| Pages:

1

..

3

4

5

6

7

..

9 |

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by PHILOU Zrealone  |

Sand will dry faster in a kind of tumble drier or into a fluidized bed (warm air from under through the sand that is lifted up (fluidized) a little

and fall back down). |

As I found out, much to my surprise, a heating cabinet and spreading out a thin layer of the stuff also does wonders

And yes....IT WERKS!!!

So I prepared a set of samples:

![WP_20170201_001[1].jpg - 1.1MB](http://www.sciencemadness.org/talk/files.php?pid=473362&aid=56616)

2* 50mg 100% SADS for baseline

1* 50mg 15% KClO3

1* 50mg 20% KClO3

1* 50mg 30% KCO3

2* 100mg 100% SADS for comparison

The cell was loaded with 40g of evaluation sand 250/100um fraction for all tests and then sieve analysis was performed with RETSCH AS200 apparatus on

100um sieve to get the fraction that passes the 100um limit as the assessment for brisance.

The first results were as follows:

Baseline <100um for 50mg SADS 100% : 3,89g

Baseline <100um for 100mg SADS 100% : 5,82g

15% KClO3 <100mg fo 50mg : 4,42g

20% KClO3 <100mg fo 50mg : 4,09g ?? (probably an error in assessment)

30% KClO3 <100mg fo 50mg : 4,45g

This proves, although inconclusively, my previous assessment of the brisanse of these mixes based on the "match shattering" method. Seems that

addition of KClO3 increases the power by quite a considerable amount compared to pure double salt.

As we can see from the baseline measurements ,the double charge of pure SADS caused about 49.6% increase in amount of <100um fraction. Where as the

addition of 15% KClO3 caused about 13,6% increase in amount of <100um fraction. Derived from that, one could quite loosely estimate that the 15%

KClO3 mix is about 27% more brisant than pure double salt. This applies only to this test under these particular circumstances and postulating that

brisance increases linearily in relation to the amount of sand crushed. Which of course is not correct, but let's just assume for the sake of

simplicity and just to make an example. All in all I'm very pleased with the performance of the cell and the first results. For further steps I will

work with 100mg samples for better resolution and make more repetitions on all datapoints to get a more conclusive result and catch the most potent

sweet point for the mix.

Oh yeah...I tried to set off the SADS KClO3 mix with friction and impact...no go, luckily it seems to be not too much more sensitive compared to pure

double salt, but extreme caution is a must.

Nice side effect which can be seen in the last picture is that the top of the sample holder is covered in a shiny well adhered layer of metallic

silver. It was deposited by the 100mg pure SADS baseline measurements. The 15% mix actually deposited a golden layer which looked even more pretty

As far as downsides of this perticular setup are concerned, then the fuse for initiation is best replaced by an electrical triggering system. The

pyrotechnical route is messy, leaves ash and stinky byproducts if a BP fuse is used and must be set off outside....but it is simple and reliable.

[Edited on 1-2-2017 by markx]

Exact science is a figment of imagination.......

|

|

|

NitratedKittens

Hazard to Others

Posts: 131

Registered: 13-4-2015

Location: In the basket with all the other kittens

Member Is Offline

Mood: Carbonated

|

|

Teeheehee, welding asses

Basket of kittens for you ........BOOM

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Great job and good lathe skills as wel!  This would be a great tool to test

small amounts of pirmary explosives for their brisance with the added benfit that it includes reasonably reinforced conditions, so also usable for

less "hot" primaries so to say. As you said, one of the things that would be interesting to do is take several repetitions of exactly the same setup

to get an idea of the variation inherent to the test. Assuming you want to be able to discern a specific effect size you can calculate how many

repetitions would be needed to reach statistical significance, by the looks of it 4-5 may be enough for 10% difference. This would be a great tool to test

small amounts of pirmary explosives for their brisance with the added benfit that it includes reasonably reinforced conditions, so also usable for

less "hot" primaries so to say. As you said, one of the things that would be interesting to do is take several repetitions of exactly the same setup

to get an idea of the variation inherent to the test. Assuming you want to be able to discern a specific effect size you can calculate how many

repetitions would be needed to reach statistical significance, by the looks of it 4-5 may be enough for 10% difference.

Also, how does the packing densitty of the sand affect the test? Can imagine this depends on kernel shape and batch wise, maybe include a negative

control (just unblasted sand) as well.

Did you design the setup after a commonly used one btw? If it does, would be interesting to compare your own data with those from literature. Very

cool!

[Edited on 1-2-2017 by nitro-genes]

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Your results matched mine. I have found the addition of 20% Kclo3 to be best for both ignitability and brisance. This is important, as not only are

we increasing the power, we are diluting it with a cheaper chemical. Above 20% it has trouble detonating in the open when exposed quickly to a flame.

I have found also that it does not increase the sensitivity. SADS is really the most insensitive primary I think...

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by nitro-genes  | Great job and good lathe skills as wel!  This would be a great tool to test

small amounts of pirmary explosives for their brisance with the added benfit that it includes reasonably reinforced conditions, so also usable for

less "hot" primaries so to say. As you said, one of the things that would be interesting to do is take several repetitions of exactly the same setup

to get an idea of the variation inherent to the test. Assuming you want to be able to discern a specific effect size you can calculate how many

repetitions would be needed to reach statistical significance, by the looks of it 4-5 may be enough for 10% difference. This would be a great tool to test

small amounts of pirmary explosives for their brisance with the added benfit that it includes reasonably reinforced conditions, so also usable for

less "hot" primaries so to say. As you said, one of the things that would be interesting to do is take several repetitions of exactly the same setup

to get an idea of the variation inherent to the test. Assuming you want to be able to discern a specific effect size you can calculate how many

repetitions would be needed to reach statistical significance, by the looks of it 4-5 may be enough for 10% difference.

Also, how does the packing densitty of the sand affect the test? Can imagine this depends on kernel shape and batch wise, maybe include a negative

control (just unblasted sand) as well.

Did you design the setup after a commonly used one btw? If it does, would be interesting to compare your own data with those from literature. Very

cool!

[Edited on 1-2-2017 by nitro-genes] |

This testing device has not been benchmarked, at least not intentionally, against any particular device design of same function that is already out

there and being used. So comparing results number by number is probably not going to be a trivial task, but that was not my intention to begin with.

Rather I would depoly it in service of establishing a better understanding of the tendencies and relationships of the parameter known as "brisance"

with regard to composition of energetic mix or substance. These tendencies have reasonably little regard towards the particularities of the testing

device (which only sets the background system so to speak), so as long as a comparative set is tested within the same device, a comparable tendency

should reveal itself.

The parameters of sand will most definately have a major effect on the outcome of the result, as the hardness, geometry, size, granulometry and

packing density all affect the way in which energy is absorbed by the medium. I used soft limestone type to better capture the relatively small

variations in brisance and prepared the sand fraction beforehand by carefully sieving and washing out everything above 250 microns and below 100

microns grain size. The unblasted sand shows close to 100% retention on 100 micron sieve....so anything passing through after test is the effect of

the released energy. The sand surrounding the sample was not intentionally compacted (which would certainly increase the effect of crushing), but

rather just poured over it and left as is. Either way will work and reveal the same tendencies as long as one keeps it consistent through the

individual tests. So operator's adherence to preparative procedure and unbiased action is required...but that goes for all experiments

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by MineMan  | Your results matched mine. I have found the addition of 20% Kclo3 to be best for both ignitability and brisance. This is important, as not only are

we increasing the power, we are diluting it with a cheaper chemical. Above 20% it has trouble detonating in the open when exposed quickly to a flame.

I have found also that it does not increase the sensitivity. SADS is really the most insensitive primary I think... |

I did not find a decreased sensitivity towards flame initiation even up to 50% dilution in my tests....the mixes seemed to remain ever so sensitive to

the slightest touch of a flame, but brisance decreased noticeably at higher dilution ratios.

Mechanical sensitivity wise I will remain very inconclusive so far, as I have not performed any quantitative tests for the mixes. It seems to be

unaffected in direction of increased sensitivity, but for now it is best to assume the worst just in case.

Exact science is a figment of imagination.......

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Nice.. could think of some comparitative test for some diazophenols.  Would

still be interesting to extrapolate results from taking some measurements from known primaries of course. Just hypothetically speaking (not really

sure what this extra data would tell you), measuring the weight of several size fractions might also be interesting, starting with the smallest

particle sizes and up, then looking at the distribution, maybe some correlations between total energy release and brisance would be apparent. Would

still be interesting to extrapolate results from taking some measurements from known primaries of course. Just hypothetically speaking (not really

sure what this extra data would tell you), measuring the weight of several size fractions might also be interesting, starting with the smallest

particle sizes and up, then looking at the distribution, maybe some correlations between total energy release and brisance would be apparent.

Regarding sand loading and packing by pouring, wouldn't round grains be optimal regarding density and consistency? Sharply edged sand grains take

quite some tapping to get optimal packing probably. Maybe the total weight of the sand poured in can provide an idea of the most consistent loading

procedure.

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by nitro-genes  | Nice.. could think of some comparitative test for some diazophenols.  Would

still be interesting to extrapolate results from taking some measurements from known primaries of course. Just hypothetically speaking (not really

sure what this extra data would tell you), measuring the weight of several size fractions might also be interesting, starting with the smallest

particle sizes and up, then looking at the distribution, maybe some correlations between total energy release and brisance would be apparent. Would

still be interesting to extrapolate results from taking some measurements from known primaries of course. Just hypothetically speaking (not really

sure what this extra data would tell you), measuring the weight of several size fractions might also be interesting, starting with the smallest

particle sizes and up, then looking at the distribution, maybe some correlations between total energy release and brisance would be apparent.

Regarding sand loading and packing by pouring, wouldn't round grains be optimal regarding density and consistency? Sharply edged sand grains take

quite some tapping to get optimal packing probably. Maybe the total weight of the sand poured in can provide an idea of the most consistent loading

procedure. |

Well yes...probably a synthetic media with closely controlled grain geometry, size and hardness would yield the most unbiased results, but I have to

work with the tools that I have at hand right now

Performing fractional sieve analysis of the crushed portion of sand is no problem from technical point of view, but I'm not really sure how to model

and interpret this data. I guess one could find out some things about the energetic as well as about the sand medium itself from these sieve curves.

This seems like a really vast field of research on its own and a rather complicated one too....

Exact science is a figment of imagination.......

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Very nice and exciting!

Your device seems to work fine (with the non negligible help of the professional "sieve analysis RETSCH AS200 apparatus").

No real need to compare vs other devices as long as you keep your results and methodology coherent with itself and use one ore more

standards...Pb(N3)3, AgN3, Hg(ONC)2, AgONC, Pb(picrate)2, DDNP...

Then any amateur building such a device can correlate with its own results...by using same standards...and finding its own specific geometric factor.

Ws(g) = G*Ei*WEi(g)*f

where

Ws(g) = weight of sand crushed

G = geometic factor

Ei = explosive factor (specific to each explosive; here explosive i)

WEi = weight of the given explosive i

f = function of weight (linear, quadratic or exponential)

You can also make:

-weight power curves (must be quadratic or exponential (or maybe linear) depending onto the substance) by plotting weight of primary vs sand crushed

to a finer fraction.

-volumic power curves (take into account the density variation between primaries)

-find the minimum amount of primary to effect detonation of a 50mg secondary charge (TNT, picric, RDX) ... characterized by a jump into the quantity

of sand crushed.

--> And really compare primaries or explosive power between each other or with itself in various quantities.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Yes, there are endless options for research here and all of them are exciting to pursue, but I guess for starters I will probe the topic of SADS/KClO3

mixes in more depth  Find out the effective limits for this particular mix from

one end of dilution ratios to the other and seek out the most potent combination. Find out the effective limits for this particular mix from

one end of dilution ratios to the other and seek out the most potent combination.

For next step I will investigate the properties of pure double salt with regard to synthesis temperature ranging from lets say 20C up to 90C with 10C

steps and see what kind of plot reveals itself. From previous experience I can say with relative confidence that the sweet spot is near 65C, but it

would be really great to see this result develop through the experimental data from brisance assessment. Perhaps there are several good spots in the

temperature range or some other details reveal themselves....

I would also like to construct a compact impact sensitivity tester to be able to check for how near the the abyss I am playing. I do have a drop

hammer device and it works like a charm, but it is bulky, noisy and uncomfortable to transport. Something spring operated with a relative scale of

potential energy should do the trick...much like a gunlock in principle. Again this would be a DIY device without a benchmark and thus lacking the

option for direct comparison of literature data. Even better if I could also come up with a compact design for friction sensitivity testing device.

The combined results from these could really lay a solid foundation for any claims on the topic. But let's see...time will tell

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Online

Mood: old jew

|

|

SADS

SADS belongs nowadays between a best primary. Not poisoned, with relatively available precursors. Therefore is this research pretty interesting,

because price silver is high always. Adding 20% KClO3 is price of course lower and power this mixture is even higher. Next questions is sensitivity

this mixture and stability after for example half of year. I Estimate, that some EM can be initiated directly with this mixture, without secondary

EM. Or secondary EM will require lower amount this mixture for full drive. Which is advantage again. Very interesting the research.

........LL.......

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Laboratory of Liptakov  | SADS belongs nowadays between a best primary. Not poisoned, with relatively available precursors. Therefore is this research pretty interesting,

because price silver is high always. Adding 20% KClO3 is price of course lower and power this mixture is even higher. Next questions is sensitivity

this mixture and stability after for example half of year. I Estimate, that some EM can be initiated directly with this mixture, without secondary

EM. Or secondary EM will require lower amount this mixture for full drive. Which is advantage again. Very interesting the research.

........LL....... |

I do concur to the opinion that SADS can be considered as one of the most reasonable choices of primaries in the amateur practice realm. When prepared

under optimal conditions (elevated synthesis temperature and strongly acidic environment), it displays inherently passive behavoiur against

impact...at least on par with heterocyclic nitramine secondaries. My drop test device was unable to initiate it at the maximum height of about 70 plus

cenitmeters with a 2kg impact weight. In comparison an early sample that was prepared at room temperature in acidic environment was highly impact

sensitive and could be set off with a slight tap of an hammer. The devil lives in details and so far friction and electrostatic branches are

unexplored from my side...a serious shortcoming that I have to rectify.

As for the cost of materials viewed from the amateur practice side are quite negligible, so the dilution with chlorates mostly just serves to satisfy

the scientific couriosity

Nevertheless an in depth investigation might unveil some details that might make it sustainable for industry practice in some "niche" applications,

but given the high content of a precious metal and the cost involved makes the chances quite slim.

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

A slight update on generic developments regarding evaluation mediums seen below:

![WP_20170203_001[1].jpg - 1.3MB](http://www.sciencemadness.org/talk/files.php?pid=473564&aid=56652)

The left one is quartz sand fraction and the right side one is limestone sand. Both have reasonably same granulometry and have been washed, sieved and

dried meticulosly to rid it of any <100um fines. Totally different animals though....and not just because of the coloration

As I suspected before, the quartz sand is too hard for testing of SADS and shows close to zero crushing effect after 50mg and 100mg samples being

fired. So it can not be used to test this substance for brisance.....which is actually great, because it opens up a way of cancelling out the effect

of the primary initiator stage when testing for secondaries and hence yields a very precise and unbiased result that is purely due to the secondary

stage firing up. A very exciting discovery

On a more sad note I have run out of limestone sand fraction and can not continue to test for the series today. I managed to get enough sand for two

test shots of 30% KClO3 dilution mix and surprisingly the results are quite exactly on par with the 20% dilution results. Both hover about 25-27%

above baseline brisance. Quite neat if one third of the costly ingredient can be replaced with a virtually free component and still get a massive gain

in output

I will have to hog a massive sample from next shipment of limestone filler and prepare a sizeable stock of testing media. Then a full run of

repetitions can be made in one go and the results lined up on a nice graph.....can't wait to get working on it

[Edited on 3-2-2017 by markx]

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Online

Mood: old jew

|

|

SADS

Once again, I would sum up the principles for the preparation yield 450 mg SADS:

1) Solution, maximum pure all reagents: 8,7g H2O + 1,82g HNO3 65% + 700 mg AgNO3 in high cylinder glass is dissolved. Temperature go to on 65 - 70C

- hold.

2) Generator acetylene : 40g pure H2O + 1,5g pure CaC2, start temperature 20 C.

3) tube (plast) for bubble with cigaret filter (or 2 filter series ?)

4) Start generator, waiting 30 second before insert pipe to solution 65 C.

5) cylinder glass cover against light

6) Bubble 4 minute, pipe out.

7) Separation on inert Buchners vacuum aparatus (cover light)

7.1) Separation on wet pure filter paper, from distilled washing (cover light )

8) Drying on this filter paper, thin layer 1 mm, dry air 25 C, (cover light)

9) waiting 12 hours on total dry EM, closing in plast container, cover light.

If is someplace error, please repair instantly from your experiences. Thanks...... ........LL ........LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Online

Mood: old jew

|

|

SADS

Still more question: Should be possible counting, how much pure Ag is added to 65 % HNO3 for preparation solution, which will directly used for

prepare SADS. Without process separation, drying a weighing silver nitrate and after again dissolving in 28% solution HNO3. Thus so, that solution

will content 28% concentration of HNO3 + silver nitrate before start of bubble gas C2H2. For example, in 10g HNO3 65% dissolved 500 mg Ag. And bubbe.

Because any preparation and manipulation with silver nitrate Introduces impurities into the process. When we have only acid and Ag powder. Which is

usual..... ....LL ....LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Laboratory of Liptakov  | Still more question: Should be possible counting, how much pure Ag is added to 65 % HNO3 for preparation solution, which will directly used for

prepare SADS. Without process separation, drying a weighing silver nitrate and after again dissolving in 28% solution HNO3. Thus so, that solution

will content 28% concentration of HNO3 + silver nitrate before start of bubble gas C2H2. For example, in 10g HNO3 65% dissolved 500 mg Ag. And bubbe.

Because any preparation and manipulation with silver nitrate Introduces impurities into the process. When we have only acid and Ag powder. Which is

usual..... ....LL ....LL |

I use 4g metallic silver in 20ml 65% HNO3 which is diluted with 20ml of distilled H2O to speed up the reaction (silver does not dissolve in

concentrated nitric acid too eagerly). After that another 20ml of water is added and temperature brought up and stabilised at 65C. Then bubble C2H2

for 10minutes under vigorous magnetic stirring and filter....wash filtrate with distilled water several times...rinse...store damp on the very same

filter paper in a plastic trip baggy or let it dry in warm dark place. Very easy ratios to remember : 4/20/20/20/10

Might not be the most optimized numbers, but simple and fully functional.

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Online

Mood: old jew

|

|

SADS

Well..! This is flash and quality answer...Thanks, all main was say. The die is cast. . ..... ........LL ........LL

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

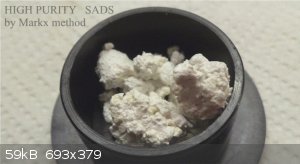

Perhaps an illustrated synthesis run starting from metallic silver is also of value:

So let's weigh out a sample of Ag

And prepare the reactor with 20ml of water as the heel and apply PID heating on magnetic stirring

Warming up to setpoint....

Let's measure out 20ml of 65% HNO3

Dissolve the silver and filter the solution into a syringe to remove any persistent colloidal leftovers (with the help of a cigarette filter  ) )

As one can see the solution has a characteristic blue coloration hinting to a copper contaminant in the metallic raw material....but no worries, as it

turns out, most of this impurity shall remain in solution after the reaction and can be removed with washing and filltering of final product.

Let's inject all of the silver nitrate solution into the reactor and let it equilibritate to 65C according to the inner mercury termometer. This

requires to overdrive the pid setpoint slightly.

The solution is ever so slightly murky....most likely the water contains some impurities that cause the silver to percipitate in various forms of

insoluble salts...a minor inconvenience.

Let's get some calcium carbide ready to feed into the gas generator.....a horrible low tech garde....dirty as sin in the dark night of Instanbul

Let's fill some into the gas generator that has an ice cold ice/water filling and start the 10 minute bubbling of acetylene into the reactor under

vigorous magnetic stirring....omit all filtering of acetylene gas!

Immediately a beautiful snow white double salt precipitate will begin to form...

After the ten minutes are up, the administration of gas is stopped and mixing is shut off, the product layer is thick and voluminous, filling

practically all of the liquid phase. As can be noticed, the solution above the solid still retains the characteristic blue hint of a copper impurity.

Seems that it mostly stays in solution and poses no hazard to contaminating the final product.

Spit, stir, filter, wash, squeeze, set a portion to dry.....and commence testing

[Edited on 7-2-2017 by markx]

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Online

Mood: old jew

|

|

SADS

Huhaha..!......white as the snow.. And in solution is absolute minimal blue. I mean, that nothing problem with copper. Nice preparation. I see pretty

sofistick aparatus for heating during a stirring. Ice water for generator ? It is better for purity C2H2 ? Or only start of gas is slowly. Because

during generate has water self heating. ..LL..

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1386

Registered: 2-9-2014

Location: Technion Haifa

Member Is Online

Mood: old jew

|

|

Look everybody on the shit on wikipedia.......

[Edited on 6-2-2017 by Laboratory of Liptakov]

[Edited on 6-2-2017 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Synthesis temperature, at least in my experience is of the utmost importance in this reaction....hence the PID temp control and secondary mercury

thermometer in the reactor to be double dead sure about the reaction medium's actual correspondence to setpoint.

Gas generator's icy guts only serve to control the rate of reaction and to extend a more stable output of acetylene over a prolonged period of

time.....it works pretty good.

Aa for the purity of acetylene gas and the copper contamination....it seems not to have a profound effect upon the end result.

Exact science is a figment of imagination.......

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Markx is dead on from my experience. I award you with the SADS certificate of the year!!

Great job. This explosive really has a future, even in industry, I think. This is one of those areas where amateurs can make great contributions.

Perhaps coating it with nanosilver would decrease static sensitivity (faraday's cage, if all silver particles are touching and coat all of the

particles)

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Maybe that the tiny copper amount helps to get a super white product...this is observed when making mercury fulminate...usually gray because of

metallic Hg...but white like snow when into the proces some Cu(2+) is present...

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by PHILOU Zrealone  | | Maybe that the tiny copper amount helps to get a super white product...this is observed when making mercury fulminate...usually gray because of

metallic Hg...but white like snow when into the proces some Cu(2+) is present... |

I was contemplating along the same lines....but currently have no other source of silver available to compare the results. Although when running the

synthesis at close to room temperature I have obtained a dark grey, highly sensitive product from the same silver source....still can't rule out the

involvement of copper in the process.

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Whilst I am waiting for my limestone sand sample to arrive with the next shipment, I went forth and begun with the creation of a primordial secondary

test cell....the "STAMMZELLE"

Round, face off and clean the main cell chamber.....

Fabricate the cell bottom and sample holder....

And the cell support stand is completed in another session of machining....fits like a glove.

Top of the cell is machined, complected, welded and the seams cleaned up on the lathe....

The top is centered on the main chamber and welded, supporting from the top end on the lathe with a live center, the seams are cleaned and the cell is

polished up.

The details are assembled and the "STAMMZELLE" is complete.....ready for the generation of hard experimental data

[Edited on 8-2-2017 by markx]

Exact science is a figment of imagination.......

|

|

|

| Pages:

1

..

3

4

5

6

7

..

9 |