| Pages:

1

..

62

63

64

65

66

..

68 |

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

The bucket looks like he go through a war zone. Good Mad attempts......

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

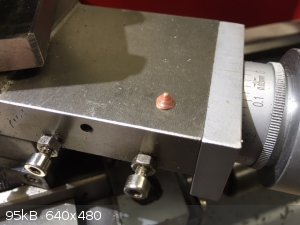

Working on refining the liner geometry a "bit".....

Indicating the support to be dead centered, the rough liner after pressing (0,3mm thickness), the adhesive for fixing the liner to support:

Taking off the high spots with a really tiny cutter until an even surface is achieved:

After a bit of polishing the outer surface can be deemed worthy....also a glimpse at the black oxide coated holder I made for the cony bits to keep

them from submitting to the call of the second law of thermodynamics (enthropy being the key word here  ) )

A wee bit of heat helps to get the liner off the support without any troubles:

The arse end of the same support is machined to accomodate the concave image of the liner for a reversed seating and a matching cone in the tailstock

shall support the copper while being glued to place:

Seems to turn out OK.....but the troubles began as I attempted to machine the inner surface flat. Seems that the seating was so perfect, the glue does

not wick inbetween the surfaces and only holds the outer rim. Two times the liner came loose during machining...I gotta figure out something to

rectify this:

I am puzzled....that adhesive is like the devil when it comes to seeping between surfaces, even the tiniest microcracks are filled instantly and

completely. And now it fails to the job....

[Edited on 21-1-2019 by markx]

Exact science is a figment of imagination.......

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

In the spirt of Axt I would like to turn this thread in the direction of unconventional liner shapes if possible. Now, with 3D printing we can’t

print any liner shape we dream of.

Does anyone have any documents or sources on active tamping, wave shaping, various liner shapes (tulip, fluted, swept, trumpet, bell, biconical,

corrugated) that produce better penetration???

A former professor says he can grant me access to a 3D metal printer... so now that any shape (including thickness variations) is possible to

manufacture... I am trying to determine which shape is the absolute optimum. My philosophy is to build on the shoulders of others... rather then

reinvent the wheel

I plan to print the liner material from copper and print the wave shapers with plastic. Any shape of any complexity is possible.

Thank you! I am much looking forward to your responses.

[Edited on 5-3-2019 by MineMan]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

You can try the "x-charge": a classic cone liner with a mirroring cone waveshaper just behind it. The tips virtually connected. The cross section

looks like a X shape....hence the designation. It was supposed to have greatly enhanced depth of penetration. For the life of me I can not remember

where I read about this design. It was some kind of a document describing the developments of shaped devices in US military structures....

It is way more productive to cast the waveshapers from epoxy. Into molds formed from play dough. One can make numerous specimens in mere minutes. The

original mold forming tool may be 3D printed if it is of a particular geometry.

[Edited on 5-3-2019 by markx]

Exact science is a figment of imagination.......

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Markx. You read that in “100 year history of shape charges”. They claimed to have accelerated EFPs to 6kms using the X Charge. Although little

detail is given. For some reason, the current wave shapers I have seen are not mirror images...

A few months ago I saw a very complex waveshaper that was being modeled. It looked like symmetric claws... I can’t find that document anymore... it

seems there has been a purge of this technology on the internet.

It sucks that I will only know the innovation of 40 years ago... it seems this material is home to so,e of the largest libraries... which are

classified??

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by MineMan  | Markx. You read that in “100 year history of shape charges”. They claimed to have accelerated EFPs to 6kms using the X Charge. Although little

detail is given. For some reason, the current wave shapers I have seen are not mirror images...

A few months ago I saw a very complex waveshaper that was being modeled. It looked like symmetric claws... I can’t find that document anymore... it

seems there has been a purge of this technology on the internet.

It sucks that I will only know the innovation of 40 years ago... it seems this material is home to so,e of the largest libraries... which are

classified?? |

You are probably right, I remember there were a lot of historic descriptions of events represented in that book.

I know the "clawy" design you are talking about....if I recall correctly it was a novel approach regarding the formation of a large diameter jet that

was almost equal to the diameter of the charge. Very complex approach from a technical side.

Old information is not of lesser value to the researcher, in fact I have often found the very opposite of that being true. And really for obvious

reasons the contemporary discoveries in that field are not public knowledge nor will they ever be. So it is of little use to feel dissappointment

about it

But on a generic level, given the emergence of destructive insanity that rises it's ugly head in the world, I fear that very soon we shall experience

a major censorship ban on a great deal of information which we regard as being freely available. It shall happen quietly, gradually, in official

denial of the fact and I feel it has already started. This process shall hardly be reversible in our lifetime and that truly is something that we

should feel very much dissapointment about.

Exact science is a figment of imagination.......

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  |

I fear that very soon we shall experience a major censorship ban on a great deal of information which we regard as being freely available. It shall

happen quietly, gradually, in official denial of the fact and I feel it has already started. This process shall hardly be reversible in our lifetime

and that truly is something that we should feel very much dissapointment about. |

You are right.

This video was made by a friend: https://youtu.be/CMYEx4hEA3g

Before you say anything: the author is a chemical engineer, retired Navy EOD and now writes safety procedures for a refinery. So dont say he shouldnt

touch it.

He made a wooden replica of that mine (shown at the end) for historical reasons, shared all the details with the World and... got a call from the

authorities.

Apparently this could give bad ideas to bad people so he was asked to remove most information he had published...

|

|

|

hellstrom

Harmless

Posts: 2

Registered: 28-3-2019

Member Is Offline

|

|

Greetings all. This be my first post though I've been lurking for quite awhile.

I've been bouncing around the interwebs in search for information referencing a shaped charge with cylindrical liner, but without much success.

However today I found a patent that describes exactly that. Link below for those who may be interested.

https://patents.google.com/patent/US2988994A/en

-hellstrom

-btw, please feel free to correct me if I break any forum rules.

|

|

|

C6(NO2)5CH2CH(CH3)N(NO2)2

Harmless

Posts: 43

Registered: 4-4-2018

Member Is Offline

Mood: No Mood

|

|

Axt did try out a cylindrical liner here a long time ago. It's what got this thread going! But he's not active here anymore, and the design was just

initiated from the back of the charge like most shape charges are. No special initiation points were used like they were in the patent.

https://www.sciencemadness.org/whisper/viewthread.php?tid=10...

Put that in your pipe and smoke it!

|

|

|

hellstrom

Harmless

Posts: 2

Registered: 28-3-2019

Member Is Offline

|

|

I'm putting together a simplified version based on the patent. Probably not unlike the one built by Axt. Images and results to follow.

-hellstrom

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Sweet. I have an idea for a conical/cylindrical hydrid.... I would be interested in large dia cylindrical because theoretical one could only have

1.5cm of explosives around the inner pipe if it is thin enough. 4 inch or larger would be interesting.

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

All. See what complex wave shaping is capable of!!

https://www.researchgate.net/profile/A_Resnyansky/publicatio...

Now my question to you fellow scientist is the paper says aluminum makes the best penetrator for copper because it matches the impedance of the

concrete target....

Can someone explain this?

I thought penetration was all about, jet length, density and velocity... once again I guesss Newtonian physics is over simplified

|

|

|

specialactivitieSK

Hazard to Self

Posts: 94

Registered: 21-10-2014

Member Is Offline

Mood: No Mood

|

|

How can working flexible shaped charge Semtex Razor ?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Could you re phrase your question? Are you asking how to CUT a SEMTEX linear shaped charge to a needed size, or how to use such a charge to MAKE A

CUT?

Or something else yet again???

[Edited on 11-25-2019 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

specialactivitieSK

Hazard to Self

Posts: 94

Registered: 21-10-2014

Member Is Offline

Mood: No Mood

|

|

The flexibility. How can work flexible shaped charge without solid liner. What type of liner is used.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I think these flexible linear shaped charges have thin lead liners which can be bent and shaped as lead is malleable in thin sheets.

The explosive filler would be a polymer or plasticizers based HE which allows for movement.

The outer case and standoff would be some sort of polyurethane or similar bendable plastic.

Be good, otherwise be good at it

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

To me, that looks more like a copper liner. I would think it is probably just annealed, but it is possible to make shaped charges with liners made

from powdered metal such as copper or tungsten. If the powder was bonded in a rubber matrix, it would be possible to make a flexible shaped charge,

though it wouldn't be quite as effective as a normal one with a solid liner.

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | | To me, that looks more like a copper liner. I would think it is probably just annealed, but it is possible to make shaped charges with liners made

from powdered metal such as copper or tungsten. If the powder was bonded in a rubber matrix, it would be possible to make a flexible shaped charge,

though it wouldn't be quite as effective as a normal one with a solid liner. |

Why not as effective? Easier for the liner to collapse... jet could have the same momentum if the thickness is adjusted. I ask as someone who is

interested in bonded metal liners.

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

The density and speed of sound in the Cu-powder will likely be lower than in the solid, annealed copper. Also, since spinning the liner (on a lathe)

from a plate reduces effectiveness due to the stresses imparted to the copper (it makes the jet spin), I am pretty sure that copper with lots of voids

will produce a more "diffuse" jet.

Nevertheless, this technique is used in the oil industry to perforate the rock and allow the oil and gas to flow into the drilled hole. The powdered

metal doesn't leave a carrot in the hole, so it is easier for the oil to pass.

|

|

|

infinity

Harmless

Posts: 6

Registered: 16-9-2019

Member Is Offline

|

|

Main issue with cylindrical liner is that jet mass will be very very small and hence penetration will be very poor especially at large stand off. One

will not get jet velocity equals to 2 times detonation velocity as collapse angle will never be zero.

|

|

|

infinity

Harmless

Posts: 6

Registered: 16-9-2019

Member Is Offline

|

|

Quote: Originally posted by MineMan  | All. See what complex wave shaping is capable of!!

https://www.researchgate.net/profile/A_Resnyansky/publicatio...

Now my question to you fellow scientist is the paper says aluminum makes the best penetrator for copper because it matches the impedance of the

concrete target....

Can someone explain this?

I thought penetration was all about, jet length, density and velocity... once again I guesss Newtonian physics is over simplified

|

Penetration to any target depends upon the impedance of penetrator and target. If penetrator impedance is larger than target, one gets maximum

penetration with less lateral damage. This is the case for copper jet against concrete target. Now when we use aluminium liner, its impedance matches

with that of concrete and lateral damage is more in such a case. Because aluminium jet deposits more energy in concrete than a copper jet during

penetration.

|

|

|

infinity

Harmless

Posts: 6

Registered: 16-9-2019

Member Is Offline

|

|

Lead is a good liner material for use in flexible linear shaped charges.

|

|

|

infinity

Harmless

Posts: 6

Registered: 16-9-2019

Member Is Offline

|

|

Quote: Originally posted by markx  | You can try the "x-charge": a classic cone liner with a mirroring cone waveshaper just behind it. The tips virtually connected. The cross section

looks like a X shape....hence the designation. It was supposed to have greatly enhanced depth of penetration. For the life of me I can not remember

where I read about this design. It was some kind of a document describing the developments of shaped devices in US military structures....

It is way more productive to cast the waveshapers from epoxy. Into molds formed from play dough. One can make numerous specimens in mere minutes. The

original mold forming tool may be 3D printed if it is of a particular geometry.

X charges and K Charges are not very effective in terms of penetration as compared to a conventional shaped charge at stand off distances of 3-4

calibers. These special shaped charges use less explosive quantity as compared conventional ones. Hence the contribution of total energy to

penetration is also less. The moment one brings the waveshaper closer to the liner, tip portion of liner gets vaporised due to high incident angles of

detonation wave. Then one needs to go for higher angle cones which naturally have lesser velocity. But then if one looks for large stand off

applications, these shorter shaped charges may be of some help.

[Edited on 5-3-2019 by markx] |

|

|

|

infinity

Harmless

Posts: 6

Registered: 16-9-2019

Member Is Offline

|

|

Quote: Originally posted by greenlight  | I have been constructing a new 44mm EFP charge over the past weeks to try and punch a hole through a target that has resisted every attempt with a

30mm design.

The specs are:

▪Diameter = 44 mm

▪Flyer thickness = 1.5 mm Cu

▪Casing = PVC

▪Charge Weight = 26 g PETN PE (16% inerts)

▪Standoff = 95cm

▪Target = 20mm steel

I usually sight the charge with a high powered laser pointer which helps a lot as it is quite difficult to get a direct hit just by eyeing it. Of

course the thing decides to shit itself today and makes sure it waits til I am at the test site to do it

The target plate is only the size of a dinner plate so it's a small area to hit but I sighted it by eye as best I could before inserting the cap and

initiating it.

Walked back to ground zero and wow, shock and awe, it hit high . .

It is quite a decent hit though and quite a wide projectile due to the low head height of the charge. As can be seen by the photos, because it was so

close to the edge of the plate it penetrated for a bit and then lost kinetic energy to the side as it took the path of least resistance and slid off

over the top of the plate (that part was the top, plate was stuck in ground). You can also see stress fractures in the steel.

Also take into account the fact that it would have hit at a 10° angle instead of straight on, and the plate was just hammered into the ground and had

some movement.

Penetration from what I can record is about 13mm before it started moving laterally. Im sure it would have almost if not fully made it if the hit was

direct. Can always try some barrel tamping if not.

Guess I will have to step it up to a 50mm and have another crack at it, but first to find another decent laser pointer.

[Edited on 15-10-2018 by greenlight]

[Edited on 15-10-2018 by greenlight] |

Experiments are fabulous. But there can be some improvements i feel. The flier thickness is too small for that caliber. It could be closer to 2-2.5mm.

The deviation from the aim point could be due to break up of the projectile. Break up of projectile leads to a shift in momentum vector and deviation

in its path. Also multiple hits are seen on the target. Best way to avoid this is to use a variable thickness liner.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thankyou..

The next variable to be changed was indeed the flyer thickness up to 2mm.

The projectile from that test did hit in one spot with minimal breakup, the other marks are from previous tests.

Unfortunately it hit on the very top and transferred a third of its energy off the damn plate

Be good, otherwise be good at it

|

|

|

| Pages:

1

..

62

63

64

65

66

..

68 |