| Pages:

1

..

3

4

5

6 |

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Ah yes, the hydroxythingymejibs. A fine anion.

Anyway, took the remaining iron/cobalt solution and added tons more skutterudite. It's still reacting, but wouldn't react with the coarser, gray

material left over from the first dissolution. I'm tempted to think that this is elemental arsenic, but the crystal grain size and color suggest

coarser skutterudite that didn't dissolve as quickly.

Also: Upon diluting the wastewater (which is going to be contained in concrete when it's done), a lighter gray powder precipitated out. This is either

also arsenic, a mixture of arsenic and arsenic trioxide, or the Philosopher's Stone.

Per the forensic test: Inconclusive, as so far the liquor is still too acidic to avoid copper dissolution.

[Edited on 5-4-2014 by elementcollector1]

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

So I filtered the cobalt-iron liquor through a bunch more skutterudite ore, in order to get as much in solution as I could. Then, I put a large piece

of coiled up Cu wire in, and waited overnight. The results were interesting: Tons more hydroxythingymejibs (to the point where I could not distinguish

the color of the solution, everything was opaque yellow) and no precipitation whatsoever on the copper, which appeared to be mildly etched. This

pretty conclusively proves to me that copper is the cause of this precipitation, because at no point previously did it occur. In addition, this also

presents conclusive evidence that all the arsenic is reacted away to insoluble arsenic trioxide (which is what the powder in the above photo probably

is), and none is present in solution. Good!

Now, to distill some more nitric acid and dissolve all of the skutterudite. After that, I'm not sure what to do to separate the arsenic from the

oxygen: Heat with powdered burnt-flour charcoal in a test tube to sublime off the arsenic? Re-dissolve with HCl, use hypophosphite?

I think I might go with the first one, as I can see it playing out well if I'm careful. What I would do is load the dried reactants into a standard

test tube, evacuate it using my vacuum pump (it's not perfect vacuum, but it should work for this purpose), and then blowtorch the reactant mix,

taking care to drive all of the arsenic into the topmost part of the tube. Once the reaction is done, I would smash the tube open and collect the

arsenic.

However, I would probably have to design this so that the pressure when I'm finished is equal or close to 1 atm (it will increase due to the

production of CO2). Would it be possible to measure the volume of the test tube, work backwards from the ideal gas-molar relationship (22.4

L gas = 1 mol gas), and calculate the moles C / As2O3 to put in? Or would I have to calculate differently?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Firstly, you need to establish whether the residue is metallic As or As2O3. I seem to recall that elemental As dissolves in hypochlorite.

A sublimation point of 615 C is quite high for a test tube.

Quote: Originally posted by elementcollector1  | | However, I would probably have to design this so that the pressure when I'm finished is equal or close to 1 atm (it will increase due to the

production of CO2). Would it be possible to measure the volume of the test tube, work backwards from the ideal gas-molar relationship (22.4

L gas = 1 mol gas), and calculate the moles C / As2O3 to put in? Or would I have to calculate differently?

|

You'll find that the amount of reagents needed when calculated that way will be very, very small.

I also very much doubt if a Bunsen burner can deliver the level of heat needed for the carbothermic reduction of As2O3. Without being an expert in any

way, I think you will need red heat at least...

A carbothermic reduction of SnO2 I carried out years ago required intense charcoal heat and lots of time to complete.

[Edited on 5-5-2014 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

The residue is much closer to white than gray, leading me to believe it's just As2O3 with some leftover ore mixed in.

True enough - I was hoping for something significant, but once I think about it I shouldn't have expected much.

My blowtorch can melt glass, aluminum, and heat steel to orange temperatures, but you're right in that it can't deliver even heat for hours on end.

Maybe a home furnace, same as used for melting aluminum? Or just go back to the wet route...

Also, you would think the BP of arsenic would be lower than 615 degrees C under vacuum, although I can't seem to find a single phase diagram.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

I'd say, 'go wet'. Dissolve the oxide in something and plate out the arsenic. On copper for instance.

I don't think it's worth potentially poisoning yourself with some ad hoc apparatus.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Heh. True that.

You think plating out will accomplish a decent yield, say with copper and AsCl3?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Should b near 100 %, I imagine.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Or you could prepare an 'As mirror', based on the chemistry of the forensic Marsh test:

http://www.emsb.qc.ca/laurenhill/science/forensic.html

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Uh... No thanks. I'll just stick with plating - no heat, no arsine...

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

No arsine, no dead *rseholes...

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

True enough! Bought some more ammonium nitrate for distillation purposes, can't wait to try that again.

What am I going to do with all this (NH4)2SO4 / NH4HSO4?

Although, if plating has such yields, why isn't it being used instead of messing around with hypophosphite / tin chlorides? I suspect purity might be

less than satisfactory, even if yield is good...

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

There could be all kinds of reasons for this, such as economical. Brute force carbothermy with sublimation is simple and might be cheaper on a larger

scale.

Plating can yield extraordinary purity: see electroplated copper for conductors.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Well, collected more of that stuff via an odd process: The whiter substance easily forms a very temporary suspension in the solution, so I stirred

heavily, decanted off the mixture into a separate beaker, waited for it to settle, then decanted back. This got (by rough volume measurement) ~40g of

grayish arsenic trioxide. (This is so much more than I actually need). There's still some skutterudite left in the reaction beaker, so I'll leave it

to digest for a few more days. I ran out of nitric acid, and am hesitant to distill more because of the water costs of distilling under vacuum with my

current setup. Fortunately, the liquid still appears to be dissolving the ore - just much more slowly.

So far, I've worked out a few reactions for this.

The initial step of dissolution:

2 Co + 6 HNO3 -> 2 Co(NO3)3 + 3 H2

2 Fe + 6 HNO3 -> 2 Fe(NO3)3 + 3 H2

Arsenic appears to be unaffected at this stage, but given that it's the same color as the inital ore I am not sure.

At higher concentrations of nitric acid / longer reaction times,

2 As + 6 HNO3 -> As2O3 + 6 NO2 + 3 H2O

This was evidenced by copious release of NO2, red fumes that quickly began spilling out of the beaker. In addition, the white powder that

results is almost always partially floating on top and releasing gas bubbles. While these are not red (perhaps suggesting NO?), they could also be

hydrogen or some other similar result.

Wiki notes that arsenic trioxide will dissolve in HCl - so all that's left to do is dissolve the oxide into concentrated, pure HCl, and plate out with

copper?

I wonder what I should do with the leftover solution - maybe try to separate the cobalt from the iron, just for kicks?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by elementcollector1  |

Wiki notes that arsenic trioxide will dissolve in HCl - so all that's left to do is dissolve the oxide into concentrated, pure HCl, and plate out with

copper?

I wonder what I should do with the leftover solution - maybe try to separate the cobalt from the iron, just for kicks? |

It should dissolve in strong HCl but if it doesn't try strong NaOH, then neutralise and precipitate back to the oxide. 'Fresh' oxide should dissolve

well.

Separating Fe and Co should be interesting. Co forms an ammine complex, if memory serves me.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Arsenic Confirmed

Welp. Plating worked perfectly... so far.

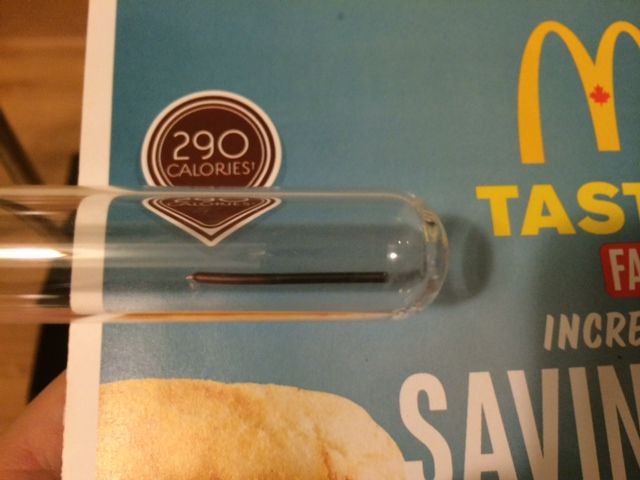

That there is a solution of AsCl3, made by treating a small amount of the white powder with strong HCl. Odd olive-green color, but

whatever. Put a heavy-gauge copper wire in, and the As immediately formed a beautiful mirror that I would love to put in Pretty Pictures if I had a

decent camera.

And now, on to larger-scale plating... I just need about 1mL or so of this, to fill up the ampoule - judging from the initial speed of the plating

reaction, this should be easy.

EDIT: Clearly I did not think this through - the plated layer of As blocks further deposition (no copper to react with), and shaking it isn't helping,

indicating good adherence.

I wonder if I should electroplate the larger solution instead?

[Edited on 5-14-2014 by elementcollector1]

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Very cool EC1! I just saw this and wanted to try it myself since I have no elemental As sample. I dissolved a small amount of commercial As2O3 in HCl,

the solution was clear but after adding the copper slowly became light green. I witnessed the same beautiful dark mirror as well, nice! Unfortunately

it's very hard to make the camera focus on a piece of wire so that didn't work so well but if you could find some thin copper sheet or pipe it might

be really neat

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Curiously, mine went green *before* addition of copper... and given my HCl was water-clear, I'm guessing this might be an iron impurity from the

original feed (Co, Fe, Ni)As3.

On the larger scale, it was much the same - olive green solution.

Even more curiously, after most of the white powder dissolved into the HCl, a small amount of darker, crystalline powder was left behind. I'm having a

hard time discerning if this itself is elemental arsenic or if it's just the skutterudite ore, as both are dark metallic powders. If I get a sample

dried out, then I'll know - the skutterudite powder was roughly the color of a medium pencil mark on a paper, while the arsenic is naturally much

darker (rather like a Taiwanese black pearl).

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Nice.

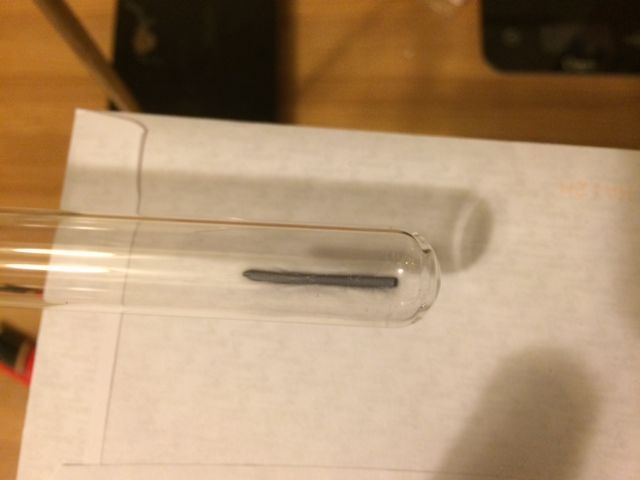

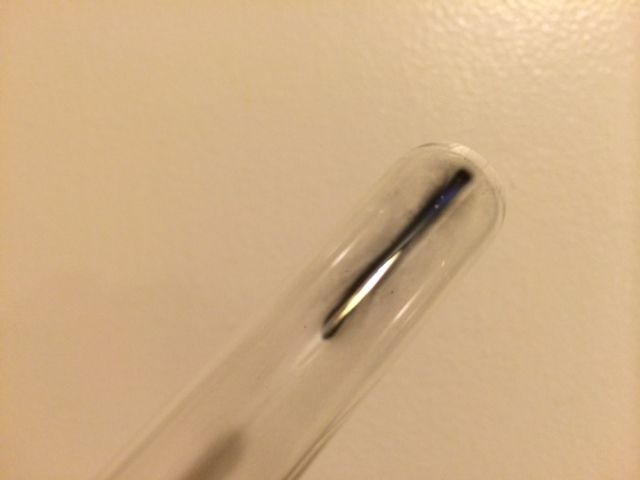

It could be worth doing the following mini-experiment. Take a small piece of the dried As plated wire and drop it into a clean test tube. Heat it

strongly with Bunsen/blowtorch: the As should sublime and maybe deposit itself on the glass as a mirror.

Alexander Gettler (the famous US toxicologist) used this to distinguish As from Bi because Bi also plates out on copper but doesn't sublime in this

test.

[Edited on 15-5-2014 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Got a bunch of white, red, and green sublimates doing this... Not enough arsenic, or too much oxygen?

On a side note, electroplating doesn't do anything in terms of yield!

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | Nice.

It could be worth doing the following mini-experiment. Take a small piece of the dried As plated wire and drop it into a clean test tube. Heat it

strongly with Bunsen/blowtorch: the As should sublime and maybe deposit itself on the glass as a mirror.

Alexander Gettler (the famous US toxicologist) used this to distinguish As from Bi because Bi also plates out on copper but doesn't sublime in this

test.

[Edited on 15-5-2014 by blogfast25] |

I gave this a shot and it seems to have worked.

Here is the bit of wire that had As plated onto it. The test tube was clamped horizontally and heated strongly. Sorry for the dumb Mc Donalds ad...

It's probably worse for you than the amount of As plated on the wire.

Eventually a black zone surrounded the wire. I stopped heating.

Viewed from underneath, a dark mirror.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Huh. Lot less contamination than mine - maybe something in the initial solution is messing it up?

[Edited on 5-16-2014 by elementcollector1]

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@MIMP:

Nice. Basically you've got a sample of relatively pure As.

@EC1:

What makes you say that?

You could purify by using As(III) 'acidity'. Add strong NaOH to precipitate iron (and others), Boil and As goes to sodium arsenite. Filter. Then cool

and re-acidify filtrate to AsCl3 and plate out.

[Edited on 16-5-2014 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Mainly due to the variety of colors produced upon sublimation, and that the solution was dark green to start with (well before addition of copper).

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

These colours aren't by any chance caused by thin-film interference, now are they?

http://en.wikipedia.org/wiki/Thin-film_interference

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

I don't think so - they're pretty constant and well bounded. The red is where the copper wire sunk into the partially melted glass tube, and the green

is all around that. The white is at the edges.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

| Pages:

1

..

3

4

5

6 |