| Pages:

1

2

3 |

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Yes, that is accurate.

I can't stress enough how friggin' difficult it is to make tools, solvents and atmosphere dry enough and clean enough. I don't believe I can do it.

No, it's the same logic I used with my Na and K ampoules (another thread). The only way to do it is in a sealed system and as a liquid or a gas.

If you think about it, if anyone could simply use a glovebox and dry supplies, there would already be silver colored metal samples. That suggests that

another approach is needed.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Very pretty and shiny Ti & Pb samples !

Googling brought up 10.1.1.16.9477.pdf (Decker et al) which is a document that references work by Bridgman (1941, 1942) who apparently worked with

elemental Ba in some kind of high-pressure piston apparatus, discovering something called Ba I-II and Ba II-IV transitions.

Tantalisingly the first document just mentions :-

"... oxidation problem encountered with cesium and barium can be minimized through more careful handling procedures".

Other people who worked with Ba are mentioned :-

Kennedy & LaMori, 1962, 1963

Barnett, Bennion & Hall, 1963

Hopefully one of them published something that could help out here.

Woo ! It also mentions Zeto et al, 1968 who used a mix of pentane & iso-pentane with the Ba.

[Edited on 23-11-2016 by aga]

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

Dan, do you need some quartz tubing?

I have a lot of spare 25IDX30 mm OD GE 214 tubing. Bit heavy walled and quite large so you'll need a beastly torch but I can give you a few dozen

feet. It won't take the pressure for black P. When I did that I used I think 12 mm tubing with 2 mm walls.

You probably know them, but check out technical glass products up in Painesville, OH. Nice guys that can probably make for you premade ampoules if

you want.

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

Heavy Walter

Hazard to Others

Posts: 127

Registered: 17-12-2015

Location: Argentina

Member Is Offline

Mood: No Mood

|

|

Dan

Quartz tubing up to 25 mm (1 mm wall) can be worked fine with oxygen/propane torch.

But protective glasses must to be special, for quartz.

[Edited on 26-11-2016 by Heavy Walter]

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Quote: Originally posted by Fleaker  | Dan, do you need some quartz tubing?

I have a lot of spare 25IDX30 mm OD GE 214 tubing. Bit heavy walled and quite large so you'll need a beastly torch but I can give you a few dozen

feet. It won't take the pressure for black P. When I did that I used I think 12 mm tubing with 2 mm walls.

You probably know them, but check out technical glass products up in Painesville, OH. Nice guys that can probably make for you premade ampoules if

you want. |

Fleaker,

Thank you for your very generous offer, but I suspect that I don't have the capacity to work it.

What I'll have is hydrogen and oxygen and it can be burned in one of two ways. I can use my oxyacetylene torch head or I can use the moderately sized

surface-mix torch I bought a couple years back (pictured). The latter is what I'm guessing is better. While I have many hundreds of hours of

glassblowing experience, 99.9+% is with borosilicate. I know enough about silica to know that there is precious little overlap.

(Oh, incidentally, in the black P work, did you use the standard Au/Sn method or did you try the more recently found method based on SnI4 alone?)

Heavy Walter,

Thanks for the caution. I'm aware that I have no sodium D lines to contend with. My understanding is that a dark grade of gas welding goggles is

totally acceptable. I tentatively plan to use my self-darkening welding mask, since it will also shield from all the radiant heat.

I wanted to avoid C based fuels because of the impurities they supposedly leave in the silica.

[Edited on 27-11-2016 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Heavy Walter

Hazard to Others

Posts: 127

Registered: 17-12-2015

Location: Argentina

Member Is Offline

Mood: No Mood

|

|

Dan

I can see you are already trained in glassblowing.

Great!

Certainly the self-darkening welding mask will be good.

We wait for your setup and results.

|

|

|

Fleaker

International Hazard

Posts: 1252

Registered: 19-6-2005

Member Is Offline

Mood: nucleophilic

|

|

The mask is the way to go. I like it for melting platinum as well.

Dan, we burn acetylene and oxygen and hydrogen and oxygen out of the same torch. They work interchangeably in my experience and the guy at Praxair who

sold me the torches said they can be used for either gas. Also, oxymethane has been OK on small quartz in my experience. A good burner is the most

important thing with quartz work.

When I did the black P prep it was using gold additionally. I have not tried the newer method--aside from the nuisance of the gold recovery, what

advantages does it confer?

Thanks!

Neither flask nor beaker.

"Kid, you don't even know just what you don't know. "

--The Dark Lord Sauron

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Quote: Originally posted by Fleaker  |

When I did the black P prep it was using gold additionally. I have not tried the newer method--aside from the nuisance of the gold recovery, what

advantages does it confer?

Thanks! |

I think that the main driver was the avoidance of having to pay for Au. Fewer co-products are formed, but my understanding is that separation of the

product isn't significantly complicated by these phases, so this isn't very important.

Are your black P syntheses written up here on SM? I'll check, because I'd love to read them.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

This will probably be slow, like my last work, but less so, I hope.

Because of funding in universities, we are hella busy from October to December or January. I've only been at home a few days in the past two weeks and

I still have a Detroit, Atlanta, and two Florida trips before end of January.

Generally, I can't contribute as much as I used to. We sell more and more gloveboxes all the time, but the people available to handle all of the

troubleshooting has gone down. At any given moment I, personally, usually have a half-dozen simultaneous emergencies across the US and Europe. Too

busy.

[Edited on 12-12-2016 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

My world was just rocked. I received an e-mail with this picture. Somebody has already achieved the holy grail. Trying to find out the source of this

sample.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

VIOLiN

Harmless

Posts: 7

Registered: 13-2-2017

Member Is Offline

Mood: No Mood

|

|

Polycarbonate Permeation and Adsorption By Oxygen Problem

Quote: Originally posted by Praxichys  | Hey, check this out:

http://pubs.acs.org/doi/abs/10.1021/am900206e

Outgassing of Oxygen from Polycarbonate

Sung In Moon , L. Monson and C. W. Extrand *

Entegris, Inc., 3500 Lyman Boulevard, Chaska, Minnesota 55318

It looks like polycarbonate is susceptible to permeation and adsorption by oxygen. Baking while scrubbing may help, or (unfortunately) replacing the

PC with stainless steel or glass sheets.

Nice glovebox, by the way.

[Edited on 23-1-2015 by Praxichys] |

Hi! I know that this was discussed earlier in the thread, but I just had an idea regarding the permeation of the polycarbonate by oxygen. It might be

especially difficult considering that your glovebox is already built, but could the permeation be reduced by taping the polycarbonate with the oxygen

impermeable metal (aluminum) tape? It surely wouldn't be as good as the glass or SS, but hopefully it could improve the glovebox's performance. ????

And thank you Mr. Vizine for all of the work you have done into sharing all of your projects. I have really enjoyed all of your work on element

samples and thorium production. It has been a joy to read, and I have gotten many ideas! Also, thanks for your ideas on the glovebox. I am currently

building a glovebox, and your ideas have helped tremendously!

Thanks!

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Hi VIOLiN,

I'm glad you enjoy my work and thank you for your comments. You are all right, of course, and I had the feeling it may be difficult or futile.

Also, whenever a new glovebox of SS and glass is started, it still takes days to hit 1 ppm moisture. Because, unlike O2 which just floats around

waiting to be removed, water has to desorb first. So, everything in the gb was giving off impurities.

And N2 diffuses through your gloves.

The atmosphere was fine for lithium, but that isn't a high bar.

I don't entertain any hopes whatsoever of handling shiny barium in a homemade purged glovebox.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Bezaleel

Hazard to Others

Posts: 444

Registered: 28-2-2009

Member Is Offline

Mood: transitional

|

|

Dan, thanks for posting all your experiences and labour in this thread in the first place! I agree, it is very enjoyable to read, not in the last

place because it is well written.

With the oxygen/water removal problem you encountered, is there a reason you have not tried the following:

Water removal. Could you use a heating element and heat the gas inside the glove box to, say, 120C? I guess this will speed up desorption of H2O

considerably. I don't know whether the gloves and sealing will withstand this temperature without deteriorating, though.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

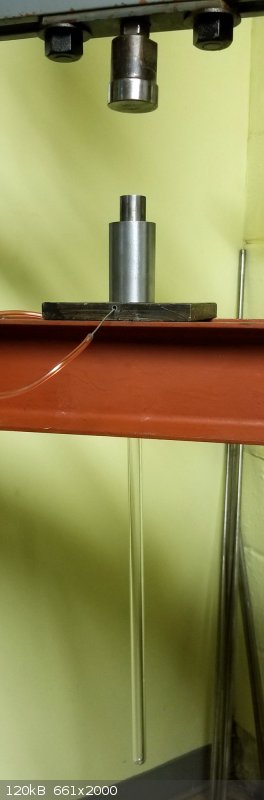

I had all but given up on ever being able to prepare good-looking samples of either strontium or barium. Now, perhaps a path has appeared. My previous

best attempts in a purged glovebox yielded what you might call mixed results. The sample is clearly metallic, yet there is very little silver

coloration, a little bit more golden color, but blue and brown predominate.

I've previously noticed, most recently with europium, that when working with certain soft metals, extruded samples of the metal often seem to be more

resistant to immediate attack by the atmosphere than samples that were prepared by scraping, filing or sanding. Maybe this implies that extruded

samples present less surface area to the atmosphere than samples prepared by abrasive methods. I've done absolutely no research to back this up and

have absolutely no proof that this is the case, but the results deserve further consideration.

I've had scraps and shards of barium metal stored under toluene saturated by argon since I began this thread. They're essentially dark gray in color.

I couldn't help but wonder what would happen to them if I simply loaded a pile of it all a into a steel die with a 1-inch diameter steel plunger and a

3/8 inch hole for extrusion drilled into the bottom and exerted a lot of force.

I set up my hydraulic press so that the die sat on a thick steel plate with a three-quarter inch hole drilled in the middle I situated the extrusion

hole of the die directly over the hole and underneath the hole was a dried stainless steel cup holding anhydrous toluene. I exerted nearly the full 12

tons of pressure that the hydraulic press was capable of, and when the ram failed to move any farther, I lifted the dye to see a clearly silver

colored extrusion of barium metal. I immediately snipped it off the dye from which it was protruding letting it fall back into the original container

from which the barium came. The attached picture shows that the metal is clearly silver on the outside. Obviously, the inside of this extrusion is

still riddled with oxides and nitrides. However, the suggestion is that if I started with a solid ingot of barium metal, the sample might be pretty

good.

It would still need to be ampouled, and you can't take anything for granted with barium, but so far this is better than I had any reason to expect.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Bezaleel

Hazard to Others

Posts: 444

Registered: 28-2-2009

Member Is Offline

Mood: transitional

|

|

Dan, I so much appreciate your persistence in pursuing this difficult goal! Thanks for giving us such a lovely read.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Hi Bezaleel,

Sorry that I missed your 2/25/17 post. I became dispirited about my chances of success and had no further ideas. Butyl rubber has a service ceiling of

150 degrees, so I could heat the walls. But, with knowledge gained in the last couple of years from a researcher using a gb that we, and he, custom

modified for the task of handling barium, I realize that I couldn't succeed in a home-built purged gb. Anyway, the glovebox was converted over for

handling thorium a while ago and it will never again be suitable for "regular" tasks.

These barium results seem too good to be true. I wouldn't have accepted this story from someone else unless he had a picture, which I do.

Consider this, the barium was in ~ 15 dark little shards, with aspect ratios of maybe 8 - 10:1. Why don't I see discontinuities along the length?

Bands of dark gray...Could it be that this picture is deceptive? Btw, by the next morning, the silvery metal was dark gray.

No sense in pondering these relative unknowables. I purchased a solid 50 g Ba ingot yesterday and when I return home from my current business trip,

I'll try some additional experiments.

PS. Please forgive my proofreading shortcomings. Word recognition software has its limits. I caught the first "dye" and changed it to "die" and

successfully ignored both following misuses.

Oh, and to follow up on the picture of the silver chip in the ampoule. I bought one. It arrived dark gray. It was returned dark gray. It (the silvery

one) was made in a glovebox right after commissioning, they cannot duplicate the results now with the nitrogen that has diffused in since then. This

guy is on eBay. He still uses the silver picture of the sample he can't actually deliver.

[Edited on 2/27/2019 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

An appropriately solid ingot of Ba metal was procured.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

After the unexpectedly good results that extrusion seems to have provided, I researched the subject and found that extrusion can be used for

purification of metals. It can also serve to distribute impurities uniformly. There is more than one type of extrusion, it depends upon what part

moves. When the ram moves it tends to push everything with it and so part of the extrusion will be lessened in impurities and other parts will be

increased. For purification purposes, the ideal configuration is a stationary container into which a hollowed out ram is pressed. This is fairly hard

to implement while maintaining a highly pure environment around the extruded sample and so I'm going to try the simpler method first.

I've included three pictures below. One simply shows all of the pieces. Another shows details of the supporting plate. It has a lip machined into the

hole which supports the expanded lip on the glass tube. A purging tube, for UHP argon, was installed by drilling sideways through the plate. The sharp

band in the tubing was achieved by putting a copper wire inside, bending it, and then removing the copper wire. The first material that I'm going to

use this with is europium because it's easier than barium. As the long extrusion of europium metal enters the tube, I don't expect that it will break

at any point. When the pressing is done it will probably just be hanging from the bottom side of the extrusion hole. This is the less than scientific

part. I'll need to quickly lift the extrusion apparatus and use a sharp chisel to separate the extrusion and allow it to fall. A small clean stainless

steel spring at the bottom of the glass tube will serve to cushion the impact. Then I'll seal the tube with a rubber stopper and lots of Parafilm

until I'm ready to try sectioning and ampouling.

[Edited on 3/29/2019 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

As an example of wasting time, I'd like to offer up my most recent experiences with the extrusion of reactive metals for a quick method of cleanup. My

goal is actually two-fold. I'd like to try and repeat my extrusion of what appeared to be a rather silver-colored sample of barium a little while ago.

I also need to find a way to purify about a kilo of europium which is partly solid ingot and partly dendritic, unfortunately, more dendritic than

solid. I decided to start with the europium because it is considerably less reactive to the atmosphere.

There's no way to clean up the dendrites, short of remelting the metal in a disposable tantalum crucible under inert gas to separate the clean metal

from the air-reacted metal. I don't currently possess the requisite equipment.

I had a length of one and three-quarter inch outside diameter steel rod with a 1-inch hole down the center. The hole was not done by drilling or on a

lathe, probably more by the process known as piercing. As such, the hole is not 100% perfectly cylindrical and it's also made of soft steel. I weld a

steel plate onto the bottom and drill a hole the size of the extrusion that I desire. The plunger is also soft steel and I made the mistake of giving

it perfectly squared off edges. There should have been a very small conical section ideally. There was also some play in the fit, I'd estimate it to

be a few tenths of a millimeter, perhaps as much as 0.5 mm.

As I attempted to extrude europium from a 1 inch diameter die through a 3/8 inch diameter hole (that calls for much lateral flow of metal and that is

pressure intensive, a larger extrusion is much easier) the high forces required caused europium to flow up the side of the die which had the poorest

fit with the plunger. With every millimeter of forward movement, I was causing more sideways pressure to be exerted on the plunger. The plunger,

having the aforementioned squared off edges, saw fit to dig into the side wall of the die and within a few more millimeters of forward motion it had

caused gouging, galling and had seized-up. The plunger wasn't going anywhere even with a full 12 tons of force on it.

I did the only thing that I could do, I removed the unit from the press, cut off the small extruded Eu nub, located a 3/8 inch diameter hardened steel

rod about 2 inches long and pushed it into the extrusion hole using the press. Eventually, I got the plunger out and salvaged the europium with

minimal loss of material.

This all leads me to precisely where I found myself when I was pressing thorium powder into metal disks prior to sintering. I need a die and plunger

set with a precise fit, preferably entirely made of hardened steel, and also one that can be adapted for extrusion rather than just pressing pellets.

A quick search of eBay revealed that not only couldn't I find exactly what I wanted, but things that were reasonably close and might be adapted were

quite expensive, which should have been no surprise. The little tiny 10 mm hardened steel die that I bought for processing thorium was $40 to $50

dollars. The price of such units goes up very quickly as the size does.

Now I have two choices. I have two lengths of very nearly 1.00-inch outer diameter hardened steel rods, each about a foot long. An abrasive cut off

wheel would allow me to take a section of the appropriate length. I also have steel blocks that were precision drilled with 1.00-inch holes. I suppose

my only practical/affordable solution at this point is to make my own plunger and then try it with these precision drilled blocks. I really hate the

idea of welding steel plates to these blocks and so perhaps I will try simply clamping a metal plate to the bottom side.

With respect to Maroboduus' suggestion, on the face, it's attractive, in practice it doesn't work very well at all.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

| Pages:

1

2

3 |