| Pages:

1

2

3

4

5 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by 12AX7

| Quote: | Originally posted by Rosco Bodine

Anyway , if you got something better for the job ,

well I've showed you mine , ........

So now show me yours ,

|

In the other thread, someone already posted one as good as I would come up with. Simulation results were even provided.

Tim |

Aside from showing a 1.5 watt control pot which by itself

costs more than my whole project , and having too low a voltage rated Mosfets , no surge or static protection , and no startup pulse logic , no level

control for defining the operating parameters , as well as requiring complementary N/P Mosfets ......it's just wonderful .

If that's the best you could do .....

then why do you have a low opinion of the practical design shown here which is sorted out in all its specifics and ready for the soldering and testing

?

[Edited on 21-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

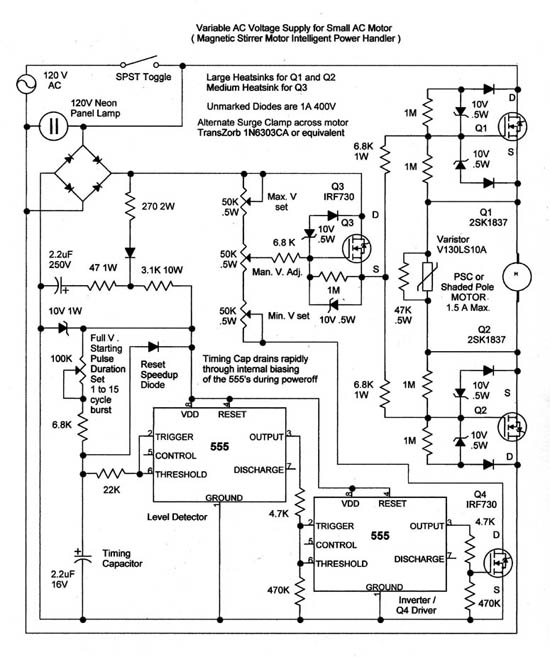

Here is the final revision schematic ( I hope ) . The graphic is cleaned up a bit and I added a couple of resistors and tweaked the values for better

noise immunity . An added resistor across the varistor is something of a safety device , since without it , and no load on the output , a meter test

or probe might show no voltage across the output , if it was a high impedance probe .

The circuit which energizes the gate and turns on the output mosfet is completed through the load , so without some sort

of lower impedance " dummy load " there across the output continuously , the " pseudo " open circuit might appear to instruments not to be energized

when it actually would be very quickly energized if it was touched by a finger for example  So I figured it was safer to have the output unambiguously energized any time the circuit is powered up , and put a small load across the

output to assure this . So I figured it was safer to have the output unambiguously energized any time the circuit is powered up , and put a small load across the

output to assure this .

Most of the parts for the project are on hand now and the few remaining parts I should have soon . I have some

other business to catch up while waiting on the remaining parts to arrive , and will probably take a break from this

work before beginning the construction of the prototype ,

since I have reached a " stopping point " with the completion

of the theoretical model . The apparent simplicity of the finished schematic for something like this is very deceptive about the amount of mental

work which goes into sorting out and specifying the details of such a design , especially when the design is unconventional . An electrical schematic

is inherently a complex mathematical expression , and

it has been plenty of mental exercise developing this idea

for what seems so simple now in hindsight . I look at this

schematic and realize it took me three weeks to sort this

idea out and get the design down on paper in a buildable

specification . It may not be perfect , it is experimental .

But it is good enough of a theoretical model for me to proceed with the build using this as my " blueprint " .

Anyway , I deserve a break now and I am taking it

[Edited on 17-5-2007 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Today I found a way to get a quality color graphic file

of compact size to export in PDF format from my

ECAD software and am attaching it here because of

the usefulness of the red highlighting which shows

the interconnections between discrete components .

This attachment can be high resolution printed in

color or in black and white if you specify a black

and white only output in your printer properties .

Sorry for all the bulky JPEGS posted earlier . Since

there is nothing in the ECAD help files about doing

any sort of exporting of the ECAD output file as

JPEG or PDF file types , I had to improvise some

way to share the file content , which involved

printing , scanning , and image editing before .

But today I found that I could use a freeware

" virtual printer " from Adobe called Acrobat PDF Writer

to " print to file " ( a .pdf file ) from the print command

in my ECAD which by default only prints a hard copy

on paper , .....except to create a PDF , I just select

a different " printer " to send the " print job " ......

which is the " Acrobat PDF Writer " , and it makes

the PDF file that I am needing . A very handy little

freeware tool from Adobe ....as good for PDF filemaking

as is Acrobat Reader good for viewing those files .

This color graphic ECAD output file as PDF is higher resolution and only one quarter the size of some of the black and white scanned JPEG files ,

which were a headache to get

clear at any reasonable file size .

Attachment: AC Power Handler for Magnetic Stirrer Motor experimental prototype schematic final.PDF (26kB)

This file has been downloaded 1706 times

|

|

|

Pommie

Hazard to Self

Posts: 70

Registered: 6-2-2005

Location: Australia

Member Is Offline

Mood: No Mood

|

|

Rosco,

An easy way to get any image into a file is:-

Get the image you want on screen in the application it was developed in at the size that you want it.

Press the key marked "Prt Sc"

Go into your favorite image editing package.

Start a new image.

Past the clipboard into the image.

Crop and resize as required.

Prt Sc copies what is on the screen to the clipboard.

Mike.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I have a screen capture and printing utility called SnagIt

which does something like what you are talking about and it will output various file types . I tried it but the file size required for achieving

comparable resolution just doesn't come near to the small file possible with a good direct output to Acrobat pdf . There is also a problem when the

aspect ratio for the image is optimized for printing on an 8.5 X 11

sheet of paper , rather than for the screen . But the print

to PDF takes care of that sizing and optimizing automatically .

Open that file I just posted above and use the enlarge

button to zoom in and magnify the page to maximum ,

which is 16 X normal view , 16 diopters or 1600% magnification ......and the image quality holds

perfectly clear and precise , which is amazing for a

a 26KB page file . That is only possible because the

PDF file is largely composed of the actual PostScript

descriptor language which is the " raster file " for

screen or printer and the efficiency and precision

is unmatched by anything else ....precisely why

PDF and PostScript are the industry standards .

I may have spoken in error about the Acrobat PDF Writer

being freeware , I think it is the PostScript Virtual Printer that was the actual freeware and , the Acrobat PDF Writer is bundled as a feature of the

Acrobat Pro Version , which I have .

[Edited on 24-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

update on prototype stirrer

The experiments which I have been doing lately

involves evaluations of several PSC motors to see

what is their variable speed performance , when

supplied with a variable voltage and driving a

fan load , which is a quadratic type load similar

to the load which will be felt by the same motor

used in a stirrer . For these bench tests I have been

using an ordinary variac as the power supply ,

as I have not yet built the solid state power supply

described in the attached schematic , which is one

of a collection of several solid state controls which

will be evaluated . For these tests I have been

looking at the PSC motor performance , and it appears

good enough that a variety of different controls may

be useful and provide satisfactory performance , the

choice depending upon how critical is the application .

The power supply type is likely not so critical as is the matching

of the motor to the driven load so that a very smooth speed increase

is produced in response to the increasing power input .

The speed decrease should

likewise track nicely with decrease in power input .

I have tested more than a half dozen different PSC motors

of various power and voltage ratings from 1/20 to 1/3 hp .

Guess which one I like  , that's right the big one , that's right the big one

The motor selected as having characteristics which fit

my best guess as a candidate motor for the prototype

is a 1/3 hp 230 volt 1075 rpm motor which was originally

built for use as a condenser fan motor for an HVAC

application . But the motor will be run in highly derated

fashion , across the voltage range of perhaps 15 to 110 volts ,

so the actual plate rating of the motor is something

like 4 times the actual maximum loading which the motor will

ever be run in the " off label " use which I am performing .

It is a 48 frame motor with a 1/2 inch shaft .

One of the things I quickly discovered from testing motor

performance is that the " dynamic range " of the motor

performance is extremely important , that is the greater

the range of operating voltage possible for the motor ,

the better the motor will perform , and some motors are

better than others in that regard . A good candidate motor needs

to be able to start reliably and run at about 13% of its rated voltage

without any further modding to enhance its low end performance .

After certain changes are made , like increasing the capacitor value

by about 66% over the plate value used for conventional fixed speed high efficiency ....

the minimum starting voltage for the motor can be decreased

by about one third below the stock performance .

The precise capacitor value which is optimum

must be determined by carefully testing

and comparing and charting the results for a particular motor ,

recording the current draw and voltage incrementally

across the operating speed range for the motor both unloaded and loaded ,

on the stall slope speeds particularly , but also looking at what happens if the speed increases into the normal operating range where the counter-EMF

or " regeneration " voltage becomes a factor and excessive capacitor current could develop .

It is a tedious process selecting the optimum capacitor value for

the particular application . PSC motors which seem to

fit the requirements best have larger than average capacitor values for their hp rating in usual stock configuration and

this is some indication of a more hefty auxilliary winding ,

a motor which will have a higher starting torque and stall torque by design than the average motor . These motors

will also have a bit lower ultimate efficiency than motors

designed to labor less and accellerate more slowly up to

their near synchronous operating speed where the main winding then does most of the work .

A factor which I have discovered has bearing on the minimum starting voltage for the motor is the static friction

of the bearings and the lubricant film on which the weight of the rotor is resting . It is something like the effect of a sled

sitting on the snow , it requires an extra force to breakaway

the runners sitting at rest , due to " adhesion " forces , but

once that initial " slippage " occurs ...away it goes in motion .

To eliminate the weight of the rotor on the thrust bearings

which is causing this adhesion , I am installing a magnetic thrust bearing consisting of ring magnets around the exit shaft which will levitate or

nearly levitate almost all of the rotor weight , so that the only remaining resistance to rotation on starting is simply the viscosity of the oil film

on the bearings . This should reduce the starting power for

the motor from its stock configuration minimum of about 15 Watts input , to less than 5 Watts being required for the motor to reliably start and run

without stalling at very low speeds which would otherwise not be possible without

using a magnetic support bearing . I will provide more

information on what are the results of my tests of the

magnetic support bearing , when this part of the prototype

is completed . I have the magnets for the bearing and also

have the magnets for the driven rotor , but the mountings

have not yet arrived for these magnets , and I will update

the progress after these parts arrive .

The motor in derated operating mode appears to be

still operating in excess of 50% efficiency at the shaft while

driving a 16" four blade fan load , and observing the

ammeter dropoff as the rpms reach past 80% of synchronous

speed .....so the top end penalty on efficiency is under thirty watts from optimizing the low end and stall slope speeds performance . The input

power and speed response

is very linear across the entire stall slope rpm range ,

and the practical range is roughly from 6 Watts to 175 Watts

or taking 50% of that at the shaft as actual mechanical

output ....the rest being dumped easily as heat .

A large blower wheel will be used as a fan canopy to

provide cooling for the motor . And the drive magnet

armature is a 5" length of 1" wide and 5/8" thick barstock

on which are mounted each end N40 block magnets which

are 2" long by 1" wide by 1/2" thick , doubling this thickness

by pairs if required . The planned configuration will allow

an actual delivered horsepower at the drive magnet

across the range from .004 to .117 hp , a 29.3 to 1 control range ,

or from 3.4% to 100% output as real power . If this

motor to load match is accomplished as predicted , then no

elaborate power control schemes will be required for open loop operation which would be adequate for non-critical

applications . The motor has enough torque to pull any

hill without needing a cruise control and without laboring too much under any but extreme viscosity change conditions ,

ordinary speed variations should be minimal even without

any active feedback speed control . The starting torque of

the motor is also sufficient that it appears that nothing

beyond an ordinary variac having its minimum voltage pinned

to a fixed limit for starting , or an adjustable minimum starting voltage relay added to the motor ....is all that would be needed in the way of a

power supply

What could you do with this stirrer ? Stir anything from

a 500 ml beaker ......up to a 200 liter barrel  , ,

even coupling through the bottom of a hardshell mantle

sitting on top . I am intending to establish a new standard

for " heavy duty "

The thing may not have to go on casters , but it is

moving that direction weightwise .....it looks like

maybe 35 pounds for the whole shebang . Ever noticed

how it seems like any equipment that is worth a damn

seems to have a bit of heft to it ?

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The magnetic support bearing works !

The mounting hub for the magnetic support bearing

arrived the other day and has now been installed on the

motor shaft . I am doing the first testing today ,

and it is already confirmed that my theory was correct

about the weight of the rotor itself and its static friction

on its thrust washer bearing , being a large determinant

for the minimum starting voltage , the breakaway voltage

for the motor . Evidently half or more of the static friction

which must be overcome by torque from the stator field magnets to cause the rotor to breakaway into rotation , is indeed friction from thrust load

present simply from the dead weight of the rotor which weighs several pounds .

Without the magnetic support bearing , the minimum

positive reliable starting voltage was 28 Volts @ .70 Amperes

which is 19.6 Watts of minimum reliable starting power .

With the magnetic support bearing installed and adjusted to

levitate the rotor , and driving the same test load , the

minimum positive reliable starting voltage reduced to

16 Volts @ .41 Amperes which is 6.6 Watts of input power ,

only one third of the previous input power required as

a minimum reliable starting power

Quite a difference , and this is important for the slow speed performance . The dynamic range from minimum power

input to maximum power is tripled (2.96) , simply by the addition of the magnetic support bearing .

It appears certain that indeed a variac alone would be

sufficient as a power supply for an open loop speed control

which would have adequate speed stability for any but

the most exacting sorts of applications . I mentioned this earlier and it appears that simply pinning the lower limit of

the variac or using a set voltage tripped relay would be

sufficient for setting a minimum powered on voltage ,

but this is not really essential as protection since the input

power is so low , it doesn't matter if the motor is stalled

or not ....it likely wouldn't overheat and has an auto reset

thermal breaker in the motor for protection anyway .

At higher power settings , some sort of " stall detection "

switch could be used to detect any abnormal condition like

could occur in stirring a thickening slush of heavy crystals

which might cause a problem . Perhaps some sort of

motion detector or airflow sensor input combined with

a voltage comparator , and a settable delayed response

relay could be configured as an automatic breaker for

the stirrer when it is left operating unattended overnight

for example . This could automatically shut down the unit

if a stall or abnormal condition occurred . It is not

certain to me that this sort of added circuitry is essential ,

given that the thermal protection breaker in the motor itself

would also function in such circumstances , although more

slowly in its response , it would still get the job done .

Anyway , the motor performance on the bench looks

good at this point with the addition of the magnetic support bearing , and the AC power simply being supplied by an ordinary variac .

The motor is an A.O. Smith #175 1/3 hp 1075 rpm 230 Volt

motor , being run at 16 to 125 Volts . The endshields were

removed and supported on phenolic blocks , and a 1/8" pin punch and hammer were used to punch out the 13 vent slugs

on each endshield , to allow for cooling airflow . The capacitor value for reduced voltage operation and improved

performance for this niche application is changed to 12.5 uF

at this designers specification , after much testing has shown

that value optimum , as opposed to the 7.5 uF value which

is the manufacturers recommendation for rated voltage

operation at rated output and rpm ....which is of course

irrelevant to this application . I have found this capacitor

value change to be about the ballpark proportional change desirable for operation of a motor in a derated scheme of

approximately half the rated voltage . It may vary a little

either way depending upon the amount of asymmetry present about the auxilliary winding versus the main winding , for optimizing lower voltage and

stall slope performance , and should be tested by trial and error

carefully charting the performance , and watching for

the power efficiency " sweet spot " for a given motor on

the stall slope , without undue circulating current losses

at the higher speeds and unloaded speeds .

The ring magnets are .51" ID X 1" OD X 1/4" thick N40 .

A sheet of .005 brass shim stock was wrapped around

the .4998" motor shaft to align the ring magnet concentrically

around the shaft , a very small amount of silicone grease

applied as a bore release agent and the ring magnet epoxied

to the bearing housing facing where the shaft exits the motor . When the epoxy was set very firmly , but not yet

completely cured , the shim was pulled out leaving the ring

magnet positioned with a .005" clearance fit between

the sides of the shaft passing through the opening

in the ring magnet .

A second identical ring magnet was mounted against the

face of a machined steel hub having a 1/2" bore and 2 set screws spaced 90 degrees . A 1/2" drill bit shank was

inserted through the hub whose bore was lightly greased

and the brass shim was again used to assure concentric

alignment of the ring magnet , epoxied to the hub , being

certain to position the like pole of the exposed face of the ring , to correspond with the exposed like pole of the

first magnet mounted on the motor . Again , when the epoxy had set firmly enough that the magnet would not move , but was not yet fully cured , the

shim was pulled

out leaving the magnet aligned concentrically with the

bore of the hub , in a way that would also assure alignment

of the faces of the two ring magnets in operation later .

After the epoxy set completely , the hub mounted magnet

was placed on the motor shaft and moved downward until

there was about 1/4" air gap between the faces of the

repelling rings , the gap adjusted until the repulsion force

levitated the weight of the rotor , and the set screws tightened to fix the position for the rotating magnet which

turns with the shaft above the stationary magnet on the face of the motor housing . The rotor can be seen to be

floating in the slight shaft endplay distance when the shaft is

pushed down by fingertip pressure on the end of the shaft ,

or lifted up slightly , and the gap can be adjusted very easily to levitate the weight of the rotor , so it has a little endplay

both up and down as it is levitated by the magnetic bearing .

It is a very slick setup  The motor manufacturers should just build 'em this

way to begin with , and save me the trouble of putting them right The motor manufacturers should just build 'em this

way to begin with , and save me the trouble of putting them right  But the

magnets are sort But the

magnets are sort

of pricey at about ten bucks apiece which makes for an expensive bearing , but one that will never ever wear out

To use this kind of magnetic bearing requires about 3/4" of unflatted clear round shaft emerging from the motor , before any milling cuts for the

flats on the shaft , some motors will

have almost no clear round shaft length , but a few will

meet the requirement .

There have been concerns expressed by the motor manufacturer about the potential for sleeve bearing damage

in a motor running less than 500 rpm due to the failure of the oil to circulate from the slinger washer . I am unsure

about how much or little problem this will prove to be for

a motor having babitt sleeve bearings with oiler wicks ,

so long as it is kept well oiled and not used continuously

at only low speed .....my opinion is it won't be any problem

for an intermittent duty application , but maybe after a month of continuous windmilling yes it could be a bearing would go dry . The cure is

replacement with sintered bearings if the dry bearing concern should ever become an issue for the solid sleeves . A ball bearing motor can be used

as is , and depending on the quality of the bearings ,

may not even need the magnetic support bearings to

start at an acceptably low voltage . The minimum starting voltage is not a figure that is published by the manufacturers

which would simplify things greatly . But the fact is that

the manufacturers don't really want to admit that PSC motors driving a quadratic or " fan load " can be speed controlled using a variac . Why tell

people who could be their customers for a six times more expensive ECM motor ?

So it is worth testing any ball bearing motors which might seem likely candidates , you might find the one that does

exactly what the manufacturer knows it will do but will never tell you about . In fact they will lie to you about it before they will level with you

about it .

Cooling could be supplied by a narrow blower wheel inverted to enclose the end of the motor which will just slip inside it , so that the wheel draws

its air through the motor .

I am unsure that this rather extreme measure will even

be needed . The rotor has some small vanes on its ends

which create a bit of airflow , and at low speeds there is very

little power dissipation which the motor housing just seems to heatsink without even feeling warm to the touch .

It may be that the main magnet rotor can simply have some

aluminum blade appendages fastened to it and this will

provide ample air circulation for cooling , as a sort of

paddle fan assembly .....and I will probably try this first

since indications are it will be sufficient and simplify things .

A tripod body band mount will probably be used to mount the motor to a heavy baseplate with rubber feet . The rotating parts will be dynamically

balanced so the stirrer runs smoothly and quietly .

Everything seems to be right on track at this point , with no

surprises really except that the motor seems to have better performance than was expected ....which greatly simplifies

the speed control scheme . This thing could end up requiring

absolutely nothing in the way of solid state electronic control , simply for the good balance of mechanical components ......being a nuts and bolts

project versus any control circuitry problem at all . I won't know for sure on that score until I actually have a drive magnet armature on the end

of the motor shaft spinning closely underneath an aluminum plate , and driving some stirbars through their test paces . But so far my guesses have

been on track and

my guess is that the eddy current and stirrer loads will

behave about the same as the 16" four blade fan load which

has been my test load on the bench ......in which case

this thing should work beautifully . The geometry of the

drive magnet is one thing I hope I get right first try ,

because I really don't want to get into six months of experiments with field shaping and coupling fine points

for magnet and armature combinations to find what works right .

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

You know what we want Rosco -- PHOTOS!

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah okay , I'll take some digital pictures of the

setup later . I had planned on doing the pics when the

assembly is near to the end stages and I have the

final components . It has been a spread of parts

and wires to this point , nothing really much to show

that is worth a photo presentation and I wanted to make sure it all works before posting the bragging pictures .

It's pretty straightforward , but I know

folks want the pics if nothing else to prove I'm not

just making all this stuff up  Hey trust me it's for real . Hey trust me it's for real .

|

|

|

armo

Harmless

Posts: 11

Registered: 23-8-2005

Location: Brasil

Member Is Offline

Mood: Cool....

|

|

PWM and triacs

Hi,Quince. I tryed the PWM + triac solution some time ago and it didint work. The reason is that triacs needs a pulse of at least 0,2 ms to go on and

will shut off on the next AC zero cross. I´m working now on a zero cross detector circuit (usin PIC microcontrolers) to phase control triacs. With

PWM you going to end up with erratic triac firing (just put a lamp bulb and watch the control ou get!)

As soon as I find a solution I´ll post it here

armo

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I'll tell you that there is for some reason more

heating loss and less mechanical efficiency ,

as well as a low power hum , and less smoothness

and linearity to the mechanical power when

the same PSC motor is controlled by an ordinary

triac " light dimmer " type of speed control .......

compared to the smooth and efficient

pure sine wave power from a variac which

works beautifully .

[Edited on 11-5-2006 by Rosco Bodine]

|

|

|

armo

Harmless

Posts: 11

Registered: 23-8-2005

Location: Brasil

Member Is Offline

Mood: Cool....

|

|

Hi Tacho,

Some time ago I found on the net a site about using stepper motors. I think it was Jones on step motors. In this site he teaches how to use damaged

hds. May be you can just use the spindle as a small centrifugue.

armo

| Quote: | Originally posted by Tacho

I tried to make a driver circuit for the spindle motor, but it didn't work. I used variations on stepper motor circuits, but it seems that this motor

works with positioning sensing, probably written on the magnetic disk.

I posted a circuit to drive a stepper motor sometime ago. It's a bit complex because I wanted do use TTL logic and have reverse spinning. One could

make a much simpler driver circuit for steppers using a 555, one CMOS chip and a ULN2003 chip.

I may do it one of these days.

I like the centrifugue idea. For the tubes I would use 2 x 5ml syringe barrels. Maybe just two wire loops passed through holes drilled on the disk

would work as the swivel (sp?)joints. Humm...

[Edited on 1-6-2005 by Tacho] |

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

armo, that's because I didn't use triacs. I used a floating gate bidirectional MOSFET switch, and tcouple of kHz). That gives me fully linear

control; no worries about phase or anything. The only thing here is that the gate supply and driver has to be floating, so I used a second small

transformer in order to do that (it's referenced to the AC line instead of ground). The PWM circuitry feeds the floating gate driver through a

standard optoisolator.

I no longer have schematics since my HD crash.

[Edited on 11-5-2006 by Quince]

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Update : The X269 Marathon PSC motor

A specific motor recently tested appears to have speed control characteristics which make it an excellent choice

right out of the box , with one minor modification which is

easily done . It is a ball bearing fan motor , which can be easily modified for stirrer duty by reducing the thrust preload force on the ball

bearings to about one third

to one fourth of the preload used in the motor as it ships from the factory . There is inside the bearing housing a

wave washer which places a thrust preload on the ball bearings to limit shaft endplay and takeup any clearance

in the ball bearings themselves . The wave washer spring is stiff enough to also oppose the thrust load of a fan blade which would in the intended use

be pulling

on the shaft . The spring is pretty stiff and causes too much static friction on the bearings for good low voltage starting and low power operation

. The factory assembled preload

tension is quite high , possibly 20 kilos , and this really causes sluggish starting at reduced voltage . For example in

the stock configuration the motor requires 46 volts @ .3 amp which is 13.8 Watts of input power to start , and

following breakaway into rotation it gradually spins up

accelerating to its rated slip from synchronous speed

at 1625 rpm . Removing the wave washer completely

and eliminating any thrust preload on the ball bearings

and retesting , the mimimum starting voltage was

reduced to 15 volts @ .060 amp which is 0.90 Watts ,

Yes less than 1 Watt of input , and the motor runs

stable at about 50 rpm , speed controlling beautifully

from a variac when driving a fan load . However it

was found that eliminating all of the preload was

unacceptable because of bearing vibration at certain speeds . A much lighter force of preload on the ball bearings

has the effect of quieting them in operation without

adversely increasing the starting voltage . After

flattening the stock wave washer and rebending it

to a lower curvature and lighter tension , it was reinstalled . The adjusted thrust force required for

quieting bearing vibration , raised the starting voltage

to about 19 volts @ 0.085 amps or which is 1.6 Watts

and again after starting the motor was well behaved

in speed response , which seems to hold true at anything

below 5 watts input unloaded . This area of low power

starting and operation seems to be a region where the

motor is actually working most simply to stir against the viscosity of the lubricants in the motor bearings which

prevents the motor from simply climbing the torque

slope and accellerating on up to synchronous speed

even with no other load whatsoever . The bearings are high enough precision that the presence of the added weight of a magnet rotor or fan seems to

only increase the minimum starting voltage by less than a half volt above the unloaded figure , essentially no difference . Ball bearings are not

dead silent like sleeve bearings . There is a slight hum or whizzing sound especially at high speed operation , a slight zishing sound almost like

escaping air from a slightly cracked open valve . Maybe

there are ball bearings that are dead quiet but I haven't found them yet . But these are quiet enough I think

for instrument use , with the reduced preload . No really obnoxious rattle or whine was noted , but more of a soft

mechanical low pitched hum with a harmonic shift at

a couple of speeds as is typical even for sleeve bearings .

One thing I also did was put about five drops of ashless

two-stroke oil at the gap in the bearing shields to slightly

thin the gluelike grease which the bearings are fully packed with from the factory . The stock grease is an extremely sticky mineral-polyurea that is

as thick and

sticky and viscous as almost cured gasket cement or

epoxy putty ....more like a glue than a lubricant . This

is the sort of grease you could fling a golf ball sized

lump against a window and come back a few years later

and it would still be hanging there , maybe sagging

slightly from where it was . It was so thick I knew a bit of oil would help loosen it a bit which was needed for the tests I was doing and for the few

hours break-in running .

Different capacitor values were tried and charted

and I was pleasantly surprised to find that the motor

designer at Marathon had indeed already worked out

the most efficient combination of capacitor value and

assymetry ratio for the way the motor was wound ,

and the best compromise value of capacitor for both

speed control and power efficiency is clamped to the

case of the motor from the factory . The stator coils

have been laced in tight bundles and the stator has

been varnish dipped and baked . The rotor has been

dynamically balanced . And even though the output

shaft is a half inch single flatted shaft , it is a turned

down exposed section of the actual rotor shaft which is ~17mm journaled in shielded ball bearings which appear

to be 40mm OD units , supported in machined

aluminum bearing housings cut directly into the cast aluminum endshields . The case and endshields are

themselves a heatsink , and there is an automatic reset

thermal breaker . The motor frame is 48Y , 5 5/8" dia.

The motor appears to be a jewel of quality hand

built craftsmanship , carrying a little blue label ,

" built with pride , made in USA "

and it looks like it

This is a motor where you can adjust the bearing preload to a reduced tension to clean up the low end low power performance and quieten it for

instrument duty use as described , put a balanced rotor magnet assembly on it and power it from a simple variac .....

and it will probably run for ten years continuously , or intermittently for a hundred years , re-bearing it and keep right on going like it was brand

new all over again

for the ones who inherit it long after you are gone .

Built like a bank vault as the old saying goes .

So it looks like this particular motor may be one of those

elusive matches which I was saying I believed was

possible early on in the process of considering a PSC

motor in open loop speed control operation for a

magnetic stirrer . I am glad to have found this one ,

which does seem to be a good match of an existing motor to the intended task , without any exotic

accomodations or modifications . The motor is

rated 1/6 hp 60Hz 230 volts 1.2 amps 1625 rpm

class B insulation , 40C ambient , continuous duty ,

air over , open enclosure , permanently lubricated .

I will probably use this motor and run it derated

from 20-125 volts . It was my original idea to use

a four pole motor anyway because of the higher rpm

capability when using smaller stirbars . The torque

is significantly lower than for the 1050 rpm six pole motor .....but there is ample power and the power

band covers a wider speed range , so I believe this is a better all purpose choice . And having discovered the

" secret " of reducing the bearing preload , the same

method could be used to tune the low end performance

of a ball bearing 1050 rpm motor , without having to

worry about any sleeve bearing lubrication issues at low speeds and not having to use magnetic support bearings either . Adjusting the bearing

preload is

a general method which could likely be used with many different ball bearing motors to adapt them from fan duty to stirrer duty applications . It has

cost me a lot of time and money to discover this simple fact . And it

sort of gripes me because it seems so simple that the

bearing and lubrication and motor experts I have consulted , likely knew this all the time , and kept the

facts confidential and proprietary .....just the same as they will not acknowledge the speed control capabilities of PSC motors themselves , much

less what factors

such as bearing preload are determinants in that area

of motor performance . And some people say they

think I am an asshole , hey shop around , there are bigger ones to be found ! Check some big corporations

for quick disvovery on that score .

If it's " not invented here " or how many thousand units

do you wish to have shipped ...they are not much help .

attached is the dimensional drawing for the X269

It is about a $140 retail motor . I scrounged a new one

for about 130 less than that

[Edited on 17-5-2006 by Rosco Bodine]

Attachment: Marathon X269 motor.pdf (100kB)

This file has been downloaded 1190 times

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I got a commercial magnetic stirrer from ebay today, the principle it uses is way more clever than any PWM circuit that only regulates the power that

goes to the motor.

There is a plastic disk with many slots in it on the stirrer shaft, and this disk goes through an optocouple sensor (LED + photodiode), giving

feedback about the actual stirring speed to the circuit. Using a special IC and an OP-Amp, this feedback is used to keep the stirring speed always

exactly constant, regardless of load on the motor due to e.g. viscosity changes in the reaction mix.

If the motor speed goes down, the circuit sends more power to the motor so that the speed remains the same.

I can scan the schematics and make a pic of the inside of the stirrer if wanted.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah go ahead and scan 'em and let's see what it is they are doing nowadays on the electronics . I can make pretty good guess .

Recently I aquired a couple of old tape reel direct drive PM 1.2 to ~42V DC servo motors in new old stock condition for cheap . They will start and

run from a single flashlight battery at about 40 rpm , with torque strong enough that you can barely grab the 1/2" shaft and slow it by hand , even at

under a half amp current . You can slave one unpowered motor to the other with test clips , and manually turn the shaft on one motor and the other

motor shaft will turn to follow it like a synchro , from the generated voltage . I think they are old Electrocraft motors

probably made for one of the old Univac? government computers from fifty years ago . Ball bearings , new brushes

they look brand new ....cost me about ten bucks each

They have encoder shafts on them but no encoders .

They are so torquey that really just give 'em a regulated voltage and they hold speed open loop good enough for any stirring application short of

maybe stirring setting plaster .

I have a couple of hotplate stirrers based on the servo motor/encoder wheel tachometer feedback design , one was commercially manufactured having a

C-frame shaded pole motor and the other was a custom aftermarket add-on servo-lock that I put in a stirrer which before had only a triac on a 3 3/8

frame shaded pole motor for speed control .

BTW , I also have a couple of overhead stirrers with encoder signaled Dart digital industrial controls which are giant sized versions that work on the

same principle to control 1/6 hp continuous duty series motors from 30-7000 rpm , and have programmable torque and speed profiles , process timers ,

and parallel cable interfaces for remote operation and monitoring from a PC  IIRC these were limited manufacture by Talboys from twenty years ago . The point being that the same manufacturer also makes puny little

IIRC these were limited manufacture by Talboys from twenty years ago . The point being that the same manufacturer also makes puny little

mini-scale laboratory hotplate stirrers that look like everybody elses cheap stuff , great for a couple of liters or less and that's about it . But

you know very well from looking at their " industrial scale " equipment that they understand the technology , and deliberately underbuild cheap stuff

strictly because of the bottom line . You couldn't buy a good true heavy duty hotplate stirrer for two or three hundred bucks and get the

manufacturers interested , until raising that price range by a factor of ten because that amount would barely cover just the motor and magnet .

The tachometer controlled speed regulation is the best setup for constant speed operation . However accurate and smooth performance is only delivered

if the motor and magnet is pretty hefty and entirely adequate to the job also , as the speed control only compensates for speed variations which the

motor torque can easily manage .

The problem is that the motor itself must have plenty of dynamic range " reserve torque" in order to be smoothly responsive to throttling by the

"cruise control" . The sin that most stirrer manufacturers are guilty of is using way too small a motor ( cheap little C-frame shaded pole fan motor

) and then add an encoder and a tachometer (frequency to voltage converter) output to an error amplifier op amp driving a vactrol ( high voltage

optocoupler ) to control the triac output to the little shaded pole motor . A signal voltage

from the wiper on a control pot represents a selected speed and the power to the motor is simply increased or attenuated

until the tachometer output voltage matches the voltage from the wiper on the speed control pot . It's like a standard servo-lock DC motor speed

regulator , the only difference

being with the Vactrol optocoupler AC biasing for the Triac ,

to enable high voltage AC output , whereas an ordinary

optocoupler would be used in a DC motor control circuit .

Really to do it best , they would need to use a precision ball bearing permanent magnet brush type DC servo

motor with an encoder , like an old computer tape reel

drive motor of 1/10 hp or so , and use a DC supply to a power op amp error amplifier . That would give a good high torque low speed performance even

down to 40 rpm or so

and upwards to 1600 rpm .....a 40:1 usable torque speed control range .

And if they are going to use an AC motor then something

like the Marathon X269 PSC motor would be ten times better than anything like a C-frame or a 3 3/8 frame shaded pole motor . A specially made

permanent split capacitor 3 3/8 frame ball bearing motor would do it as a something of a compromise at about 1/20 hp and would still be at least five

times better than a C-frame shaded pole POS motor .

But what the manufacturers are presently building in terms of both medium and heavy duty mag stirrers , with regards to not only the base units but

the design of stirrer magnets themselves proves that they either just don't get it , or aren't about to spend the bucks on the components to put into

the equipment what they ought to put into it .

[Edited on 19-5-2007 by Rosco Bodine]

|

|

|

alancj

Hazard to Self

Posts: 76

Registered: 16-6-2006

Member Is Offline

Mood: No Mood

|

|

Has anyone looked into possibly using induction? A series of electromagnets in a ring (say, 6 of them) and a controller turning them on and off and

reversing polarity in the proper sequence to spin the magnet bar in the flask. It would be like an axial brushless DC motor. No moving parts except

for the stir bar. Maybe it could be more reliable and more compact then a mechanical one. Not less complicated, may use more power, and heat could be

an issue if it was embedded in with a heating mantel. Anyway, Just a thought...

What do you guys think?

-Alan

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

You want not to run a DC motor with a variable voltage, but with pulses of full voltage and control the rotation rate by pulse width and pulse rate

modulation. That way you get full torque at low rotation rates, the concept is used in various variable rate motor setups.

I tried the induction route some years ago, effectively making a stepper motor where the armature is the stir bar. It looked like I would need 10 to

16 poles, this could be because I was lousy at winding electromagnets or because my controller design wasn't good. Whatever the cause the fewer pole

prototype didn't work well, the stir bar tended to lose lock and hop about, and was stuck up on the shelf. I still like the concept, though.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

PWM averages out to variable DC in the winding's inductance and resistance. The whole point of PWM is to provide a variable DC voltage without

dissipating the power of a linear regulator.

A stirrer is an AC motor. A magnetic field is created which is rotating. Two windings can be used, on an appropriate armature, to produce a rotating

magnetic field. Tesla's original distribution system was four wire, two phase (quadrature). Later, it evolved into today's triphase system, with a

phase of 120 degrees between legs. Three windings produce mutually rotating fields which, because each is a sine wave, sums vectorially to the same

magnitude of field (producing a smooth torque output) rotating versus time. Two phases, one following a sine and the other following a cosine wave,

accomplish the same goal; triphase only has the advantage that three wires can have the same voltage between legs.

In practical terms, we need a core to distribute the magnetic field as close to the stirbar as possible. It is utter foolishness to attempt any sort

of motive device, generator or motor, without iron. Air gaps must be minimized. A piece of laminated iron in the shape of two "U"s merged at the

bottom of the "U" and having 90 degrees between the two would be suitable. Windings go on the legs, say. The legs should be round for ease of

winding, spreading to nearly intersecting at the top (to minimize air gap between the windings).

The best way to excite such a motor would be a low frequency quadrature oscillator. This could be done with a clock generator, variable divider, an

EPROM programmed with a sine table and a DAC, but somehow I doubt three hundred thousand transistors are necessary. For instance, a

switched-capacitor filter is used in Figure 5.38 (p. 292) in Art Of Electronics, 2nd ed., Horowitz and Hill; mention is made (on pp. 293-4) of

linear-to-trigonometric conversion chips by AD; and a fixed-frequency quadrature oscillator is shown on page 304 (c.).

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Actually a plain permanent magnet servo motor like I mentioned , the old tape reel drive motors or huge aluminum platter hard drive motors , is the

cheapest substitute for something like a Kollmorgen servo motor

you will find . And they have plenty of torque to run open loop and maintain good virtually constant speed with

nothing but a constant voltage applied , plenty accurate enough for any usual stirring application . PWM is for the most part an energy conservation

method for high power

usage or battery powered equipment where the efficiency

is more critical than any concerns about insulation on the wiring or the compatability of the motor with that sort of

chopped power delivery . A piece of bench equipment

which is going to draw maybe 150 watts at most and generally much less , and is powered from a wall outlet

is not exactly begging to be powered from a PWM controller , especially if you are using a scrounged motor

that was designed for smooth pure DC . A regulated DC supply , or the rectified and lightly filtered output of a control transformer energized by a

light duty variac is

kinder to the windings and easy enough to buy or build .

I have an electromantle stirrer mantle which uses the magnetic drive that is produced from sequentially energized electromagnets , and it's cute but

nothing

so powerful nor smooth as a conventional motor drive

with a hefty rotor .

Variomag is one of the companies that makes the solid state type stirrers and there are others , but they don't have the performance of motor drive

stirrers .

Really it isn't engineering the control means that is the

challenge , nearly so much as choosing the right motor and other components , matching the parts that work together well .....the control becomes

greatly simplified .

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Magnet arrangement

Hello,

Can anyone with a purchased (or a good working homemade) magnetic stirrer tell me what is the magnet arrangement. Do theses things have 1, 2, ....4

magnets?

I have made a magnetic stirrer out of a CPU cooling fan(quite a big fan, about the size of what is in a computer PSU) with one hard disk magnet stuck

to it with epoxy. Don't know rotation speed. I am going to guess about 400revs.

I have tried a number of different shapes/size of Magnetic stirrer bars but most are not stable. They will 'come off' and go the the edge of container

and sit there jittering. One short thick cylindar shaped bar is OK. An egg shaped one is bad. Other cylindar shaped ones, both bigger and smaller than

the one I am using will work sometimes for a while but are totally unpredictable.

I have the magnet as close to the bar as is possible. Perhaps if I had two magnets?

Why are the bars magnetic? Would a piece of Iron work OK?(plastic coated).

If I could slow the moter down it would work, I guess, with any bar but that is not possible.

TIA,

Dann2

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

About the minimum technology that was ever serviceable here is described as follows.

For an older Cimarec 12" stirrer hotplate the drive magnet is two high grade ceramic block magnets 1" wide by 1 1/2" long by 1/2" thick which are

superglued to a piece of cold rolled 1" barstock 3/8" thick and four inches long . But that design would have improved coupling and centering for

smaller stirbars if the length and center gap between the blocks was reduced by 1/4" to 3/8" . The block magnets poles are on the 1 by 1 1/2 faces ,

each having the opposite pole upwards . An aluminum plate provides an eddy current loading which acts as a crude speed regulator , for the shaded pole

motor , whose power is controlled by a 50 watt 250 ohm 0.45A rheostat .

The motor is a fasco 1/125 hp 1500rpm 1/4" shaft

sleeve bearing motor 0.42A impedance protected 3 3/8 open case cooled only by the draft from the magnet rotor.

Open loop control only works well when everything is carefully matched together for the task so that you have a pretty linear response without any

active speed regulation .

The bars have magnetic cores to increase the coupling force between the drive magnet and the driven magnet .

When stirring a thick slush of crystals or a viscous solution , the stirring magnet will decouple and hop around when the torque limit is exceeded .

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Thanks for that.

The stirrer/magnet bar combination that I have has worked fine for about 3 days but today the bar was back sulking over at the edge. I am running a

tall chlorate cell. Stirring is essential as the top of the liquid will reach 73C without stirring (the bottom staying cold).

Will put a second magnet on the fan.

Dann2

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

On something having a light duty motor like that , a single rod magnet with poles at the ends laid horizontal with

the axis at the middle would work better and it needs no

backing plate so it will be lighter in weight . But it will only

couple well with driven magnets which are close to the same length .

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

measuring rotation rate

I'd like a reasonably simple way of measuring rotation rate of a lab stirrer. I have in mind the over head motor type as this gives me the torque I

need.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

| Pages:

1

2

3

4

5 |

|