| Pages:

1

..

55

56

57

58

59

60 |

JScott

Hazard to Self

Posts: 51

Registered: 23-8-2018

Member Is Offline

|

|

Quote: Originally posted by Hunterman2244  | Quote: Originally posted by JScott  | @Hunterman2244,

Thanks, when I scale up, it is my intention to work in a metal apparatus. However, I am a ways from there at this point. As mentioned, I really just

wanted to recreate what I had seen in that video. Though it only appeared to be partially successful, I thought for me, it would make a good first

step.

Partial successes can be instructional, and a bit more fun than absolute failure ;-) Further, I have been stymied by not having any inert gases on

hand. I was sent down this path when I found that wine connoisseurs used Ar to replace the air in opened bottles. Though I'm sure 15$ for that much

gas is a gouging, it's a lot cheaper than buying even the smallest refillable canister of Argon.

Any experience I can gain using these small, easily located cans of Argon will be helpful until I can afford more substantial supplies.

Still, your advise is right on point and very much inline with what I hope to do as I move further along in my studies. Thank you very much for

getting back to me.

[Edited on 9-1-2018 by JScott] |

Thanks. My intention was to eliminate the need for inert gasses due to the production of CO2. It also reduces the potential for accidents due to the

fact it's not an energetic redox. I hope to try it out myself. |

Ah, so you did, and I clearly missed your assist. My apologies, I should have read your advice more carefully. Clearly I had thought my use of the

balloon was so clever I stopped listening <LOL>, avoiding the use of the gas would be even better.

But, fascinated by the idea of that particular video I have already purchased the materials. Still, saving that expensive gas would be key.

Also, this was one phosphorus experiment that looked doable in the fume hood. It is sometimes difficult for me to use the yard.

|

|

|

Hunterman2244

Hazard to Others

Posts: 105

Registered: 6-6-2018

Member Is Offline

|

|

Quote: Originally posted by JScott  | Quote: Originally posted by Hunterman2244  | Quote: Originally posted by JScott  | @Hunterman2244,

Thanks, when I scale up, it is my intention to work in a metal apparatus. However, I am a ways from there at this point. As mentioned, I really just

wanted to recreate what I had seen in that video. Though it only appeared to be partially successful, I thought for me, it would make a good first

step.

Partial successes can be instructional, and a bit more fun than absolute failure ;-) Further, I have been stymied by not having any inert gases on

hand. I was sent down this path when I found that wine connoisseurs used Ar to replace the air in opened bottles. Though I'm sure 15$ for that much

gas is a gouging, it's a lot cheaper than buying even the smallest refillable canister of Argon.

Any experience I can gain using these small, easily located cans of Argon will be helpful until I can afford more substantial supplies.

Still, your advise is right on point and very much inline with what I hope to do as I move further along in my studies. Thank you very much for

getting back to me.

[Edited on 9-1-2018 by JScott] |

Thanks. My intention was to eliminate the need for inert gasses due to the production of CO2. It also reduces the potential for accidents due to the

fact it's not an energetic redox. I hope to try it out myself. |

Ah, so you did, and I clearly missed your assist. My apologies, I should have read your advice more carefully. Clearly I had thought my use of the

balloon was so clever I stopped listening <LOL>, avoiding the use of the gas would be even better.

But, fascinated by the idea of that particular video I have already purchased the materials. Still, saving that expensive gas would be key.

Also, this was one phosphorus experiment that looked doable in the fume hood. It is sometimes difficult for me to use the yard.

|

Cool, get back with your results, would love to see how it turns out.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by Magpie  | yes, I believe the intimate contact provided by molten aluminum/SHMP greatly augments the reaction rate. I don't understand how Monsanto and FMC get

such good production using Apatite, sand, and coke at 1200°C. Perhaps the apatite is molten at that temperature.

I wish I could find a simple way to make briquettes about 1/4" in diameter. |

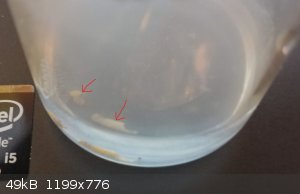

I recently roasted apatite crystals from an igneous rock I crushed up into a fine powder. There was plenty of silicon based mineral as part of the

composition. I had noted the previous day, I was observing the apatite crystals to melt into a black glassy substance. At hot temperatures it seemed

to be a bit tar like but quickly cools into a glassy like condensate. I used a stainless steel crucible with a narrow tube exhaust port, which

condensed a hot black tar like substance on the collection vessel ceiling. I then took this black substance and broke it off into my agate mortise

and pulverized it into a fine powder.

I figured I would try to reduce it if I could thinking that would help identify the mystery end result compound. I mixed this with carbon and heated

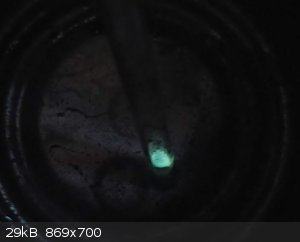

until it was red hot. The inside of the test tube became coated in white substance and the thought occurred to me that this could possible be

phosphorus and I assumed it was at first out of pure excitement. The white substance glows brightly under UV light and it appeared to still emit a

soft glow with the lights out.

I don't have a sense of smell, so I can't reference that observation. The little bit of exposed white material did seem to react energetically with

water, but since my knowledge level and experience are still limited, I can't say for certain "I made phosphorus!" Not when I see all you other guys

that have been working so hard over years to produce this element.

The two other test tube pictures that are obviously different than the first two were experiments with ammonium phosphate I created after isolating

the phosphoric acid from Naval Jelly. Removing the xanthum gum is a gooey mess, but coagulated fairly well with ethanol and can be twisted around a

glass stir rod into a globular mass. I neutralized the phosphoric acid with ammonium hydroxide to form ammonium phosphate, then heated the salt mixed

with carbon dust. I don't know if any of the residue that formed in those last two test tubes were anything buy recrystallized salt. It didn't seem

to glow under UV light like the first test tube did.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

I've learned quite a bit more since my last post just a couple weeks ago on this thread. I've successfully created white P and have been having fun

despite the incredibly small amount.--I don't feel safe with my hands on any volume greater than what I made.

|

|

|

BromicAcid

International Hazard

Posts: 3272

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

In your previous post you mention an energetic reaction with water, do you figure this could be aluminum phosphide? Very cool stuff, thanks for

sharing.

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Has anyone during these experiments gotten white P that stayed liquid no matter the temperature ?

I have a drop sitting in water in the fridge that wont harden. Could this be impurities ?

It smokes like WP when exposed to air, burns when small globules reached the surface in boiling water so I figured it should be WP.

Interested in your opinions.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by BromicAcid  | | In your previous post you mention an energetic reaction with water, do you figure this could be aluminum phosphide? Very cool stuff, thanks for

sharing. |

I'm not sure. I wish I could go back and record everything in detail so that I could be more accurate / have others duplicate my results. I have a

bunch of that unknown substance still in solution from the igneous rocks I dissolved. I'm not sure what to do with it other than neutralize it and

store it as a solid.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by Herr Haber  | Has anyone during these experiments gotten white P that stayed liquid no matter the temperature ?

I have a drop sitting in water in the fridge that wont harden. Could this be impurities ?

It smokes like WP when exposed to air, burns when small globules reached the surface in boiling water so I figured it should be WP.

Interested in your opinions. |

What is your ambient room temperature? That could be a huge factor in determining this one property of the substance you have. The micro quantity I

have/had was still solid in storage this morning, but the ambient room temperature was 10 degrees Celsius in my home office / lab.

[Edited on 27-9-2018 by Doped-Al2O3-fusion]

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Doped-Al2O3-fusion  |

What is your ambient room temperature? That could be a huge factor in determining this one property of the substance you have. The micro quantity I

have/had was still solid in storage this morning, but the ambient room temperature was 10 degrees Celsius in my home office / lab.

[Edited on 27-9-2018 by Doped-Al2O3-fusion] |

4 degrees in the fridge, 20 in the room. It should be solid at that temperature.

That's why I'm thinking of impurities but... except for a thin "skin" on the droplet it's transparent. I has no resemblance to the white / yellow waxy

substance one would expect. But when exposed to air it's behaviour is exactly what one would expect.

|

|

|

simple-guest-7125

Harmless

Posts: 3

Registered: 21-11-2018

Member Is Offline

|

|

Home Made Electric Arc Furnace on the Cheap!

https://www.youtube.com/watch?v=VTzKIs19eZE

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

main reasons for failure in P4 preparations:

1-you can not reach needed temperature. for example you need minimum 700'C for C+H3PO4 mixed powder

2-you can not provide air free environment. no need to fill/purge the container with nitrogen or any inert gas as

air inside container will be consumed very soon and P4 vapour will release but slightest crack/opening even if

you can not see it, is enough to prevent any P4 from formation.

easiest mixture used as raw material: C like granulated C used in fish tank as filter+H3PO4 85% mixed in a

stainless steel bowl(>100% extra C based on molecular ratio: 4H3PO4+4C==>P4+4CO+6H2) and heat on

electric or gas stove with constant mixing up to 400'C till all extra water removes. use granulated powder to

release P4 at higher T by one of following methods:

notes: granulated charcoal should be used[like 1x1x2 mm particles(like activated charcoal used in fish tank filter packs)] not fine powder as

otherwise powder will be

going out under released gas and also other problems will arise.

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

easiest method to make on small amounts up to 0.2g: microwave method[consider H2 release that may lead

to possible explosion although I never encounter when used MW oven with good ventilation in the unit]

method: best as using fused silica test tube but can be done also by pyrex although will melt soon.

put some 4H3PO4+4C as granulated powder at the bottom of test tube. push a small piece of rock wool or

aluminosilicate ceramic blanket mat or even glasswool on the H3PO4/C mix but not pressing and leave it a bit

loose. piece of wool should not be thick to prevent P4 vapour and released gasses to pass through.

for best results, end of test tube should be wrapped in glasswool or rockwool or ... externally. this helps as

thermal insulation as MW waves pass it and make the charcoal mix inside hot but heat insulation prevents heat

to go out and this lead to easily increasing T.

then put this test tube upside down inside a metallic bowl(bottom) filled with little water[test tube end should be

at water and no air can go inside but just little bit more than needed] and microwave it[system should be

placed on a piece of refractory brick to avoid MW oven bottom metal contact. metallic bowl should let test tube

stand straigth or at least slant to avoid air entering at bottom. can place a piece of rockwool at contact point of

test tube and metallic container to avoid sparking if tst tube glass melt ]. the top closed heat gets red[should be

well above the small metal containet to absorb waves] then will release P4 and gas will bubble through water

and fire and smoke can be seen over water level at less than 2-4 mins. some P4 will collect underneath the

water layer and some inside test tube at the bottom close to water level.

do not use this method for making more.

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

for larger amount like 10-15g in one run: ***do at your own risk***

use tube furnace with like 1000'C capability.

use the above mix filled inside like

1.25" diameter screw threaded: cap+iron nipple like 10" length and then reducer to 1" or 3/4" then 90 degree

bent 10" and 2" iron nipple[it inserted under water level[water level is just little bit under water or otherwise

upon cooling, it sucks water inside hot reactor and lead to sudden steam generation and explosion***]]

cover the iron nipple assembly with a thin layer of ceramic fiber math paper in places that has contact with

heating element coil to avoid metal contact with nichrome wire contact and spark/shortcut creation but let heat

pass through it.

use a cut piece of refractory brick to block one side of tube furnace entrance and seal the other side around the reducer with rockwool.

should put a metal sponge like kitchen stainless steel scrub piece(small piece only to cover the hole) just

before reducer inside to avoid carrying charcoal particles and blockage of smaller nipple and explosion***

If you calculate by Gib and delta H and delta G==>it needs miniumu 700'C and in practice also you can exactly

see the same T when P4 release and firing exiting gas can be seen.

distillation nipple(after reducer) should not be long. actually if you calculate heat transfer by iron tube

considering its thickness and length and its heat transfer constant, you will realise that just short distance after

inside tube furnace, T of iron tube falls under 340'C(boiling point of P4).therefore if it is long, P4 easily

condense just inside nipple and does not go into water.

other methods:

using thin iron tube blocked in one side by hammering and filled with granulated H3PO4/C powder and kept in

place by inserting a small piece of rockwool on charcoal level and and placed upside down inside water then

using a **induction coil heater[like >1KW or better 1.8KW], heating the area filled with charcoal.

I did not get good results although P4 released

using charcoal kiln with air blower will also work as heating source mentioned in old chemical literatures as well but

too much smoke

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

***I do not recommend doing any of them. if do, do it at your own risk and if you have complete understanding of everything***

very promissing: using iron nipple system as mentioned above without end cap and instead using a reducer then using the mixture of

Kaolin+sodium silicate 40% solution+4% CaSO4 putty mixed with little bit of rock wool fibers and casting

graphite rod in the middle[you can put nipple end on ground and fill it with sand till like 2" under the top then insert graphite rod then fill 1" gap

till top with putty and push and cover all end and going out covering even outside nipple on threads for best seal] and let it dry. after drying, with

a brush, loose solution od sodium silicate mixed with

little kaolin powder was brushed on the dried putty for best seal. upon heating, most of the time, the mix will not

crack and is perfect for air exclusion and sticks very hard on threaded iron nipple.

for heating needs like 2 microwave oven transformer paralelled and controlled by minimum 4KW

semiconductor dimmer should work perfect. needs to use clamp meter[non contact] to monitor amper on wire

from electricity outlet 110v and avoiding more than 2.2KW total for 2 transformer[20A].

outside voltage is high voltage like 2kv***danger***

I did on 3/8" and then upgraded to 3/4" and electricity easily pass and upon like 10A, gas release starts right

away and should control amperage by dimmer to avoid getting very violent release of gas. I used brass ending

and flare fitting and used copper tube and iron nipple placed inside pot and filled with sand. released P4 and

most of P4 condensed inside copper tubing and stick to it.***looks like P4 gas reacts with copper***

in another test:

I used a terra cotta jar and made 2 holes by rotary tool(engraver) and inserted 2 graphite rod, sealing by above

putty[putty used also inside to create a 1cm layer at the bottom inside jar as well as a layer outside to seal

perfectly the holes and graphite rods] and brushed afterward and submerged system under sand==>it

released little bit P4 as later upon close observation, some cracks revealed in the jar.

|

|

|

fusso

International Hazard

Posts: 1922

Registered: 23-6-2017

Location: 4 ∥ universes ahead of you

Member Is Offline

|

|

PhD?

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

note: terra cotta jar got cracks but not on the putty but at farther at its own clay. also its stainless steel distilling is very long and should be

shorter and should also be wrapped by rockwook for thermal insulation. glass tube at end not necessary and should be omited

in metallic one: copper tubing is long and P4 can not come out easily.

**note: none of them creates real arc. for real arc version, graphite rod should be movable and touch at forst then move away

***Unfortunately I am unable to post more videos or fotos or answer any questions regarding my posts at this point.

also these tests need shield to cover the area when doing to protect person.

all given information in all posts I did are completely incomplete therefore should not be replicated other than at your own risk if you are already

master in the field.

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

heat transfer calc. on iron nipple:

https://en.wikipedia.org/wiki/List_of_thermal_conductivities

Fe: using T at between 1000&60=1000+60/2=530'C==>at 500'C

61.3

thickness: 2mm

OD: 1.72cm ID: 1.3cm

12.5cm length

delta T=1000-60=940'C or 'K

A=2pR*h=3.14*(1.3+1.72)/2x0.2 cm^2=0.942 cm^2=10^-4 m^2

https://en.wikipedia.org/wiki/Thermal_conduction

W=k*delta T*.A/d

wat= 61.3x940x10^-4/0.125

wattage=46.0976 wat of tube furnace electrical power get lost by heat transfer from iron nipple at most if inserted the end in water

delta Gibs calculation for T is attached as file

Attachment: G calculation-H3PO4-C RXN.rar (4kB)

This file has been downloaded 672 times

|

|

|

halogenstruck1

Harmless

Posts: 10

Registered: 21-12-2018

Member Is Offline

|

|

assembly for tube furnace. I will update video on youtube soon and put link here.

[Edited on 22-12-2018 by halogenstruck1]

|

|

|

j_sum1

|

Thread Closed

17-1-2019 at 04:01 |

j_sum1

|

Thread Opened

17-1-2019 at 04:15 |

Hunterman2244

Hazard to Others

Posts: 105

Registered: 6-6-2018

Member Is Offline

|

|

Anything new on this project? Haven't got a chance to try myself.

|

|

|

charley1957

Hazard to Others

Posts: 174

Registered: 18-2-2012

Location: Texas

Member Is Offline

Mood: Winter’s winding down. Yay!!

|

|

Anyone know what happened to blue planet? He was really active in this thread until about four pages back, then he just dropped out of sight. Hope

all is well with him.

You can’t claim you drank all day if you didn’t start early in the morning.

|

|

|

cyriac1999

Harmless

Posts: 4

Registered: 3-8-2019

Member Is Offline

|

|

Hey,

Since yesterday, I try to develop a method to produce white phosphorus from the red allotrope (400g) with only common glassware, heat mantle and

aluminium foil.

naturally, I've chosen to distill the red phosphorus at 400 ° C under an inert atmosphere (argon) with a simple distillation setup without condenser.

I've try to do my best to isolate the setup with a huge amount of aluminium foils (to keep heat and to protect the product from sunlight and to

collect the potential white phosphorus produced during the distillation, I've used a 2 necks round bottom flask with a small condenser on the second

neck to prevent any toxic white phosphorus vapors go to the rest of the assembly (two bubblers in series: one serving as a vial of the guard and the

other filled with water to isolate the assembly of the atmosphere).

Honestly, I was very surprised by the result because after 1 day of continuous distillation, after

K2Cr2O7/H2SO4 purification (which is still in progress) I produced more than 150g of quite pure

white phosphorus...

Before any purification :

During purification (1.5L beacker) :

I really didn't think I've could produced as much so I'm pretty happy even if I'm organic so I will not do much ^^

CB

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Now that meth making using red p isn't so common isn't red p a bit easier to get now?

|

|

|

cyriac1999

Harmless

Posts: 4

Registered: 3-8-2019

Member Is Offline

|

|

In USA I don't know, in France it was never a problem to find it...

I've bought 2kg of red p two years ago without any problem

CB

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

The lead phosphate and H2 sounds like a good method to work on.if the lead phosphate is easily accessible and common and H2 can be made easily enough

from NaOH and Al foil the only hard part is how do you do it? bubble H2 through the molten salt? Sounds easier than welding a ss vessel shut and

baking at 1000'c.

[Edited on 5-8-2019 by draculic acid69]

|

|

|

cyriac1999

Harmless

Posts: 4

Registered: 3-8-2019

Member Is Offline

|

|

"The lead phosphate and H2 sounds like a good method to work on.if the lead phosphate is easily accessible and common and H2 can be made easily enough

from NaOH and Al foil the only hard part is how do you do it? bubble H2 through the molten salt? Sounds easier than welding a ss vessel shut and

baking at 1000'c."

This seems quite hazardous...

|

|

|

| Pages:

1

..

55

56

57

58

59

60 |