| Pages:

1

..

3

4

5

6

7

..

13 |

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

Everything could go wrong. It's only a matter of how much you want to take the blame for.

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

SAM4CH

Hazard to Others

Posts: 162

Registered: 16-7-2004

Location: TA

Member Is Offline

Mood: PERFECT

|

|

New HomeTechnic for Nitric acid

I'd like to make full mechanism for production my nitrci acid, I finished my nitric acid reactor for production NO2 by Electrical arc, it was

good yeild of red-brown gas (NO2 and some N2O4), Now I search for small mechanism that let NO2 disslove exactly in water by puting some water in Empty

Oxygen Jar and pump the gas by strong Compresser, I think I will get high pressure (around 50 bar) and this will make high dissloving rate for NO2 in

water.

I would like to add safty valve which control the pressure but I am afraid of (explosion) So I ask all experienced in this field to advise

me.Note: I will use stainless steel Jar.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

High pressure is needlessly dangerous. A series of bubblers will provide reasonable concentration of acid (50-60% from an arc chamber).

For more than this the easiest way is to concentrate the resulting acid. A process more suited to industrial work would first concentrate the NO2

from the output stream.

|

|

|

SAM4CH

Hazard to Others

Posts: 162

Registered: 16-7-2004

Location: TA

Member Is Offline

Mood: PERFECT

|

|

Long time for bad results!

I bubbled my (air/NO2) mixture for about 36 hours but I did not get a hopeful result (I get in first flask 8-9% nitric acid of 200 mL and in the

second 4% of 300mL water) and I run my Jacob's ladder constantly, so are these true results for using a 15KV 200mA NST or there are a problem

with my work.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Without a power meter on the input to the transformer its difficult to say. If those are the correct ratings for the transformer and it really was

drawing 3 kW then upwards of 5Kg of nitric acid (as a dilute solution) could have been produced.

|

|

|

SAM4CH

Hazard to Others

Posts: 162

Registered: 16-7-2004

Location: TA

Member Is Offline

Mood: PERFECT

|

|

Okay.. Really I am not sure about my NST but when I bought it the seller told me that, as you say the NST Ampere output is important as its voltage

then its power increases producing NO2 gas (Is it right?).

What about the best transformer for producing NO2 and its power (V, A output KW), is it NST, OBITs or potential tranformer, please see http://www.kronjaeger.com/hv/index.html

Finally Can I get 1 Liter or more of (55-60%) HNO3 daily using some of high power transformer?

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

The transformer you have is ideal, but if you arnt getting in the region of 50g nitric acid per kilowatt hour there is either something wrong with

your power measuring system or something wrong with your spark gap.

Have you thought about the possibility of turning everything else off in the house and using your consumer box meter(Where power from the grid enters

your house) to measure the power? I've not used it for this purpose but I was surprised how rapidly and accurately they repond to a 60W

lightbulb being turned on and off. (This was a spinning disk mechanical one, yours may differ).

|

|

|

SAM4CH

Hazard to Others

Posts: 162

Registered: 16-7-2004

Location: TA

Member Is Offline

Mood: PERFECT

|

|

Is this effective?

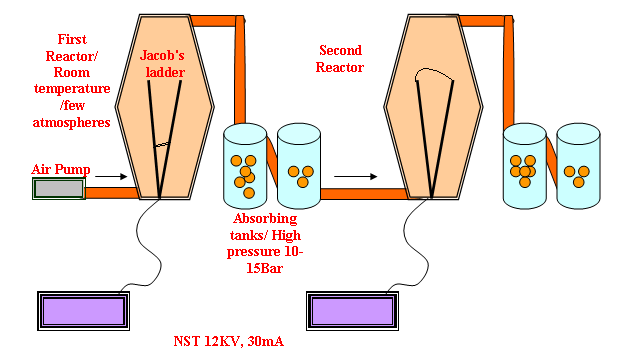

Is this effective design for producing HNO3 by using Brickland method?

I want to test it in my small laboratory!

Please advise me before!

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

It is unclear if the first jacabs ladder is pressurised, if it is this is far from ideal, as would also be pressurising the nitrous gasses. The

second ladder is being fed from the waste of the first one, this would be better fed with fresh air, ie cascading is not useful.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

"The transformer you have is ideal"

I don't agree, it is far from ideal. There seems to be a misconception here about NST's and their short circuit protection. Or rather, about

the duration of it. What you should use here is the oil ignition transformer from an oil furnace. An NST is not designed for the heat buildup of a

steady short circuit for long periods of time. An arc has a very low impedance, probably drawing more than the 60 mA rating. I would remove the

potting from the transformer and put it in a container full of Shell Diala-X, with radiating fins on it. Actually, this would be a good idea even if

using an OFT (oil furnace transformer). You could also pump the oil through a transmission cooler with a fan cooling it, very good idea.

I once built a Tesla Coil with Extra Coil that stood 18 feet tall, powered with two 10 KVA pole pigs (pole transformers), and they were very happy

with my transmission cooler(s), (even if my mains supply was not). I don't know if you have ever watched one of those PBS or Nova shows with

Robert Golka and his coil at Wendover (so that you would know who he is), but I have a picture of him in my front yard playing with the coil I built,

I got many good ideas back in the 80's from him about running transformers to the extreme, and the forced air cooling for the oil was one of the

better ones we played with. While you may not need these extremes, at the very least oil would be better than the potting and an OFT would be the

right choice instead of an NST for a continous arc over long timeframes.

I also am not so sure recycling the air is a bad idea, there is little chance that the arc is converting all of the air in the stream, and at the end

of the chain the air has to go somewhere (hopefully outside). It would seem to me that the more efficient the conversion was the less air contaminated

with NOx you would be dumping outside in your neighborhood, considering the fact that less air would be running through the system for a given amount

of acid produced. The downside would be greater erosion of your electrodes, a problem I faced often with a 14,400 volt arc at 1.5 amps. Not even my

tungsten carbide electrodes with cooling fins stood up to that very well.

I agree with a previous post that more bubbler cells would not only raise efficiency it would also make for less NOx in the enviornment at the output

end of the airflow.

Have you ever thought about getting hold of some bricks that are used in kilnbuilding (firebrick)? It is very easy to drill or saw if you are careful,

it seems you have problems finding things that would hold electrodes and take great heat for long periods, while providing little leakage for the high

voltage. The only drawback I see is you would have to pay attention to any cracks that may occur, so as to eliminate possible leaks of O3 or NOx into

your home. Just some ideas I had while reading this thread.

All I can say axehandle is that no matter what else goes on, I am far more impressed with a hands on Mad Scientist than a theoretical one. So keep up

the good work, best if done in the safest possible way. I never do anything without a long period of research on not only what I am doing but also as

much if not more on what can go wrong, and what every possible hazard may be involved in the process.

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

The transformer is ideal. A neon sign is an arc, the pressure is lower than air which allows it to go a lot furthur on a given voltage/power but its

essentially just an arc.

An NST is a magnetically limited system, which makes for a more reliable unit under experimentation and they are designed to run continuously.

The air arc should not drop a low voltage, and the NST should not exceed its normal ratings or very little of the power put in goes to nitric acid at

the end. Repotting, often done anyway by shorting the secondary winding and letting it cook for a day should not be required.

The design of the arc chamber is as important as the electronics for good yeilds both for EE and chemical reasons.

Given a history of tesla coil building I understand why you would make those assumptions about the arc itself but its wrong and colouring your whole

interpretation of the arc process.

The output gas post scrubbing is depleted in oxygen, though not by much, which is slightly bad, and it is wet, which is very bad. The ideal amount of

oxygen is 50% and were oxygen added recyling this gas and drying would be worthwhile, but cascading would still not be the best way.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

"Given a history of tesla coil building I understand why you would make those assumptions about the arc itself but its wrong and colouring your

whole interpretation of the arc process."

You are assuming you know how much knowledge I have. In your defense I should have worded it better and said "make it want to draw more than 60

Ma" rather than sounding like it was going to do so. This does not change the fact that I am not in error about any processes going on in the arc

as may have been gleaned from my post.

I can tell you this, a man with experience is never at the mercy of a man with an argument.

I took my first NST apart and repotted it with oil in 1965 and built my first Jacobs Ladder. In the last 40 years I have worked on many of them, I

think I know quite well how the current is limited and this has nothing to do with my statement that the OFT is a better choice. This is based upon

the NST's I have smoked in various and sundry mad scientist experiments in the last 4 decades.

Put quite simply the OFT is designed to withstand the transients from power arcing better than the NST, not surprising since industry does not put

NST's in oil furnaces, they use OFT's and so should you. Myself I don't use either any longer, I have several pole pigs from 5 to 25

KVA to play with and a variable core Lincoln Arc Welder to use as a current limiter. I was just trying to teach axehandle from my years of experience

a better way, seeing as how he wants to maintain arcs for periods of a day or longer while saving on his pocketbook.

To depot an NST you short it for 30 minutes not 20 hours, and even this has no bearing since it is the transients which the OFT is designed to

withstand better than the NST, and these transients are worse for a power arc in air than they are in a rarified gas tube.

"An NST is a magnetically limited system"

So is the OFT.

"The air arc should not drop a low voltage"

The impedance of an arc in air can be as low as 50 milliohms to 2 ohms. This is how in a 2KW Tesla coil with a spark gap between the capacitor and

primary there are still circulating currents in the hundred amp range, in the thousands of amps in the coils I have built. These hundreds or thousands

of amps are flowing through the arc in the gap, and if the impedance was not extremely low such currents would not be possible. I can tell you this

from direct hands on experience. This was in reference to your impedance statement.

In any case his transformer is not going to let over 60 Ma flow, but this does not reduce the possibility of arcs between turns, which would be the

death of his expensive investment.

A transformer designed to handle a power arc is going to stand up longer to it than one not designed for such service, before shorts occur in the

secondary turns, and I was just giving advise for the next time he buys one to look into OFT's, seeing as how he already has an NST now. Also,

100 or 120 Ma might make his conversion more efficient than 60, if he ever decides on finding another transformer. It does not take many volts to tear

apart molecules, so even in the low voltage across the arc conversion occurs, and on a larger scale if there is more power in the arc to create

greater heat. Higher currents are going to give greater conversion, all other things being equal, assuming a high enough voltage to create the arc in

the first place. This is no mystery since current is merely a measure of the number of current carrying entities, whether electrons or ions.

"Repotting, often done anyway by shorting the secondary winding and letting it cook for a day should not be required."

Using oil would allow his transformer to self heal for minor arcs between turns, whereas one arc between turns in the secondary now will destroy his

investment.

In any case the point is moot as so far his transformer is still alive and repotting is quite a job, but it may provide some good ideas for his next

project for what it's worth.

It would also seem that adding O2 by powering an electrolysis cell would increase production, the hydrogen also produced could be burned separately or

safely vented outside.

|

|

|

SAM4CH

Hazard to Others

Posts: 162

Registered: 16-7-2004

Location: TA

Member Is Offline

Mood: PERFECT

|

|

I need more effective method!

I work with two transformer (12KV, 30mA) and I put two Jacob's ladder in a reactor then I allow air to enter and exit from a small open and put

some of Al2O3 as a catalyst for converting NO to NO2 and it was do well, but I did not get a good amount of NO2 or not enough to reach 1% in exit air,

I try to bubble it through water (I used two oxygen weter bottle) I reach a density of 1.02 in 24 hours?!! I belive I did not get a good yelid of HNO3

as it knows (1KW gives 50-62 pure HNO3 per hour), please advise me I really want to make 50-60% HNO3 and my dream is making 1Kilogram of HNO3 per day.

Now I think my main problem is not in absorption but in yeild of producing NO gas from Jacob's ladder.

please what do you say in this ARCs

http://www.kronjaeger.com/hv-old/hv/do/sparks/index.html

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

axehandle, I have been looking into patents on the subject, and two things which are going on in your setup serve to reduce the final product, by

breaking up the NOx products just formed in the arc. The gasses must be cooled right after the arc and protected from the UV radiation coming from the

arc. It would seem to me that one way to do this would be to have a quartz tube which the air passes through a small chamber which has a steady arc

perpendicular to the flow, where the air passes rapidly out of the arc. In one design the air is cycled back and forth. Following are a list of the

patent numbers I have found so far on the subject.

U.S. Patent Documents

----------------------------------

1388112

1547714

2898277

2992980

3049488

3117068

3421988

3453196

3832513

3983021

4039412

4125754

4267027

4324971

4451436

4833293

Just a thought.

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Why quartz? It is transparent to UV, so wouldn’t this be the opposite of what you’re trying to do?

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

IrC,

"The impedance of an arc in air can be as low as 50 milliohms to 2 ohms. This is how in a 2KW Tesla coil with a spark gap between the capacitor

and primary there are still circulating currents in the hundred amp range, in the thousands of amps in the coils I have built"

This is exactly my point. The design of tesla coils involves a set of design assumptions and rules of thumb that within this application work very

well, matched impedences, resonant energy transfer, quarter wave radio engineering and so on. One of these is that the spark gap is used like a

thyratron and has a very low dynamic impedence in the 'on' state, neerly a direct short. Transients caused by sparks degrade dielectrics and

the faster the gap, eg rotary or forced air, the more this is the case. The obvious conclusion is that our nitric acid plant resembles a forced air

quenched spark gap in a tesla coil.

For something as simple as two wire ends seperated by air this is about as far from the truth as its possible to get and still be EE. For a decently

designed 'home' sized arc chamber the dynamic impedence can be (depending on many variables) in the 10's or even 100's of kOhm

range. Yes, kOhm. This is not a direct short by any stretch of the imagination and ensures the majority of the energy drawn by the transformer is

dumped into the air not into its windings. Tha arc is not sparking in any decent design, so transients are not a problem.

Now we have corrected the assumptions lets look at NST's versus OBITs as general classes of transformer.

NSTs, reasonable short circuit protection. 100% duty cycle.

OBITs, designed for sparking/arcing so better insulation. Higher current but designed for low duty cycle (amounts to poorer current limiting

essentially), intended for ignition only.

Aside from the duty cycle advantage there is another consideration. A typical NST jolt is considerably less likley to kill someone than a typical

OBIT, and since the majority of people building nitric acid arc systems are teenagers frustrated about being unable to buy nitric acid I consider this

relavent to what constitutes an 'ideal' transformer for the job.

"Also, 100 or 120 Ma might make his conversion more efficient than 60, if he ever decides on finding another transformer. "

I can see why you would think that, but its wrong.

"It does not take many volts to tear apart molecules, so even in the low voltage across the arc conversion occurs,"

I can't see why you would think this, its garbage. For this specific case the production of NO is by thermal equilibrium.and Ive explained it in

nausiating detail before, possibly not here. The rest of that paragraph isnt even worth quoting, its just wrong.

Adding oxygen is useful, but unless the full recyling system is setup most will be wasted for only a small increase in yeild.

You are correct about the length of time an NST needs to be shorted to depot, but it serves my point, it can be shorted for long enough for mishaps,

arc ignition etc.

SAM4CH,

Try a better arc design, this has been discussed, read the whole thread. Is the volume of water the same as before? How rapid is the air flow? How

strongly coloured is the gas exiting the arc chamber?

Why are you using a 'catalyst'? I'm unconvinced this is helping.

[Edited on 17-3-2005 by Marvin]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Would a corona discharge work better? It can cover a much greater volume than an arc.

BTW, low voltage high current arcs (say between carbon rods) also work nicely.

For arcs, voltage is length, current is thickness, voltage times current is power.

Tim

|

|

|

Twospoons

International Hazard

Posts: 1388

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

Since an arc has a negative resistance characteristic (i.e. resistance drops as current increases) Marvin and Irc are both correct in their respective

contexts.

This PDF on Spark ignition is interesting

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Twospoons, not wishing to sound like I have a planitary sized ego, but I have been correct in both contexts of the arc from the start

12AX7,

Corona discharge is electrically active but not 'hot' so it produces ozone and nitric pentoxide in rather poor yeilds. As Ive said,

production of nitric oxide is thermally driven.

"BTW, low voltage high current arcs (say between carbon rods) also work nicely. "

Nicely for what....

My understanding is that low voltage high current arcs deposit most of the energy in the electrodes, hense the use in welding. All of the highest

yeilding benchtop processes for NO are high voltage low current for a whole bunch of reasons. Power is the ultimate limit of course.

"For arcs, voltage is length, current is thickness, voltage times current is power"

Voltage determines the spark breakdown distance but a combination of voltage and current and airflow determine the maximum length it can be pulled.

Assuming the current is a measure of thickness is almost completely wrong. If you pass a very low current through a discharge tube the glow fills the

tube. This is normal because the electrons/ions are accelerated by the field and scatter off the gas in the chamber randomly. As the current is

increased the discharge starts to collapse to a single arc between the electrodes. This is due to a second force. When currents are sent through

parrallel conductors they each produce a field, which overlaps. The overlap produces a force and if the current is in the oppasit direction the force

is repulsive and if the same is attractive. Exactly the same is true of the current by the electrons and ions. They each have their own field and it

attacts eachother, so the magnetic field the current produces has the tendency to make the discharge collapse into a tight straight arc.

|

|

|

SAM4CH

Hazard to Others

Posts: 162

Registered: 16-7-2004

Location: TA

Member Is Offline

Mood: PERFECT

|

|

More help!

I tried to improve my arc but no chance to get more effective system, I used two arc with two NST and my first bottle contains 300mL water (100mL more

than before) and I used a reactor which has a volume of (15000 cm3) and my air flow was around 20-30 bubbles per second, I noticed a slightly white

gas flow through my silicon hose (I could see it clearly) and after I add few grams of Al2O3 I noticed a slightly red/brown gas flow through my hose.

Finally I got around 300mL of 10% HNO3 (1.05 g/cm3) within 24 hours (very very bad yield)

I want to ask about heating my entrance air to increase the efficiency of my system?!

Please help me to get 1 kg HNO3 per a day!

[Edited on 18-3-2005 by SAM4CH]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Marvin

"BTW, low voltage high current arcs (say between carbon rods) also work nicely. "

Nicely for what.... |

Well, heating things and making fat arcs, at least.

| Quote: | | My understanding is that low voltage high current arcs deposit most of the energy in the electrodes, hense the use in welding. |

Ah, true. HV arcs do go much longer, heating just air instead...

| Quote: | | Assuming the current is a measure of thickness is almost completely wrong. |

To a very gross approximation, it is.

BTW, what is it with this forum and people going off on long paragraphs just to say someone is wrong? A quick "fuck no" is much more

succinct.

Tim

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Marvin the only thing you are proving here is that you are arrogant and full of yourself. To state someone is wrong without stating where and why is

as useless as your ego, not to mention the fact that if you carefully read all 5 pages of this thread it is clear you contradict youself more than

once. If long thin very high voltage arcs from toy transformers worked then everyone would be making acid instead of ending up in failure. The 2

million volts out of my Tesla coil produces lots of ozone and little NOx. But in the rotary gap with closely spaced electrodes, much lower voltages,

and very high currents, the smell of NOx is overwhelming, and the interior of the box and components inside are constantly being attacked and corroded

away. Rather than trying to impress people with your lack of people skills why don't you actually do something useful and tell how us all with

carefully detailed plans how it should be built. Better yet, build a working one yourself rather than verbally abuse others who do while you merely

talk about it.

The very purpose of a forum like this should be for others to give their ideas and best advise, without worrying about whether or not someone like you

is going to tear into them seeing as how they are not as cool as you perceive yourself to be. If you were as smart as you want the world to believe

you are you would be capable of making intelligent posts without the use of foul language and verbal abuse such as the remarks you made on previous

pages of this thread. This I state not from your comments to me but to others in many threads as well. Seeing as how you are not paying them for

their time and input I would assume they have a right to try and help with ideas without being abused by persons such as yourself, just because they

do not meet your criteria. In short if you had people skills instead of the personality of a rope you would be able to artfully and cheerfully guide

and help others in their efforts to learn and grow in the sciences. I had hoped this was a forum where ideas and scientific insights could be

exchanged freely without the childish pissing contest antics of a reject from junior high school.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | | Originally posted by IrCIn short if you had people skills instead of the personality of a rope you would be able to artfully and cheerfully

guide and help others in their efforts to learn and grow in the sciences. I had hoped this was a forum where ideas and scientific insights could be

exchanged freely without the childish pissing contest antics of a reject from junior high school. |

:thumbsup:

|

|

|

fizzy

Harmless

Posts: 9

Registered: 10-3-2005

Member Is Offline

Mood: bubbling

|

|

Back to your regularly scheduled topic

I found the following at a forum dedicated to discussing the book 1632 (SciFi: a small town in W. Virginia is sent back in time to a spot in Germany

in the middle of the 30 years war) at Baen's Bar.

The process is from Nitrogen In Industry by Marshall Sittig.

In the Birkeland-Eyde process air was passed through a flaming electric

ark at about 3500 deg Whereupon a small percentage of the nitrogen in

the air was burned to nitric oxide (NO).The arc was distorted by a

magnetic field until it broke, a new ark formed and this cyclic process

was repeated at .02 sec intervals. Water cooled copper electrodes were used

to carry the 50 cycle current at 500 volts. The arc furnace was a narrow iron

chamber insulated with fire bricks. The gases leaving the furnace at 1000 deg

Contained about 1% nitric oxide. The product gases were cooled rapidly to quench

and retain the NO.It was then passed through the reaction chamber lined with

acid proof brick where the reaction NO+1/2O2 yields NO2 is completed at about

50 deg C. The NO2 was dissolved in water to give nitric acid. The yield was

62.5 grams of pure HNO3 per kilowatt hour.

So the people who actually had to make money at this used 500 V arcs.

[edit] By the way the first two books in the 1632 series (1632 and 1633) are available as FREE electronic books at the Baen website.

http://www.baen.com/library/

[Edited on 29-3-2005 by fizzy]

|

|

|

Twospoons

International Hazard

Posts: 1388

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

It occured to me that an HID lamp ballast and ignitor circuit might be the way to go. The ignitor provides the 5kV pulse (or so) to strike the arc,

then the ballast maintains the arc current. Ballasts are available for a few watts up to multi-kilowatts.

|

|

|

| Pages:

1

..

3

4

5

6

7

..

13 |