| Pages:

1

..

21

22

23

24

25

..

60 |

mr.crow

National Hazard

Posts: 884

Registered: 9-9-2009

Location: Canada

Member Is Offline

Mood: 0xFF

|

|

The inverted funnel is a good technique to stop suckback. The phosphorus vapor inside would burn when it hits the air if this were to occur. Still way

better than a steam explosion.

Aluminum would be molten at the operating temperature but I would still go with powdered Al so it makes contact. Molten metals have a high surface

tension.

Being exothermic the reaction would really take off. Maybe it would be too fast at large scale?

Well enough armchair chemistry from me. This sounds like its going to be legendary

Double, double toil and trouble; Fire burn, and caldron bubble

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

ok i built a new reactor with emt since it has thinner walls. blogfast you were on the right track about the propane. it can work but not with a BBQ

tank. the volume of gas is just too low. anyhoo i ordered a lb. each of aluminum and sodium meta. we gonna get some phosphorus before its all over!

6(NaPO3) + 10Al + 3SiO2 = 3Na2SiO3 + 5Al2O3 + 6P

per mole (approx)

(NaPO3)=102

Al = 27

SiO2 = 60

prep

34g Sodium Hexametaphosphate

9g Aluminum

20g Silicon Dioxide

i will mix these reactants and use maybe half the mixture for a charge. does this math look correct? your input is valued. i have one curiosity.

aluminum always has a surface layer of oxide. does that play into the reaction or is the amount negligible?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The eyes of the world are on you! ;-)

|

|

|

ScienceSquirrel

International Hazard

Posts: 1863

Registered: 18-6-2008

Location: Brittany

Member Is Offline

Mood: Dogs are pets but cats are little furry humans with four feet and self determination!

|

|

Your reactant masses look a bit off to me.

If your reaction is stoichiometric and I doubt that it is with all sorts of crap being formed you would have a ratio of 6:10:3.

Hence;

34g 0.33M Sodium Hexametaphosphate

15g 0.55M Aluminum

10g 0.165M Silicon Dioxide

In practice the best yield will probably be achieved by using one or two of the reactants in excess.

The aluminium oxide coating on the aluminium powder will be negligble and can be ignored.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ScienceSquirrel  | Your reactant masses look a bit off to me.

If your reaction is stoichiometric and I doubt that it is with all sorts of crap being formed you would have a ratio of 6:10:3.

Hence;

34g 0.33M Sodium Hexametaphosphate

15g 0.55M Aluminum

10g 0.165M Silicon Dioxide

In practice the best yield will probably be achieved by using one or two of the reactants in excess.

The aluminium oxide coating on the aluminium powder will be negligble and can be ignored.

|

Correct. I'd use a 10 - 20 % excess of Al.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

thank you. a bit excess Al would be a good idea if it won't react with the P4. it will burn up any extra O2 from the atm in the reactor.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

well...that was fast. the new reactants are here so tonight is the night. i will post results asap.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

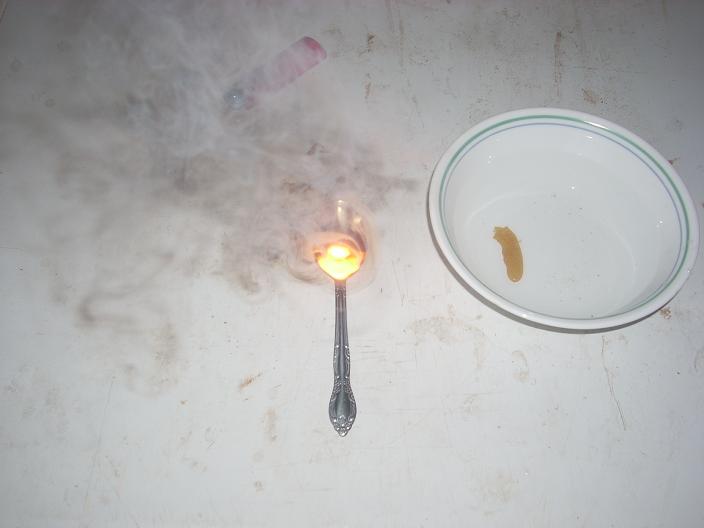

i have done it!!!!!!!! i will post pics soon as i clean and solidify it all. they will be up tonight!!!

[Edited on 4-9-2010 by Rogeryermaw]

the phosphorus came over easily. the reaction was stable and controlled and i could easily have scaled it up much further and will tomorrow. i didn't

take pics of the process because it's essentially the same as last time with minor changes to the furnace that wouldn't show on film anyway and of

course the reactor which is designed the same but with thinner metal and instead of 1.5 inch rigid i used 1 inch emt for better heat transfer. the P4

is fairly pure. the pics don't do it justice. it's yellow but transparent and smokes freely in air. also you see the bright yellow flame and

voluminous smoke. sorry...i would be more clear and detailed but i'm more giddy now than my first joint, sex, or roller coaster!!! ready to go again

tomorrow.

[Edited on 4-9-2010 by Rogeryermaw]

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Let me be the first to say congrates, I have always thought this to be a fairly easy reaction(while sitting in my armchair) that people tend to over

think putting P4 on some sort of unreachable height that they will never achieve but have always dreamed of. Thank you for showing that with a little

dedication and creativity is not the shit storm people make it out to be while they also sit there in there armchair.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

thank you and all too true. however i think it IS a little more difficult to achieve on a lab scale to obtain useful amounts and i did cheat on that a

bit by having space for an outdoor furnace. but those of you who suggested the lower temp reaction of sodium meta and aluminum were the ones who made

it possible. now to scale it up and send out free samples to some of the more dedicated among the chemist community...

i will say this though...i will have to develop a more convenient process to collect and filter the product...it smokes instantly and when the

collector is hot, if it is sloshed at all and P4 surfaces, it will ignite and float on the gasses produced, burning away costing you product. tonight

i will work on design for an apparatus to help with this.

[Edited on 4-9-2010 by Rogeryermaw]

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

I have a kiln that up till recently cost me to much to operated however I envisioned a simular setup as yours just a better heat source ect... ect...

My main question is what is your plans for conversion to the red variety? For storage it would be the best way to go since its less toxic and performs

many of the same functions as long as time isn't a factor.

Knowledge is useless to useless people...

"I see a lot of patterns in our behavior as a nation that parallel a lot of other historical processes. The fall of Rome, the fall of Germany — the

fall of the ruling country, the people who think they can do whatever they want without anybody else's consent. I've seen this story

before."~Maynard James Keenan

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

that is an excellent question that keeps me up at night. there are many proposed methods such as under water with iodine in sunlight or heating under

inert atmosphere... i'm not sure what method i will use yet...it's so much easier to turn red into white. ehow has a neat article on this: ehow has a neat article on this:

http://www.ehow.com/how_6063919_convert-white-red-phosphorus...

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

IMPORTANT!!!

for anyone wanting to try this synthesis: your results may vary but i was outside attempting to knock the slag out of the reactor i used and the most

unusual thing happened. emt or electrical metal tubing is, i believe, galvanized. that may or may not play into this experience. after about 4 or 5

inches of slag was removed and as i kept working at it, along the side of the pipe there was an audible (and fairly loud) pop and a visible flash. in

all, with the down pipe removed, the reactor pipe is about 14 inches long. i was holding it about 3-4 inches from the sealed end and the flash was

close to my hand...outside of the pipe. no idea how it happened. it was P4 related as the smell is unmistakable but how it was generated and how it

occurred i could not tell you but phosphorus usually burns. this was either a rapid decomposition or a small explosion. thinking it may be a fluke i

continued but after a second time i decided it was safer to build a new one. i am sure some P4 must have been trapped in the slag but how this

happened outside of the reactor i cannot guess. can anyone shed light on this? i see no loss of integrity to the wall of the pipe so it has me at a

loss. i have worked metal for years and anyone who has knows that when you heat steel to glowing it will form a layer of slag that will chip away but

i have never seen it ignite so i can only guess it has something to do with the reaction materials in combo with P4 trapped in the pipe...melon

scratcher

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Spontaneously flammable phosphine formed from reaction of metal phosphides and moisture in the air? Your slags may be more toxic and dangerous to

work with than the phosphorus.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Congratulations, Rogeryermaw!

Can you post some details on formulation used and quantity? Any idea of yield?

Awww... a phosphine 'explosion' seems indeed by far the most likely cause and worrisome too! Could moisture in the ingredients be the source of

hydrogen? Without a source of hydrogen, no phosphine. Or did moisture seep in after the main reaction?

Try thoroughly oven drying all ingredients before the next run...

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

those are excellent suggestions. thanks. i will dry the ingredients first and consider the reactor disposable as they are rather cheap to build and

can be left to "air out" far away from the house. as for the formula: i ran (NaPO3)6=32g + Al=14g + SiO2=20g. unfortunately i did not weigh the

product but i will after this run as i have dug up an old plastic tub i can fill with water to work under. i will put the liquid phosphorus into a

small glass container of hot water and draw the P4 into a syringe. with a test tube with a glass wool filter under the water in the tub i will slowly

pass the P4 through the glass wool to clean it and then just pour the contents of the tube into a glass dish to cool so the P4 can be broken up and

stored in an amber bottle with water.

now that you mention it there must have been moisture in the ingredients that yielded H2 because as the vapors bubbled through the water some of them

ignited as they surfaced indicating PH3. no worries though as i figured it was just safest to stay well clear of the output till the reaction was

completed.

[Edited on 4-9-2010 by Rogeryermaw]

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

ok i ran the synth again with the same measurements and i yield about 2 grams of phosphorus every time but there is significant loss through

turbulence. when the bubbles break the surface and churn the water there is a good bit of P4 that burns away so i need to work on my receiver to beat

this problem and increase yields but i will keep you all abreast of any new developments...now then... can anyone point me toward a thread that has a

good workable synth for PCl3 and or POCl3?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

PCl3 can be obtained from direct union of the elements, not sure about POCl3. There must be threads on both on this forum: search and ye shall

find...

What do you want with these two lovelies?

|

|

|

woelen

Super Administrator

Posts: 8084

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

@Rogeryermaw : Thanks for sharing this great result with us and congratulations with this result!

I consider this a major breakthrough, because it makes phosphorus available also for US-based home chemists. I have many interesting things to share

which require the use of phosphorus and it is so sad that a big part of the amateur chemistry community cannot obtain this element. Your efforts show

that this can be changed.

I myself can buy red P and I have made a small amount of white P from that. Especially if you do not make large quantities of phosphorus, I would

leave it under water as white P. From a synthetic point of view, white P is much more useful. It dissolves in quite a few solvents and it tends to

react more completely. With red P I always notice that part of it does not react or does so very slowly. This part must be some less reactive kind of

phosphorus (violet P?). I have the impression that red P is not a single chemical entity, but a mix of all different kinds of phosphorus, which have a

different degree of reactivity.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

@ woelen thank you very much. i will keep some of the P4 as white but also want to use the red for projects because it is less toxic and does not

react quite as violently as white.

@ blogfast PCl3 is of interest to me because you can turn it into POCl3 by bubbling O2 through it with stirring under an inert atmosphere. POCl3 is of

interest to me because the first "science" i fell in love with was electronics and POCl3 is a good dopant for layering silicon for home brew

electronic transistors.

[Edited on 6-9-2010 by Rogeryermaw]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by woelen  | @Rogeryermaw : Thanks for sharing this great result with us and congratulations with this result!

I consider this a major breakthrough, because it makes phosphorus available also for US-based home chemists. I have many interesting things to share

which require the use of phosphorus and it is so sad that a big part of the amateur chemistry community cannot obtain this element. Your efforts show

that this can be changed.

|

I'm guessing that much could be gained from actually scaling down the reactor somewhat and simply using bunsen heating or a propane flame torch, to

produce small amounts of P4 without much hassle or risk... Perhaps with an improved condenser...

|

|

|

woelen

Super Administrator

Posts: 8084

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

I'm sure a lot can be optimized and tailored to one's personal needs, but the most important thing is that there is reported success and that white P

is not only synthesized, but also isolated in more than microgram quantities. I have seen many other reports before, but that always was in the line

of that some white glow could be detected, indicating that some posphorus is formed, but never have I seen before that a macroscopic blob of white P

was isolated. That is the good thing of this achievement.

I personally have enough white P with 10 grams or so, good for a few nice demo's but of course, if you want to make PCl3 or whatever chemical, then

it is nice to have a little more.

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

a couple points of interest i have noticed after several runs: the slag formed is quite foamy due to the gasses evolved forming bubbles. it will

expand to roughly 3-4 times its original volume so be sure there is plenty of space in the reactor. if your slag reaches too far and expands in the

pipe outside of the furnace it will solidify and block the flow of P4. dry reactants are important for reducing the amount of P4 lost to the

production of PH3. also i am still testing with this but it seems the reaction happens in phases. first the heat expands the air in the pipe and there

will be some bubbling of gases in general (probably last traces of moisture and atmospheric gases) then when reaction temp is reached there may be a

bit of PH3 evolved but the P4 definitely seems to come over last. my most successful run involved heating far beyond when i thought the reaction was

complete...near a full hour of the most intense heat i could muster. also if you use hot water to collect in the condenser needs to be more deeply

submerged as the hotter your H2O is the slower it will cool the P4 gas. if the P4 gas doesn't cool fast enough it will remain gaseous and surface,

igniting and becoming a total loss. i will not attempt to claim that suckback is not a danger but i have not encountered it yet so i am trying to get

more creative with my condensation setup to increase yield. any progress will be reported here.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The foaming is normal of course, even w/o PH3. I was just looking at the slag in the crucible of my only run with NaPO3/Al/SiO2 and it's highly

bubbly/foamy (now frozen of course). I wonder if there's an inert ingredient that could be added to reduce the slag viscosity and thus facilitate

releasing the P4. Something like ordinary salt (NaCl) with an MP of 801 C might just be the ticket. The eutectic NaCl/KCl has an even lower MP at 658

C.

Slag fluidisers (or fluxes) are very commonly used where slag viscosity is high, see also the use of CaF2 (fluorite) as a flux in Thermite reactions

or other metallurgical reductions... The salt would condense way before the P4 of course...

A low melting flux can improve contact between the reagents, and even depassify Al because it 'dissolves' Al2O3...

[Edited on 7-9-2010 by blogfast25]

|

|

|

Rogeryermaw

National Hazard

Posts: 656

Registered: 18-8-2010

Member Is Offline

Mood: No Mood

|

|

those are very interesting ideas worth exploring. perhaps the P4 can bubble out with less resistance if the melt is less viscous. definitely worth

investigation... one last thing i forgot to mention: a syringe with a 20 or 22 gauge needle is perfect for drawing out the product without

contaminants. just be sure to keep it warm and when you "inject" it into your storage container (also warm) don't push too fast or small globs will

surface and ignite. after you complete this operation just cap and allow to cool.

|

|

|

| Pages:

1

..

21

22

23

24

25

..

60 |