| Pages:

1

..

50

51

52

53

54

..

66 |

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

Forgive me if this has been mentioned or done before:

Why not add KOH + solvent to the flask and heat for a period of time, cool, add Mg + catalyst, ramp up to reaction temp?? The idea is to drive off

excess moisture from the KOH before the reaction is run. Maybe this is why Mg turnings seem to produce better results compared to powder. Less surface

area to initially react with moisture...

One other thing, could there be a product from a side reaction that MUST be vented off in order to keep it from reacting with K? That could explain

why Blogfast and others(?) had success with a glass pipe and wet paper towel while others(?) who use fancy schmancy condensers fail sometimes in spite

of careful prep, etc. Perhaps something is fouling the reaction or newly formed K because it condenses and returns to the pot??

Tank

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I believe the consensus was that powder is beneficial to the dehydration step, and turnings are better for the potassium formation. Dehydration isn't

just driving the water off by heating - I don't think you can do that to KOH without very high temperature. Rather, its a reaction with magnesium: Mg

+ H2O --> MgO + H2

On Woelen's page he mentions airing out the apparatus after the dehydration step, to eliminate any remaining water vapor. But, he uses the "staggered

addition" approach and I think in my case that would lead to loss of much of the alcohol as vapor. Plus, I believe the initial reaction and reflux

serves to saturate the air above the flask with other vapors, which mostly keeps out air.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Tank:

There are no solid reasons to believe that one total reflux system is to be preferred over another. Water cooled (mantle, like Liebig or Allihn)

could potentially lead to freezing the catalyst onto the cooling surface, as observed by elementcollector1.

Mr HS:

I wouldn’t go so far as to call it a ‘consensus’: there was len1’s spectacular failure with shavings, as reported on a pre-pok thread, for

instance.

Again, I don’t really see the point in ‘airing’ the set up. Water is supposed to be scavenged chemically by that excess Mg we add. But as I’ve

postulated, very small amounts of water may be needed to regenerate the catalyst.

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Only outside hose water led to freezing, the water form the fume hood was fine.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

HOLD THE PHONE: It did work!

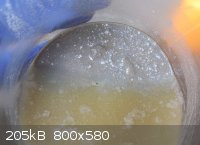

Like elementcollector1 did some time ago, it looks like I spoke too soon! My first run on this experiment did indeed produce elemental potassium! I

just didn't notice because the oil had gone opaque, and as it turns out the metal barely did any coalescing. Take a look at the sand leftover from the

reaction:

Zoom in: all those bright pieces are thousands of tiny potassium spheres! I am astounded by how many there are. I managed to salvage most of the

larger balls, the largest of which is only about 4 mm across.

So it appears my problem is coalescence. What has been people's experience getting these things to come together? I read the coalescence thread, but

nothing really jumped out at me as being particularly good. If I remember right, the method Nurdrage used was to heat the salvaged balls to melting,

then using the magnetic stirrer to push them together (taking advantage of paramagnetism). That video is gone, of course, so I can't review it. Even

so, that method is more for easily recoverable balls, not my potassium sand. Any ideas?

Possible Sources of Problems

- Flask geometry. Since I am using a round-bottom flask, there's a lot of space in the solvent for potassium to float around without touching each

other. The narrow neck of an erlenmeyer might be beneficial here, constricting the balls to run into each other more often.

- Not enough agitation. Since my oil boils at ~250C, there was only a gentle boil. Perhaps a lower boiling solvent or higher temperatures (see below)

will cause more agitation and allow things to come together neater.

==============================

In the meantime, I'm running Trial #2 to test if higher temperature will help. This time I'm keeping things at 250 C instead of 200. Most of the way

through and it's looking much like Trial #1, but with a more steady boil.

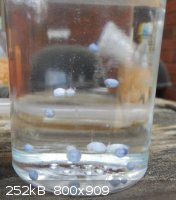

Interestingly, this time the white smoke actually solidified in the condenser:

After a second burst of smoke, this condensate melted and now looks like a small amount of liquid on the condenser walls. This is pretty convincing to

me that this smoke is mostly t-butanol, and it looks like I might be losing a good amount of my catalyst as it escapes.

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

That smoke would be your alcohol. Too powerful cooling, is my guess.

I had heavy stirring; this led to a large, very irregular lump of K in the center (not at all spherical).

Be sure to store this potassium well, as it annoyed me to no end trying to store this stuff under oil and kerosene. I'll have to try ampouling when I

next get a chance.

To coalesce these later, simply heat to the melting point of potassium, and swirl. Repeat as necessary.

An additional note: NurdRage's video on the subject was misleading. The potassium does not stir itself, even when molten (no instance of

paramagnetism). I wonder if it's my hotplate or my potassium, though...

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Nice work, Mr HS. I had a feeling yours would work.

Coalescence is the thing that takes up the most time in this experiment. Flask geometry may have a little effect but from my experiments its influence

is much smaller than you might expect. Most of us used flat bottom reactors too.

Coalescence is essentially a game of chance, as len1 once put it. Most collisions between droplets of molten potassium do not result in union because

there’s a layer of oil separating them. Once in a while two drops merge. What you see in your first photo is of course in itself the result of even

smaller droplets having united into larger ones. Keep going and going and with swirling of the flask gradually even larger balls of K will result.

It can help a lot to separate the larger ones from the sand by straining it (COLD, of course!), then continuing the coalescence more or less in the

absence of MgO sand, at about 100 C. But you’ll lose many fines (K) in the process.

So the crucial question is: what was your total run time?

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

blogfast,

Thanks a lot for the vote of confidence! I had thought straining it might be my best bet, too. Many of those spheres are just miniscule, though, so I

would definitely lose a lot. Personally I think a somewhat lower boiling solvent will help, as it provides some more agitation. I'll investigate the

results of Trial 2 tomorrow afternoon and see if the higher running temperature (and thus more vigorous bubbling) helped at all.

Trial #1 was run for 3h 45min after reaching the running temperature of 200C (5 hours if you count the initial warm-up), and Trial #2 ended 3 hours

after the running temperature of 250C was reached (4 hours counting warm up). #2 ended a bit early because I had to leave for Easter dinner.

So both were a bit shorter than recommended, but I'd have thought I'd get bigger spheres than I did - Woelen had 3 huge balls 3.5 hours in to the one

on his page. It's also possible my actual temperature is a good bit lower than my measured temperature, since I can't measure the mix directly.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Mr HS:

Yes, with about 4 h run time, most of us get better coalescence and bigger globules than you achieved. Like you wrote, perhaps a slightly lower

boiling solvent (250 C really is borderline) could help with the coalescence because of slightly improved agitation (boiling).

Several of us worked on the problem of coalescence but nothing very effective was unearthed. Perhaps Nurdrage’s use of Tetralin, in which molten

potassium floats, is the one thing that seemed to cut down run time considerably: he reported one experiment that was over and done with in about 1 h,

with good yield and coalescence. But Tetralin is expensive and hard to get for non-institutional chemists.

It could also be interesting to play with the clean K balls in clean solvent, to try and merge them into larger units: you'll experience just what a

slow process it is!

Question: when and how did you add the catalyst?

[Edited on 1-4-2013 by blogfast25]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

The catalyst was added in the very beginning along with all the rest of the chemicals, before the apparatus was assembled, ala your "one-pot" method.

I'm fairly certain the plumes of white smoke I observed around 100C were mostly the alcohol boiling off and recondensing. I'm not sure if this is

detrimental in any way.

One thing I thought of, beyond straining my mix of potassium and MgO/Mg sand, is to separate via density. Magnesium oxide (and to a lesser extent,

unreacted magnesium) is much more dense than potassium, so there must be an appropriate solvent in which K floats and MgO doesn't. The picture I have

in my head is having this solvent with a layer of mineral oil on top (which my K sinks in), and pouring the sand mix into that. The K should sit at

the interface, remaining protected from air, while the rest sinks to the bottom. Dioxane seemed a good choice, but synthesizing it totally dry would

be difficult and I don't really have a good source for purchasing solvents.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

So further evidence that one pot works. I remember seeing such a mist too, it could be H2 dragging some stuff with it. It's nothing remarkable.

Re. floatation, unfortunately molten K has a density that's very close to most hydrocarbon solvents. To make them heavier you need to introduce 'exo

atoms' in the chains or branches but most exo atoms render the solvent reactive towards K! A conundrum... Dioxane does offer a way out (tested and

tried) but like you say, it's not easy to get, and hard to home make completely anhydrous. I bought some glycol for that purpose but never got round

to trying to synth it.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Hm. I guess if I can find a fine strainer I'll try that, or just put the whole mix back in the sand bath for more time. I'll look around for a lower

boiling oil as well.

I took a look at the products of Trial #2, and they are much the same as #1 - lots of tiny K balls mixed in with fine Mg/MgO sand. I'd hoped this one

would yield larger spheres because of increased agitation by heating closer to the boiling point, but maybe the somewhat shortened run time

counteracted that. I also took one of the dirtier balls and dropped it in some water, resulting in the beautiful lilac flame of K. First time I'd seen

that with my own eyes, so it was very satisfying!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Careful with the disposal of fines! I once had a bit of 'bang!' when putting spent MgO down the drain. I had rinsed the MgO with alcohol first to

react away the K but a bit must have been left behind. There was no damage to anything but it was quite startling!

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I actually had a similar experience. I had been rinsing my larger balls in some mineral oil before transfering them to my storage bottle, and this

rinse oil had a lot of K-fines in it. To destroy them, I added a few drops of isopropyl alcohol (rubbing alcohol) and swirled. It made a crackling

sound, and I had a bit of a "flare-up" when some of the alcohol on the surface ignited. It was just a flash and disappeared quickly, but was

definitely startling I agree! It worries me greatly how I going to dispose of what I can't coalesce. Woelen uses t-butanol in his disposal, but I do

not want to use up my hard-to-obtain catalyst.

[Edited on 4-2-2013 by MrHomeScientist]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MrHomeScientist  | I actually had a similar experience. I had been rinsing my larger balls in some mineral oil before transfering them to my storage bottle, and this

rinse oil had a lot of K-fines in it. To destroy them, I added a few drops of isopropyl alcohol (rubbing alcohol) and swirled. It made a crackling

sound, and I had a bit of a "flare-up" when some of the alcohol on the surface ignited. It was just a flash and disappeared quickly, but was

definitely startling I agree! It worries me greatly how I going to dispose of what I can't coalesce. Woelen uses t-butanol in his disposal, but I do

not want to use up my hard-to-obtain catalyst.

[Edited on 4-2-2013 by MrHomeScientist] |

Use lots of IPA or methylated spirits: lots of it so the alcohol won't heat up too much and won't ignite. Stir well to keep temperature homogeneous.

Allow time for reaction to complete.

[Edited on 2-4-2013 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Running a one-pot reaction as we speak, we'll see if any K results.

Any tips on removing solvent before ampouling? It's been a nasty problem for my sodium...

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Reaction: Success

Extraction: Partial success

I waited until the stuff was slightly warm, then strained out the potassium. Surprise! Even at that temperature, it caught fire. I managed to salvage

a few tiny bits of potassium, which will coalesce into a sphere about a quarter-inch big by my estimate, but nowhere near my actual yield.

Fortunately, I was expecting it this time around, so nothing was hurt.

Reaction time seems to be significantly faster with the one-pot method - the reaction was done in just 2 hours!

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by elementcollector1  | Reaction: Success

Extraction: Partial success

I waited until the stuff was slightly warm, then strained out the potassium. Surprise! Even at that temperature, it caught fire. I managed to salvage

a few tiny bits of potassium, which will coalesce into a sphere about a quarter-inch big by my estimate, but nowhere near my actual yield.

Fortunately, I was expecting it this time around, so nothing was hurt.

Reaction time seems to be significantly faster with the one-pot method - the reaction was done in just 2 hours! |

Fire again? Strange. Still glad to see you got K!

If one-pot did seem shorter (I didn't conclusively observe that), it may simply be that adding the catalyst from the start cuts down time by avoiding

that silly 'timed, step by step' addition.

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

You know, I always see my reaction mix turn chocolate brown. Although it's a good indicator that the reaction took place, I have to wonder whether

it's K2O and why it's there: Is my potassium getting consumed again somehow? I don't see anyone else having this problem.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Well, this one worked! I got a sphere about 1/2" in diameter, and nothing else (everything coalesced, apparently). Unfortunately, the sphere was so

large that it wouldn't fit through the neck of the RBF, and I was forced to mutilate it...

Oh well, I'll just coalesce them again tomorrow.

Pictures may follow, once I get the camera up and running.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by elementcollector1  | | You know, I always see my reaction mix turn chocolate brown. Although it's a good indicator that the reaction took place, I have to wonder whether

it's K2O and why it's there: Is my potassium getting consumed again somehow? I don't see anyone else having this problem. |

I’ve had browning too, up to the point where the potassium is hard to see. I think it may be due to a bit of Diels-Alder on the solvent but that is

merely an idea of mine right now.

Sounds like you’re in business now. Pix would be nice.

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

It doesn't look nearly as pretty as the last bunch, but I digress: I'm probably just going to ampoule it anyway.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

@elementcollector1: I've also seen browning of the solvent, which you can see in one of my posts a few pages back. It turns out all the color is just

a suspension of extremely fine particles - upon standing overnight, it all settles out and leaves perfectly clear oil. Looks like you're having great

results now! So yours finished reacting and coalesced in only 2 hours? What's the boiling point of the oil you use?

@AJKOER: This whole nascent hydrogen business is unnecessarily complex. You're introducing new things that aren't required for this reaction to run

(as far as we understand it). What you also aren't understanding is that len1 and blogfast have essentially proven that MgO is the final product by

measuring gas outflow. If you don't want to scroll all the way back to their testing, I believe I included it in my word document summary on page 51.

Again, there's no need to postulate extra things. Why don't you do some experimenting yourself?

|

|

|

elementcollector1

International Hazard

Posts: 2689

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by MrHomeScientist  | @elementcollector1: I've also seen browning of the solvent, which you can see in one of my posts a few pages back. It turns out all the color is just

a suspension of extremely fine particles - upon standing overnight, it all settles out and leaves perfectly clear oil. Looks like you're having great

results now! So yours finished reacting and coalesced in only 2 hours? What's the boiling point of the oil you use?

|

Well, at any rate, it's over 200 C. If I had to guess I'd say 205, 210 maybe?

I know that the oil itself isn't changing color (I observe the same thing upon standing), but I have to wonder just what the brown particles are. If

they're K2O, that means yield is being destroyed. More likely, they're a mix of some K2O and a lot of MgO.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

A more fruitful line of investigation may be to try this reaction using other potassium alkoxides (other than t-butoxide), synthesised from KOH (or

another common K salt).

Alkali metal alkoxides are usually prepared from the target metal and the target alcohol because that’s the only way to avoid water in the reaction

product mix. But that defies the object of the exercise here.

At a glance and w/o any further research, maybe refluxing of anhydrous IPA with KOH, followed by removal of the water by distillation with an

azeotrope forming solvent could bring solace? Toluene perhaps as an azeotrope former? This may lead to a product that is a relatively

pure potassium alkoxide.

[Edited on 17-4-2013 by blogfast25]

|

|

|

| Pages:

1

..

50

51

52

53

54

..

66 |