| Pages:

1

2

3

4 |

Ium

Harmless

Posts: 24

Registered: 21-4-2004

Location: Australia

Member Is Offline

Mood: Cleaved

|

|

What you are after is pharmaceutical grade Non-Flavoured Ascorbic Acid. Avoid buffered Calcium or Sodium derivatives. Check on the container or

package for a reference to purity or active constituents.

While searching for the same particular brand you mention, I came across that errror. "Strength: 1065 g" is supposed to mean the serving

size in mg. They also mention 1/4 teaspoon as the suggested serving size for a more general measurement. Both measurements are approximately the same

amount. The refernce to "8 oz." is the weight of the full amount of Ascorbic Acid.

[Edited on 20-10-2004 by Ium]

[Edited on 20-10-2004 by Ium]

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

I can't believe I didn't see that, thanks for pointing it out. I don't see any mention of anything other than vit C, so it should be

reasonable pure unless they 'cut' it with some inert stuff.

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

"Ascorbic acid WORKS. It takes a bit long though. Some copper deposits on the glass surface (possible mirror?) after 1/2 hour. Overnight a

deposit forms." quote from Tacho

I just repeated the Copper Sulfate / Ascorbic Acid experiment and got a very fine reddish powder that acts just like copper, a strong magnet slowed

it's fall down the side of the test tube, showing it conducts.

It would be very nice to make a copper mirror. Google showed a site that gave a copper mirror with hydrazine hydrate and copper acetate. It was done

in a test tube that was heated while the copper was reduced by the hydrazine. Maybe if the glass was cleaned as the glass on a telescope mirror, with

nitric acid, after being degreased, it would form a mirror? Has anyone seen a copper mirror form?

[Edited on 20-10-2004 by Mr. Wizard]

[Edited on 20-10-2004 by Mr. Wizard]

|

|

|

Theoretic

National Hazard

Posts: 776

Registered: 17-6-2003

Location: London, the Land of Sun, Summer and Snow

Member Is Offline

Mood: eating the souls of dust mites

|

|

neutrino: probably the amount of air dissolved in the acid worked as an oxidizer.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Copper mirror recipes

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

I got some reagent grade ascorbic acid and did some tests. I noticed a few things: 1) heat strongly accelerates the reaction but, using heat, the

precipitate has that “plasticized” look that rogue chemist displayed in his pictures. Since there is only pure reactants, I assume the copper

agglomerates by itself. 2) I could get no mirror, even treating the glass with Sn ions. 3) Just for the record: The green solution left after the

copper precipitates makes a good plating solution, I got a beautiful copper plating on graphite on my very first try. Maybe I was lucky, but next time

I want to do copper plating, I’ll try this solution (I saved it).

I’m a bit disappointed, because I was expecting quantitative yields using pure reagents, but the reaction is… my English fails… Temperamental?

Any other use for 40g of ascorbic acid? The label says "laboratory use" and mentions heavy metal residue, so I don't think I should use

it to cure my next cold...

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Yes I agree the reaction is temperamental. Boiling does the job very quickly, that's how I always did it. I don't know why you get some

'plasticed' look, all I got with reagent grade Vit C/CuSO4 was fine grains as in the pic above. These don't stick to each other, and

can be easily crushed to dust.

What confuses me is the quantitative yield, too. How can they, in that paper, claim 95% of the theoretical yield if you still got enough left to do

some plating? By the way, I tried the reduction in the presence of 30% polyethyleneglycol (6000 average MW), but the powder was visibly not finer or

coarser- but then I boiled it too. What was interesting is that the PEG is nicely soluble on its own, but as soon as I added the CuSO4 to this, the

CuSO4 seemed to form an emulsion, i.e. as a dark blue liquid! I have the impression that a variety of inorganic salts could be purified/concentrated

that way, i.e. add the salt in question to a conc. solution of PEG, shake/mix for a while, let it settle, and decant off the PEG/water, to be left

with a concentrated solution of the salt!

Anyway, i will try the experiment with PVP at some point, as I managed to obtain some.

What to do with the remaining Vit C? Comon, the obvious! Test it with Ni, Co, Mn, etc etc salts! Who knows, maybe this works on other metals too!

PS interesting page on the copper mirror - shame only it requires some very expensive metal salts.

[Edited on 25-10-2004 by chemoleo]

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

About quantitative yields: I didn't do any carefull measurement, but the ammount of copper precipitated is clearly not proportional to vit C

added.

About the use for leftover vit C: Yes! Of course! Obvious. How embarassing...

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Condutive paint powder...

I tested the vit C in 3 metal salt solutions: Circuit etching ferric chloride, nickel chloride and silver nitrate. Nothing happened to nickel; ferric

went from yellow-brown to green and, with extra vitamin, to a clear colorless solution (nice way to remove those ferric chloride stains). No

precipitates.

Silver nitrate, OTOH, gave very interesting results: a fine gray sludge of metallic silver powder. Unfortunately, this powder did more than

precipitate, it coagulated (sorry, but this word is perfect to describe what happens) in a blob in the same way that the “silver tree” crystals

do.

Even so, this powder is very conductive, the best conductive powder I’ve seen and it’s certainly the thing to make homebrew conductive paint. If

rubbed on a gypsum surface with my finger, it made a nice, very conductive surface (0 ohms) even on my fingertip.

I tried different solvents for the reaction, mixes of isopropyl, methyl, ethyl alcohols, acetic acid and ethylene glycol. No improvement.

I also tried different bonding glues: PVA, sodium silicate, acrylic latex and some alcohol soluble varnish. So far, PVA glue gave the best results,

but far from a perfect paint.

I presume that, to obtain a good homemade conductive paint, one of this three routes should be used:

1- Carefully pick the coagulum and put it on filter paper to dry. After it’s dry, crunch it to a fine powder and mix with some bonding agent. I

think this is the best route, silver does not oxidize and AgS is condutive, so the powder can be handled and stored safely.

2- Mix something with the reactants that will keep the silver in emulsion; an emulsifying agent or just a different solvent.

3- Do the reaction in a rotating flask with some coarse sand in it, so that the silver never has the chance to coagulate.

This is a very interesting result. Thanks chemoleo. I knew this vit C thing would give me something new to my list of voodoo tricks.

|

|

|

Mephisto

Chemicus Diabolicus

Posts: 295

Registered: 24-8-2002

Location: Germany

Member Is Offline

Mood: swinging

|

|

Ascorbic acid works for all reactions with a higher redox potential than +0.166 V, since ascorbic acid itself has this redox potential (according to

the Merck Index XIII).

Cu<sup>2+</sup> + 2e<sup>-</sup> → Cu EΘ = +0.34 V

Ag<sup>+</sup> + e<sup>-</sup> → Ag EΘ = +0.80 V

Fe<sup>3+</sup> + 3e<sup>-</sup> → Fe EΘ = -0.04 V

Fe<sup>3+</sup> + e<sup>-</sup> → Fe<sup>2+</sup> (yellow to green)

EΘ = +0.77 V

Ni<sup>2+</sup> + 2e<sup>-</sup> → Ni EΘ = -0.23 V

For example Hg and Au from their salts will work, too.

Many thanks to Tacho, for verifying this in such scientific manner!

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

What books don’t say:

Electroplating with some quality is difficult. To obtain solid metallic deposits demand know-how and problematic chemicals.

I could never obtain a good NICKEL deposit using nickel chloride as electrolyte... until I tried the leftover solution of nickel chloride plus

ascorbic acid.

I obtained a beautiful solid metal deposit on graphite and on copper cathodes. Almost shiny and easily polishable. I tried different concentrations of

the chloride with equal results.

I used very low voltage. I didn’t check voltages or currents, and won’t be able to check them today or in the next few days, due to personal

problems. Further tests will have to wait a while.

I believe THIS is news.

Who was looking for a nickel crucible?

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

If any of you one wants some food grade pure ascorbic acid to do great stuff with and isn't scared of customs taking an initial interest in the

white powder in that strange overseas letter, PM me. I've got close to 4kg left, of which I need only a small part.

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

Ium

Harmless

Posts: 24

Registered: 21-4-2004

Location: Australia

Member Is Offline

Mood: Cleaved

|

|

Ascorbic acid has found use in electroplating solutions for various metals for some time now. However I am unable to find much information on the

exact role of the acid in plating baths. Most articles seem to suggest that it is used because of it's strong reducing effect on metallic salts

and so aiding the plating process by creating salts more easily freed of the metal.

It may help for other members to search for additional references to ascorbic acid's use in electroplating, as so far I have had little success.

Edit: Patents have some juicy info.

| Quote: |

In this technique, ascorbic acid is used in the presence of an electrolytic aid. The purpose of adding ascorbic acid is to (a) control the pH of

electrolyzed water of cathode side and (b) remove the free chlorine in electrolyzed water of anode side

|

http://www.bandwidthmarket.com/resources/patents/apps/2002/3/20020027079.html

[Edited on 28-10-2004 by Ium]

|

|

|

Mephisto

Chemicus Diabolicus

Posts: 295

Registered: 24-8-2002

Location: Germany

Member Is Offline

Mood: swinging

|

|

Low yield

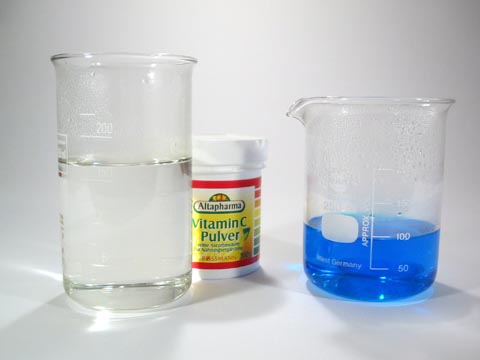

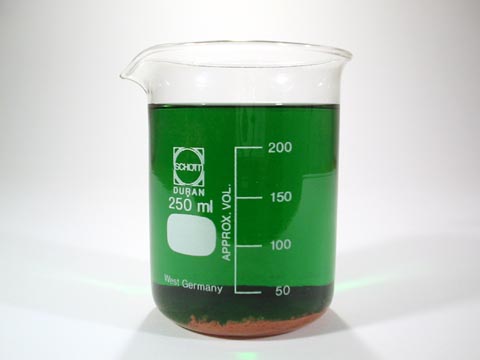

A solution of 43.2 g (≈ 245 mmol) ascorbic acid in 140 ml 50 °C warm, distilled water was added to a second solution of 25 g (≈ 100 mmol)

copper(II)-sulphate pentahydrate in 80 ml 50 °C warm, distilled water.

↑ Before mixing.

↑ After 30 minutes reaction time (the mix was stirred in this time).

The formed copper powder was filtered off and washed two times with distilled water and once with spirit to give 1.8 g (dry) copper powder. This is

28% of the theoretically possible yield. (Note: scale inaccuracy ±0.2 g)

Maybe higher concentrated solutions of CuSO4 and ascorbic acid were yielding more copper powder. Since I need only some grams Cu-powder to catalyze a

reaction, the yield isn't very important for me.

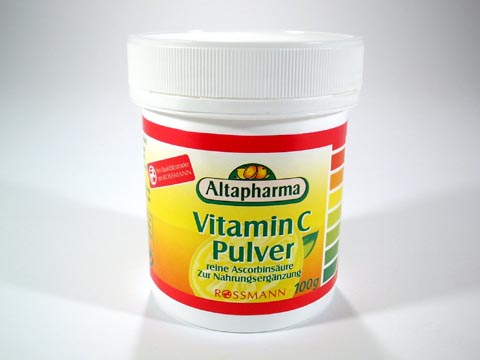

I found easily a Vit C product that consists of pure ascorbic acid, without any contaminants. 100 g costs 1,49 € but it could be somewhere cheaper,

since I bought it in the first drugstore, which was on my way.

BTW: German version of this experiment on www.LambdaSyn.org

[Edited on 29-10-2004 by Mephisto]

<!-- bfesser_edit_tag -->[<a href="u2u.php?action=send&username=bfesser">bfesser</a>: fixed

external link(s)]

[Edited on 7/22/13 by bfesser]

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

LambdaSyn is a great site! I just read some of the other syntheses and they're GREAT! There are some syntheses there which are completely new to

me.

I especially like the Ammonium chlorate synthesis from KClO3, (NH4)2SO4 and Ethanol

and the Ethyl nitrate synthesis.

|

|

|

Mephisto

Chemicus Diabolicus

Posts: 295

Registered: 24-8-2002

Location: Germany

Member Is Offline

Mood: swinging

|

|

Nice to hear that. After a period of stagnation I will work more on the website. Actually I got 102 synthesis-texts in the Rich Text Format on my HDD

(many of them with photos), within the next weeks I try to convert a large part of them into HTML an put them online. So, I think, it's worth to

visit the website once a week to check out the updates.

|

|

|

TheBear

Hazard to Self

Posts: 78

Registered: 17-10-2002

Location: Sweden

Member Is Offline

Mood: distilled

|

|

Just a thought about the conductivity tests: Cu2O is a semiconductor with photoelectric properties.

|

|

|

chloric1

International Hazard

Posts: 1159

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

| Quote: | Originally posted by kevinlimse

Is there a method for Aluminium powder? |

If a am not mistaken aluminum could be isolated from an electrolyte based on DMSO as a solvent. I am not sure what aluminum compound though.

Besides, by the time you work it out, the immense investment in reagents would far outweigh what puny yeilds you could possibly obtain.

Fellow molecular manipulator

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

The point isn’t obtaining large amounts of superpure powder; it’s knowing how to make anything potentially useful at all.

|

|

|

Theoretic

National Hazard

Posts: 776

Registered: 17-6-2003

Location: London, the Land of Sun, Summer and Snow

Member Is Offline

Mood: eating the souls of dust mites

|

|

"Just a thought about the conductivity tests: Cu2O is a semiconductor with photoelectric properties."

Maybe a Cu2O mirror can be created on a suitable surface with slow depositing (low concentration), then playing around with the photosensitive element

thus made? Integrate it into an electric circuit with an alarm in it, so the first rays of the sun at sunrise wake you up and you start your day nice

and early?

|

|

|

Archimede

Harmless

Posts: 33

Registered: 13-5-2005

Member Is Offline

Mood: No Mood

|

|

As an electrician I can find fair amounts of scrap clean copper. Can I just dissolve it in solution using acetic acid/NaCl for then use it with

electrolisis to plate stuff?

Same apply for Zinc scrap pieces.

Is there a way to process the vinegar to get a higher concentration of acetic acid?

I am new to this subject so throw me a bone pls.

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Not to be rude, but questions like this are better asked in the 'beginnings' section. Ask there and it shall be answered.

|

|

|

CD-ROM-LAUFWERK

Harmless

Posts: 30

Registered: 23-4-2005

Member Is Offline

Mood: No Mood

|

|

a methode of producing very very very fine Cu powder is to form coppernitrate, leting the solution react whit NaOH-pellets and reducing the CuO whit

glucose!

this power is much finer as that on the foto from chemoleo!

u cant see a singl particle!

it takes hours to siting down in water!

that stuff is the finest powder i'v ever seen, no Al power is finer!

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

And you are sure it isn't Cu2O? Try dissolving it in HCl.

It'd surprise me if the reduction potential of glucose is as high as that of ascorbic acid.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

CD-ROM-LAUFWERK

Harmless

Posts: 30

Registered: 23-4-2005

Member Is Offline

Mood: No Mood

|

|

i fergot to say that u have 2 cook the mixture of NaOH, CuO and glucose for a few minutes (~5min), i did that in the microwave, dont know if that

mater...

i will test it later, no problem!

|

|

|

| Pages:

1

2

3

4 |