| Pages:

1

..

36

37

38

39

40

..

68 |

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

packaging

Well! It looks good. I see that a lot of copper is annealed. That is good. I made a few more unsuccessful attempts. Attention. The packaging is very

important. It must be hard, preferably steel wall at least 2 mm thick. It is minimum. If the packaging is soft (plastic only) or weak (only Cu clutch

1mm), EFP does not work good. Use soft or weak packaging waste EM... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thanks, good to know about the casing requirements. I might try one more test before I go for stronger confinement anyway though.

What you are looking at in my last post is an old piece of copper plumbing pipe that was cut down the middle, lengthwise, and folded out. The black is

black copper oxide. Annealing probably would be a good idea though.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

LL, are you anchoring the steel target? I have been just standing the target up and using a small spring clamp to steady it. Trying to decide if

anchoring the steel plate/target better would make much difference.

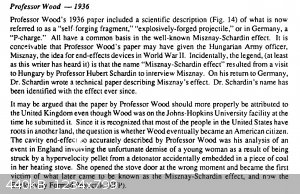

The following snip-it was taken from, "History of the Shaped Charge Effect - The First 100 Years", by Donald R. Kennedy. I thought it was kind of

interesting.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

gold sands

Henning, I know how attached the target. It is in the figures, the photo. If the target is large and heavy, so it's unimportant. The target may be in

the air or sand. This does not affect the result. If so, I guess only difference is 5%. Maximum 10% of the whole assembly sand versus air. The sand

will always be a little better results. And most importantly, it's safer. In particular, if the device is made of steel... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I didn't try to work it out, at least not yet, but that is what I figured too. The diameter of the projectile is small and moving at very high

velocity and the target is relatively heavy (a lot of inertia).

Success with Conical (Munroe Effect) Shaped Charge

I bought some of the steel cones that Markx discussed earlier in this thread here:

http://www.sciencemadness.org/talk/viewthread.php?tid=10575&...

I got a half order of the 1"W X 1"H (~53 degree apex angle) UK cones that Markx was using and the other half in 1"W X 1/2"H (~90 degree apex angle) US

style cone studs. I used one of the 1" X 1/2" cones for my first test. An aluminum tube was bored out on the lathe so that it had an inside diameter

slightly larger than the cone with a lip left for the cone to sit on. A section of hardwood dowel was turned down, so that it would fit the aluminum

casing snugly. The wooden dowel section was also bored so that one end could accept safety fuse and the other end could have 0.15g LA, and 0.5g of

PETN pressed in. Plastic explosive was used (3g of 80% ETN/10% polybutene/10% mineral oil). The PETN was in direct contact with the plastic explosive

when the wooden bushing was put in place. Standoff used was 1.5 CD (charge diameter). Cone/liner diameter was ca. 1/2" (12.7mm). Charge diameter was

ca. 15mm.

The charge easily penetrated the 3/8" (ca. 9.5mm) steel plate. Hole diameter was ca. 4mm at entry and ca. 3.4mm at exit. I know Markx has already been

here with a similar type of charge, but it really is impressive how well these work. I feel I should have tried a thicker steel target, especially

since I see looking back that Markx penetrated 15mm of steel with the more acute angled cones of the same type.

I don't have a lot of pictures because I forgot my phone when leaving for the test site. I did take one before assembling the charge and a couple of

the target once I returned home.

[Edited on 9-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

dangerous amateur

Hazard to Others

Posts: 148

Registered: 8-7-2011

Member Is Offline

Mood: No Mood

|

|

Do you have an opinion on EFPs based on rather slow explosives? Like AN or even Chlorate binaries?

When I tested such charges on metal witnes plates I found that often holes with charge diameter where punched, and the loose material hit the ground

with a lot of penetration power.

But the standoff was only 30mm or so. I wonder what would happen with the right standoff?

2500 or maybe 3000m per second is not hypervelocity, but maybe there will still be some kind of flowing or maybe forging of the metal into a

"penetrating something"?

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I don't have a lot of experience with it, but the literature indicates that those low velocity type explosives don't perform well in shaped charge

applications.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

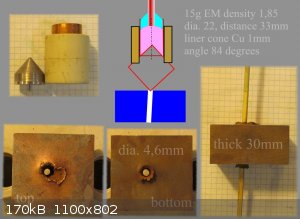

cone 84

For deep penetration cumulative effect better is VoD + 6000 m/s. For EFP + 7000 m/s. (for quality efects). Use of plastic / copper / for the SC

device. Construction steel 30mm / 1.18 inch. Inclined cone a few degrees. This is the error impact on the TOP... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That was a nice result you got there. I am anxious to try again with one of those little steel cones on a thicker piece of steel. I am looking at a

piece of 3/4" (~19mm) steel plate right now which might just be the next victim.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

armor

Amateur human mind is difficult to understand how this is possible. A piece of soft copper pierces thick armor. Unbelievable. But it works ... ...LL ...LL

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

It is very amazing that it works, yes. Steel, and other materials also, behaves very differently when subjected to very high velocities and pressures.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 650

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Hennig Brand  | I am anxious to try again with one of those little steel cones on a thicker piece of steel. I am looking at a piece of 3/4" (~19mm) steel plate right

now which might just be the next victim.  |

These little buggers really leave a mark, don't they  For 19mm steel plate I

would suggest charge masses upwards of 5g (more likely 7-9g of nitroester/nitramine base for a clean penetration with mediocre confinement and

presicion). For 19mm steel plate I

would suggest charge masses upwards of 5g (more likely 7-9g of nitroester/nitramine base for a clean penetration with mediocre confinement and

presicion).

Really excellent work on the steel plate btw! Very clean uniform penetration, no deflection or divided jet patterns. Looking forward to the test

results with 19mm plate

Exact science is a figment of imagination.......

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

A long time back, in high school, I combined some of my metal working shop and art class projects- I tried making my own Copper blanks and then

enameling these, besides other metal jewelry work. Never considered back then, I could have added some of my organic chemistry extra curricular

activities to those projects? Probably not with instructor approval though.

I always wanted some of the nicer specialty tools for small metal working jobs...

Like these precision punches

Or this set which also makes concave/convex discs...

Even if the profile wasn't exactly correct, a little free hand work with a diamond home on a punch mounted in drill press chuck could be done to alter

such punches.

I am a tool slut.

[Edited on 9-1-2015 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

markx

National Hazard

Posts: 650

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

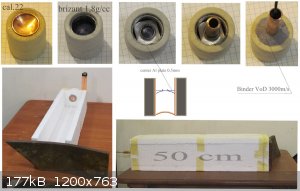

Here's the results of a 7g phlegmatized (10% PIB+methyl riccinoleate) PETN charge on 15mm steel plate:

I managed to recover the carrot...what a blessed find....the bastard was stuck at the outer exiting verge of the crater

I guess just 100mg more energetic would have sufficed and it would have left the target to never be found again.

[Edited on 9-1-2015 by markx]

Exact science is a figment of imagination.......

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Such a cute little hole punch.

It would be really nice to include a scale with such pictures, or use a piece of graph paper of a specified size for the background?

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

markx

National Hazard

Posts: 650

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Bert  | Such a cute little hole punch.

It would be really nice to include a scale with such pictures, or use a piece of graph paper of a specified size for the background?

|

I know, I know....I stand ashamed, facing multiple accusations of chronical incapabablity to include a proper scale reference in the graphical

evidence of experimental results. But I was having just too much fun and the excitement of success can do weird things to ones' judgement for

executing the correct scientifical method

In light of this the reported thickness of the plate can be viewed as anecdotal reference and I have no intention to file an appeal on the matter.

I promise to correct my wicked ways in future reports

Exact science is a figment of imagination.......

|

|

|

Fulmen

International Hazard

Posts: 1749

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

But it's hard, isn't it? Doing the experiment is fun, even measuring the result is fun. But to document things properly, that's actually hard work. At

least it is for me, and I suspect I'm not the only one. I think we owe our self to push each other, not only to do good note-keeping but also to share

our work with enough detail so that others can replicate it. That's what science is all about really.

Other than that little derailment, I just wanted to say: Keep up the good work! I love reading about them, all the cool experiments you do.

I'm seriously considering revisiting my experiments with drawing liners, especially now that I have my furnace working. Sadly I have so much on my

plate I can barely focus on the things I <i>have</i> to do even though it's my own projects that keep me going. I don't have time to do a

write-up, but if others are looking into this route I'm sure I could offer up some advice.

This of course requires access to a lathe and quite a bit of theory, I have a PDF of "Handbook of Die Design", second edition from McGraw-Hill that

was quite useful there. Don't know where I got it from but I'm sure you will find it if you search.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Nice work Markx. I like those cutters and dies Bert, but I think I am going to make one on the lathe to start. I think most of my problems have been

because of asymmetrical liners, which may be what you were picking up on.

Yes Fulmen, the research, the experimentation and the documentation all take work. Most things done of any significance take work. People who do the

work generally don't like to be belittled. We have been getting a look at LL's greatest hits, which is nice and I appreciate it, but there is maybe as

much or even more to learn from some of the things others did (like myself) where things didn't go perfectly.

[Edited on 9-1-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Fulmen

International Hazard

Posts: 1749

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Access to a lathe greatly improves your chances. Accuracy, not only in the manufacture of the liner but equally in the assembly greatly affects

performance. If you can, make tools for the assembly as well. As always, the more effort you put into something the more you can expect in return. I

suspect EFPs are somewhat more forgiving in this aspect.

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

I agree hennig, for all our successes how many failures have we had? I know I tested at least 10 charges before I got any significant penetration nd

these failures are what presses us to try again. If we got it perfect first go then where is the incentive to keep researching? Keep it up guys this

is a great thread and its great to see it revived. In the near future I plan to attempt some EFP devices for myself. Its been a while since my last SC

test and have found some nice old AUS pennies to try. They are copper only and 1.8mm thick. getting other factors right they should work well. Also

hennig did you aim the efp somehow? Like a laser dot from the center of the charge and a mark on the target to match, just to see how far off supposed

center the projectile strikes? If it hits close to the prediction then increased standoff should not be a worry with missing the target. NP

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Glad to hear you are enjoying the thread. Regarding aiming an EFP, I was on rough ground, but the target and charge were both placed on a piece of

plywood, which was relatively flat, which lined them up. A carpenters square can be used to make sure the charge is parallel to the wood rest and

perpendicular to the target. The target and charge can be placed close together to ensure that they are lined up at the right height and then pulled

apart to the desired standoff. Once at the right standoff I literally lied down on the ground behind the charge and sighted the EFP in by looking down

the top of the charge casing. It is amazing how well the EFP can be aimed by sighting down the casing. A laser level would likely be a great way to

line up an EFP with a target.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

smart container

Using polystyrene container is very easy. Production takes 20 minutes. The entire device buries itself in the sand. EFP warhead can be very precisely

adjusted. At the right angle 90x90 deg. Easy, cheap, fast. Safe. For the brave hero (for video) Needless to bury... ...LL ...LL

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

You are using the plasticized perchlorate explosive described elsewhere as a an "active" backing plate/counter charge on the side of propelling charge

opposite the EFP?

Thanks for the graph paper background! What size are the squares?

[Edited on 11-1-2015 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

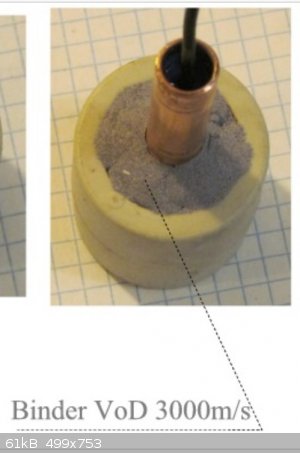

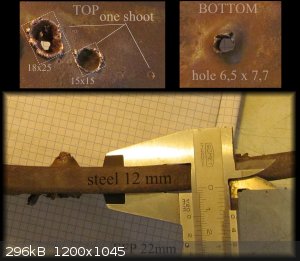

steel 12

Yes, slow plastic explosive is described in the thread cheddite, pag. 7, title AP plastic. Squares on the paper are 5x5mm. The mass used around 4g.

Slow AP plastic as an active supporting plate. The detonation propagates in two directions. Thus it is meant. Here are the results of this report.

Unfortunately, the device was not accurate. I do not know where the error is. Everything was made very accurately. EFP-quality effect is difficult to

create. Despite this, 12 mm steel shot through. Although little, but still... ..LL ..LL

|

|

|

markx

National Hazard

Posts: 650

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Congratulations! Excellent results LL! Now this impact looks more like the projectile had time and space to form into a rather decent slug. It also

looks like the projectile parted or perhaps it is the impact of the separation plate that you had between the main charge and the backcharge. I guess

the root cause of the partitions lies in the overcomplicated design of the separated charges. The separation plate, the copper tube through it coupled

with the initiator....all this creates quite a mess at the back end of the main "brizant" charge when fired and can possibly do more harm than good to

the overall performance of the device (by disrupting the uniform propagation of detonation wave in the main charge)

If one could embed a centrally placed initator between the main and backing charge in direct contact with both of them and with no penetrating

channels through the backing charge then I think this concept might work magnificent. Technically very demanding task though...

Exact science is a figment of imagination.......

|

|

|

| Pages:

1

..

36

37

38

39

40

..

68 |