| Pages:

1

2

3

4

5

6 |

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

Sorry, I've been unable to reply for a couple of days, and I'm still awaiting delivery of my laser modules...

That said, has anyone got any ideas on how to attach (adhesive obviously, but what type?) the grating film from Edmund Optics (they sell it through Anchor Optics too) onto an acrylic/glass substrate and maybe even onto an aluminium adhesive tape/ aluminium sheet (for the mirrored reflective

gratings)...

I was just wondering, it would seem to allow for much more reproduceable results, with a much better 'feel' (almost like it was being done

properly )... The holographic grating sheet is so cheap it is scandalous, if we

can utilise a fairly common adhesive (maybe methacrylate?) to bond it to a clear/reflective backing and then a clear front, it would be bloody useful

and very difficult to damage too easily... )... The holographic grating sheet is so cheap it is scandalous, if we

can utilise a fairly common adhesive (maybe methacrylate?) to bond it to a clear/reflective backing and then a clear front, it would be bloody useful

and very difficult to damage too easily...

It would also allow for the gratings to be made, not just improvised, which would allow us to design Littrow-configuration setups with 1, 2, 3 or even

more stages of monochromation in order to get what we want. Personally, I'd prefer a filter that just cut off everything over 800nm (the two main

sources of stray light), then try and narrow the actual beam-width and stabilize the wavelength of our module.

The blaze-angle, plus the choice of 500-1000l/mm would allow for some interesting designs (from a physics perspective - almost echelle grating like)

of that "decent" film, which should allow us to narrow the beam dramatically with some thought, and a little ingenuity.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by unome  | | That said, has anyone got any ideas on how to attach (adhesive obviously, but what type?) the grating film from Edmund Optics (they sell it through Anchor Optics too) onto an acrylic/glass substrate and maybe even onto an aluminium adhesive tape/ aluminium sheet (for the mirrored reflective

gratings)... |

Epotek sells a number of optical-quality epoxies. Their basic optical 301 would likely do what you want. The only problem is that if you buy from

them directly, you're talking half-liter quantities (as I recall) and hazmat shipping fees, all of which means a might expensive joint cost, assuming

you only need a few of them. I saw some reference that it was available from a repackager in 4 g packets, just right for occasional use, but I haven't

been able to track it down.

|

|

|

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

I'm posting again because I found a truly interesting article on the subject under discussion from the fbi.gov site (stranger things have happened ) )

I'm in the midst of reading it at present, I'll have to look into the epoxies, is there any specific reason why I'd need them rather than the methyl

methacrylate polymer that is used in joining the component parts of DVD's (multiple parts methyacrylate polymeric base, a colored dye (to allow for

writing to it), a grooved substrate, a grooved top then a false layer IIRC, I was looking at a diagram of one just last night).

If they can perform the job, but we are only dodging them due to the curved grating, I suspect we could also use the same adhesive...

Attachment: Eckenrode.etal.Portable.Raman.Spectroscopy.Systems.for.Field.Analysis.pdf (236kB)

This file has been downloaded 1157 times

PS Looked for optical adhesives and got this which is used for right through the VIS-NIR range and is even available in Oz for a decent price

PPS I was just thinking, if I got a decent optical density piece of glass in yellow (transmits >500nm) and some mid-orange (transmits<550), then

that would remove most of the stray light wouldn't it? Prior to the dual monochromator - really, just two reflective gratings on the opposite side of

a slit that can be tuned to be on a certain angle (both on the same angle, but opposite)

EDIT

I am sorry to put this here (but I felt strongly that it had to somewhere), but I am truly humbled by the amount of time and effort some VERY

intelligent people, some of whom are very senior members of this forum, have expended in helping me to comprehend the difficulties of this project and

the multifarious challenges involved therein. That said, I would like to thank everybody who has taken the time and effort to help, not just me, but

everyone who stands to benefit from this if it can only be made to work. I'm not in the habit of 'pissing in pockets' and I suck badly at

brown-nosing, which makes it hard for me to express my thanks. Please, if you are one of the people involved, take it as it meant, wholeheartedly and

with absolute honesty.

[Edited on 19-3-2010 by unome]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Reflective gratings should be reflective on the front, especially for resolving spectra. Consider what light must

pass through in your proposal:

* the front of the grating

* the bulk of the grating

* the back of the grating

* the adhesive

* the reflector's surface

* the adhesive

* the back of the grating

* the body of the grating

* the front surface of the grating

each of those at least potentially scatters light. For cleaning up the laser beam, especially if filters are used as well, the intensity of the

scattered light is likely to be low enough to let you slip by. But on the post-sample dispersive section that scattered light could be important,

remember the intensity ratios involved.

If you fill the groves of a transmissive grating, it may stop being a grating if the filling material has a refractive index close to that that of the

grating base.

Also the blaze wavelength is more important when separating the Raman light. Gratings work best for wavelengths from 2/3 to 3/2 of their blaze

wavelength, so you want to make sure the Raman wavelengths don't get too close to the 3/2 edge.

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=25

Filters - standard IR absorbing glass will do a decent job. It's better at the 1064 than the 808, but generally such glass will be OD2 or 3 for both

bands. Specs on the glass are needed because some types have moderate absorption in the green, no sense wasting the 532 beam as the gratings will do

plenty of that. In a handwaving fashion, glass doped with Fe and/or Ni will work at the IR end, as will light cobalt glass - the dark blue kind will

absorb too much of the 532 nm but the lighter blue type might work well. Solutions of CuCl2 and NiCl2 in water just might do the job as well. CuCl2

starts absorbing around 580 and goes at least into the 600s, NiCl2 starts around 620 and I believe goes further into the NIR.

The laser diode puts out several percent of its total light emission from activities similar to those of LEDs, and so dribbles light out from the far

red down into the yellow and even green. A friend had a 5 watt 808 diode that put out 100 mw of blue in the 450-490 range as well. Quickly filtering

out the 808 and 1064 nm laser light is as much as of a safety thing as just general light cleanup.

It might be useful to build a simple "visible light" spectrometer using bits of a DVD to examine both the output of the laser and pass/block bands of

prospective filters. The CCD camera, if the IR filter can be pulled, will detect at least up to 900 nm and down to somewhere around the edge of the

UV-Vis. Use fiber optics to feed light from a neon bulb to the outer edges of the slit, bracketing the same light. This will give you a system that

processing software can be developed for:

* Merge the colour channels into a combined data channel, which is more than simple grey scale conversion as the CCD colour changes respond to light

wavelengths outside of their assumed colour range - red sees some violet-UV for example.

* recognize several lines of the neon spectrum, knowing approximately where to find them.

* use those Ne lines to determine how to rotate the spectrum image to compensate for small rotational misalignment between the slit and the

camera/CCD, net result is that columns of pixels represent wavelengths to the resolving power of the system.

* Adjust the column values for the sensitivity of the CCD channels for each wavelength. This can be done by taking the spectrum of a known temperature

black body, a tungsten lamp is commonly used, and comparing reads at each wavelength against the expected value for a blackbody.

* Present the polished data as an intensity vs frequency graph, or as an absorbency vs frequency graph.

It'll give you experience with building using gratings and other optical stuff, and working with CCD data. Plus it gives you a useful lab instrument,

lets you check the purity of the filtered laser output, and might be able to see some Raman lines.

|

|

|

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

I'm in the process of building the software and then cobbling it together with a TWAIN interface so that I can acquire the image.

I'm still awaiting arrival of the lasers, hopefully I'm not going to have to argue them through customs, although I am fully prepared to so do.

I've previously pulled the IR filter out of a CCD camera, there really is nothing to it, just undo the optics, to expose the CCD itself, look inside

the optics and there is a tiny square of colored glass (very light blue). Remove it, reattach the optics (lens assembly and focus etc.).

Insofar as the color - if I use a neon lamp (they are cheap and the drive-electronics are simple), the spectra I want is going to have to be accessed

via iterating through the pixels (as an array) and converting each pixel from an RGB color to 8-bit greyscale which is done using an algorithm, which

can be modified to give the lumen at each pixel position. As each picture is several hundred pixels high, getting the average luminosity/intensity for

the column (@ each pixel position, ie. x, y[1:200]) should enable me to draw a line, pixel position v average intensity (which will be fucking useful

for noise reduction).

With Raman & a >550nm cutoff, if we use the long-side for the spectra (assuming we'll only want the visual) we have 500 pixels (out of 640),

therefore we can move it back or forwards to line up with the known spectra of the neon bulb, plus have 2 pixels/nm, so 0.5nm resolution is possible

(although not without some serious work).

EDIT

PS Why not use transmission gratings to clean up the laser light? I've seen several dozen articles on using such designs (the holographic grating in

most of them 'is' (sic - how many years of schooling & I write that ) formed

by laser interference with a photoreactive substrate wedged between two layers of non-reactive clear outer layers, volume phase holographic gratings IIRC), and was thinking if the filters were utilized as the outer layers of the wedge (glass/grating/glass),

then that potentially kills many birds with one stone, while protecting the rather fragile grating film from damage by effectively making it into a

slide-type arrangement, which would protect the gratings from fingerprints, dust, etc. and also remove the need for adhesive, plus, quite probably

allowing us to use less monochromatic stages... ) formed

by laser interference with a photoreactive substrate wedged between two layers of non-reactive clear outer layers, volume phase holographic gratings IIRC), and was thinking if the filters were utilized as the outer layers of the wedge (glass/grating/glass),

then that potentially kills many birds with one stone, while protecting the rather fragile grating film from damage by effectively making it into a

slide-type arrangement, which would protect the gratings from fingerprints, dust, etc. and also remove the need for adhesive, plus, quite probably

allowing us to use less monochromatic stages...

NB I've actually got some articles on how it is done, they use lasers to react with 1,2-naphthoquininone/methacrylate between two sheets of

methacrylate. The naphthaquinone is photoreactive and forms an opaque line where the laser hits it. It is actually quite interesting and may be an

answer in itself later on.

[Edited on 20-3-2010 by unome]

|

|

|

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

Sorry for the double-post, but for anyone who is interested, the supplier linked to by not_important has in fact supplied the 20mW Laser Diode Modules and a single 2MP (1600pxx1200px) CMOS iPhone camera module (they now also have an alternative, cheaper version of the same thing) which they wrapped EXTREMELY well and labeled as "Electronic Components" (without any suggestion to do so from

me) so as to ensure minimal issues with Customs.

As a result, I happily endorse that supplier (which I know is somewhat frowned upon on this & other boards, but there is nothing remotely

suspicious about this, or not_important wouldn't have linked to them either).

Now, I am searching high and low for any reported experiments of using a NIR filter (to remove both the 808nm & 1064nm stray light from the actual

laser module - nb. both wavelengths are generated, so unless they are removed, expect them to be present) as a backing for a slide (sandwich the

grating film between two sheets of thin glass - as is done elsewhere, in order to protect the grating from scratches, fingerprints, dust, etc., which

to me would appear to turn the surface-relief grating into a variant of the volume-phase holographic grating anyway, but utilize an NIR filter

instead of one of the glass sheets (ie. preventing the entry of NIR wavelengths into the sandwiched grating) and maybe even utilize a narrow-bandpass

filter on the other side of the slide,* allowing the exit of ONLY those wavelengths falling within a predetermined range - those outside it would

presumably be absorbed or reflected back through the grating sandwich and absorbed in the first module of the laser-setup).

That would enable us to avoid multiple, loss producing (eg if all the components have 90% transmission, the more components, the lower the overall

transmission) if components can be combined, then that will improve transmission. On top of which, if we can dramatically restrict the wavelengths

exiting the transmission grating sandwich, that will improve our chances of isolating only the target wavelength by use of simple mathematics/physics

(they intertwine in this, as well as other areas), with fewer monochromatic stages than are used by other designs.

* This is not a known variable, it is completely unclear whether this would actually work, it is a hypothesis... If it does not work as advertised,

I'd advise inserting an NIR filter prior to the transmission grating-sandwich, with the colored-glass, narrow-bandpass filter used as the entry side

of the sandwich - thereby preventing wavelengths outside the bandpass region entering the grating-sandwich, plus the use of the NIR filter + the

colored glass bandpass filter complement one another, as the relevant colored glass which corresponds to the required bandpass range, is a

double-bandpass filter, transmitting 90% of incident light in the targeted bandwidth and in a large section of the NIR region - by removing the NIR

prior to it, it becomes a single-bandpass filter).

In this instance, the Hoya G-533 green glass filter transmits the band we want, plus with a basic NIR filter, would not transmit the NIR that it DOES transmit normally,

as the NIR light would not reach it. I'm wondering, how would green acrylic (transparent - tinted) filters go? Acrylic is a lot easier to fuck around

with (ie. cut, shape) than glass and is normally a LOT cheaper to purchase.

Does anyone have any knowledge of how to make optical filters/components out of acrylic/methacrylic monomers? Also, ideas on how to tint them so as to

better control their behaviour, transmission bands (eg. could we combine the NIR blocking filter with the green transmission filter?)...

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

IR filter - look at Schott BG39 Glass http://www.optical-filters.com/bg39.html which is at least OD 4 for both wavelengths.

Trying to make your own filters would be interesting but likely with a long learning curve. Getting the needed dyes may be difficult, casting thin

uniform sheets is problematic, and then there's the time getting the nice smooth finish on the filter. There's a reason DIY filters are often

solutions, microscope slides make decent cell windows.

I'd want to put the IR filter right at the laser, and dink around with further filtration and dispersion a bit of the ways off it. That way you only

need eyewear for 532 nm, and have room to mess about with the isolation of that line.

Simply gluing a standard relief grating to a sheet of glass does not create a volume phase grating, it might make a poorer performing grating than the

starting point. Sandwiching works, as it still has the grating-air interface.

As I already suggested, building a simple spectroscope using a bit of a DVD is a good way to check out filter materials for at least the visible to

900 nm range (depends on the CCD used) Neon has some good reference lines in the 800-1000 nm range, including one at 813.64 and a medium one at

808.25; it also has some sets that are useful for determining resolution of your devices.

|

|

|

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

OK

I am just working on accessing the image using DTwain - then (given that the image will contain 3 sub-images), in RGB, working out the central area of

each (about half width) and then establishing the pixel postion (x,y) for the bottom left corner of each slice...

Then iterate through by averaging the lumen value (established by the rather simple equation cited above) of the array, x(n), y(200:500), then

outputing an integer for the average lumen of the array at that pixel position, then iterating through, let n=n+1... until we get an average lumen

integer for each pixel position of all 3 pictures (and the central slice ONLY of each). From that, given we can assign absolute wavenumbers to the

peaks in the neon light, we can mathematically assign absolute wavenumbers to each pixel.

As the sensor involved (now) is a 2MP CMOS sensor, and the neon light draws fuck all power, it may just be possible to power the whole thing from the

USB 2.0 port (the laser is 3V - inbuilt regulator, 250mA) and the USB 2.0 specification allows for almost double this...

I am actually seriously considering saying fuck it and buying the cheap 10nm bandpass filter (or the more expensive 1.2nm one) - passing that through

a grating and only taking the target wavelength is obviously going to be the easiest option.

I'll also need a 550nm colored glass longpass filter (to remove the reflected light, etc. from the source wavelength).

Given the 2MP sensor, that should allow us to go into Angstrom-units, and by averaging out the intensity of the light from the central slice of each

sub-picture, we would reduce noise significantly (although, if necessary, we could always factor in noise - just work out a signal-noise ratio and

utilize that in determining the average intensity per x-pixel).

The integers returned for lumen/intensity, would, given absolute wavenumbers could be attached directly to the peaks in the neon spectrum (and the

angles involved in the increasing spectral orders are mathematical, thus solvable using the PC) assign wavelengths and parts thereof, to EVERY

x-pixel, thus allowing us to graph the x-axis (pixel position) v y-axis (avg lumen/intensity at that x-position).

[Edited on 22-3-2010 by unome]

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

I just spied this article from last month's JCE:

Inexpensive Raman Spectrometer for Undergraduate and Graduate Experiments and Research. They're using a commercial visible spectrometer for data

acquisition, but the illumination is with a green laser pointer.

Supplementary information

[Edited on 3-22-2010 by Polverone]

PGP Key and corresponding e-mail address

|

|

|

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

Hell, notice they used EXACTLY the same OG550 Schott-glass bandpass filter I was talking about earlier? They also got a useable Raman spectra from a

4mW 532nm Laser, which means if I use a beamsplitter (to split the 532nm beam into two beams - reference (solvent) and analyte+reference

(solvent+whatever) raman spectra are within reach).

Can anyone tell me why they bothered with the super-expensive notch filter when they already had a >550nm filter that would exclude the Rayleigh

peaks anyway?

Also notice, they did not use any filter on the 532nm laser source whatsoever (from what they've written themselves).

The microscope objective would be an interesting idea - use one for each of the laser inputs and outputs - although to save fucking around, I'd

suggest putting the laser in @90' to the output, that way you can place a mirror on the other side to the orange OG550 Schott glass filter >550nm

(everything under that is cutoff).

Of course, given the diode laser modules I have are KNOWN to have no IR filter, we'd need to use that at least (I've included a PDF file, which is

essentially just a cleaned up webpage describing the module laser's under discussion - I also added the schematic it cited (and linked to)).

[Edited on 23-3-2010 by unome]

Attachment: Section5.20mW.532nm.sku26887.Green.Laser.Module.Surgery.pdf (106kB)

This file has been downloaded 957 times

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Those two files cannot be downloaded from the scipics folder, because sciencemadness.org does not have a valid security certificate. Please attach or

upload them by some other means.

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

Accept the security certificate. It is a self-signed cert designed to protect your traffic from snooping by third parties, not to prepare and validate

this site for commerce.

PGP Key and corresponding e-mail address

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

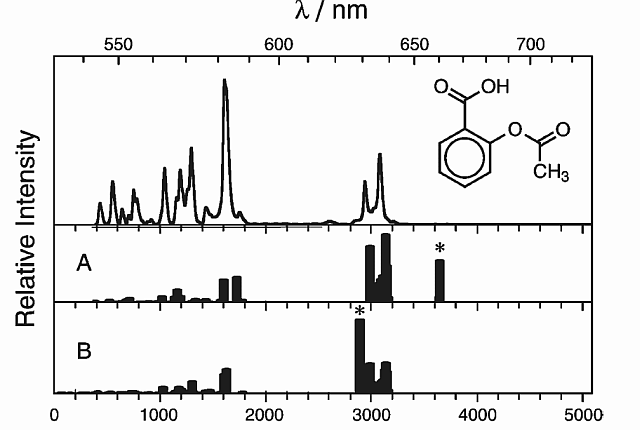

Quote: Originally posted by unome  | Hell, notice they used EXACTLY the same OG550 Schott-glass bandpass filter I was talking about earlier? ...Can anyone tell me why they bothered with

the super-expensive notch filter when they already had a >550nm filter that would exclude the Rayleigh peaks anyway?

Also notice, they did not use any filter on the 532nm laser source whatsoever (from what they've written themselves). |

But some laser pointers have IR blocking and good 2nd harmonic (532) optics. Unless you know the full specs on their pointer it's tough to compair.

The answer to your question is in the article you're referring too, and the spreadsheet I uploaded

| Quote: | An inexpensive orange-color glass filter can be

used that absorbs light with shorter wavelengths than ca. 560 nm, thus, blocking the 532 nm excitation light and being transparent to red-shifted

Stokes scattered light with wavelengths longer than ca. 560 nm. The transmittance cutoff, however, is not very sharp, and Raman light near the

cutoff of ca. 560 nm is lost, which prevents the observation of Raman shifts below ca. 1000 cm-1. |

Below 1000 cm<sup>-1</sup> includes most of C-C ring breathing range as well as the C-halogen, C-S, S-S, C-O-C bands among others. See

the table below and the attached image for common compounds that have bands below 1000 cm<sup>-1</sup>.

4-Acetamido-phenol

shift calc. wavelength

213.3 538.1

329.2 541.5

390.9 543.3

465.1 545.5

504 546.7

651.6 551.1

710.8 552.9

797.2 555.6

834.5 556.7

857.9 557.4

968.7 560.9

---------------------------------------------

1105.5 565.2

1168.5 567.3

1236.8 569.5

1278.5 570.8

1323.9 572.3

1371.5 573.9

1515.1 578.6

1561.5 580.2

1648.4 583.1

2931.1 630.3

3064.6 635.6

3102.4 637.2

3326.6 646.4

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Polverone  | | Accept the security certificate. It is a self-signed cert designed to protect your traffic from snooping by third parties, not to prepare and validate

this site for commerce. |

Unfortunately, that security certificate is not capable of being "accepted" by a downloader, and I cannot see anything about it being "self-signed".

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

Quote: Originally posted by JohnWW  | Quote: Originally posted by Polverone  | | Accept the security certificate. It is a self-signed cert designed to protect your traffic from snooping by third parties, not to prepare and validate

this site for commerce. |

Unfortunately, that security certificate is not capable of being "accepted" by a downloader, and I cannot see anything about it being "self-signed".

|

Unless you're using some obscure browser I have never heard of it is certainly possible to add an exception for the certificate. Or just manually edit

the URL to change https to http so everything is transmitted in the clear.

PGP Key and corresponding e-mail address

|

|

|

unome

Hazard to Others

Posts: 134

Registered: 17-10-2009

Member Is Offline

Mood: No Mood

|

|

Schott OG-550 Glass Filters do NOT fall into that range the transmittance at 550nm is down around 0.5% admittedly, but at 560nm it is up to 78%.

As to the secondary harmonics, I suspect (Strongly) that the article using the 4nm pointer wasn't really interested in mode-hopping and all the rest.

That said, with a single transmission filter I can line lock it and remove the extraneous 808 & 1064 nm bands with a filter.

Apart from that, it should be only too easy to adjust the program to take into account the percent transmission and adjust it so that the relevant

spectral image is corrected. In terms of noise reduction, on top of averaging the column luma, I was also thinking of finding the median and those

numbers lying outside an 80% range of the median/mean (can't think which would be better to use) could then be transposed with the mode integer, then

the mean is taken.

I was also thinking - we wouldn't have to iterate through the entire pixel range for each sub-picture - we could convert EVERY pixel in the

sub-picture to a luma value, then simply work with the column array, average that and get a string of x, y(integer). Which we can correct for both the

known transmission curve of the filter and for noise. Use of the trigonometric classes within C++ (for example) would allow us to assign absolute

wavelenths from the grating, once we can compare known wavelengths with pixel position.

For example, the grayscale image is purely intensity - nothing more, so if we average out the columns in the grayscale image, we get an average intensity for that column/pixel position. The

more rows, the better the average. If we identify the most repeated value (the mode), then identify the median, we can determine the central point of our column's intensity values, if we then replace anything falling outside a predetermined range of

the central point (ie. the median) with the mode value, that will, in conjunction with the high number of rows averaged, give us some very useful

information (ie the mean), with noise and dud pixels pretty well removed from the equation(s).

This will give a single value for each column, which we could adjust for the variable transmission of each wavelength through the OG-550 filter, in

order to give a true representation of the Raman spectra if the filter gave 100% transmission purely mathematically. In order to do so however, we

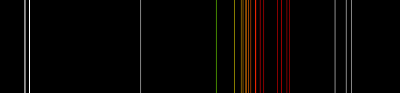

would have to find the peaks of the neon spectra (from the central image), it looks like this:

(NB Taken from Wikipedia)

Now, we can assign the peaks from that spectra (which is our central sub-picture), from that, we can backtrack (whether we are using a transmission or

a reflective grating, to determine the angle of each spectral peak from the incident light source. That gives us the coefficient for the grating &

our sensor, we then utilise that to determine and assign wavelengths to EVERY pixel.

If needed we can then modify the column value for various pixels, by the known transmission of that wavelength through the OG-550 filter, in order to

model all spectral data as if transmission at EVERY wavelength were even.

No small task, not at all... In fact it is every bit as challenging as building the bloody spectrometer. Not only do I have to work out what bits to

buy, what angles they are needed at, where the fuck I am going to get a decent, cheap, beamsplitter, as well as everything else, I also have to work

within my USB 2.0 Power budget.

The neon bulbs are a doddle to buy, they are super cheap and require fuck all power, the laser takes 250mA/3V (which is more than I have available

without pretending to be a mobile phone battery ). ).

I need some help here... Anyone want to help work out the circuit diagram(s)? I have contacted the OEM Company that supplied the original iPhone 2MP

CMOS Unit and have asked for the specs (but had to sign a confidentiality agreement to even request them). I badly need to work out what connector I

need to access the data therefrom.

[Edited on 24-3-2010 by unome]

|

|

|

peach

Bon Vivant

Posts: 1428

Registered: 14-11-2008

Member Is Offline

Mood: No Mood

|

|

You could have the the higher power components run from an on board power supply, powered by the USB port.

I mean, you could stick a big capacitor (maybe a super capacitor) in there, then have the USB charge it between readings, on the normal limit, as you

don't need a continuous supply.

Another option, which may be cheaper, is to actually use an on-board rechargeable cell and simply have the port top it up between readings. Lithium is

good for high density, NiMH is better for charge cycles I think (500 versus 1k to 80% capacity). Bypass it with a cap if you need to draw pulses for

the laser that are close to the cells limit, or parallel them up.

[Edited on 6-7-2010 by peach]

|

|

|

aliced25

Hazard to Others

Posts: 262

Registered: 31-7-2010

Member Is Offline

Mood: No Mood

|

|

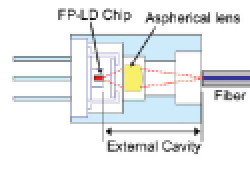

Ok, back on this because I've been thinking about it, there are two real options that I can see

Either purchase the 808nm 1W Diodes (not too bad pricewise) and some NdYAG / KTP Crystals and make a properly designed and properly aligned 532nm

laser (with reflective mirrors on the first and second stages - reflecting the feedback back into the lasing medium the diode in stage 1 and the

KTP/NdYAG crystal in stage 2), with luck that will phase/line lock it. Then use a 70-90 l/mm laser beam splitter to remove the stray wavelengths and get the whole down to at most a 1nm line. Making those gratings should be a cinch, get

some UV curable polymer sheet (the PCB one would do), or a UV cure epoxy resin (preferred option) and use a cad program to draw 70-90 lines /mm then

print it out on a high quality printer directly onto a transparency sheet. Etch the non-cured epoxy off the glass/acrylic sheet and bam, one low

resolution grating.

The same could be done, with much more ease, using one of the 200mW 650nm Diodes (but I can find fuck all on them for Raman). What would the relevant

shifts be for that? Has anyone got any resource (or link thereto) that will enable schmucks like me to work out the extent/percentage shift? Is it

that easy? Or is there some other trick?

Personally I like the idea of locking the 650nm Diode (as the designs evolved, they have basically returned to where they started, the interior of the

external cavity is separated from the diode cavity by a filter and a small aperture. As the filter is reflective to every bit of light that doesn't

get there on the right angle, if we built a pseudo etalon inside the first external cavity with the entirety of the returned/reflected light being

directed DIRECTLY at the diode, then the feedback should be solved (so the device will lock). A mirrored surface behind the diode would then direct

the remainder of the light back at the diode too (from behind - ie. a mirrored surface each end = an etalon - Here is the thesis I got it from.

The phase/line locked diode could then be line-narrowed by running it through one of the laser line splitting transmission gratings (mentioned above).

But we come back to precisely where the *)(& )&()* raman shifted chemical

groups will be, is there some formula? I really HATE not knowing this shit & I can't even find it anywhere I've looked. )&()* raman shifted chemical

groups will be, is there some formula? I really HATE not knowing this shit & I can't even find it anywhere I've looked.

[Edited on 25-10-2010 by aliced25]

|

|

|

aliced25

Hazard to Others

Posts: 262

Registered: 31-7-2010

Member Is Offline

Mood: No Mood

|

|

I found some of them (in the attached paper), but in order for the "Raman Shifts" to make sense, one has to get the concept of "wavenumber" and

"wavelengths" straight. It took me a little while . I'll attach an image from www.semrock.com, which shows the problem: . I'll attach an image from www.semrock.com, which shows the problem:

Notice how few wavenumbers there (comparatively) between 800nm-1000nm? Only 2,500cm<sup>-1</sup>? But there are

30,000cm<sup>-1</sup> between 200nm-500nm?

This shows why Raman Spectroscopy is usually done anywhere but the lower half of the spectrum (UV-NIR). The wavenumbers are so numerous that the

shifts would be impossible to measure/discern. Whereas at the upper half of the spectrum, the closer we get to the 800-1,000nm section the better

(although it needs a stronger laser & a camera without an IR Filter, because imaging with a CMOS/CCD Image Sensor between 800-1,000nm (invisible)

requires a fairly big spike to be noticeable.

I'm actually busily transcribing the shifts in the paper I've attached, when I'm done transcribing the shifts, what I'll do is work out the shifts in

nm for each group listed from a 405nm, 532nm, 650nm and an 808nm laser diode, where we would expect to see the Raman Spectral result for those groups

using each laser.

PS The relevant tables are on pages 4-7.

Attachment: Tables.Wavenumber.Shift.Frequencies.pdf (738kB)

This file has been downloaded 1690 times

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aliced25  | ...

But we come back to precisely where the *)(& )&()* raman shifted chemical

groups will be, is there some formula? I really HATE not knowing this shit & I can't even find it anywhere I've looked. )&()* raman shifted chemical

groups will be, is there some formula? I really HATE not knowing this shit & I can't even find it anywhere I've looked.

|

Seems to me I uploaded a little spreadsheet that lets you plug in the exciting wavelength and gives a list of Raman shifts back a page, shift values

for common groups over the range of 300 to 3000 wavelengths - pumps out the nm value based on the given excitation freq.

And once again a word or two of warning - while it may look simple to mess about with laser optics, the damned things don't always work the way you

want them to, or even work at all. I worked at a company that did nothing but lasers, research jobs developing laser assemblies for OEM use. Lots of

guys with years uni research and more years in the industry. And there were times they spent many days coxing a solid state laser chain to function,

using a lot better grade of equipment than you're likely to have.

The other thing is that you absolutely needs eye protect for all wavelengths used once you get above a class 2 or 3A laser. It's amassing how often

assemblies that are intended to lock up light and just can't physically fail do fail and bounce watts of laser light about - the holes in the

safety drapes were evidence of this.

[Edited on 31-10-2010 by not_important]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aliced25  | | Notice how few wavenumbers there (comparatively) between 800nm-1000nm? Only 2,500cm<sup>-1</sup>? But there are

30,000cm<sup>-1</sup> between 200nm-500nm? |

If you multiply the wavelength times the wave number,

you get a constant.

|

|

|

aliced25

Hazard to Others

Posts: 262

Registered: 31-7-2010

Member Is Offline

Mood: No Mood

|

|

not_important,

Thanks for that spreadsheet - I have looked at it several times, but until I could work out the shift for each group and the wavenumbers themselves,

it didn't make sense. I dislike not knowing HOW something works, for that I needed 2 pieces of the puzzle, the shift in wavenumbers, and the

calculation of the shift in nm based upon the excitation laser is a whole lot easier if the reasons why it works are known.

I didn't see the calculation in that spreadsheet sorry, dumb of me, but hey... Ah hang on, I'm not getting it to work - the numbers are just sitting there, no calculation. I'll try downloading it again, but even if there is an

issue with the download, if the calculation was there, surely it would show up regardless? I mean, even if the calculation wasn't carried out, the

formula would still be there?

Ah hang on, I'm not getting it to work - the numbers are just sitting there, no calculation. I'll try downloading it again, but even if there is an

issue with the download, if the calculation was there, surely it would show up regardless? I mean, even if the calculation wasn't carried out, the

formula would still be there?

Here, I did a pdf with the solutions for 405, 532, 650 & 808nm & I also attached the Workbook (Open Office Version). Just type the Excitation

Laser wavelength into the box at the top of the first page.

[Edited on 1-11-2010 by aliced25]

Attachment: RAMAN.TABLE.405.532.650.808.pdf (325kB)

This file has been downloaded 5687 times

Attachment: Raman.Solver.Chart.ods (16kB)

This file has been downloaded 636 times

|

|

|

aliced25

Hazard to Others

Posts: 262

Registered: 31-7-2010

Member Is Offline

Mood: No Mood

|

|

Anyone got any papers on the use of Lumogen on the CMOS/CCD Chips? For mine I'm wondering how well they perform in the wavelength(s) that they upshift

the UV light from. Is it possible to just coat a window and place that in front of the Image Sensor (or part thereof), so that only the UV light can

be incident upon it? Then the rest of the window show the visible-NIR spectra?

The other alternative is to have one coated chip and one uncoated, put a UV filter in the way and record the VIS-NIR Spectra, then a VIS-NIR Filter in

the way and record the UV. This would be a fall-back position though.

PS Anyone seen the all-fiber Michelson interferometers WITHOUT mirror/beamsplitter? They just use a Fiber beamsplitter (multiplexer), etc.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

The further the phosphor is from the face of the CCD, the more cells see a given spot, the lower the resolution. Work out the trig - size of a sensor

cell, distance to it; ordinary phosphor films are spherical emission sources (you can do better with microchannel arrays).

You'd be using this in a dispersive system you'll need at least two gratings to cover the full range, and a deuterium lamp to go very far into the UV.

It would likely be less useful for Raman stuff than a system designed for that purpose, lower sensitivity and more noise+scattered light. OTOH

there's no need for the filter swap, just place the two chips to get the proper range of the spectrum. Use a prism+grating, dispersing at right angles

to each other, this keeps the grating's high order stuff from landing where it will confuse the results.

The all-fiber Michelson interferometer - did you actually read the article. Looks to be for narrow wavelength use, as a wavelength measuring device,

as a part of a sensor where some environmental variable causes changes in the light.

|

|

|

aliced25

Hazard to Others

Posts: 262

Registered: 31-7-2010

Member Is Offline

Mood: No Mood

|

|

I was actually just thinking about that, the phosphor merely sensitizes the CCD/CMOS Pixel, the light incident upon that pixel is controlled by the

grating. So even if the UV-phosphor fluoresces at a higher wavelength, the position it fluoresces will be determinative of the spectral region.

The only problem is if the phosphor emits at the same color as the incident wavelength (is that even possible? Fluorescence is the conversion of a

wavelength to another wavelength, surely a wave cannot be converted to itself?)...

I'm looking up <sup>2</sup>D lamps now, there is one in which there is no arc, the <sup>2</sup>D is excited by RF. Has anyone got any idea how this works?

|

|

|

| Pages:

1

2

3

4

5

6 |

|