| Pages:

1

2

3

4

5 |

violet sin

International Hazard

Posts: 1480

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

as I said before I broke open the crystals to make sure they were not clear inside. and they were not. just a beautiful citrine(gem) color. but I

did notice (and forgot to mention)that when left in air for a while(15min or > they turned a bit frosty white on edges. reminded me of HCl frosting stuff around when evaping CuCl2 or the like( didn't have any acid out or heated

salts though).

they turned a bit frosty white on edges. reminded me of HCl frosting stuff around when evaping CuCl2 or the like( didn't have any acid out or heated

salts though).

also I am ~4 hours away from home for the next 2 months working so I can't answer any of your inquiries on the crystals until I can set foot in my

lab(aka the basement) again  i will do some investigation for sure and post my

findings. i will do some investigation for sure and post my

findings.

oh ya, another thing I noticed... when I filtered the solution off, it was still quite yellow but noticeably less so than before. like it might have

taken a decent quantity of chromate with it.  one can only hope it is all

chromate one can only hope it is all

chromate

also, seeing as how it was filtered while hot to remove flocky light colored

stuff after H2SO4 addition. then left to sit n crystalize, after which I relieved the solution of large yellow crystals, I got more of it( flocky

ppt). thinking concentration dependent release by say common ion Na+1 but sol was not green or violet so chromate wasn't reduced or ligand bound by

SO4-2 *to the best of my knowledge* also, seeing as how it was filtered while hot to remove flocky light colored

stuff after H2SO4 addition. then left to sit n crystalize, after which I relieved the solution of large yellow crystals, I got more of it( flocky

ppt). thinking concentration dependent release by say common ion Na+1 but sol was not green or violet so chromate wasn't reduced or ligand bound by

SO4-2 *to the best of my knowledge*

[Edited on 21-10-2012 by violet sin]

|

|

|

Salmo

Harmless

Posts: 42

Registered: 20-9-2012

Member Is Offline

Mood: No Mood

|

|

I think that if you want to be sure you should make a test with some Barium chloride or calcium chloride, if no precipitate it should be pure enough.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Salmo  | | I think that if you want to be sure you should make a test with some Barium chloride or calcium chloride, if no precipitate it should be pure enough.

|

The test for sulphate ions with a Ba salt solution would be best carried out on the recrystallised product because the test is so sensitive.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

So here are a few experiments I conducted with the products obtained above.

The supernatant liquid was carefully decanted off and the brown insoluble residue caught on a filter and washed free of (presumed) potassium chromate

solution.

To the presumed potassium chromate solution (150 ml) was added 10 ml of HCl 36 %. Colour firstly darkened a lot, a bit of fizzing occurred and then

the colour settled after a few seconds to the familiar amber of dichromate. I estimate the solution to be about 0.1 M in K2Cr2O7. About 1 ml of

solution was further acidified with H2SO4, then MeOH was added and on steam bath the green colour of Cr (III) appeared quickly, confirming the amber

colour is caused by K2Cr2O7 (oxidation of a primary alcohol to its coresponding carboxylic acid).

The insoluble residue had in the mean time acquired a slightly greenish hue, less dark than yesterday. A good pinch of the filter cake dissolved very

quickly in hot 36 w% HCl to green Cr(III). With hot KOH (unknown but strong) dissolution of a similarly sized pinch to green chromite (III) took a

little longer but happened too. Both tests were done in test tubes. At NO POINT did I observe gas evolution (oxygen or chlorine) which if observed

would have been indicative of either a peroxo complex or an unexpected (higher) oxidation state of the Cr.

The chromite test tube was then cooled under running tap water and an arbitrary amount (a few ml) of 35 % H2O2 was slowly added in two lots (cooling

in between) and the oxidation to chromate took place swiftly.

Conclusion: in the absence of other data I must conclude that the failure to oxidise and dissolve all ‘Cr(OH)3’ was due to lack

of alkaline reserve and that the unusually coloured residue was in fact nothing else than ‘Cr(OH)3’ (or a hydrated form of chromic oxide).

I might have another go at this, this time using 3 mol of KOH per mol of ‘Cr(OH)3’ instead of the previously used 2 mol/1 mol ratio.

Had the synthesis proceeded as planned (and at 100 % actual yield), a solution of about 7.3 g/100 ml of potassium dichromate would have been obtained,

just over the reported saturation point of 4.7 g/100 g at 0 C.

[Edited on 21-10-2012 by blogfast25]

|

|

|

tetrahedron

Hazard to Others

Posts: 210

Registered: 28-9-2012

Member Is Offline

Mood: No Mood

|

|

KOH/air oxidation of chromite in aqueous suspension

Green metallurgical processing of chromite

| Quote: | A mechanical agitator was used at a stirring speed of

800 rpm to keep the slurry suspended during the leaching

experiment. A gas pipe with a distributor on one end

was fixed inside the bottom of the reactor and compressed

air was introduced through the pipe after prewetting.

Generally the gas flow rate was set at 0.4 m3/h. |

| Quote: |

The desired amount of reagent KOH was first placed

in the reactor and mixed with a desired volume of distilled

water. The heating furnace was then switched on

and the system was heated. After most of the KOH was

dissolved, the agitator was turned on to improve the

mixing. When the temperature reached the preset value,

the chromite ore was fed into the aqueous solution and

the air compressor was started to provide the compressed

air. |

with a ratio of KOH to chromite ore of 4:1 and after 2 hours of heating at 340°C, 80% conversion to chromate is reported.

edit. related article from the same authors: Oxidation decomposition of chromite ore in molten potassium hydroxide

[Edited on 24-10-2012 by tetrahedron]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Very interesting find, tetra!

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Chromite is blue-green? I think I might have a flask of that, my Cr(III) turned from emerald green to that color when baking soda in hot water was

added.

More base turns it right back to chromate, though.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

tetrahedron

Hazard to Others

Posts: 210

Registered: 28-9-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by elementcollector1  | Chromite is blue-green? I think I might have a flask of that, my Cr(III) turned from emerald green to that color when baking soda in hot water was

added.

More base turns it right back to chromate, though. |

i don't understand, by chromite the oxyanion of Cr(III) is meant. do you have other cations in there besides chromium and sodium?

glad you find it interesting =)

i did it this way and i have to say i never felt any kind of danger. the lye easily melted in the crucible (a small stainless steel saucepan) on a

propane stove, without splashing or other violent behavior

Quote: Originally posted by plante1999  | Don't forget that if you want dichromates salts you need to pass CO2 gas in the chromate solution and then add a satured solution of potassium

chloride to your sodium chromate solution. Cool it down and filter precipitated potassium dichromate.

2Na2CrO4 + 2CO2 + H2O -) Na2Cr2O7 + 2NaHCO3

Sulphuric acid do the job too, but CO2 is cheaper and safer. |

how would you generate the CO2 without an acid? maybe coal combustion, but the CO coproduced might cause some reduction of the valuable

Cr(VI).

|

|

|

Salmo

Harmless

Posts: 42

Registered: 20-9-2012

Member Is Offline

Mood: No Mood

|

|

Hey everybody I just want to let you know that I'm proceeding with this thing even if university steal me almost all my time, tomorrow I will post you

some new photos, I precipitated everything with NaOH and I washed the sludge with a lot of water to get ride of the sodium sulfate impurity, tomorrow

I will add the NaOH to the sludge, I will heat everything first and than I will cool and add H2O2, I will then filter to obtain impure chromate that I

will acidify and reduce with hydrogen peroxide to obtain chromium chloride that I will precipitate with sodium hydroxide.

I will than wash really well the precipitate, I will dry and weigh it and I will add the stoichiometric sodium hydroxide amount (heating and stirring

well) plus hydrogen peroxide to obtain what I think will be almost pure sodium chromate.

|

|

|

Salmo

Harmless

Posts: 42

Registered: 20-9-2012

Member Is Offline

Mood: No Mood

|

|

So long process.. anyway today I washed well the precipitate and heating the mass I added 20 grams (10grams excess) of sodium hydroxide (conc.

solution) to the sludge, than I added 110ml of hydrogen peroxide ( I think it's enough, I had not time to do the calculations..) and I heated

everything, tomorrow I will filter and I will go on with the procedure.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Below is a photo of my potassium dichromate/KCl solution as obtained in the posts above, now with a small amount of K2Cr2O7 crystals:

Crystallisation (at the bottom of the 250 ml beaker) started a few days ago because it is now very cold in my lab. I helped it along by putting it in

my lab fridge a couple more days.

Although the yield is clearly much lower than expected, it also shows I made enough dichromate for the solution to be saturated at about 5 C.

|

|

|

weiming1998

National Hazard

Posts: 616

Registered: 13-1-2012

Location: Western Australia

Member Is Offline

Mood: Amphoteric

|

|

Purification of contaminated chromate

A lot of the time, crystallisation of the crude chromate/dichromate will yield large amounts of salt, among other substances, that makes the crystals

look almost white. I have found a method to purify such contaminated chromate.

1, Add excess CuSO4 to your crude chromate solution (please note that dichromate cannot be purified by this method). A very fine, lime-green

precipitate will form. The CuSO4 doesn't have to be pure, it will work as long as it isn't adulterated by reducing agents or insolubles.

2, Heat the solution to make the precipitate clump together into less fine particles that can be filtered/decanted more easily.

3, Cool down solution, then filter/decant.

4, If you want really pure chromate, filter, dry and weigh the precipitate, then add a stoichiometric amount of NaOH to it. Add water and heat. If you

don't care that much about the exact purity, then add water to the decanted/filtered precipitate, then while the solution is heated, slowly add NaOH

solution to the mixture until the suspension of lime-green, insoluble particles turns black.

5, Whatever method you used, the solution will now be full of copper (II) oxide. Filter that out. Now boil down/evaporate the solution. This time, the

resulting crystals will be bright yellow. The copper (II) oxide can be disposed, kept or recycled into CuSO4.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

This solubility products table:

http://www.csudh.edu/oliver/chemdata/data-ksp.htm

… has Ks = 3.6 x 10<sup>-6</sup> and 2.2 x 10<sup>-20</sup> for the respective solubility products of CuCrO4 and Cu(OH)2.

That would fit what you claim quite nicely.

But it’s a fairly expensive way of separating, since as you obtain somewhat useless CuO as a by-product.

It could also be used to purify dichromates, by alkalising them slightly: even at neutrality the equilibrium dichromate < === >

chromate will have been pushed sufficiently to the right for CuCrO4 to form.

[Edited on 4-11-2012 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by tetrahedron  | Molten NaOH is dangerous overkill, as far as I'm concerned.[/rquote]

i did it this way and i have to say i never felt any kind of danger. the lye easily melted in the crucible (a small stainless steel saucepan) on a

propane stove, without splashing or other violent behavior |

Tetra, could you describe what you did more accurately?

For CO2 you'll need a generator (limestone + HCl e.g.) or bottled CO2 or soda water + acid. Something like that...

[Edited on 4-11-2012 by blogfast25]

|

|

|

tetrahedron

Hazard to Others

Posts: 210

Registered: 28-9-2012

Member Is Offline

Mood: No Mood

|

|

nothing special, i was referring to my attempt at the method suggested by plante:

i don't have the numbers with me but i used about 10% excess pottery grade Cr2O3 and technical or better KNO3 powder

and 85% KOH pellets. the mix was stirred on the flame (low setting) until molten, then stirred occasionally while left mostly unattended for a few

hours. better stirring would have probably promoted air oxidation and improved the yield. when i decided to stop the heating, it didn't look like much

had happened. i let it cool, then leached the solid with distilled water and kept both phases with the prospect of quantitating the chromate formed as

well as recycling the unreacted Cr2O3. hope this answers your questions, otherwise just ask specifically =)

i find the electrolytic methods more interesting and original so i'm concentrating my efforts on those. i tried the molten route for comparison.

agreed..in that case why not use the acid to convert the chromate to dichromate directly? as to sodastream bottles, they are stoichiometrically in the

same price range as hydrochloric or sulfuric acid. that's why i found plante's suggestion to 'just use CO2' excessively nonchalant.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by weiming1998  | A lot of the time, crystallisation of the crude chromate/dichromate will yield large amounts of salt, among other substances, that makes the crystals

look almost white. I have found a method to purify such contaminated chromate.

1, Add excess CuSO4 to your crude chromate solution (please note that dichromate cannot be purified by this method). A very fine, lime-green

precipitate will form. The CuSO4 doesn't have to be pure, it will work as long as it isn't adulterated by reducing agents or insolubles.

2, Heat the solution to make the precipitate clump together into less fine particles that can be filtered/decanted more easily.

3, Cool down solution, then filter/decant.

4, If you want really pure chromate, filter, dry and weigh the precipitate, then add a stoichiometric amount of NaOH to it. Add water and heat. If you

don't care that much about the exact purity, then add water to the decanted/filtered precipitate, then while the solution is heated, slowly add NaOH

solution to the mixture until the suspension of lime-green, insoluble particles turns black.

5, Whatever method you used, the solution will now be full of copper (II) oxide. Filter that out. Now boil down/evaporate the solution. This time, the

resulting crystals will be bright yellow. The copper (II) oxide can be disposed, kept or recycled into CuSO4. |

Well, this gives me an excuse to make CuSO4. Are you sure this gets rid of all the other stuff?

(Reducing agents meaning acids?)

Is the CuSO4 in solution or on its own?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

tetrahedron

Hazard to Others

Posts: 210

Registered: 28-9-2012

Member Is Offline

Mood: No Mood

|

|

this is a metathesis (precipitation) reaction based on the low solubility of copper chromate. any soluble non-reducing Cu(II) salt will do, as long as

the anion won't precipitate any other cations in the crude chromate solution. e.g. CuCl2 should work just as well. the Cu salt should be

dissolved first. note that alkali sulfates are not as soluble as the corresponding chlorides (risk of co-precipitation).

|

|

|

Salmo

Harmless

Posts: 42

Registered: 20-9-2012

Member Is Offline

Mood: No Mood

|

|

weiming this is what is was looking for!! CuSO4 is cheap and OTC, i will def try your method!

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Made my own CuSO4 from sulfuric acid and copper electrochemically. It was still acidic, so I neutralized most of it with NaOH (never saw any Cu(OH)2,

unfortunately) and added it to my chromate (heavily contaminated with NaCl, but still yellow). So, yellow solution + blue solution = green solution.

No precipitate here, either. Have it cooling in the fridge.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@tetrahedron:

Thanks.

Yes, I used direct acidification with HCl (KCl is more soluble than K2SO4, as Tim pointed out).

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

I don't think that copper precipitation method works for some reason. Unless my chromate or sulfate wasn't concentrated enough, I observed no

precipitation at all. Someone want to try with concentrated, pure reagents and see if it works for them?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

That's altready been done by Weiming (see up). There's no reason at all to doubt his results, especially since theory predicts that such a method will

work.

Your chromate solution is likely to be very dilute: after all you claim to make chromate without using an oxidiser (something which theory predicts to

be impossible).

Be careful with making unsubstantiated claims...

[Edited on 5-11-2012 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

I made chromate with bleach and electrolysis of stainless steel, which I'm sure has been well documented thus far.

The dilution problem is likely to be correct, though.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

tetrahedron

Hazard to Others

Posts: 210

Registered: 28-9-2012

Member Is Offline

Mood: No Mood

|

|

thank you all for the updates. i made some quick qualitative tests based on weiming's method of my three attempts at synthesizing

chromate.

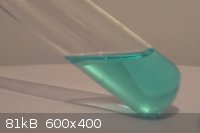

the CuSO4 solution employed in all three tests:

1.

the first test appears to confirm the electrochemical oxidation of Cr(III) to Cr(VI) in NaOH/NaCl(aq) with inert anode as i

described on page 3 of this thread:

Quote: Originally posted by tetrahedron  | | yesterday i took some of the sludge that i got when "electrodissolving" stainless steel in a Cl- containing electrolyte and poured it into

a fresh solution of NaOH and NaCl (about 1 spoonful each in 400ml tap water), which i then electrolyzed for a couple hours with a 5mm diameter

graphite "gouging rod" anode, initially @ ~7V, soon reduced to 4.4V & 3A in order to reduce the loss of chlorine. |

each set of pics shows the sample of filtered product before and after the addition of the CuSO4. note that in none of the tests did i

neutralize the electrolyte beforehand. immediately a lime green precipitate formed:

2.

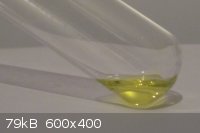

the second set refers to plante's method of electrolyzing Na2CO3(aq) with a stainless steel anode:

Quote: Originally posted by plante1999  | | Only electrolysing S.S at 20V in Na2CO3 electrolyte. Sodium chromate go in to solution but iron and nickel don't. It take a large amount of time to

get a product but it work really well. |

clearly the basic Cu2+ precipitate completely overshadows any lime green (if present at all):

3.

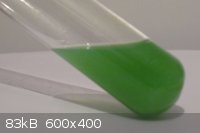

the third and last set refers to the tried and true molten salt method:

a rust-colored precipitate (arguably CuO) appeared in addition to the green:

conclusion. for method 2. (inefficient and frustrating) the result is inconclusive. method 3.

obviously works, but the product needs workup (a lot of spurious anions). method 1. seems to work quite efficiently, safely and

cleanly. i plan on investigating this one further and reporting on its profitability.

oh and sorry for repeating the word method so many times..method

[Edited on 6-11-2012 by tetrahedron]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

How concentrated was the chromate in each case?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

| Pages:

1

2

3

4

5 |