium bromide and only got a yellow precipitate. No free

bromine. Anyone a pool expert out there? I would like to hear some input on the stabilized chlorinators No free

bromine. Anyone a pool expert out there? I would like to hear some input on the stabilized chlorinators

Fellow molecular manipulator

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Electrolytic Chlorination

Is anyone familiar with a method of producing chloroform by electrolysing aqueous CaCl2 and acetone? I saw this a few years ago but I'm having

trouble locating the details.

[Edited on 18-2-2005 by Eclectic]

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

GC, what was the yield of chloroform?

Lately I've been in demand of big amounts of cheap chlorine, in synth of things like S2Cl2. Since calcium hypochlorite here is 40$/2 kg, TCCA

even more, KMnO4 is 11$/0,75 kg and MnO2 is 8$/kg..

...therefore I wanna finally try the electrolytical way.. Since I like mspaint here I've drawed the theoretical setup I'll use. It suppose

to work continiously.

http://img.photobucket.com/albums/v113/frogfot/chlorineelapp...

I've tried to keep it as simple as possible and doable with OTC parts.

So the electrolyte in anodic cell will be continiously refilled by KCl soln so it will have slightly higher level of liquid than in cathodic cell.

The membrane will be composed of glass wool (glassfiber blankets). I dunno if some filler/binder will be needed.. probably yes..

Important thing is to keep appropriate current dencity above membrane, so it wouldn't boil from inside (had some bad experience with salt

bridges..).

9V would be probably enough.

Everything seems to be quite easy to make. Anyone see some obvious mistakes in the design?

[Edited on 18-2-2005 by frogfot]

[Edited on 18-2-2005 by frogfot]

|

|

|

Esplosivo

Hazard to Others

Posts: 491

Registered: 7-2-2004

Location: Mediterranean

Member Is Offline

Mood: Quantized

|

|

Nice method to produce chloroform, nice and cheap. The chloroform though being organic would probably result in the remains of hydrolysis of TCCA, or

excess TCCA being dissolved in it though. Distillation might be enough to seperate them, but the organic products of hydrolysis might be as volatile

or nearly as chloroform and share the same boiling point (although I don't think so). Am I correct in assuming that the chloroform synthesized in

this way will contain a lot of contaminants?

[Edited on 18-2-2005 by Esplosivo]

Theory guides, experiment decides.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I only got some white precipitate and no liquid chloroform. Actually, the smell of chloroform disappeared rapidly from the mix...

You can experiment if you want, maybe you've got more luck than me.

However, I would convert the TCCA into NaOCl via chlorine (from TCCA + HCl) and NaOH and then add acetone to this. This reaction is much cleaner, the

produced chlororform doesn't need to be distilled and the yields are much higher, anyway.

@ frogfot:

Your cell looks good. But the chlorine production will be slow. To make S2Cl2, you would have to run it a long time and keep the sulfur molten the

whole time.

Or you could condense the chlorine into a liquid with dry ice. If you can get dry ice, this would be ideal. Then you can let the chlorine boil off at

the required rate.

The MnO2 seems cheap though. Or is it still too expensive for you?

[Edited on 18-2-2005 by garage chemist]

|

|

|

chloric1

International Hazard

Posts: 1142

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Boiling point

You are right about liquifying chlorine at dry ice temperatures. Actually -30F should work. But, I should mention that the plain ice will not have

enough contact surfaces with your receiver to chill it. You need to add it to a nonfreezing liquid until the liquids temperature approaches that of

the ice itself. Try a nonflammable solvent like trichloroethylene. Anywho just realized I have no way to measure extreme cold myself so I need to

find me a voltmeter with a thermocouple! Off to Jameco I go! Off to Jameco I go!

Fellow molecular manipulator

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

Liquifying chlorine is a bit scary. I do smelly things in homemade fume hood that could vent an acccidental leakage from a normal chlorine generator..

but accident with liquid chlorine would be too much for it..

As for speed, at 10A it would give me 1,16 ml Cl2/s (at 100% efficiency) which is suitable in most experiments..

[Edited on 18-2-2005 by frogfot]

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

Anyone ever tried to build a DeNora cell?

Basically it uses brine as an electrolyte, graphite as the anode, and mercury as the anode.

When electricity is passed thru the cell, Chlorine gas is formed at the anode, and Sodium is evolved at the cathode. The sodium forms an amalgam with

the mercury, which is then drained off and placed into water. The sodium reverts into sodium hydroxide and the mercury is reloaded into the cell.

The reaction is:

Hg

(Cathodic reduction) Na+ + e- ------> Na (Amalgam)

2Na (amalgam) + 2H20 ------> H2^ + 2NaOH

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I've always wondered how you keep the Na from reacting with the electrolyte; or does the voltage tend to keep that "sealed in"?

Aside from a small contaminant of mercury, it makes very high purity lye industrially, so I've read. Seems to me it would take a lot of mercury

and be kind of complicated in a continuous process (not necessary of course, but with only 2% Na (also as read), almost a necessity) though.

Given this thread is about the other product, it might work for that purpose, just loading the mercury with sodium until it starts fizzing or

something.

Tim

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

@ Organikum:

I have been wondering about the exact amount of chlorine which is produced when a given amount of TCCA is reacted with an excess of HCl.

Today I tried to measure the gas volume, but the chlorine layer above the water was shrinking before my eyes as it dissolved to make sterile water.

But I also found out that the reaction indeed goes to completion, as I used 3,5mol of HCl on 1mol of TCCA and boiled to expell all chlorine, and on

further addition of HCl, no more chlorine was produced on boiling.

In your "Practical production of chlorine" thread, you said that 6mol of Cl2 are produced from 2 mol of TCCA (I saw that you took in account

that the commercial material is only 92% TCCA and therefore the "molar mass" of this product is 250 g/mol).

But in your downloadable calculations on TCCA, you stated that only 2mol of Cl2 are produced from 1mol of TCCA!

What is true now? Am I missing something?

[Edited on 19-5-2005 by garage chemist]

|

|

|

chloric1

International Hazard

Posts: 1142

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Preliminary workup

Recently purhcased two 8 oz giant 3 inch TCCA tablets and ground them up with my high tech granulator(ball ping hammer+ziplock freezer bag) . Anywho, I took about 2 or 3 grams in a small beaker and added 50 ml of 31.45%

HCl all at once. It definately made chlorine but the reagents bubbled to a surprising volume. Two thoughts I have; First dilute my muratic acid to

exactly one half with water,Secondly slowly drip the HCl on the solid with extremely low heat. I wanted to see if it was possible to generate a

gentle yet consistant flow of chlorine. Any creative thoughts welcome. Maybe a Kipp generator setup? . Anywho, I took about 2 or 3 grams in a small beaker and added 50 ml of 31.45%

HCl all at once. It definately made chlorine but the reagents bubbled to a surprising volume. Two thoughts I have; First dilute my muratic acid to

exactly one half with water,Secondly slowly drip the HCl on the solid with extremely low heat. I wanted to see if it was possible to generate a

gentle yet consistant flow of chlorine. Any creative thoughts welcome. Maybe a Kipp generator setup?

Fellow molecular manipulator

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

The concentration of the HCl is very important.

Someone found out that the reaction of TCCA with concentrated HCl does not go to completion. Reaction with dilute HCl gives much more chlorine and the

reaction almost goes to completion.

The TCCA needs lots of water to be able to dissociate into HOCl and cyanuric acid.

The HCl must not be stronger than 15- 20%.

For making chlorine, I use a two- neck 500ml rbf with a pressure- equalized dropping funnel on the middle neck and a hose adapter on the side neck

where the chlorine can be withdrawn.

All joints must be greased and secured with wire, otherwise they may get loose without you noticing until the chlorine gets into your nose.

The TCCA is coarsely granulated, not powdered (to prevent excessive foaming) and wetted with a little water.

When all HCl has been added, the mix must be heated to complete the reaction.

|

|

|

chloric1

International Hazard

Posts: 1142

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Thank you

I admit I have been out of the loop as far as practical hands on chemistry goes for awhile. I have a three month old daughter and am going through a

career hiccup. But, Everything now will find its place I am going to stop being

an armchair chemist and get going soon. I am going to stop being

an armchair chemist and get going soon.

Buy the way, if I add water to my TCCA will it help to coalulate it again and give me a satisfactory Cl2 stream or is it too late for my powder? I do

have a few larger particles but 80% is probably 50 or 60 mesh or finer. Ahh, I will play around a little more with it today and tomorrow.

By the way, a little off topic but still chlorine related. I have a pickel jar I will to use as an electrolytic cell/battery and I am sterilzing with

sodium hypochlorite. This morning while doing the TCCA workup, I also added conc HCl to my very dilute hypochlorite(less tahn 1%) to destroy more

organics and left it in the sun. I fugured that would be interesting as we are approaching record heat today. I wanted to see with how fast oxygen

would be liberated from water in sunlight. What I found was that the gases evolved only when a foriegn object introduced. This is of absolutely of

no value except in its academic realizations. But its cool

[Edited on 6/5/2005 by chloric1]

[Edited on 6/5/2005 by chloric1]

Fellow molecular manipulator

|

|

|

chloric1

International Hazard

Posts: 1142

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

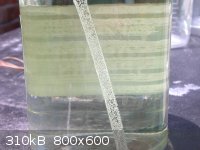

Here is a photo that demostrates the photodissocation of chlorine and water

<!-- bfesser_edit_tag -->[<a href="u2u.php?action=send&username=bfesser">bfesser</a>: reduced

image size(s); attached]

[Edited on 9.8.13 by bfesser]

Fellow molecular manipulator

|

|

|

Analytiker

Harmless

Posts: 1

Registered: 20-7-2005

Member Is Offline

Mood: No Mood

|

|

Chlorine gas/liquid color

I worked with liquified chlorine with a headspace quite a while back. I had a sight glass installed at the liquid/gas interface.

Green gas, red liquid. Very Christmas-like.

|

|

|

kickflip_333

Harmless

Posts: 3

Registered: 11-7-2005

Member Is Offline

Mood: nine and a half

|

|

festive AND fun.

|

|

|

Mason_Grand_ANNdrews

Hazard to Self

Posts: 63

Registered: 19-1-2006

Location: New Berlin City !!

Member Is Offline

Mood: crabby

|

|

I have any useful stuff to the chlorine source. If anyone interested, i will make a samll HTML to the subject.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I've been wanting to try some chlorination reactions using UV light to generate free radicals for some time. I had read through this thread some time

ago and decided to try the TCCA + HCl method for generating chlorine. My goal was to produce a steady stream of relatively pure, dry chlorine, with

good control. Good control included being able to stop the reaction quickly should something go wrong.

My chlorine generator is a 1 liter suction flask. 18% HCL was to be dropped as required onto coarsely ground TCCA using a 250 mL separatory funnel.

This assembly was sitting on a stirrer-hotplate for heating/agitation, if required.

For a drying train I set up two wash bottles in series partly filled with Rooto sulfuric acid (~96%). The inlet dip tube in each bottle was about

4cm below the acid surface. The glass tubing was 6mm OD and was connected together with 6mm ID Tygon (soft PVC) tubing. Following this is a 250mL

Erlenmeyer flask as safety bottle in case of suckback. Finally, the Tygon tubing was connected to a 7mm OD gas dispersion tube having a fritted end

to produce fine bubbles. This dispersion tube was placed in the chlorination vessel which is a large test tube. In the test tube I had placed some

DCM.

Everything seemed tight so I turned on the 500w halogen lamp and the hood fan, and started dropping in HCl, just a few drops at a time. A

yellow/green gas could be seen in the generator flask right away. But also right away a fatal flaw in my setup was apparent. Due to downstream

resistance an adequate Cl2 pressure had to be built up and maintained in the generator flask. But when this pressure began to build it would vent Cl2

up through the stopcock of the dropping funnel. This can be easily understood when the backpressure is estimated: (2)(4cm)(1.85) = 14.8cm H2O back

pressure just to overcome the sulfuric acid heads alone. Then add in the glass frit resistance and the DCM head of about 8cm and I come up with ~23cm

H2O of backpressure. This was just about right to overcome the head of HCl in my dropping funnel. So now I see why addition funnels with pressure

equalization are useful!

Actually, after reviewing this thread again, it seems like a another absorbant might even be advised. That is, shouldn't the first bottle contain an

absorbant to take out the HCl gas that will surely be a contaminant in the Cl2?

It seems to me that the every gas delivery situation can be different. That is, some will require contaminant removal via solid absorbants (ie,

CaCl2, mol sieves, etc), some will require absorption through a liquid (ie, H2SO4, NaOH, etc), and some may require some of each. In all cases some

amount of driving pressure head will be required. This seems like an important and generic problem that may be encountered by the home chemist. But

I find little or no information, guidelines, etc, in any of my books or on the internet.

This is a long story. But I wanted to get it out as an example of problems that can be encountered in gas generation, cleanup, and delivery. I think

chlorine generation is a good example of typical problems that must be overome.

Below is a picture of rev1 of my chlorinator. Critique, suggestions, and discussion are welcome.

[Edited on by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

I use acid filled syringes, with the tubing to the generating vessel secured well, to add the acid to the generator vessel. No issues with the

pressure anoyances here.

Also just realized I have not worked with chlorine for around a year and a half...weird.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

There is no need to remove HCl gas from the chlorine stream, as your reaction (chlorination of DCM) produces HCl anyway, like most organic

chlorinations do.

Only removal of H2O vapor is necessary (but this is important). Conc. H2SO4 can be used, CaCl2 too.

CaCl2 may be a better choice for you, since it creates far less pressure drop than H2SO4.

While your method of chlorine production sounds good (apart from the issue with the dropping funnel), your method of chlorination has to be improved.

For instance, a reflux condenser is absolutely vital if you are chlorinating anything. Those reactions either have to be done at the boiling point of

the substance, or they produce a lot of heat. Cooling slows down the reaction too much, so refluxing is necessary.

Or did you just want to create a solution of chlorine in DCM? Then you would have to cool with ice.

I doubt that you will be able to get more than one chlorine attached to the DCM, since I have done chlorinations of things like red P in boiling

chloroform and upon recycling of the solvent, no noticeable CCl4 was present.

One last thing: granulated TCCA does not react completely with HCl, since it gets coated with cyanuric acid. You either have to finely powder the

TCCA, or you have to heat the gas generator to boiling after all HCl has been added.

[Edited on 19-5-2007 by garage chemist]

|

|

|

| Pages:

1

..

5

6

7

8

9 |