| Pages:

1

2

3

4

5 |

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

Isopropanol purification

Hey,

This might be a little off-topic but I feel it's relevant to aluminium isopropoxide synthesis.

I'm attempting to purify isopropanol. I started off with a blue-dyed cleaning solution, claimed to contain 60-100 % 2-propanol. I filtered it through

activated charcoal and a cotton plug to remove the dye, that was a success. Now, I'm not sure about the water content, but I know it's not anhydrous.

I'm refluxing 250 mL of iPrOH over 30 g dry sodium carbonate right now. Potassium carbonate is normally recommended for drying of alcohols, but I

don't have any. I take it that the sodium salt would do pretty much the same?

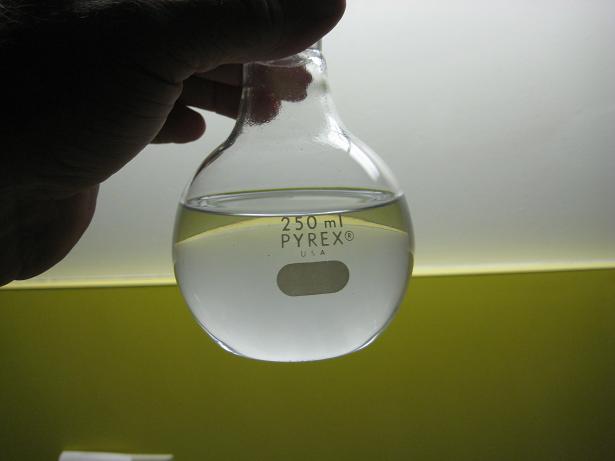

Setup: the boiling flask is a 500 mL Kimax round bottom boiling flask. A claisen adapter with a rubber thermometer adapter is attached. Also attached

is a 300 mm Kimax Liebig condenser. On top of that is a 105° distillation adapter used as a drying tube, filled with calcium chloride. The heat

source is a salt water bath heated with an induction stove.

Here are some pictures:

Now, the alcohol tested negative for peroxide with KI + starch, but I like to be better safe than sorry. Vogel recommends SnCl<sub>2</sub>

for removing peroxide. I don't have any of it on hand, but I do have half a kilo FeSO<sub>4</sub>∙7H<sub>2</sub>O. I

suppose it would be just as good as stannous chloride for removing any possible peroxides?

As of now, the alcohol has been refluxing vigorously for an hour. The thermometer is reading just below 81°C, indicating the 91 % iPrOH/water

azeotrope. My plan is to reflux for another hour, filter, add ~5 grams of ferrous sulfate and sodium carbonate, then arrange for downwards

distillation with protection from atmospheric moisture, discarding the last ~50 mL that doesn't come over.

Does that sound sensible?

[Edited on 19-3-2010 by Lambda-Eyde]

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

I'm pretty sure you will need to go to greater lengths to dry it before it is dry enough to make the isopropoxide. First of all, '60-100%' is such a

big range that it would be nice to narrow it down some before even starting the project; you're talking about the difference between using a little

drying agent and filling the flask full of it. As an alternative to analysis you could just distill over the azeotrope, which would give you a known

amount of water to deal with, before drying and distilling again.

As for the drying agent, I would assume that different drying agents have different partition coefficients that would describe their effectiveness,

with things like sodium metal way way up there and sodium carbonate not nearly so high. Practically speaking, I like to use quantities of drying

agents such that they remain solid at the reflux temperature of my solvent, because I feel like the partition coefficient can't possibly be that high

once the drying agent forms a hydrate melt (this may however be error and confusion on my part). I'm curious whether your Na2CO3 is still solid; the

monohydrate does not melt until 100C, but that only amounts to 6g of water absorbed (!); while the Na2CO3 also forms a decahydrate this is a liquid

hydrate melt at the reflux temperature of IPA, so I would expect it to form a separate liquid phase unless the IPA was quite dry to start with. I

personally dislike both Na2SO4 and Na2CO3 because they need low temperatures to absorb a decent amount of water, and when those conditions are met

they have a tendency to suddenly crystallize into a big hydrate mass that also traps a bunch of whatever it is you're trying to dry. Magnesium sulfate

is a better choice for IPA in my opinion. But even so I suspect you will have to dry multiple times.

|

|

|

entropy51

Gone, but not forgotten

Posts: 1612

Registered: 30-5-2009

Member Is Offline

Mood: Fissile

|

|

The stuff you bought was probably 91% already. There's no need to reflux it with anything, although refluxing with CaO would remove the remaining

H2O; Na2CO3 will not. If you shake it up with K2CO3 or NaOH, a lower aqueous layer will settle out and can be drawn off. Dry Na2CO3 might work as

well using an extraction like this. The peroxide (that you don't have) is only problematic if you distill it to near dryness. FeSO4 only removes

peroxide in an acidified aqueous medium. SnCl2 is the only thing I know of that will remove peroxides while anhydrous.

There are threads here that describe a proper procedure, which this isn't. I think a paper describing the use of NaOH to get it anhydrous has been

posted. See here

[Edited on 19-3-2010 by entropy51]

|

|

|

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

Thanks to both of you for answering.

bbartlog: I wasn't hoping to get absolute isopropanol from this procedure, just a more concentrated than the 91 % solution I (presumably) have.

I am ashamed at my selection of drying agents; I only have sodium carbonate, sodium hydroxide and calcium chloride! When I asked for epsom

salts/bathing salts at the drug store, I was given some hippy crap tainted with dyes and perfumes...

Right now my economy is rather poor, but I will eventually buy K<sub>2</sub>CO<sub>3</sub>, CaO, KOH,

P<sub>4</sub>O<sub>10</sub> among others.

Quote: Originally posted by entropy51  | | The stuff you bought was probably 91% already. There's no need to reflux it with anything, although refluxing with CaO would remove the remaining

H2O; Na2CO3 will not. If you shake it up with K2CO3 or NaOH, a lower aqueous layer will settle out and can be drawn off. Dry Na2CO3 might work as

well using an extraction like this. The peroxide (that you don't have) is only problematic if you distill it to near dryness. FeSO4 only removes

peroxide in an acidified aqueous medium. SnCl2 is the only thing I know of that will remove peroxides while anhydrous. |

Thanks for the advice on reducing agents, I wasn't aware of that. I will have to get some tin and pure HCl.

Quote: Originally posted by entropy51  |

There are threads here that describe a proper procedure, which this isn't. I think a paper describing the use of NaOH to get it anhydrous has been

posted. |

While doing this experiment I found exactly that paper in my chemistry folder. At least I got some valuable lab experience.

Next, I'll dry it with NaOH according to the method in the mentioned paper and distill.

By the way, is there any easy method for quantitatively analyzing the water content of the alcohol?

[Edited on 19-3-2010 by Lambda-Eyde]

|

|

|

entropy51

Gone, but not forgotten

Posts: 1612

Registered: 30-5-2009

Member Is Offline

Mood: Fissile

|

|

| Quote: | | By the way, is there any easy method for quantitatively analyzing the water content of the alcohol? |

Probably

not. You can probably find a table of specific gravity vs. concentration, but it won't be that sensitive. If it doesn't turn anhydrous CuSO4 blue

it's probably fairly dry. Even if you made it absolutely anhydrous it would absorb H2O from the air.

It probably need not be extremely dry to make isopropoxide. I use gas line anti-freeze straight out of the bottle with no problems. This is

garage chemistry after all.

|

|

|

Reduce-Me

Harmless

Posts: 25

Registered: 11-2-2010

Member Is Offline

Mood: Negative

|

|

Why is the product distilled with vacuum?

|

|

|

maryam

Harmless

Posts: 6

Registered: 14-5-2010

Member Is Offline

Mood: No Mood

|

|

what was the exact T and pressure used in the proceess. I cant get the alcohol distilled and i got only small amount of Al(iso)3 in solid state not

liquid. I dont know Why the product doesnt sit in reciever flask.. vaccum must be so intense! any ideas?

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

This may be slightly off topic, can titanium tetraisopropoxide be synthesized in a similar manner? The standard procedure is the reaction of titanium

(IV) chloride with isopropanol. If this compound could be synthesized in this manner, this would open up many new synthetic options to the advanced

amateur organic chemist. Titanium metal filings are fairly inexpensive, reaction with chlorine would not be very hard to conduct. Possibly, chlorine

could be passed into a suspension of titanium powder in anhydrous 2-propanol, resulting in the formation of the desired titanium tetraisopropoxide.

Amateur NMR spectroscopist

|

|

|

Lambda-Eyde

National Hazard

Posts: 860

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

Doesn't 2-propanol react with chlorine gas in the presence of a Lewis acid? Or does this only apply to HCl + 2-propanol?

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Chlorine may oxidise the isopropanol. If you can make the titanium tetrachloride it should be fairly simple, just provide sufficient scrubbing to

catch all that HCl given off when reacting the alcohol.

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

I have recently duplicated the synthesis as described by Klute. I used 91% IPA. It was combined and shaken with NaOH (10% by weight) and left to

settle out the aqueous layer and then distilled. It was then refluxed and distilled over Na and under nitrogen.

I then used the dry IPA (400 ml) with 1.65g HgCl2, .2g Iodine and 30g aluminum foil to synthesize the Al(O-i-Pr)3. This was done by first removing the

air from the reaction flask and condenser with N2. The pot temp, when refluxing began, was 77*C. I refluxed for about 2 1/2 hours to dissolve all of

the Al. After sitting over night, the IPA was removed by distilling. The still head temp was 78*C. As soon as the still head temp started to decrease

and pot temp began to increase, I removed the condenser and placed the 105* vacuum adapter and a fresh receiver directly to the still head. Vacuum was

then started and gradually increased to 10mm. At 185*C the product was vigorously refluxing on the top portion of the 1liter flask but not coming

over. At this point I completely insulated the top of the flask and the product began to come over in a hurry. Approx 250ml had collected when it

abruptly stopped. I removed the insulation and saw that there was only a dark gray semi solid mass left.

The product was a clear, somewhat refractive, thick liquid, which after 2 days, solidified.

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

Here are a few pics of the process

removal of excess water by NaOH

Distilling over sodium

Isopropoxide reaction complete

driving off the excess IPA

distilling over the isopropoxide

final product

|

|

|

maryam

Harmless

Posts: 6

Registered: 14-5-2010

Member Is Offline

Mood: No Mood

|

|

Did you use high vaccum(pump)?(less than 5mm Hg)

|

|

|

maryam

Harmless

Posts: 6

Registered: 14-5-2010

Member Is Offline

Mood: No Mood

|

|

Also Is it enough to use just molecular sieve to dehydrate the alcohol?

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

The vacuum pump I used only got down to 10mm and molecular sieves with work just fine if you use enough of them.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

You shouldn't be pulling a vacuum on flat bottom flasks.

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

True! But I like the way they sit on the counter when I'm done and that one is really thick.

|

|

|

maryam

Harmless

Posts: 6

Registered: 14-5-2010

Member Is Offline

Mood: No Mood

|

|

my Aluminum starting material is Al metal(Granular) in place of aluminum foil..Is adding iodine important in this case?

|

|

|

maryam

Harmless

Posts: 6

Registered: 14-5-2010

Member Is Offline

Mood: No Mood

|

|

In first step of solid liquid reaction did you take out released H2 gas(purge N2, Use ballon) ? How log the disstilation took? Actually I am

inorganic chemist that s why i have hard time in making it!!thanks for the help..

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

I just left the N2 flowing about two bubbles per second and a CaCl2 guard at the top of the condenser. The first step took about 4 hours including all

the reflux time. I added the Iodine dissolved in a solution of IPA after the reflux had started. After the addition I noticed an increase in reaction

rate. The second step, under vacuum, only took about 40 minutes.

The granular aluminum will work ,however, the reaction rate may be quite a bit slower because of the lower surface area, (I'm assuming that the

shredded aluminum foil has more). You need to have enough Hg to properly amalgam the aluminum.

|

|

|

un0me2

aliced25 sock puppet

Posts: 205

Registered: 3-2-2010

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by UnintentionalChaos  | Quote: Originally posted by unome  |

I was wondering if it would be possible, given that the Hg salts are only there to remove the oxide layer, thus allowing the alcohol to come into

contact with the bare metal, if it would be technically possible to utilize a solution of NaOH/iPrOH (which would according the equilibrium be

composed also of NaO-i-Pr and H2O), which would clean the oxide layer off the aluminium, and activate it.

|

That would hinge entirely on whether sodium aluminate is soluble in isopropanol, which I suspect it isn't.

I strongly suspect that gallium salts would work here as a nontoxic alternative, however. A small amount of iodine might also work.

[Edited on 1-25-10 by UnintentionalChaos] |

The insolubility of the aluminate in the isopropanol is the reason I suggested it. It could be removed by filtration, or left behind by distillation.

The reaction with the aluminium would remove the oxide, the clean aluminium would react with the alcohol. There is a similar procedure starting from

aluminium with HCl to give aluminium dithionite in this patent which of course could also be tried (1-2M HCl gas dissolved in anhydrous i-PrOH) would also clean the oxide layer off the aluminium -

forming AlCl3 in situ, or at least a catalytic amount thereof.

Don't know why, but that appeals to me - whether that would be enough to initiate the reaction I could not say for certain.

quam temere in nosmet legem sancimus iniquam

|

|

|

Random

International Hazard

Posts: 1120

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

Could I put small amount of copper chloride to the al-isopropanol mixture to "activate" the al without hg salts? CuCl2 dissolves the aluminium alone.

|

|

|

digitalemu

Harmless

Posts: 38

Registered: 21-10-2010

Member Is Offline

Mood: No Mood

|

|

Just watch it with your own eyes being performed with some background music  Nice work ytmachx... Have some great vids.

Nice work ytmachx... Have some great vids.

http://www.youtube.com/watch?v=axxbIWOge_o

|

|

|

maryam

Harmless

Posts: 6

Registered: 14-5-2010

Member Is Offline

Mood: No Mood

|

|

Anyone knows how to measure purity of aluminum isopropoxide?

|

|

|

Cloner

Hazard to Others

Posts: 150

Registered: 7-12-2004

Member Is Offline

Mood: apocalyptic

|

|

aluminum isopropoxide prep problem

Using isopropanol, aluminum foil, mercuric chloride and iodine crystals (the latter two in catalytic amounts) I am trying to prepare aluminum

isopropoxide. The reaction seems to proceed but at some point the hydrogen evolution stops.

Can atmospheric water be the problem? I have no idea how sensitive this reaction is to water and in what manner water disturbs it. The IPA is dry to

begin with (sodium was dissolved in it, then it was distilled).

[Edited on 6-8-2011 by Cloner]

|

|

|

| Pages:

1

2

3

4

5 |