| Pages:

1

2

3

4

5

6

..

13 |

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Lithex is primarily a secondary substance, but its sensitivity to hot wire is relatively low. For this reason, it is recommended to use a more

sensitive mixture in the area of the resistance bridge, ie Lithex with CuO 5%, or Al 5%, or Mg 5%. The CuO additive has the advantage that the surface

does not oxidize as in the case of aluminum or magnesium during drying at a temperature of 165 -170 Celsius. I remind you again that Lithex requires a

solid cavity, preferably steel, for a reliable deflagration detonation transition. With construction a like at the beginning of this thread.

LiClO4 was also tested with some fuels in stoichiometric ratio. Fuels in list do not have any energetic properties on the anvil.

Glycine, Glycerine, Ethyleneglycol, Erythritol, Potassium Ascorbate, Urea.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

LITHEXAL

A new measurements shows (reccommended of MineMan) that adding 10% aluminium powder (bright type) into Lithex as two dry mixed fine powder

compounds, provides very good results. Mixed at 150 celsia against moisturity, at dry. Time of mixing 2 minute. The brisantion is same but total

energy of detonation is demonstrably bigger. Thus:

1) Aluminium (10%) can provide advantages of use less amount of Lithex, at retention same brisantion.

2) Aluminium (10%) increasing sensitivity for ignition to reliable level.

3) Because Lithex is neutral salt and mixing run in dry, the degradation of surface of Aluminium can be low in order weeks, months. ( only estimation

yet)

4) Aluminium (10%) increases overall energy of detonation at same weight of compound.

By others examinations shows on variability of content of Aluminium, which can be from 3% to 12%. And always lends better properties than pure Lithex.

A new mark LITHEXAL from Liptakov-MineMan research center....

[Edited on 13-2-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Lithex and Lithexal

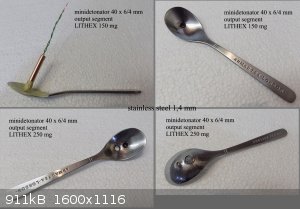

To verify the critical diameter, a structure with an inner diameter of 4 mm was tested. Pure Lithex 150mg and 250mg were used as the output segment.

For the starting DDT segment, 250 mg of low density Lithexal was used in both experiments.

The result is a coffee spoon with reduced resistance at stirring....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | A new measurements shows (reccommended of MineMan) that adding 10% aluminium powder (bright type) into Lithex as two dry mixed fine powder

compounds, provides very good results. Mixed at 150 celsia against moisturity, at dry. Time of mixing 2 minute. The brisantion is same but total

energy of detonation is demonstrably bigger. Thus:

1) Aluminium (10%) can provide advantages of use less amount of Lithex, at retention same brisantion.

2) Aluminium (10%) increasing sensitivity for ignition to reliable level.

3) Because Lithex is neutral salt and mixing run in dry, the degradation of surface of Aluminium can be low in order weeks, months. ( only estimation

yet)

4) Aluminium (10%) increases overall energy of detonation at same weight of compound.

By others examinations shows on variability of content of Aluminium, which can be from 3% to 12%. And always lends better properties than pure Lithex.

A new mark LITHEXAL from Liptakov-MineMan research center....

[Edited on 13-2-2022 by Laboratory of Liptakov] |

Thank you! That is very kind LL! What micron size do you report for Al?

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | To verify the critical diameter, a structure with an inner diameter of 4 mm was tested. Pure Lithex 150mg and 250mg were used as the output segment.

For the starting DDT segment, 250 mg of low density Lithexal was used in both experiments.

The result is a coffee spoon with reduced resistance at stirring....

|

Fantastic! At a total of 500mg it works very well! And it’s safe. In copper housing it should even resist large hammer impact. It is stable in high

temperatures… nor does a stray spark ignite.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Lithex from Schweizer's reagent

I have no idea how is finelity of aluminum. It is aluminum for use as a silver colorant. So probably very fine, with oxidation protection. But we

also need to think about those researchers who have no powdered aluminum or magnesium. For those, there is a variant with CuO. A new method for

preparing flame-sensitive Lithex was also tested. Dissolve 1 g of Lithex in 10 g of Schweizer's reagent. The exact value of concentration of reagent

are not important. Briefly, concentrated Schweizers reagent 25% NH 4 OH in aq. The solution is poured onto a pan (at 20C) and dried at 170 ° C.

At 80 C arise green heterogenous mixture. The dry mixture has a light brown color and is very sensitive on flame. Its brisance is about 10% lower than

that of pure Lithex. His sensitivity on impact it higher. But as a starting - wire segment, it is excellent. The disadvantage of Lithex remains his

hygroscopicity. Filling must take place at 40 Celsius. This applies to all handling tools and components. I guess the copper detonator wouldn't

explode even if hitted with a hammer. But I won't try ....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

For pigment type bright Al powder the typical particle size is 40-70 microns.... PAP-4 type powder e.g.

Exact science is a figment of imagination.......

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

SWL

To diversify of thread, I enclose the production and test of SWL, ie Lithex, prepared from white basic Lithex (LiClO4 77 / hexamine 23) + Schweizer

reagent. The concentration was 2g Lithex per 10g reagent. Thus, twice the Lithex content than stated above (1:10) The results are almost the same.

High sensitivity on flame.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

underground

National Hazard

Posts: 703

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

EnergeticHeretic, a youtuber, almost always use Na piperazine perchlorate for his initiations. Give a try on this energetic, it looks promising. I am

sure Ag piperazine perchlorate would be even more interesting. Dewormer consists of 45% piperazine citrate the rest is lactose.

[Edited on 16-2-2022 by underground]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Thanks,

It may be tried sometime in the future. At present, this thread deals mainly with primary-secondary compositions based on LiClO4....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

What about rhodium perchlorate hexamine clathrate??

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Lithex - shaped charge

Rhodium is obviously interesting, but also very expensive. I doubt anyone will try. Including me.

Next: A test was performed to determine if Lithex was able to create a beam. The insert: Copper 0.4 mm, diameter 8 mm, angle cca 80 deg. , distance

12 mm from target. Unfortunately, the experiment was not very successful, two rays were generated. The penetration depth was estimated at 5 - 7 mm.

So the beam did not penetrate even the first steel target 10 mm.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Nitrosio

Hazard to Self

Posts: 57

Registered: 31-3-2018

Member Is Offline

Mood: No Mood

|

|

Attachment: LPG.pdf (10kB)

This file has been downloaded 350 times

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Nitrosio from time to time appears as a mysterious spirit and utters a cryptic formulas mixtures that only the greatest experts understand ....... ..... .....

[Edited on 17-2-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

underground

National Hazard

Posts: 703

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

Quote: Originally posted by Laboratory of Liptakov  | Nitrosio from time to time appears as a mysterious spirit and utters a cryptic formulas mixtures that only the greatest experts understand ....... ..... .....

[Edited on 17-2-2022 by Laboratory of Liptakov] |

He just posted the optimum % of chemicals needed for optimum performance.

The 1st example is w/o AL powder, while the 2nd one is with AL powder

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Oh yes, I know ethyleglycol...In short, it came to me as such a mysterious link....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

underground

National Hazard

Posts: 703

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

LL LMAO

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | Rhodium is obviously interesting, but also very expensive. I doubt anyone will try. Including me.

Next: A test was performed to determine if Lithex was able to create a beam. The insert: Copper 0.4 mm, diameter 8 mm, angle cca 80 deg. , distance

12 mm from target. Unfortunately, the experiment was not very successful, two rays were generated. The penetration depth was estimated at 5 - 7 mm.

So the beam did not penetrate even the first steel target 10 mm.

|

Either the cone or the centering is a problem. Can you use copper bullet jackets from surplus ammo? And yes. Rodium is a joke

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

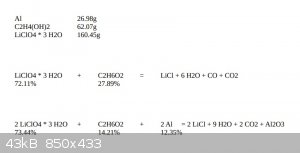

TACP from LiClO4

TACP can be prepared from LiClO4. In same method as with NH4ClO4. Unfortunately, it is a trihydrate. And crystalline water is impossible to remove. At

180 C, TACP decomposes to copper and LiClO4. However, this compound it is possible to decompose in boiling water to CuO + LiClO4. The LiClO4 thus

obtained can be used again for the production of Lithex. (80:20) Which provides a standard brisance, like Lithex prepared from pure LiClO4 + hexamine

80:20.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

To those of you who don’t quite understand LLs research or are just ignoring it, you have to understand this is very advance work. Detonators like

these have been wanted by nuclear powers for insensitive, reliable detonators for warheads before exploding foil and laser detonators took over.

Although, this material would respond great to laser initiation well also. You won’t see a lot of work like this in patents and paper because it’s

deeply classified in national labs. But yours truly, LL has once again shown this can be a safer area of research without dealing with hazardous and

exotic chemicals. After this thread I don’t know why even entertain posts about lead azide, or even NHN. I promise you LL will uncover something

even more valuable from this research, near ETN pressure at only 70% density. Something that spilts the road into a new area of research will be found

from this. I think of the ultra theoretical posts, and comments that were posted by members long gone (not PZ, he was invaluable) who showed off

their inorganic and chemical knowledge of molecules to exist, but in one thread LL showed he brings more value than the endless theoretical

discussions.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Thanks. MineMan. Thanks for the great support. Much of what you write is true. Many similar substances (with DDT capability) end up in the vaults of

national laboratories. I'm sure of that. But Lithex is hygroscopic and requires a solid cavity. So it is not a particularly revolutionary invention.

On the other hand, Lithex is interesting in that:

1) is highly thermally stable.

2) can be easily overdried before filling. (at 170 C in 10 minutes)

3) its preparation consists in simply mixing oxidizer and fuel.

No need for desiccator, Buchner device + vacuum pump, pH measurement, distillation, cooling, crystallization. Or other laboratory equipment or

procedure. All you need is a pan and a steel scraper. There are not many pyrotechnic compounds in the world that can withstand frying in a pan. And

scraping at 170 C. Often similar mixtures decompose. Or they explode when scratched. However: I think, that Lithex has pretty good international

interest. The thread is 6 weeks old and has over 6,000 views. Not everyone wants to present a comment. Especially in this strategic field. It will be

similar to CHP. Takes years than Lithex (or derivates as Lithexal) will recognized as usefulness compound for safetely initiation. The history of

inventions has one thing in common. Any new thing in the first place ... I repeat in the 1st row ..has meets with distrust... ..This is a natural law. ..This is a natural law.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

MineMan

International Hazard

Posts: 1004

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | Thanks. MineMan. Thanks for the great support. Much of what you write is true. Many similar substances (with DDT capability) end up in the vaults of

national laboratories. I'm sure of that. But Lithex is hygroscopic and requires a solid cavity. So it is not a particularly revolutionary invention.

On the other hand, Lithex is interesting in that:

1) is highly thermally stable.

2) can be easily overdried before filling. (at 170 C in 10 minutes)

3) its preparation consists in simply mixing oxidizer and fuel.

No need for desiccator, Buchner device + vacuum pump, pH measurement, distillation, cooling, crystallization. Or other laboratory equipment or

procedure. All you need is a pan and a steel scraper. There are not many pyrotechnic compounds in the world that can withstand frying in a pan. And

scraping at 170 C. Often similar mixtures decompose. Or they explode when scratched. However: I think, that Lithex has pretty good international

interest. The thread is 6 weeks old and has over 6,000 views. Not everyone wants to present a comment. Especially in this strategic field. It will be

similar to CHP. Takes years than Lithex (or derivates as Lithexal) will recognized as usefulness compound for safetely initiation. The history of

inventions has one thing in common. Any new thing in the first place ... I repeat in the 1st row ..has meets with distrust... ..This is a natural law. ..This is a natural law. |

Nearly all DDT mixtures need a solid tube. Although a .5mm Al or Carbon fiber tube is enough. Lithex could do this with tweaking. I know it. It’s

similar to my DDT formula that self extinguishes in the open but can DDT in .5mm aluminum tube. Perhaps we should be more careful in what we say, I

didn’t know so many viewed this forum. I just can’t imagine there are DDT compounds locked in national vaults that perform better than Lithex. I

am interested in sark gap detonators, and think Lithex would work well for that. But now, we need to test a main charge with 90% density or produce a

way to produce in quantity. I have an idea. Nitroguanidine works quite well at DDT! It is also extremely stable to shock. If 30 percent NQ were

added to Lithex with aluminum, would be interesting.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

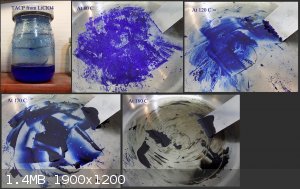

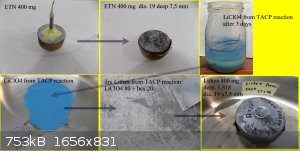

It looks like there has been another breakthrough in the Lithex brisance. The unsuccessful reaction of TACP production from LiClO4 gave a change in

color and consistency after 3 days. The dark blue turned to a light blue suspension. The light blue color is most likely copper hydroxide.

Hydroxy-contaminated LiClO4 was dried. At 180 C. The hydroxide decomposed to CuO. (estimate) A sample of thus contaminated LiClO4 was mixed with

hexamine in the usual ratio of 80:20. The maximum pressure was used when filling the cavity. A density of 1.818 g / cm3 was achieved. For an output

segment weighing 400mg. The brisance at this density is the same as that of highly pressed ETN 400 mg.

Thus, the depth of the crater is 7.5 mm with a crater diameter of 19 mm. Because the tests are shot in lead, an error of at least 10% must be taken

into account.

Anyway, MineMan had truth. If the Lithex can be compressed to high density, its brisance will be identical to ETN. Which has just been confirmed. The

mixture thus prepared has, of course, excellent flame sensitivity. Therefore, it is not necessary to use a different chemical substance for ignition

in the cavity. Lithex with CuO (xy%) works as a monopropelant with incredible brisance.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

underground

National Hazard

Posts: 703

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

LL i have a question, i have seen your video on youtube about the cavity but, i was wondering, what are you using to close it ?

[Edited on 23-2-2022 by underground]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1395

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Video The cavity: time 2:35, alu foil ball + hammer.

But at testing Lithex,

the cavity is not closed at either end. This is also evident from the pictures in this thread. The side of the output segment is pressed with a force

of about 100 Kg on density of 1.4 g / cm 3. Or recently on 200 Kg on density of 1.8 g / cm3. Side with wires is pressed force about 10 - 20 Kg.

Because it is a test (laboratory) kit, protection against moisture is not necessary. The design without lid (on the outlet side) provides the

strongest detonation pressure. And accurate result. For example at density 1,79g /cm 3 pure Lithex 400mg created craterof diameter 17,5 mm and deep

7,4 mm into lead metal.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

| Pages:

1

2

3

4

5

6

..

13 |