| Pages:

1

2

3

4 |

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Back to the OP and the home spun det cords?

I've been looking at an application calling for a VERY light det cord. Customer specified 4 grains/foot. No one around here admits to stocking, or

even KNOWING of such a product- Orica may make/sell something like this, otherwise, nada.

What is the smallest Dia./lightest loading of det cord or similar product anyone has encountered? A nominal 15 grains/foot is about as low as seems to

be in common use around here. The OP material is in the ball park at 3.3 grams/meter as well.

If one wanted a true det cord (as opposed to the "shock tube" which doesn't even have the energy to rupture it's plastic caseing), what is the

smallest critical Dia. filler HE available- PETN seems to be easily made reliable in cords down to 15 gr/ft., what would allow 1/4 or less of a

loading and remain reliable? Has anyone ever made a det cord filled with mannitol hexanitrate, for instance? Bloody awkward crystal shape to run

through the filler funnel!

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

This is not really useful, but might still be interesting for you Bert. I have made det cord, filled with nano-Armstrong's mixture, containing as

little as 0.5 grains/foot (1 mg/cm). It was in the shape of a very thin, flat tube of aluminium foil. Not very durable but then I never made more than

4 cm in length. It goes off without a primer (surprise!) and easily sustains detonation. The filler material has a critical diameter well below 40

µm.

15 grains/foot, assuming a density of 1.5 g/cc is a cylinder with radius 0.82 mm. According to Fedoroff, thin sheets of a 85/15 PETN/natural rubber

mixture at 1.4 g/cc detonates down to a thickness of approx 0.8 mm. So stretching your det cord to 4 grains/foot seems a bit too far. I can't find

critical diameter values for MHN but does it differ enough from PETN to actually matter?

The only foolproof materials I can think of are some primary explosives, tetrazole derivatives and liquid ozone... The latter has a reported critical

diameter of 0.15 mm.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

| Quote: |

This is not really useful, but might still be interesting for you Bert. I have made det cord, filled with nano-Armstrong's mixture, containing as

little as 0.5 grains/foot (1 mg/cm). It was in the shape of a very thin, flat tube of aluminium foil. Not very durable but then I never made more than

4 cm in length. It goes off without a primer (surprise!) and easily sustains detonation. The filler material has a critical diameter well below 40

µm.

|

Ah, I will be needing to HANDLE the stuff, about 10' per shot- Bemding it into a molded in channel in the back of a series of plaster of Paris props.

No thanks , even at that low of a loading , accidental explosion of a 10' length at fingertip distance will probably be more than just embarrassing.

I would not care to handle DRY Armstrong's mix- But I COULD see applying a wet slurry of Armstrong's, water and a gelling agent in the bottom of the

channel originally specified to model makers in order to hold the det cord. Certainly wouldn't want to handle the dried props after setup!

Shoot is @ 1,200 frames per SECOND. The difference between Armstrong's and PETN cord should be quite striking at that rate of capture.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

4 grains per foot is really stretching the limit for conventional secondaries...I guess PETN will be your best bet in achieving a goal close to the

one specified. There may be some synergic mixtures, but from my experience it is only a theoretical speculation and will not help you further with the

practical task at hand. MHN is a rather nasty option really...I have not practically tested the minimal critical diamater of the compound , but I

would not be very optimistic about it being much lower than the specific value for PETN. Apart from that it is markedly more unstable due to steric

hindrances and poses a significant challenge in the purification stage. A lot of persitant impurities are formed by the mixed acid synthesis route of

MHN and this translates into multible purification rounds to get a more or less pure end product. Including primaries into the equation is a very

hazardous venture and I would avoid this route if ever possible. Perhaps the client can be persuaded to accept a "more conventional" loading rate for

safety reasons? I mean that the lower charge of unconventional or primary material is most likely not safer than a conventional charge of reliable and

"more or less predictable" secondaries in larger amount. If unavoibale technical limitations do not pose a restriction in this direction then perhaps

it is still the way to go....

And perhaps again, if technical reasons do not oppose the application, then maybe commercial shock tube might do the trick without having to resort to

exotic means? Not knowing the exact background of the project these are just some ideas from the top of my head...

[Edited on 28-9-2015 by markx]

Exact science is a figment of imagination.......

|

|

|

ganger631

Hazard to Self

Posts: 53

Registered: 15-8-2014

Member Is Offline

Mood: Plata o plomo

|

|

Quote: Originally posted by Dornier 335A  | | This is not really useful, but might still be interesting for you Bert. I have made det cord, filled with nano-Armstrong's mixture, containing as

little as 0.5 grains/foot (1 mg/cm). It was in the shape of a very thin, flat tube of aluminium foil. Not very durable but then I never made more than

4 cm in length. It goes off without a primer (surprise!) and easily sustains detonation. The filler material has a critical diameter well below 40

µm. |

Hey, are you going to post it on your channel?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

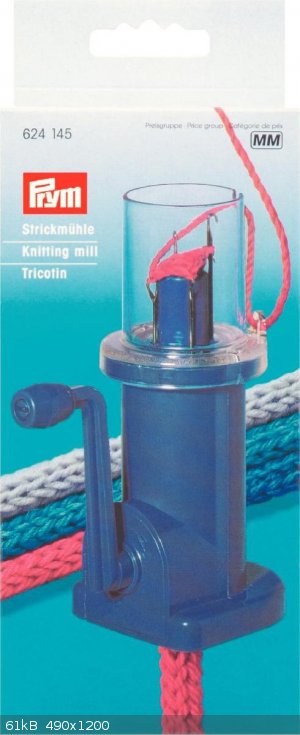

No need to re-invent the wheel-

I now realize that Franklyn suggested these years ago.

Many types available, starting around $10 US.

https://m.ebay.com/itm/i-Cord-maker-Knitting-Machine-Spool-K...

For home made bickford style fuse or woven jacket det cord machines, all you would need to engineer is the powder funnel and an agitator or tracer

thread spools to ensure even filling, a drive motor and possibly a "snail" to wrap the powder column in a plastic tape just before it enters the tube

knitter to prevent powder escape.

[Edited on 28-2-2018 by Bert]

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

I bought the cheapest variety of these cord knitting machines from ebay,, about $9 delivered.

I also bought a 500 meter spool of fluorescent yellow 10lb. test braided spectra fishing line (ultra high molecular weight polyethylene, AFAIK- this

is a VERY strong, slippery and thin line).

I just tested the combination. IT WORKS REALLY WELL.

I tried running various long thin solid objects such as dowels, cords, etc. through the center of the knitting process, it neatly and happily

enveloped anything from 1/8" Dia. up to around 1/4" in a knitted tube, it might be able to do larger, but I can't envision making a detonating cord

with a core wider than 1/4".

The weave is too coarse for the type of operation the various Bickford fuse machine makers here have done, where granulated black powder falls through

a powder die and is contained by spinning on a couple layers of multiple threads at different pitch, or even countersun layers. The fine PETN powder

would just fall through the weave this machine knits.

I intend to make a powder funnel and outlet die that feeds finely powdered PETN, RDX, ETN or other suitable HE into the center of a "snail", wrapping

the powder exiting the die in a spiral of Teflon plumbing tape. This PTFE tape wrapped HE column would then enter the tube knitting machine and

receive a knitted jacket of spectra or kevlar thread to prevent unraveling, also to provide tensile strength and durability.

After the tube knitter, it could be fed through a coating bath of lacquer to lock the whole thing together and water proof it, or through the center

of a plastic extrusion die to coat it with a thermoplastic as some commercial detonating cords and blasting fuses are.

One could add a second funnel surrounding the HE funnel, for dusting the PTFE tape with fine Aluminum powder on the inside as it goes around the HE

core. Or arrange a second "snail", applying a counter wrap of very thin Aluminum foill or aluminized mylar over the PTFE tape. It would be a shame to

waste the oxidizing potential of all that PTFE. Thermobaric det cord?

[Edited on 7-3-2018 by Bert]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Nice find, Bert!  Dirt cheap and effective, although the weave really is too

coarse to hold any reasonably sized grains on its own. As a final arming coat on the cord it will do just fine I guess... Dirt cheap and effective, although the weave really is too

coarse to hold any reasonably sized grains on its own. As a final arming coat on the cord it will do just fine I guess...

Perhaps there are some machines out there that weave a tighter structure with more needles? The tape wrapping part might be quite complicated to get

to work consistently, but we all love a good challenge  ! !

Exact science is a figment of imagination.......

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Yes, please update us Bert....! Still a little confused on how you will hold grains with the weave being so course. Is there a very very thin

(.2mm-.5mm)(wall thickness) plastic tubing available that you could wrap around, I wonder?

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Stuffing a solid down a narrow tube is not feasible for more than a foot or two, it would have to be a continuous wrap applied at output of funnel,

then the wrapped powder core entering the weaving machine to hold the spiral wrap together and provide strength.

I am trying to do too many things at once right now, I'm sitting next to.a stage waiting to do an effect, so have time to look at the forum-

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I refurbished my fuse weaving machine and now it really works consistently and smoothly. Owning a small lathe really allows one to create fully

functional solutions

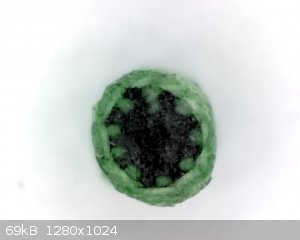

Fig. 1 General view of the contraption

Fig. 2 Feeding funnel and vibratory agitator

Fig. 3 Lower layer weaver with pretensioning for threads

Fig. 4 Upper layer weaver and entry point for powder (also pretensioned)

Fig. 4 Closeup of the vibratory agitator for consistent powder feed

Fig. 5 Cross section of the product with BP core

Fig. 6 Anoter view of the product with cross section and closeup from side

[Edited on 26-3-2018 by markx]

Exact science is a figment of imagination.......

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Nice. You don't pull a thread or threads THROUGH the powder funnel to ensure powder flow?

Pics of the lathe, tooling? Any brands or models you recommend, I learned to use lathe, mills, precision grinders & etc. about 40 years ago, but

have not had access to a good metal working machine shop for quite a while. Pretty well set for wood working and some light welding though.

Just finishing off a workshop building now, might have space for a few new toys.

[Edited on 26-3-2018 by Bert]

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

No Bert, I went in the direction of vibratory agitation to ensure the flow, but for some applications it might be more advisable to use the "guide

thread" method.

In fact I gave up on using fine powders as the feed (like meal powder)...it was messy, inefficient and produced varied results, none of which were

acceptable neither visually nor by function.

I now use slightly granulated feeds that do not create dust or fall through the threads....also they flow excellent and require minimal effort to

ensure a constant feed rate. But one must work out the proper granulation technique and adhere to it religiously to produce a constant burn rate. If

the powder is too coarse or segregates in the funnel, then a widely varied and unpredictable burn rate can be the result....something that is very

dangerous.

Exact science is a figment of imagination.......

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Bert  |

Pics of the lathe, tooling? Any brands or models you recommend, I learned to use lathe, mills, precision grinders & etc. about 40 years ago, but

have not had access to a good metal working machine shop for quite a while. Pretty well set for wood working and some light welding though.

Just finishing off a workshop building now, might have space for a few new toys.

[Edited on 26-3-2018 by Bert] |

A shot of my small lathe (Holzmann ED 400FD) that I consider to be my best investment so far  I've wanted one for years. It is nothing special and for a serious metalworker this might be closer to a toy than a

lathe, but for small tinkering it is just perfect.....it does not weigh a ton, runs quiet like a sewing machine and delivers quite good accuracy after

some adjustments. Also it is has some torque to it and I've never felt like it lacks the power to make the cut. I managed to drill a 22mm hole through

a steel round stock with this little machine in one go (just a small 6mm guide hole was drilled to keep things centered). I've wanted one for years. It is nothing special and for a serious metalworker this might be closer to a toy than a

lathe, but for small tinkering it is just perfect.....it does not weigh a ton, runs quiet like a sewing machine and delivers quite good accuracy after

some adjustments. Also it is has some torque to it and I've never felt like it lacks the power to make the cut. I managed to drill a 22mm hole through

a steel round stock with this little machine in one go (just a small 6mm guide hole was drilled to keep things centered).

Exact science is a figment of imagination.......

|

|

|

| Pages:

1

2

3

4 |