| Pages:

1

..

4

5

6

7

8

..

14 |

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Why not lead the NO2 back into your acid reactor?

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

Nah, too much trouble unless I can absorb all of it. Somebody suggested using H2O2, but I don't know about its effectiveness yet.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

If you simply use PbO, or PbCO3 or whatever, you'll have no problem. I suppose H2O2 might help, the solution will turn basic and the lead will

dissolve, both in the presence of H2O2 which will decompose and oxidize fine in those conditions.

Tim

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

OK, I think I've narrowed down my choices in making Pb(NO3)2 using lead metal:

1. Pb = > PbCl2 => PbCO3 => Pb(NO3)2 as discussed here

2. Electrolysis of ammonium nitrate using lead as anode

For 1, can I use only HCl and no nitrate, or will that reaction be too slow? Could I speed it up by electrolysis? Also, I don't see how the chloride

gets converted to carbonate. Assuming PbCl2 + Na2CO3 => PbCO3 + 2 NaCl is the path and it's reversible, it seems the products aren't favored

because PbCl2 has very low solubility, except at high temperature, and PbCO3 is much more insoluble?

For 2, are there any impurities formed? How do I separate Pb(NO3)2 from the NH4NO3?

Please share any practical experiences

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

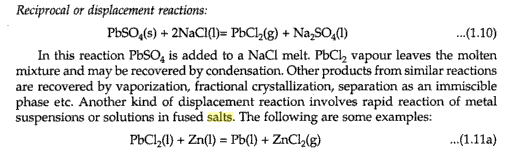

The products ARE favored because PbCl2 is very slightly soluble, PbSO4 is much less soluble, and PbCO3 a bit less soluble still. So, it is possible

to make the sulfate or carbonate from the chloride in excellent yield, and the carbonate from the sulfate in reasonable yield.

Tim

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

12AX7,

I see you have a lot of experience with making lead salts on your web page. Can I make lead carbonate directly by electrolyzing lead with a sodium

bicarbonate solution, which would be a lot easier than first making PbCl2? Then I can react the PbCO3 along with any lead that plated on the cathode

with nitric acid to get what I want.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

The anode may passivate. Inevitably a goodly amount of lead will dissolve (carbonate complex? high cathodic pH?) and deposit on the cathode as a

spongy mess.

If you can prevent the deposition process (or don't mind screening it out periodically), it works.

But there's one more caveat. Bicarbonate is just fine, but as PbCO3 leaves solution, HCO3- turns to CO3(2-) and then CO3(2-) is depleted leaving more

OH-. And lead dissolves in a hydroxide solution, enough that even more will be plated across. What's more, what does precipitate is Pb(OH)2, not the

desired PbCO3 -- although that doesn't matter for your purpose at least.

The best approach, which I recall reading in a book in the SMDB library about industrial electrolytic production, involves adding CO2 to compensate.

Ideally you'd have a bubbler, possibly under pressure, basically to maintain your electrolyte as salty club soda. That keeps the carbonate levels

high, minimising pH (a soda solution concentrated with CO2 will hover around what, pH = 6?), keeping lead out of solution.

Tim

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

This may be of some use.

http://www.geocities.com/CapeCanaveral/Campus/5361/chlorate/...

Dann2

|

|

|

UncleJoe1985

Hazard to Self

Posts: 88

Registered: 30-9-2008

Location: Sunnyvale, CA

Member Is Offline

Mood: No Mood

|

|

| Quote: |

That keeps the carbonate levels high, minimising pH... keeping lead out of solution |

If I add HCl, will that keep the Pb ions from being reduced at the cathode?

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

HCl will increase chloride ion concentration resulting in PbCl2 fouling the anode. The only acid you want is carbonic, as that's what's being removed

from solution.

Tim

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Can accross the following here:

http://books.google.ie/books?id=0eGe5wDUEa0C&pg=PA13&...

Anothe way to Lead Chloride.

Dann2

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Sure, PbCl2 is nice and volatile. Just don't do it in a steel pipe (unless you want crusty holes and FeCl2 instead!).

Tim

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Link below to a book on Lead.

Worth a look for those big into this heavy stuff.

http://www.ila-lead.org/factbook/

Dann2

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

Bumpity - I am one of the lead dioxide nuts who can't stop attempting to plate this catalytic material for electrochemical purposes. Recently, I

bought a home lead detection kit to see how far (and if) any Pb traveled from the reaction area, to settle on innocent surfaces.

The kit consists of tiny absorbent pads. You wet the pad with H20, then rub. When it encounters lead, the light orange color turns a brilliant

scarlet. I verified this by wiping down my plating rig, which I knew would have Pb on it. The color was intense and unmistakable. A bit further

away, I could still detect traces, but in general, the Pb did not travel far.

The question - anyone know the chemistry behind this kit? Two pads the size of a postage stamp was $10... I suspect the reagents used to make the

kit costs maybe 8 cents. If something like this could be made at home, it would be both interesting and money-saving.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Swede  | Recently, I bought a home lead detection kit to see how far (and if) any Pb traveled from the reaction area, to settle on innocent surfaces.

...

The question - anyone know the chemistry behind this kit? Two pads the size of a postage stamp was $10... I suspect the reagents used to make the

kit costs maybe 8 cents. If something like this could be made at home, it would be both interesting and money-saving. |

http://www.cpsc.gov/cpscpub/prerel/prhtml08/lead.pdf

http://www.ojp.usdoj.gov/nij/training/firearms-training/modu...

http://afte.org/Journal/aftejourW01shem.htm

rhodizonates

http://www3.interscience.wiley.com/journal/117952298/abstrac...

http://nvl.nist.gov/pub/nistpubs/jres/067/2/V67.N02.A06.pdf

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

Thank you, that is some excellent information. Sodium Rhodizonate... too bad it is not something simpler, but it is what it is.

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

not_important, thanks again. I found a source of Sodium Rhodizonate! Not too expensive for a somewhat exotic indicator. I already have tartaric

acid and the correct buffering salts, plus HCl. It should be easy to prepare the test according to those interesting forensics websites.

I like the style of the commercial kits. I understand they are limited for certain applications, but for mine, which is simply wiping surfaces to

find lead nitrate creep and mist, they're perfect. Heavy filter paper can be loaded with the reagents and activated with water.

|

|

|

no1uno

Harmless

Posts: 30

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Lead carbonate is being used as a way of removing lead from used lead-acid battery electrolyte. They precipitate the lead carbonate from the solution

by adding sodium carbonate to the lead sulfate/sulfuric acid mixture, forming sodium sulfate and lead carbonate.

Heating the lead carbonate to 400C or so should turn it to lead oxide/dioxide.

As used batteries aren't exactly difficult to get hold of, nor expensive, I cannot see why this route is not being taken up by home chemists.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

How does one distinguish between Lead(II)Acetate and Lead(IV)Acetate? They are both clear crystals IIRC so if one where to attempt to synthesis one

from the other how would the know they achieved the results they desired?

[Edited on 4-4-2009 by Sedit]

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by no1uno  | Lead carbonate is being used as a way of removing lead from used lead-acid battery electrolyte. ...

As used batteries aren't exactly difficult to get hold of, nor expensive, I cannot see why this route is not being taken up by home chemists.

|

Possibly because a liter of electrolyte has only a fraction of a gram of lead sulfate in solution.

As for distinguishing between plumbous and plumbic acetates, add a small bit to a ml or 2 of warm water, the Pb(II) salt will simply dissolve while

the Pb(4) salt will decompose into insoluble brown PbO2.

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Easy enough. Thanks!

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

I have an odd request for lead chemists... there is a small but dedicated group of shooters who enjoy using legally-purchased silencers, especially

for .22LR pistols and rifles. In the U.S., it requires a signoff by a local law-enforcement officer, and a $200 tax, but once those are done, Joe

Civilian can buy his silencer.

The problem is buildup of metallic lead, especially in .22LR. These are dirty little cartridges that continuously vaporize lead and deposit it on the

walls and in the chambers of the silencer. It is not unheard of for a 12 ounce silencer to weigh 64 ounces after a few thousand rounds have been

fired; and it's all metallic lead, maybe a bit of carbon or nitrate residues.

There is NO traditional firearm cleaner that will get rid of such a horrendous lead buildup.

A few years back, someone suggested vinegar + peroxide to dissolve the lead, and turn it into lead acetate solution. It does work, and is what most

guys are doing, but there was a lot of pooh-poohing when I mentioned the danger and toxicity of the remnants of this process.

My recommendation was to continue the recipe "as published" but to then add NaCl or some other salt to precipitate an insoluble form of lead, and then

sequester those lead salts, rather than dump lead acetate down the drain, which is unfortunately what is probably happening, although no one will

admit to it.

The silencers are made of aluminum, stainless steel, and occasionally titanium, and are usually sealed and impossible to take apart.

The challenge, then, is to improve upon the following: "Create a mixture of 50:50 household vinegar and OTC H2O2. Soak the suppressor for a week,

agitating occasionally. Clean thoroughly with water when done." Something a bit more effective, safe, and responsible, and something that will not

damage their toy. Any thoughts?

|

|

|

no1uno

Harmless

Posts: 30

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

not_important, there is NO shortage of dead batteries at the local dump and I suspect that this would not be all that unusual. They are just sitting

there... Apart from that, how hard is it to dissolve additional lead in sulfuric acid? It kicks shit out of electrolysis and using nitrates... Couple

of kilo's of sinkers, wait for them to go shiny & filter... Put in more, keep going until you have 20kg of clean, shiny sinkers It's lead for god's sake, it will oxidise easily enough It's lead for god's sake, it will oxidise easily enough

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

@Swede.

You could use Ammonium Sulphate (cheap readily available fertilizer from any gargen store) instead of NaCl so you will end up with insoluble (much

less soluble than Lead Chloride) Lead Sulphate to dispose of.

Dann2

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by no1uno  | | not_important, there is NO shortage of dead batteries at the local dump and I suspect that this would not be all that unusual. They are just sitting

there... Apart from that, how hard is it to dissolve additional lead in sulfuric acid? |

Quite hard, once you reach the solubility limit of PbSO4, after which the sulfate will remain as a solid - a saturated solution is a saturated

solution. Consider that PbSO4 is sitting there on the battery plates, a small amount dissolves in the electrolyte while the majority just sits there.

This is part of the reason lead containers were used to concentrate H2SO4 up to 78%, and why sulfuric acid plants used lead linings. Lead is near

hydrogen in the electromotive series, the low solubility of PbSO4 gives the extra push that results in good resistance to less concentrated H2SO4.

|

|

|

| Pages:

1

..

4

5

6

7

8

..

14 |