| Pages:

1

..

52

53

54

55

56

..

68 |

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

The 30mm liners are always made with a dapping block so they always have a curvature depth of 5mm.

That sounds like a good idea though Nux I could add an extra 1mm to the depth of curvature to elongate the slug more when I get some better PE made

up.

Be good, otherwise be good at it

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

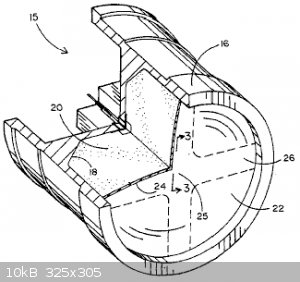

Patent : 5365852 How to create an EFP with fins.

A thin cross shaped foil between the liner and explosives.

The patent does not tell what the foil is made of, but it says about 25% of the liners thickness.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Why do they not specify what the liner material or foil cross is made out of?

Something like this Tantalum foil maybe?

http://www.ebay.com/itm/10-gram-0-35-oz-99-98-Pure-TANTALUM-...

[Edited on 4-10-2015 by greenlight]

Be good, otherwise be good at it

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I would assume the material would be the same as the liner. Why shouldn't it, it has the same requirements (ductility, density etc).

We're not banging rocks together here. We know how to put a man back together.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

I would assume the easiest way to make a cone with a cross on it would be to form the cross at the same time the cone is being formed, sort of like

strikeing a coin out of copper at the mint.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Here's some pics from a recent test on another successful small scale EFP on steel target.

The diameter was 14mm and this time a metal casing was used for stronger confinement.

Charge was 7.5 grams PETN/RDX/plasticizer-binder and explosive head height ended up being 2x the diameter of the liner which is the highest I have

ever had.

Target was 6mm thick square of steel and standoff was 30 cm.

It has made a clean 9x9mm hole and unusually another smaller hole directly above that looks like liner breakup but has formed another round hole. Two

for one deal

[Edited on 5-10-2015 by greenlight]

[Edited on 5-10-2015 by greenlight]

[Edited on 5-10-2015 by greenlight]

[Edited on 5-10-2015 by greenlight]

Be good, otherwise be good at it

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Just came back from testing a new batch of PE using the usual 30mm EFP on steel.

Target was 10mm steel again but this time a slab of remelted (not as clear as fresh stuff) ballistics gel was placed behind to give a rough idea of what happens behind the target. ballistics gel was placed behind to give a rough idea of what happens behind the target.

Charge weight was 17 g which was enough to punch a nice 19mm diameter hole and push through the ballistic gel as well,

Standoff was 60cm.

It seems that as soon as the slug hits flesh like material at a lower velocity it fragments into wide wound channels of varying size. Some of the

stray copper pieces separated inside the gel so much that the width of damage by the fragments is around 100mm diameter.

After the ballistic gel was cut along the wound channel lines, it was dissolved in boiling water leaving the copper fragments which are also pictured

after being recovered. A lot of copper powder was also found lining the channels in the gel which gives them a brown colour.

I will use fresh ballistics gel next time but that test is enough to confirm that it would not be good at all to be in the firing line of one of these

even if your behind a steel target.

[Edited on 16-10-2015 by greenlight]

[Edited on 16-10-2015 by greenlight]

[Edited on 16-10-2015 by greenlight]

Be good, otherwise be good at it

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Nice one greenlight, your going all mythbusters on us with the balistic gell, did the main part of the efp go through the gell or did it all break up

inside it.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Haha, there was a small main fraction of the slug that passed straight through. The rest fragmented.

I think this is why sawdust or other low density material is going to be required to catch the slug without it breaking up in future tests.

I am also on the hunt for a target thick enough for the conical SCs Nux

[Edited on 16-10-2015 by greenlight]

Be good, otherwise be good at it

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Why do you consider the breakup to take place on contacting the gel? I would think it more likely to occur as the slug passes through the steel.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I have caught a couple of deformed slugs in a tree behind the steel target and they usually retain a lot of their weight aside from the added steel

coating on them.

Most of the weight of the liner was in the gel and my explanation was that the lower velocity and the stress from passing through the steel first

caused instant fragmentation upon contact with the gel.

The gel was 10 cm from the back of target.

Next time I will put the gel further back and find out if the breakup comes from the gel contact or before.

Be good, otherwise be good at it

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

EFP

I appreciate the enthusiasm Greenlight. I also have my experience. Catch slug is very difficult. I grab his piece, without fragmentation, of course. I

believe that the gel is too short and too dense. Before gel need any other brake. For example, 2 pillows. Or something like that. Hay or straw.

Liptakov.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks LL, yes catching the slug undamaged is a difficult task.

I wasn't trying to catch it in the last test I just wanted to see what sort of wound channel it would make.

I am collecting sawdust at the moment to make a massive 3 metre long 1 metre wide and high soft-catch box because the EFP projectile always escapes

out the side or top. I think it tumbles a lot when it loses some velocity because it always happens about half a metre into the soft recovery

material.

Be good, otherwise be good at it

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

That's a LOT of sawdust-

Water is more easily sourced, perhaps? Probably much easier to search for slugs, as well!

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I'm worried that water would cause the slug to deform or frament more hitting at that high a velocity. Maybe the front section sawdust as it is

softer to slow it down and the last section water to actually catch it.

Be good, otherwise be good at it

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

If you have a metal detector, maybe straight up on a windless day would work, assuming the projectile follows a reasonably stable trajectory in the

air What goes up...

[Edited on 10-11-2015 by nitro-genes]

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thats not a bad idea nitro, if my next soft recovery system fails I might give that a go. Wouldn't be too bad if you used a spirit level to make sure

it is aiming dead straight up.

As long as the projectile didn't form badly it should fly pretty much straight.

Be good, otherwise be good at it

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Shoot vertically into the air is a good idea. The epicenter may be buried EFP. So 50 centimeters below ground, I think the sand around the EFP.

Established perpendicular to the pipe, and 1 meter long for the spirit level. No wind at night (often). Another thing. The space can be a grassy

field. Meadow. The grass is laid microtene film. On average, about 8 meters bags, thus the radius of 4 meters. Microtene is rustling material. Will

hear the impact. The impact liner may be expected in about 60 seconds. This is only a guess. Perhaps it is calculated. (it's all nonsense, nothing is

returned... ) )

Liptakov

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

First conical CSC bad time

Had a first attempt at a conical shaped charge courtesy of Nux vomica's cones today but with a bad end result.

Copper cone was 18 mm diameter and 42 degrees and charge casing was steel tube.

Charge was 10 grams PETN PE and was 2x cone diameter in head height.

Target was a 90mm thick steel cylinder and standoff used was 3.5x cone diameter.

There is a 15.5mm deep hole and it appears most of the copper is splattered

around the area of entry not directed inside it like it should be. and it appears most of the copper is splattered

around the area of entry not directed inside it like it should be.

I think the most likely cause is too much explosive behind the cone. I have one more cone and I think I will try 5-7 grams next time and hopefully

get a better result.

[Edited on 18-11-2015 by greenlight]

Be good, otherwise be good at it

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Maybe make the explosive diameter larger greenlight to help the cone jet form, I think the cone walls are thicker than the ideal size.

How far away was the detonator to the top of the cone?.

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Try also to "boat tail" the plastic and the detonation wave should hit the cone flat and greatly aid an ideal liner collapse which in turn will help

penetration. It took me quite a few disappointment charges before I even got any decent penetration at all. Once you let off a few you get a feel for

how to make them well. Don't be dismayed though, practice makes perfect. And even then There are the occasional failures. Nice first try.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Shaped charges are pretty finicky, photo's look familiar.  In case of

unsymmetrical liner splatter, it is most likely due to a prematurely disrupted jet due to either an asymmetrical liner, or non-homogenous explosive

loading (air cavities). These are absolutely the most important factors determining clean jet formation. For this reason, either liquid explosives or

very homogeneous plastiques (containing enough plasticiser to fill all air spaces) are best, an other option is pressing. In case of

unsymmetrical liner splatter, it is most likely due to a prematurely disrupted jet due to either an asymmetrical liner, or non-homogenous explosive

loading (air cavities). These are absolutely the most important factors determining clean jet formation. For this reason, either liquid explosives or

very homogeneous plastiques (containing enough plasticiser to fill all air spaces) are best, an other option is pressing.

Wall thickness of the liner is much less important for clean jet formation. Very thick liners generally produce a well formed jet, but with lower

velocity, thus penetrating less deep. Extremely thick liners, and/or driven by a relatively slow explosive can even lead to a completely "filled" jet

canal, filled with liner material. In one occasion, firing a steel hemisphere (7% of CD liner thickness using an AN/NM/NC plastique left the carrot

sticking out of the target plate, but no splatter at the sides was present. Should still have the picture of that somewhere.  Very cool to see a steel carrot welded seamlessly into place into solid 5 cm steel. I

contemplated it might even have some applications, similar to explosive welding. With some shaped charge explosive modelling, it may be possible to

"shoot" predefined structures into very thick steelplate material, where welding might be impossible. Like sort of a nailgun on steroids, though not

very practical probably in real life. Very cool to see a steel carrot welded seamlessly into place into solid 5 cm steel. I

contemplated it might even have some applications, similar to explosive welding. With some shaped charge explosive modelling, it may be possible to

"shoot" predefined structures into very thick steelplate material, where welding might be impossible. Like sort of a nailgun on steroids, though not

very practical probably in real life.

Supersonic liner wall jets ( from very thin liners) look like more broad homogenous splatter. Det or liner offsets produce more of 1 sided elongated

penetrations, and a curved jet (picture posted by Axt in the beginning of this thread somewhere).

[Edited on 19-11-2015 by nitro-genes]

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@Nux, the detonator was only pushed in about 5-8mm into the charge so there was a lot of head height for the detonation wave to push through before

interacting with the cone liner. I think the amount of explosive I used was still a bit too much.

@Neonpulse, Thanks, do you mean make a boat tail shape at the end where the detonator will be inserted?

@Nitro-genes, The liner was a perfectly formed cone and I packed the explosive in small quantities with a small pen around the cone so there was no

air cavities. Next time I will pack it as hard as possible and then place the charge in a vice and press it to eliminate any air cavities.

The carrot sticking out of the actual entry with no spalling around the hole sounds quite interesting I would like to see that photograph.

Be good, otherwise be good at it

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Second attempt with a conical liner shows an improvement with penetration but nothing like it should be.

This time I pressed the plastic explosive in small increments around the cone with a thin piece of metal and pressed the whole charge as hard as I

could with a metal rod to make sure there were no air gaps. Charge weight was 6 grams this time and the detonator was centered just pressed about

2-3mm into the main charge.

Target was a 75mm wide piece of steel.

Result is a cleaner hole than last time but it still looks like there is a bit of spalling around it. I placed a video camera near the charge and can

see what looks like a smoke ring coming out from the top right after detonation which I thought was a sign of a good shaped charge.

I can stick a small metal rod about 30mm into the cavity but I think the carrot is blocking the rest. Is there any way to cut this down the jet path

more delicately than using an angle grinder to find out?

[Edited on 20-11-2015 by greenlight]

Be good, otherwise be good at it

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

@greenlight , good work.

I don't know if PETN has low detonation velocity or not but i found this link : http://onlinelibrary.wiley.com/doi/10.1002/prep.19760010504/...

I have a question : what is your primer(weight, type ,..) and how did you place it ?

All successful experiments i saw was : PETN + NG

would you be able to try this ? you won't probably need to worry about air bubbles.

[Edited on 20-11-2015 by ecos]

|

|

|

| Pages:

1

..

52

53

54

55

56

..

68 |