| Pages:

1

..

40

41

42

43

44

..

68 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Interesting, depending on who is asking that is maybe not a bad cover story. Personally I know I am taking a risk, but I try to keep unwanted

attention to a minimum by experimenting in areas with very low population, not antagonizing my neighbors, keeping the quantities used fairly low and

being very careful not to cause injury to myself, others, or peoples' property. Still a risk though.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Maybe too digression from the topic. However, loud noise, bumps, that's the main problem. Therefore, all tests are under a pile of sand. It is best to

charge 5 -100 g.

Directional, SC, EFP. However, I found a great problem of use sand pile. I do not feel the detonation wave on the body. I no hear a sharp bang. I say,

I believe it is only half the experience. If it is "on air", for example 50-100 g, VoD 6500 and more, it's a different story. At a distance of 15

meters, it is an amazing experience. Echo lasts 10 seconds. It's like a bolt of lightning. Finally, no worries, God started it first, so what. The

last attempt "on air" NM mix 70 g gel. Distance 10m, cover. As if opening 5 dimensions. In short, amazing, beauty. Exactly, in detonation must be

beauty... ...LL ...LL

|

|

|

Gargamel

Hazard to Others

Posts: 166

Registered: 9-3-2013

Member Is Offline

Mood: No Mood

|

|

Why so much binder?

Why do you guys use so much binder in your ETN or PETN?

Since it will be pressed in shape, is it really necessary to use 15%, 20%, or even more?

Have you ever tried something like 5%, then granulate and use like pyrotechnicians do with kitty litter in rocket nozzles?

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1387

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

But of course, I use for SC and EFP only 4% plasticiser. And pressing hydraulic. 96% TACP + 2% PIB + 2% 5W40 oil.

This is a sufficient quantity of plasticiser for the enclosure. Power explosives determines explosive content. If is the plasticizer passive (PIB +

oil) is a good idea to add a little. For active plasticizer (NG + NC, and more) is different, depending on many variables. I charge for stamping

adding as little as possible... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Less inert binder will of course make an explosive with higher performance, but then it will not be mouldable. The ETN plastique used was made as a

general purpose mouldable explosive, not specifically for shaped charges, but it still performs reasonably well in shaped charge applications.

Just found these interesting presentation slides on Gurney velocity. Another interesting one as well.

Attachment: Gurney Velocity Presentation Slides.pdf (222kB)

This file has been downloaded 650 times

Attachment: Is Higher Detonation Velocity Needed for Shaped Charges.pdf (564kB)

This file has been downloaded 869 times

Here is a really interesting one on conical shaped charge optimization.

Attachment: Optimized Conical Shaped Charge Design.pdf (1.4MB)

This file has been downloaded 894 times

[Edited on 10-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I remember the idea of using a fast HE as an outer shell around a slower one (such as TNT) to create an overdriven detonation through Mach-effects

that I don't really understand. IIRC, it was possible to reach a Pcj of more than 400 kbar with TNT as the inner HE. I don't remember what the outer

HE was, but probably something based on HMX.

I hadn't seen the principle applied to shaped charges before though (even though it is an obvious application).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I found a picture of the mini commercial EBW initiated SC and EFP that diagrams were posted of here:

http://www.sciencemadness.org/talk/viewthread.php?tid=10575&...

And another picture of them with other assorted commercial items from RISI:

[Edited on 20-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Very cool....the aluminium (supposedly) confinement seems pretty heavy. I guess it helps the jet formation quite considerably. Still not a setup that

I would be comfortable testing in open field...tempting though

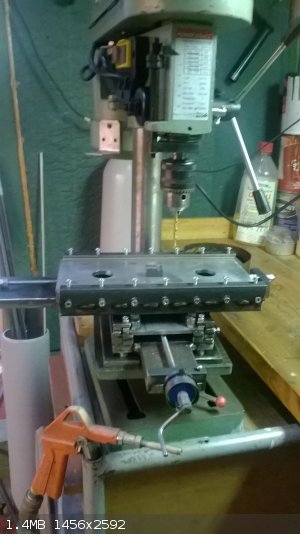

Just finished my "milling machine" to be able to make dove tail ways for a mini lathe that I'm building:

Once the lathe is functional it really becomes tempting to try such a SC configuration. Damned mechanical inclination.....

Exact science is a figment of imagination.......

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I think the heavy confinement improves performance a lot, at least with tiny charges such as those. Nice looking equipment you have there.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Hennig Brand  | | I think the heavy confinement improves performance a lot, at least with tiny charges such as those. Nice looking equipment you have there.

|

Yeah, trying to hand lap the box ways of the cross slide is a pain, but it turned out quite good. Even the axis orientation happened to be rather

exactly at 90 degrees.

With a little bit of patience one can mill intricate contraptions of quite good precicion:

Exact science is a figment of imagination.......

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Attached is an article discussing the results of a study done on the miniature EBW initiated shaped charges manufactured by RISI.

Attachment: Characterization of Jets From Exploding Bridgewire Detonators.pdf (1.8MB)

This file has been downloaded 824 times

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Just wanted to report a final success with small size EFP after a couple of failures.

Instead of a coin, a piece of copper pipe was cut, annealed and flattened out to a small sheet. It was then annealed again and shaped with a ball

hammer into a almost perfect 30mm diameter hemisphere of 1mm thickness.

The liner was placed on the end of a cardboard tube, taped in place, and the tube hand packed with 30 grams PETN.

It was placed at a standoff of 120cm and sighted with a laser pointer and the target was a 1/4 inch thick steel/iron beam.

It penetrated fairly well but as can be seen in the photo on the right of the hole, there is a piece of liner embedded right there from another

attempt which the liner broke up a little before hitting the plate and some ended up there as I have been using the same target. It looks like a

small part of today's liner didn't make it all the way through, I wonder if that is the cause.

The resulting hole is 1.1cm wide by 2cm tall and the slug was caught in the tree behind the target.

Initial liner weight was 5.70 grams.

Final slug weight is 5.01 grams.

Pictures are rotated 90 degrees left and I don't know how to reset them straight.

[Edited on 28-5-2015 by greenlight]

[Edited on 28-5-2015 by greenlight]

[Edited on 28-5-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Nice test! The laser pointer is a good idea. I rotated and resized the images for you. I am not sure that they are exactly the size you wanted though.

A picture of the target thickness, with scale, and maybe one of the liner would have been nice too. Too late for the liner shot I guess now though.

I also had a test that splattered the target with copper blotches from a fairly crude liner made from copper pipe. Not saying your liner was crude,

but mine definitely was. It was not very symmetrical and had some pretty heavy corrosion roughness on one side.

[Edited on 28-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thankyou for resizing the images I have no idea how to do it

I have uploaded a picture of target thickness with measurement, it is 7mm so turns out a little thicker than 1/4 inch.

I use the laser pointer now because I used to line them up by eye and as you can see in the picture there is a chunk taken out of the top of the plate

from another test where it hit the very edge because I wasn't quite accurate in sighting it.

You are probably right about the liner breaking up more because of it not being 100% symmetrical. I think another cause could be that too much

explosive is used and over drives the liner so it breaks up, because the splatter was observed when trying 37 grams as the charge.

I think I used a little under what I could have with the latest one, I think an extra 2 grams or so could have pushed a cleaner hole yesterday without

breaking up too much.

[Edited on 29-5-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I think more explosive force would normally result in higher SC or EFP performance, but it would also amplify the effects of inaccuracies in the

charge and liner, I think, inaccuracies such as deviation from charge & liner symmetry and alignment.

For image resizing and some other manipulation try the free image manipulation software "GIMP". It is free to download and is fairly easy to learn

how to use. There are image manipulation programs with more functions, but I have found GIMP has done pretty much everything I have needed it to do.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

That may explain why the half- hole from the 37 gram EFP that skimmed the top of the plate produced a much cleaner, smoother channel. I think I will

detonate EFP of the same specifications against same target except I will use 35 gram PETN charge instead of 30 grams and see if a nicer hole is

produced.

Would you recommend purchasing a dapping block for forming copper liners without imperfections

Thanks for the image resizing info as well.

[Edited on 29-5-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Never used a dapping block, but it looks like it would be a big improvement for consistently forming symmetrical liners with the same amount of

curvature from one liner to the next. I plan on eventually buying or making something like this myself.

A problem may be getting the right amount of curvature from a commercial set. Making, or having made, a tool set is more difficult and probably more

expensive, but the advantage is that you can get exactly what you want. Actually, the more I think about this, I guess if less curvature was needed

just go to a bigger sized die. The dies go up in increments, but the sizes should be close enough I would imagine. It should work fine, if you can get

the blank centered properly in the die.

[Edited on 29-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I have not had any success finding any metal formers on the internet useful for SC liners apart from theses dapping blocks and I don't have the

equipment to make my own.

I think it might be worth giving them a try as most go up to about 50mm diameter impressions. The steel or brass blocks are expensive but the wooden

formers are pretty cheap. There is even a 6 inch diameter hemisphere former on there which would be interesting . .

http://www.ebay.com.au/itm/Wooden-Dapping-Doming-Bending-Blo...

http://www.ebay.com.au/itm/2-BRASS-DAPPING-BLOCK-PUNCH-DOMIN...

I think I will try one and see how they go.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Copper is actually much harder to work than you might think. I would judge you should have steel tools to work with it. Then again, all of the copper

I have worked with was never annealed right before working and it was probably work hardened to a fair extent before I got my hands on it.

Bert suggested buying some of these tools earlier in this thread here:

http://www.sciencemadness.org/talk/viewthread.php?tid=10575&...

LL also made a block and punch which he posted about around the same time.

I am getting one of these which should be quite durable if only used for shaping copper:

http://www.amazon.com/SE-JT3403DS-Polished-Stainless-Cavitie...

Dimensions (inch): 2 x 2 x 2

• Cavity sizes (mm): 4, 5, 6, 7, 8, 9, 10 ,11, 12, 13, 14, 16, 18, 20, 25, 30 , 35, 40

• Polished stainless steel

I have access to some steel ball bearings in an assortment of sizes which I can probably use to fashion whatever punches I need. Even if starting with

a bolt or round stock the punches are the easy thing to make in my experience.

[Edited on 29-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I always anneal the copper sheet before forming a liner now since neonpulse told me it would be easier and it definitely makes a huge difference.

That dapping block looks perfect, I will be buying something similar too. I think it will work great and all the liners should be pretty much

identically symmetrical to each other.

This would be very useful when testing different amounts or types of explosive trying to find the best result, it is one factor that would remain the

same every test.

[Edited on 29-5-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I just checked it out on Google and annealing copper is very straightforward apparently, much more so than I had imagined. I will be annealing as

needed from now on too.

[Edited on 29-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

It's as simple as heating to a dull red color. No quench or holding time required.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Yes indeed. I remembered seeing annealing data for various materials and the impression I got was that the temperatures were normally very high, very

precisely defined and the high temperature holding time was critical, plus I had seen the somewhat elaborate ovens used to carefully control the

annealing of lab glass all of which made me suspect that annealing copper was more tricky than it really is. From the couple of links I saw yesterday

it really does appear to be as simple as heating it up red and letting it cool.

[Edited on 30-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Annealing can be complicated if you are after specific properties in structural alloys. Rifle cases (brass) are annealed at the mouth and

shoulder to increase ductility and reduce the risk of cracking. But it should not be completely annealed as this will be too soft for proper bullet

retention. In this case a moderate temperature and soak time is applied to give a partial annealing.

You can also get undesirable grain growth if kept too long at an elevated temperature, but this is of little consequence in copper sheet.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

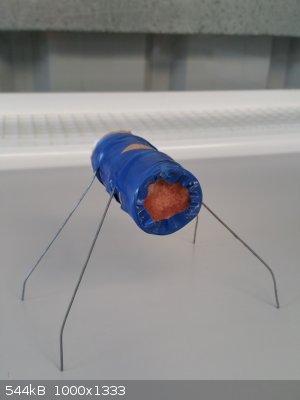

EFP - Copper Blank Annealing followed by Shaping using Dapping Block and Punch

Got the dapping block a few days ago. A friend welded pieces of 10" steel spikes to two steel ball bearings which are the start of my punch

collection. It works extremely well and of course now that I have thought about it a little more, and examined the block and punch, the blank does not

need to be centered in the block at all nor centered on the punch, since the radius/curvature is always the same anywhere on the punch or in the

block. Works beautifully!

Have started annealing the copper blanks too in between working them. Even a propane plumbers torch can easily heat copper up to red hot when the

blanks are this small (ca. 1" diameter, 1.2mm thick).

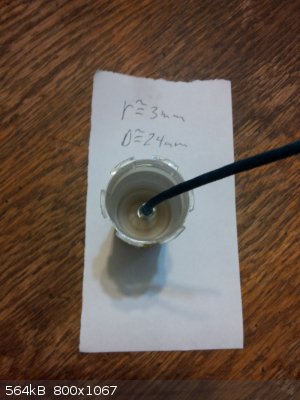

An EFP was made using one of the copper blanks. Depth of the curve was ca. 3mm and the diameter after bending was 24mm. Liner mass was about 4.5g. ETN

putty explosive was used (14.5g, 80% ETN). Standoff was about 42" and the target was 3/8" steel plate. The target was not penetrated but a piece was

blown out from the back of the plate and there are visible cracks which go through the plate. Complete penetration was very close. As can be seen from

the size of the entry hole the slug was very blunt, which is one of the reasons for the mediocre penetration. A higher velocity explosive may have

made a big difference too such as a pure nitric ester. Certainly a more deeply curved dish should increase slug elongation as well, though I have had

problems with slug breakup when using curvature close to the upper limit and consequently even less penetration than with a shallow dish. A stronger

casing should help, how much I don't know yet.

Note: In the images the piece of paper says r = 3mm, it is actually depth = 3mm (liner specifications).

[Edited on 17-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

| Pages:

1

..

40

41

42

43

44

..

68 |