| Pages:

1

2

3

4

5

..

9 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Tim, I hear what you are saying. I'm not comfortable with the situation either. It does bother me, however, that the heat sink is designed for the

TO-220 component style and has the 2.6C/w rating that indicates that it will do the job. Yes, the circuit board and the case are plastic.

If the sink gets too hot then would an externally mounted fan, blowing through the holes drilled in the enclosure possibly suffice?

If I do have to mount the quadrac on a bigger heat sink outside of the box it too will have to be "enclosed" for safety as the terminals are at

230VAC.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

It would, but then you have the hassle of a fan, which must run at all times, is noisy (compared to no noise whatsoever), attracts dust, may need

another power supply, and probably other things.

Even a small fan moves a lot more air than convection does; one of those dinky microprocessor fans would suffice. Poke plenty of holes (or an opening

covered with a fan guard), and use a loose filter type deal if you'd like to keep it somewhat cleaner at the expense of some airflow. And, of course,

what goes in must come out... you need two sets of holes!

If you mount it outside, can't you mount it with insulating hardware, so the thyristor faces the chassis and no voltage is exposed? Some sheetmetal

could block the ends of the slot the thyristor mounts in, so even a very determined pinky finger couldn't reach the leads.

Tim

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I ran temperature tests this afternoon with the sink mounted in the enclosure. Conditions were about 20C ambient and the power draw was 1800w (7.5a).

With the lid off a steady-state temperature of 46C was reached after 25 minutes. I then put the lid on. After another 9 minutes the temperature had

risen to 60C and was still rising. At this time I terminated the test.

I'm going to have to exercise one of the options we have been discussing.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

The quadrac/heat sink was remounted about 1" (2.5cm) outside the enclosure. When operating at 8.7a (2000w) the sink temperature quickly stabilized at

36C. Ambient was 27C and rising . I will have to make sure I don't get my

"pinky" in the wrong place, however. It will help that nobody else will be operating this puppy but me. . I will have to make sure I don't get my

"pinky" in the wrong place, however. It will help that nobody else will be operating this puppy but me.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Just put some duct tape over it.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

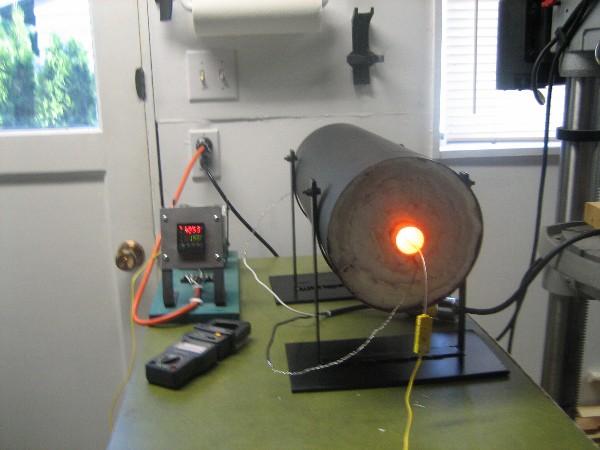

In consultation with garage chemist I have completed the tube furnace construction that I put aside last fall after completing the power control

thyristor circuit. This furnace could almost be given serial no. 2 of the garage chemist design shown upthread.

Differences are as follows:

1. I used 8" (200mm) stove pipe vs GC's 4.8" (120mm) stovepipe.

2. I used an alumina tube vs GC's mullite tube.

3. I used ITC-100-HT to coat the Kanthal wire vs GC's Al2O3/MgO mix.

4. I used 1" (25mm) Kaowool insulation vs GC's 25mm insulation that he suspects contains some ZrO.

My design is for 2kW, same as GC. I used 18 ga Kanthal A-1 wire (1.02mm), GC used 1mm Kanthal A-1.

Edit: My tube is 40mmx34mmx500mm, GC's is 40mmx32mmx500mm.

(GC please make corrections where required.)

Below is a picture of the furnace in operation. It reached 1252C and rising before I shut it down. Maximum amps I put to the furnace was 9. At the

end, temperature was rising at about 1C/min with Kaowool plugs in both ends. I am quite pleased with the performance and saw no reason to push my luck

by taking the furnace to higher temperatures.

It should be noted that even though I had an extra 40mm of insulation the stovepipe was too hot to touch at the higher temperatures.

I will post 2 more pictures and comment about my use of ITC-100-HT.

[Edited on 19-6-2008 by Magpie]

[Edited on 20-6-2008 by Magpie]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's a picture of the tube geing coated with ITC-100-HT. I had never worked with this before. The directions on the bottle said "Add water and mix

thoroughly." That's all. So I added just the minimum amount of water to make it workable and brushed it on with a 1" paintbrush. It is sticky and

was easy to apply, not dripping off at all. I just kept applying it until I had a thickness of about 5mm. I let it dry for about 3 days at room

temperature.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

This last picture shows the ITC-100-HT after drying. As you can see it cracked all over. But it stayed on and never spalled off. Dryed pieces of

waste coating showed that the product has good strength.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Beautiful! Great work!

I am very pleased that your project became such a success. So my design has proved to be workable even with somewhat different components.

Using the ITC-100 paste was a very good choice, I see. My Al2O3/MgO mix became very powdery and flaked off in some spots. If I wanted to build another

tube furnace, I would definately not use this again (I'd probably use calcium aluminate cement, even though this would be good to 1250°C only).

ITC-100 does not seem to be easily available here.

A question: what kind of heatup rates did you get with your furnace on full power? I get over 100°C/min at low temperatures, and at 1000°C still

60°C/min.

You said you got 1°C/min at over 1200°C- I think mine still heats up much faster at those temperatures!

Does your alumina tube + ITC-100 have such a large heat capacity, or are there other reasons, like heat loss?

My mullite tube has quite a low thermal conductivity. I remember alumina ceramic having a much higher conducitvity. Does this lead to increased heat

loss at the ends?

The free ends of the ceramic tube on my furnace stay below 600°C (no visible glow) even at 1250°C inside the furnace.

Is that different with your alumina tube?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you gc and yes this shows that your design is robust. But I'm sure that the selection of materials is still critical because of the high

temperatures.

Yes, the ITC-100 was nice to work with. Time will tell how it proves out in the long run. Perhaps someone with more experience can tell us how to

prevent it from cracking. How thick was your Al2O3/MgO layer?

The relatively slow heat up rate is something that I noticed also as I remember you saying how fast your furnace heats up. I have to think that you

are right about the tube/coating heat conductivities being higher. My Kaowool conductivity may also be higher. I will see if I can find some

conductivity data for these materials.

| Quote: |

The free ends of the ceramic tube on my furnace stay below 600°C (no visible glow) even at 1250°C inside the furnace.

|

This was true for me too.

[Edited on 19-6-2008 by Magpie]

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

I would've used much more kaowool than you did Magpie. I think 2" as a minimum.

I have a forced-air propane furnace that I've lined for 1760C/3200F and I used 3" of 2400F kaowool and 1" of the 2700F material. That is topped off

with 3/4" inch of 3200F and an ITC wash. It is a large furnace, perfectly accommodating a #16 SiC crucible. Insulated as it is, if I hold that

furnace at about 1600C for an hour or so, the outside of the furnace becomes hot enough to melt the rubber off of my shoes! Around 750C for aluminum

casting, the shell is not warm at all.

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

I would've used much more kaowool than you did Magpie. I think 2" as a minimum.

|

Fleaker, I don't understand this comment. The alumina tube w/coating is 1"radius and the stovepipe has a 4" radius. My Kaowool thickness is

therefore 3".

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

GC I found the data for the 99.5% alumina. First of all I have an ID of 34mm vs your 32mm. Therefore your wall thickness is 4mm whereas mine is 3mm.

This means your tube has nearly 33% more mass (assuming equal densities) than mine.

The alumina has a sp. gr. of 3.8.

Its thermal conductivity is 50 BTU-in/(ft2-hr-F) at 800C, which, if I have done the conversion correctly, is 7.2W/(m-K).

I'm still looking for the conductivity for the 8 lb/ft2 Kaowool.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's a nice data sheet that compares mullite to alumina:

http://www.ortechceramics.com/material_compare.htm

It shows the mullite thermal conductivity at 3.5 W/(m-K) vs a value of 30 W/(m-K) for alumina. But this is at 20C. At 800C the k for the alumina

drops to 7.2 W/(m-K). I don't know what happens to the k for mullite at 800C. But it is likely still no more than half of that for the alumina.

2nd Edit: This website gives k = 3.3W/(m-K) for mullite at 800C:

http://www.techceramics.com/pdf/mulliteMV20.pdf

[Edited on 20-6-2008 by Magpie]

[Edited on 20-6-2008 by Magpie]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Magpie

I'm still looking for the conductivity for the 8 lb/ft2 Kaowool. |

Of course, you would have to integrate over the radius, because the thermal gradient cross-section has cylindrical geometry and is therefore expands

with radius, while at the same time the temperature falls and the kaowool becomes a much better insulator. If you want real numbers, that is. As I

recall, in the limit it comes out logarithmic, so you don't gain much by using a lot of insulation around something narrow.

120V * 8A is just shy of 1kW. Evidently, this furnace has an efficiency of roughly 1.3C/W.

Tim

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Tim I'm not trying to calculate a thermal resistance. I'm just trying to compare conductivities of my materials to those used by garage chemist in an

effort to explain my relatively slow heatup rates.

2nd Edit: The maximum voltage I can put to my furnace using my thyristor control circuit is 230VAC. At 230 volts and 9 amps the power would be 9*230

= 2070W.

[Edited on 20-6-2008 by Magpie]

[Edited on 21-6-2008 by Magpie]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

GC I have measured the electrical resistance of my furnace at 18 ohms at room temperature. It should be 26.5 ohms. So instead of delivering 2070W at

9 amps I was actually delivering something like 1458W. This is no doubt caused by internal shorts (coils touching). I suspect this is the main

culprit for my slow heatup rate.

It was difficult to keep the wire coils tight and evenly spaced. I tried to correct uneven spacing but the coils wouldn't stay in place. I should

have given this more attention, throwing on more nooses or even rewinding.

Could you measure your furnace resistance for comparison?

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Not sure if this is of interest, but the resistance of my 2070W Lindberg is 6 ohms. BTW it did not come with the controller that connects to the 4

contacts at the base...if anyone happens to have an extra one...Not that I really need it, because the Watlow 988 controller and Din-a-mite SSR are

outstanding little items. Works great on my little electric bunsen even. Glas-Col's too, using their built-in thermocouple, after switching the

controller from K to J. Highly recommended.

| Quote: | Originally posted by Magpie

I have measured the electrical resistance of my furnace at 18 ohms at room temperature. It should be 26.5 ohms. So instead of delivering 2070W at 9

amps I was actually delivering something like 1458W. |

Now, how did you figure your wattage? Please humor someone a little slower than many here with electricity; why isn't the observed potential and

current combined with Ohm's thingy relevant to wattage calculation in this circumstance?

[Edited on 21-6-2008 by S.C. Wack]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

Please humor someone a little slower than many here with electricity; why isn't the observed potential and current combined with Ohm's thingy relevant

to wattage calculation in this circumstance?

|

Yes, Ohm's law is relevant here. E = IR and P=IE, where E is voltage, I is current, R is resistance, and P is power.

By substitution then P = (I^2)R. So for a power of 2000W at 9 amps, the resistance should be:

R = P/(I^2) = 2000/81 = 26.7 ohms

With R at 18 ohms and I at 9 amps, P = (I^2)R = (81)18 = 1458W

For your Lindberg you say you measured a resistance of 6 ohms. Assuming your voltage is 120 volts, then the power calculation would be

I = E/R and P = EI = E (E/R) = (E^2)/R = (120^2)/6 = 2400W. I don't know why the discrepancy with your rating of 2070W, but the calculated result is

in the ballpark.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Power dissipated by a resistive load is defined as V*I. If you measured 240V and 9A, you were dissipating 2160W. Evidently, the resistance at that

moment was 240/9 = 26.7 ohms. Anything else contradicts either the voltage or current you in fact measured; 9A through 18 ohms develops V = I*R =

162V, far less than the 240V you know you have; likewise, P = V^2/R = 240^2 / 18 = 3200W is a current of 13.3A, which is not the 9A you measured.

The cold resistance will, of course, be much lower than the hot resistance. A factor of two difference shouldn't be at all surprising; over the same

range, the resistivity of pure iron increases something like tenfold.

If you measure the current draw at the instant of turn on, I think you will find nearly 13.3A. It's a much safer assumption that line voltage is

constant rather than current draw!

Tim

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I'm using a thyristor circuit to supply power to the furnace so don't really know the effective voltage applied to the furnace. I did not have it set

at full voltage.

I used a clamp-on ammeter to measure the 9 amps, which I'm assuming is a fairly reliable value.

The resistance of Kanthal A-1 increases 4% from 100C to 1200C as can be seen here:

http://www.kanthal.com/

[Edited on 21-6-2008 by Magpie]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

The clamp-on amperemeter only gives a sensible reading if you don't use a thyristor circuit.

The thyristor circuit "chops up" the sine wave of the current and makes an accurate measurement impossible for the amperemeter, which needs a sine

wave to function properly (that's what I think, although I don't have a clamp amperemeter. What I've said is certainly true for a normal electronic

amperemeter.).

You would have to use an analogous, electromechanic amperemeter in order to obtain the true value of the current.

With your ca. 18 ohms (as you've correctly pointed out, the resistance of Kanthal wire changes only little with temperature), the power of your

furnace will indeed be over 3000W, which is currently reduced by the thyristor circuit.

Try running the furnace without the thyristor circuit (not over 1000°C!)- I am fairly sure that you will get a temperature rise of over 100°C/min

then.

You didn't use preoxidised Kanthal wire, did you? Preoxidised wire avoids short-circuited windings due to the insulating properties of the Al2O3 oxide

layer on the wire.

The wire you used looks bright, so it was probably not preoxidised- this seems to be the reason for the too low resistance.

I did not use preoxidised wire either, but I did not have any touching windings.

The resistance of my furnace was the calculated 26,5 ohms.

Now, after repeated use, it has increased to 27,5 ohms (measured yesterday) due to oxidation of the wire, so the power has dropped to ca. 1926W (not

that this would be a big problem, but it demonstrates that the power of an electric furnace that uses resistance wire will slowly decrease with

continued use, and heating spirals are always a wear part).

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

GC thanks for measuring your resistance.

No, I did not pre-oxidize my wire. Never had heard or thought of such a technique.

I know the voltage sine wave is being chopped up but I still suspect that I'm measuring reasonable values for effective current at the higher amperage

levels.

I just now plugged in the furnace, turning up the power until I measured 9 amps. Then I measured the voltage at the furnace terminals. It was 140

volts. This would yield a power consumption of 140*9 = 1260W. Again, I know this is just a rough value.

The reason I have been limiting my current to 9 amps is concern over burning out my Kanthal wire.

Edit: Using the two crude measurements of 9 amps and 140 volts R = E/I = 140/9 = 15.6 ohms is calculated. This is not too far off from my measured

18 ohms, which should be solid.

[Edited on 21-6-2008 by Magpie]

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

@Magpie,

Sorry, for some reason I read

"4. I used 1" (25mm) Kaowool insulation vs GC's 25mm insulation that he suspects contains some ZrO."

and actually thought you'd be fool enough to use an inch of insulation. Reading it over again, I wonder what exactly I was thinking when I read that!

Still though, it seems odd that your furnace is becoming too hot to touch on the outside and that it takes so long to heat up?

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Fleaker I was pretty sure you had just misread something, but I wanted to clear it up.

Now that I have realized my lower power input, it is not surprising to me that my furnace heats up much slower.

My shell being too hot to touch did surprise me, but when you think about it the power has to be dissipated somewhere. Garage chemist said his shell

might char wood at 1300C. I don't know if mine was that hot but it was getting there. It seems that the commercial tube furnaces all have a

secondary shell of perforated metal, probably for the same reason.

An interesting experiment would be to compare the power required to keep our respective furnaces at a selected temperature, say 1000C or 1200C.

Getting believeable, or at least comparable, E or I measurements would be tricky, however, since we are both chopping the sine wave with thyristors.

|

|

|

| Pages:

1

2

3

4

5

..

9 |