| Pages:

1

..

3

4

5

6

7

..

31 |

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Does the same reaction work with sodium ferrocyanide and sodium carbonate or hydroxide? You might be able to get ferricyanide from

iron reduction of cyanate (brake turnings). References?

Definitely a MAD science project.

You can't get much cheaper starting materials than sodium bicarbonate, urea, and brake turnings.

[Edited on 5-15-2007 by Eclectic]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

What do you mean by brake turnings? Iron turnings?

The melting of ferrocyanide with carbonate to decompose the complex does only work with potassium salts as far as I know, due to their much lower

melting point.

Also, I cant get sodium ferrocyanide, only the K salt which costs something like 26€ a kg. A kg will make a huge amount of HCn though.

I'll probably try out the NaOCN + C process first, and if it doesnt give enough HCN to be worthwhile, I'll purchase K-ferrocyanide and K2CO3, which is

pretty much guaranteed to work.

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

Use isopropyl nitrite to turn acetone into oximinoacetone, degraded with heat and catalyzed by triphenylphosphine into HCN, acetyl chloride, or

molecular sieves.

http://www.google.com/patents?vid=USPAT3307905&id=5FxLAA...

http://www.google.com/patents?id=A6RXAAAAEBAJ&printsec=a...

Overall it seems like a fairly straightforward reaction... all thats needed is sodium nitrite, sulfuric acid, acetone, and a catalyst and perhaps some

carboxylic acid as a solvent.

[Edited on 15-5-2007 by evil_lurker]

Not all chemicals are bad. Without chemicals such as hydrogen and oxygen, for example, there would be no way to make water, a vital ingredient in

beer.

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

When automobile service shops turn brake rotors and drums they end up with a lot of cast iron/steel turnings in little flakes, spirals with a lot of

surface area. You can probably get them for free.

I'm thinking reducing a sodium or potassium cyanate melt with iron turnings will make ferrocyanide.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

If iron reacts appreciably with NaOCN at the temperature at which reduction by carbon takes place, it would be bad news as I want to use a soup can as

the crucible.

[Edited on 16-5-2007 by garage chemist]

|

|

|

kmno4

International Hazard

Posts: 1517

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

As I see it is neverending story, because of its ostensible simplicity, I think. If you cannot reach about 1000 C - just forget about good (> 50%)

yield. If heating is prolongated - KCN will oxidate to KOCN and ->.....-> K2CO3.

From some book:

Take 160g K4[Fe(CN)6] + 60g K2CO3 + 6g C and melt as long as all gases (CO) will go away. Extraction with 60% EtOH gives 80-100g KCN.

Much simpler version: heat (>700 C) K4[Fe(CN)6] in almost closed vessel (to prevent oxidation). Melt contais only KCN, traces K2CO3, Fe and iron

carbide (I forget formula). Nor K2CO3 nor KOCN reduction is needed.

To both variants the best is resistance furnace.

Good luck(yield) and do not kill yourself

[Edited on 16-5-2007 by kmno4]

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Muspratt, Vol. II, page 451 gives a preparation of potassium ferrocyanide. Nitrogen rich materials (blood, hooves,etc.) fused with carbonate of

potassia in iron vessels at red heat. Resulting grey mass, lixivated with boiling water and concentrated yields yellow prussate of potassia. See

also the very first post in this thread, and page 3...

A cheap lidded cast iron dutch oven might hold up to the red heat better than a thin steel can, and do a better job of keeping out oxygen.

Dutch Ovens

[Edited on 5-16-2007 by Eclectic]

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by evil_lurker

Use isopropyl nitrite to turn acetone into oximinoacetone, |

Do you have reference to that reaction? I have the attached article, which uses the less then convenient gases; methyl nitrite and HCl. Did u you just

assume isopropyl nitrite due to analogy or have you seen it documented?

[Edited on 24-5-2007 by Axt]

Attachment: Experiments on the preparation of oximino-derivatives - J. Chem. Soc., Trans., 1920, 117, 587 - 590.pdf (239kB)

This file has been downloaded 1397 times

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

Well according to this patent, it works.

http://www.google.com/patents?id=cB9IAAAAEBAJ&printsec=a...

To a stirred solution of 465 grams of acetone and 5 milliliters of concentrated hydrochloric acid cooled in an ice bath, 178.4 grams of isopropyl

nitrite was added dropwise. When the addition was completed, the isopropyl alcohol formed and the unreacted acetone were removed from the product

under reduced pressure. Oximinoacetone weighing 164g (94% conversion, nitrite basis) with a melting point of 61-64ºC was obtained. Recrystallization

from an ether-petroleum ether mixture yielded white crystalline oximinoacetone having a melting point of 64.5-65ºC.

In the foregoing example, the hydrochloric acid-nitrite weight ratio was 0.030:1 and the acetone-nitrite mole ratio was 4:1.

Isopropyl nitrite is rather easily obtained by this:

http://www.orgsynth.org/orgsyn/prep.asp?prep=cv2p0108

http://www.orgsynth.org/orgsyn/prep.asp?prep=cv3p0191

A mixture of 147 g. (80 ml., 1.5 moles) of concentrated sulfuric acid (sp. gr. 1.84), 60 ml. of water, and 180 g. (230 ml., 3 moles) of 97%

isopropyl alcohol, previously cooled to 0°, is added to a solution of 227.7 g. (3.3 moles) of 97% sodium nitrite in 1 l. of water, cooled to

−5°. About 2 hours is required for the addition of the alcohol solution, during which time the temperature of the reaction mixture is

maintained at −2° to 0°. The product may be isolated and purified as described under butyl nitrite. After drying over 15–20 g. of anhydrous

sodium sulfate, the nitrite is distilled from a steam bath using a 20-cm. column. Practically all the isopropyl nitrite distils at 39–40°/745 mm.

as a pale yellow oil; the yield of product is 191 g. (71.4%). Isopropyl nitrite, when stored in a refrigerator, has been found to be much more stable

than butyl nitrite.

The catch for making HCN is a decomposition catalyst to which triphenylphosphine works wonders with yields as high as 95% based up on the

oximinoacetone.

http://www.google.com/patents?id=A6RXAAAAEBAJ&printsec=a...

Not all chemicals are bad. Without chemicals such as hydrogen and oxygen, for example, there would be no way to make water, a vital ingredient in

beer.

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

I can buy diethylether in the drogerie by the liter - no questions asked. And formic acic. And acetic acid. Except "One or more liters?" Because they

have to fetch them from behind and dont want to go twice.

I cannot buy methylalcohol though as its a "poison". Funny. But red phosphosphorus by the kilo. They have no smaller batches.

Funny world

[Edited on 24-5-2007 by Organikum]

|

|

|

jackson2004

Harmless

Posts: 38

Registered: 22-6-2007

Member Is Offline

Mood: No Mood

|

|

Sodium Cyanide Synth

Has anyone tried the method involving iron oxide, soda ash and charcoal mixed together and fired to a red hot heat.

If so, how did it turn out?

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Are you talking about some obscure method for producing steel?

This thread is about cyanides preparations (mostly by cyanate reduction) and if you check the formula for sodium cyanide it is NaCN, meaning that you

need a source for the nitrogen (N) which is obviously lacking in your mixture (unless you impute N2 from air to chemically react there).

PS: It is customary in this forum to provide references for extraordinary claims (hence the word "science" in the forum's title).

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

| Quote: | Originally posted by Nicodem

Are you talking about some obscure method for producing steel?

This thread is about cyanides preparations (mostly by cyanate reduction) and if you check the formula for sodium cyanide it is NaCN, meaning that you

need a source for the nitrogen (N) which is obviously lacking in your mixture (unless you impute N2 from air to chemically react there).

PS: It is customary in this forum to provide references for extraordinary claims (hence the word "science" in the forum's title).

|

I believe he's referring to the Bucher process for fixation of atmospheric nitrogen as cyanide. It seems to be (in)famous among non-professional

chemists because it or a closely related process was recommended either by Kurt Saxon or Uncle Fester (can't recall which now) as an accessible method

for cyanide production. Someone who was obviously cribbing from this source and had never attempted the process also did a first-person writeup that

was enshrined on the inorganic section of rhodium.ws.

As an industrial process, its advantage was that it actually fixed nitrogen from the air rather than transforming already-fixed nitrogen. That is no

great advantage for the home chemist, though. This process offers high-temperature obstacles like those of cyanate reduction, but no further

advantages that I can see.

For a fairly comprehensive review of archaic cyanide processes, some fairly obscure yet perhaps suited to amateur use, see The Cyanide Industry Theoretically and Practically Considered. It was unfortunately published a decade before the Bucher process, but

Google Books can provide further information on that particular process.

PGP Key and corresponding e-mail address

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

The method goes back to 1839. There is quite a bit of info on it in many old IEC articles. Thorpe has a long account by the chief chemist and later

director of a company in Glasgow that used this process.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

I know the Bucher process is mentioned in Textbook of Organic Chemistry by Joseph Scudder Chamberlain, which archive.org has. While the

process goes way back, Bucher optimised it and made it commercially practical. When done on a large enough scale the overall process can be made

exothermic, or you can capture the CO to make formate.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

A relatively simple method of fixating N2 at 900-1000°C without the use of bacteria or other fancy chemistry? That is what I call some interesting

inorganic chemistry. I was not aware of much N2 chemistry, besides certain metals like the alkali ones that burn in the atmosphere of N2 and certain

industrial processes like hydrogenation of N2 or the cyanamide process. Searching for the nitrogen fixation and the Bucher Process I found this

encyclopedic entry:

| Quote: | Bucher Process.-The synthesis of sodium cyanide by the interaction of sodium carbonate, carbon and nitrogen in the presence of iron as a

catalyst, according to the equation Na2C03+4C+N2 = 2NaCN+3CO 3 constitutes a promising method of nitrogen fixation, the commercial development of

which is still in its infancy. The catalytic effect of iron in promoting this formation of cyanides. at relatively low temperatures (800-1,000° C.)

was noted by Thompson in 1839. Bucher (Jour. Indust. and Eng. Chem., 1917, 9 . 2 33) drew renewed attention to the process, which has recently been

developed industrially in the United States by the Nitrogen Products Co. According to the procedure adopted at Saltville,Virginia (Jour. Indust. and

Eng. Chem., 1919, II. Imo), coke is ground to a fineness of 200 mesh, and after the admixture of a small quantity of iron the required quantity of

soda ash is added. The charge is moistened slightly, kneaded, and extruded in the form of briquettes, which are dried by the action of flue gases. The

briquettes are placed in vertical iron or nichrome retorts, which are heated externally in firebrick furnaces to a temperature of 900 to 1,000° C., a

current of nitrogen being led through the retorts. The briquettes, after treatment, contain about 20% to 30% of cyanide, which, in the plant in

question, is removed in a somewhat novel manner by subsequent extraction with liquid ammonia, in which sodium cyanide is readily soluble. During this

extraction process, the main structure of the briquette remains undestroyed, and the uncombined residue may be used for further treatment with

nitrogen. The chief technical difficulty lies in the rapid deterioration of the iron retorts at the temperature employed for fixation, the life of

these being about 7 to 12 days. Nichrome retorts last longer, but are more expensive to replace. It has been proposed to use an electrically heated

type of furnace in which the charge itself forms the resistance. Further, pure nitrogen, although conducive to a high yield of cyanide, is not

essential for commercial success. Ferguson and Manning (Jour. Indust. and Eng. Chem., 1919, II. 94 6), in reviewing the replacement of nitrogen by

producer gas containing carbon monoxide, state that at 1,000°C. the presence of 15% of carbon monoxide in the nitrogen reduces the yield of cyanide

by about 30%, while, if the producer gas contains 60% of carbon monoxide, the yield is one-half of the value obtained with pure nitrogen. This

inhibitive effect of carbon monoxide, the reason for which lies in the reversibility of the equation Na 2 CO 3 +4C+N 2 2NaCN+3CO, is even more

pronounced at lower temperatures.

From: http://www.1911encyclopedia.org/Nitrogen_Fixation |

OK, the process is too tedious as an amateur method of sodium cyanide production when compared to the discussed NaOCN reduction with carbon. Not only

because of the need of oxygen free nitrogen, but also due to the messy workup. Still, I find it fascinating that Fe (or in situ formed Fe when Fe2O3

is used) can catalyze the reaction. How does it "capture" N2? Does iron form or equilibrates with Fe(II) nitride when heated in N2 atmosphere?

Given that not all have access to this paper I also pasted the excerpt regarding the industrial economics of the Bucher Process from:

Nitrogen: Its Fixation, Its Uses in Peace and War

Grinnell Jones

The Quarterly Journal of Economics, 34 (May, 1920), 391-431.

DOI:10.2307/1883359

| Quote: |

Cyanide Process

The only other process which merits discussion is the

Bucher process, which depends upon the fact that when

soda, carbon, and iron are intimately mixed and heated

to a red heat in the presence of nitrogen gas the nitrogen

is rapidly absorbed, resulting in the formation of sodium

cyanide mixed with the unchanged iron. The iron takes

no direct part in the reaction but the reaction will not

occur with any useful speed in the absence of iron. Altho

considerable difficulty has been encountered in the

operation of this process, it has been developed on a

commercial scale so recently that experience with it is

very brief but the best available information indicates

that the difficulties are not fundamental but can be surmounted

by changes in detail of design. The process

appears to be the most rational method known for the

manufacture of cyanides. Its development up to the

limits of the cyanide market may be predicted.

There is also a possibility that this process may produce

sodium cyanide at a cost low enough to make it a

suitable raw material for manufacture of many other

chemicals now made by quite different methods. If

sodium cyanide is steamed, it yields ammonia and sodium

formate. Sodium formate in turn will serve for the

manufacture of formic acid, for which a market of many

million pounds per year could easily be developed if its

price could be lowered substantially. Sodium formate

may also be readily converted into sodium oxalate and

this in turn into oxalic acid. Both the oxalic acid market

and the formic acid market of the world were dominated

by German manufacturers before the war; the new

process may destroy this German advantage. The output

of ammonia from the Bucher process may not, however,

necessarily be limited by the market for formic and

oxalic acids. By the action of air and steam at a low red

heat, sodium cyanide yields ammonia and soda. Since

the soda obtained may be used over and over again in

the process itself with consequent reduction in cost of

raw material, the development of the process, if financially

successful, is limited only by the demand for ammonia.

At present there is little prospect that ammonia

can be made as the principal product by this method,

but it may be produced as a by-product of the manufacture

of formic and oxalic acids.

Bucher even dreams of revolutionizing the process of

making steel, and obtaining sodium cyanide as a byproduct

of a new steel-making process. Pig iron, the

primary product of the iron and steel industry, contains

about 4 per cent of carbon. The process of making steel

consists essentially in reducing the carbon content to a

figure varying from about one-tenth of 1 per cent to 2

per cent, according to the variety of steel desired. In

the Bessemer converter, the carbon is burned out by

blowing a blast of air through the molten pig iron. Bucher

hopes to replace this air blast by a blast of nitrogen

carrying powdered soda and thereby to remove the

carbon as sodium cyanide. Sodium cyanide thus produced

would be so cheap that it might be converted by

treatment with steam into ammonia for fertilizer, and

soda for reuse in the steel-making operation. Since this

process has not yet passed the laboratory stage, prediction

of success would be rash. However, chemical science

has to its credit scores of triumphs inherently no

more difficult or improbable than this. There is at least

a hope that, within the next decade or two, the steel

industry may yield large amounts of nitrogen fertilizer

material as a by-product. |

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

The only problem with that process, making NaCN from Na2CO3, C, and N2, heated together under pressure, as an intermediate to NH3 via steam

hydrolysis, is that hydrolysis of NaCN produces, either as another intermediate or as a competing byproduct, HCN (prussic acid), which is a highly

poisonous gas. Any escape of it would be a safety hazard.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

The most relevant aforementioned IEC's

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

Well I decided to attempt to whip up a bunch of cyanide this weekend.

I'm starting with the isopropyl nitrite synthesis as a reagent to manufacture oximinoacetone... basically I'm using the orgsyn reference above doubled

in volume.

The reaction is going smoothly, with just a little bit more of a temperature rise than I would prefer (4ºC).

Not all chemicals are bad. Without chemicals such as hydrogen and oxygen, for example, there would be no way to make water, a vital ingredient in

beer.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Wouldnt it be easier and less dangerous to melt potassium ferrocyanide with potash, directly giving KCN?

Anyway, its a new and interesting method. Keep us informed how it goes.

[Edited on 28-6-2007 by garage chemist]

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

That is, if Evil_Lurker lives to tell the tale. He had better wear a pretty good gas mask, and preferably diver-type breathing apparatus.

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

Well the IPN synthesis went fairly well... there is a nice yellow non-polar layer on top of the spent NaNO2 solution just as orgsyn said there would

be.

Total crude yield, 398g.

Not all chemicals are bad. Without chemicals such as hydrogen and oxygen, for example, there would be no way to make water, a vital ingredient in

beer.

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

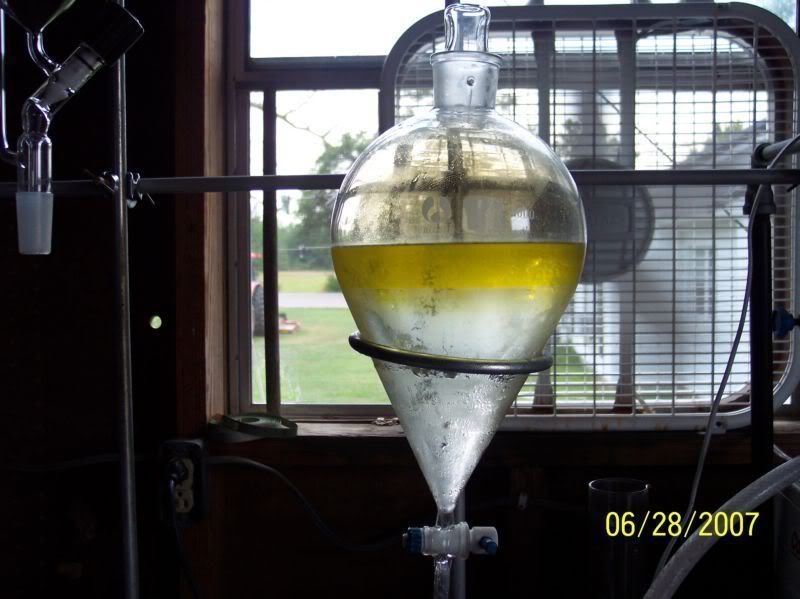

Better pic of IPN in separatory funnel.

Not all chemicals are bad. Without chemicals such as hydrogen and oxygen, for example, there would be no way to make water, a vital ingredient in

beer.

|

|

|

tito-o-mac

Hazard to Others

Posts: 117

Registered: 30-6-2007

Member Is Offline

Mood: No Mood

|

|

the poor man's James bon is crap... don't trust it.

|

|

|

Antwain

Hazard to Others

Posts: 252

Registered: 21-7-2007

Location: Australia

Member Is Offline

Mood: Supersaturated

|

|

Hi all.

This is my first post of what will hopefully be many. I have always been fascinated by cyanide, even before I learned the reasons for its very strong

binding to transition metals last year. Im hoping to make every metal cyanide complex possible (probably an unattainable goal, but my goal

nonetheless).

Anyhow, recently I managed to distill some ferrocyanide + sulfuric acid into sodium hydroxide and I am going to clean this up ( the crappy hydroxide

had carbonate in it I think, but it seems to still be insoluble in the resulting solution). Unfortunately it has been sitting in solution for some

weeks, and I was wondering if anyone here knows about the hydrolysis to ammonium formate in aqueous solution. For instance, its winter and the

solution will never have been over about 10*C - Does heating matter a great deal. And, I used a 5% excess of base (so that if a drop of sulfuric acid

come over I wouldnt kill myself) does the pH affect the hydrolysis, and if so how.

Wiki has nothing on this, and google searches mostly reveal stuff about enzyme catalysis, and destruction of cyanide solutions - which is obviously

not my goal :-). Any help would be appreciated. Essentially what I am wondering is whether or not much of my cyanide will have been destroyed.

Incidently, I am going to dump my neaer saturated solution (~50mL) into 200mL of ethanol to precipitate it and hope for the best. Unfortunately

acidified bleach will probably react with ethanol...? so how should I destroy that solution? In the meantime I will leave it in a bottle and see what

you guys come up with.

|

|

|

| Pages:

1

..

3

4

5

6

7

..

31 |